Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-01-23 12:41.

How to get an optically almost invisible joint seam using cold welding of linoleum

Good day to all readers of our blog "Do it yourself with us."

Continuing the series of articles on the selection and laying of linoleum, its cutting to the inner and outer corners, today I want to devote the article to how linoleum is welded at the joints and cut at the joints of the sheets. There are two methods of welding linoleum - hot, which is based on the thermal effect on the joint, and the so-called cold welding of linoleum. Let us briefly consider the first method and dwell on the cold welding method in more detail.

Hot welding is mainly used to weld commercial linoleum using a welding torch (soldering iron) and filler cord. Very briefly, the welding technology is as follows: using a soldering iron, the filler cord and the joints of the coating to be welded are heated. When solidified, a strong bond is formed. Subsequently, the seam is slightly sanded. This method requires specific equipment (soldering iron) and consumables (filler cord) and is used on very long seams of commercial flooring, such as in public buildings with high mechanical stress on the floor.

You can, of course, use an ordinary soldering iron to heat the junction, but the result will not be very good. It is impossible to obtain a beautiful, uniform seam along the entire length of the joint. As a result, the use of this method in everyday life, when laying the flooring in your own apartment with your own hands, is impractical and much cheaper to use the cold welding method.

Cold welding of linoleum

So why is this method called cold linoleum welding? The thing is that the principle of joining the material with this method is based on melting the adjacent edges by a chemical method. In fact, the glue is a solvent that for a short period of time turns the edges into a liquid state, they bond, and after evaporation of the solvent, a strong and very aesthetic bond is obtained. Since no temperature is applied, hence the name cold welding.

The connection is in no way inferior in strength to the connection using the thermal melting of the edges, but there is no need to purchase an expensive soldering iron. Therefore, when welding linoleum in everyday life, it is more rational to use this method of joining joints.

There are two types of cold welding glue - type "A" and type "C". Their difference is that a certain type can be used for different sizes of the gap between the sheets being welded.

Glue type "C" can be used for welding seams with a gap between sheets up to 2 mm. It is thicker and its principle of action is based on filling the seam, melting the edges of the joined sheets and joining them. It is advisable to use this type of glue when two canvases do not fit tightly to each other, if there is a mistake in trimming the strips, or if two sheets of linoleum after laying have been in a free state for a long time and a gap has formed between them.

Adhesive type "A" can be used for welding sheets, between which there is a minimum gap. It is more liquid in consistency compared to type C glue, which allows it to flow into the seam and fuse the material.

Let us consider in more detail the entire technology of obtaining a high-quality seam at the joints of the coating.

The first thing that needs to be done for a good welding result is to get a very tight, gap-free fit of the sheets to be welded to each other.

If two strips are connected with factory cutting of the edge - everything is clear here, you need to push the strips tightly to each other and the fit will be perfect.

If it is necessary to connect two cuts of linoleum at the junction between rooms to achieve a snug fit, we cut two canvases at once at the same time. This is done as follows.

1. When laying linoleum, we leave an overlap of the canvas on the canvas of 4-6 cm. This point must be considered even when buying a floor covering. How to calculate linoleum correctly I wrote in the article " How to calculate linoleum and save a lot of money on it."

2. Mark the joint so that it is in the middle of the overlap. For example, if you have an overlap of a sheet on a sheet of 6 cm, then we mark the joint at a distance of 3 cm from the edge of the upper linoleum.

3. Place a flat wooden ruler or a piece of linoleum under the cutting site. (In order to completely cut through two sheets at once along the entire thickness).

4. We apply a metal guide ruler to the marked cutting line and press it firmly, make a cut using a sharpened blade or a clerical knife.

5. We remove the separated parts of the upper, lower linoleum and the lining on which they rested. We connect two canvases joint to joint.

Thus, we received a very high-quality joint of the canvases without gaps. You can start welding them.

Weld seam production technology

1. Glue paper tape on the seam to prevent spreading of glue over the coating surface.

2. With the help of a clerical knife, cut through the tape, trying not to damage the joint and not cut the linoleum.

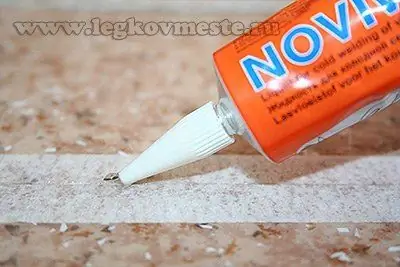

3. Put the needle cap on the glue tube. Starting from either side of the seam, insert the needle into the seam to be welded. With one hand, gently pressing the needle and holding it at the junction, with the other smoothly pressing on the tube, we begin to feed the glue. When glue with a diameter of 3-4 mm is formed on paper tape, we begin to smoothly draw the needle along the seam. Make sure that the width of the glue strip is uniform 3-4 mm. With such a width, the glue is guaranteed to fall into the seam and the linoleum ends are connected (fusion).

4. After 10-15 minutes, the tape can be peeled off by pulling from either edge at an acute angle towards the other edge.

5. We give exposure for 2-3 hours, for the final evaporation of the glue.

6. Admiring the seam that we got.

As a result of correct cutting and the use of type "A" glue, a seam on linoleum is almost invisible, very high quality and durable.

Advice: if the glue accidentally got on the linoleum, unprotected with paper tape, or accidentally dripped somewhere on the floor surface, wait until it is completely dry and remove it with a clerical knife. If you start immediately wiping off the dripping glue, you can damage the outer protective layer of linoleum - just grease the drawing.

Using the same glue, you can easily repair damaged linoleum. Acting in accordance with the above instructions and threading the needle tip into the place of the cut or break in the coating, you can easily cope with this task.

That's all for me. In the coming articles, I plan to cover the issue of how to hang and connect a chandelier with your own hands and how to install plastic floor skirting boards.

See you soon on the pages of our blog "Do it yourself with us." I am waiting for your comments and suggestions for improving the linoleum welding process.

In conclusion, I suggest watching a small video "Welding linoleum" (video).

Recommended:

How To Choose The Right Olive Oil In The Store: Signs Of A High-quality Cold-pressed Product And Other Types + Photos And Videos

Olive oil is a valuable nutritious product. What benefits does it bring to the body? How to distinguish and choose the right olive oil in the store?

Joining Of Plastic Pipes By Welding - Installation Of Plastic Pipes Using A Welding Machine

Welding plastic pipes with your own hands. Replacing the plumbing in the bathroom and kitchen with your own hands using a plastic pipe welding machine

The Phone Turns Off In The Cold Or Quickly Discharges: Why This Happens And What To Do

Reasons for discharging and turning off the phone at low temperatures. Whether it depends on the phone model. How to prevent a problem or turn on your phone

What Kind Of Nose Should A Healthy Cat Have - Wet, Cold, Warm Or Dry And What These Indicators And Their Changes Indicate

How important regular observation of the cat's nose is. What diseases will this help to recognize and consult a doctor in time, avoiding complications

Why You Can't Look At Welding

Welding arc and its radiation. Danger of welding for sight by types of radiation. Myths about the dangers of welding. Is it possible to get blind due to welding