Table of contents:

- We insulate the house for winter: installing underfloor heating on our own

- The most common methods of installing an electric underfloor heating

- Tools and materials necessary for installing a warm floor with your own hands

- We distribute heating units and control elements

- Surface preparation before installing the warm floor

- DIY electric underfloor heating installation

- Video about laying a warm cable floor

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-01-23 12:41.

We insulate the house for winter: installing underfloor heating on our own

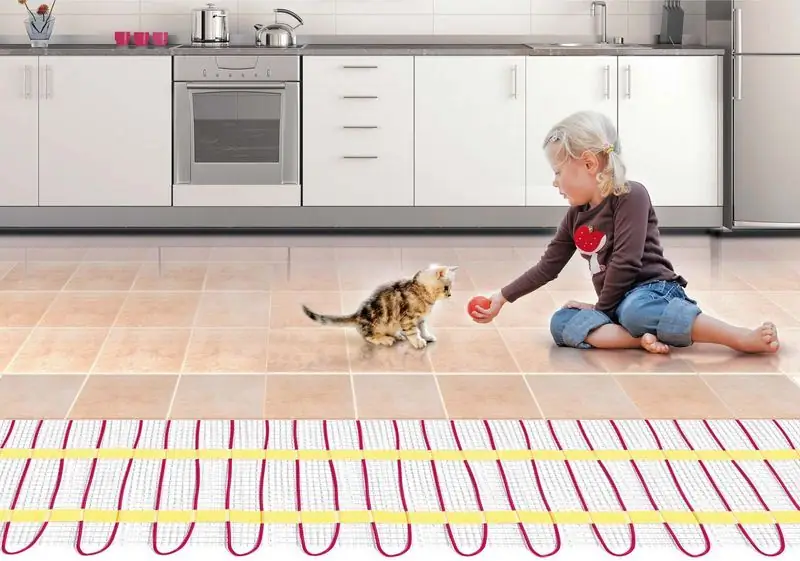

In winter, especially in cold weather, traditional heating is not enough. We are often faced with the fact that "blowing from the floor", and this is inconvenient, because it is very important to keep your feet warm. Underfloor heating is especially relevant for those who have small children.

Especially often electric floor heating is used in a bathroom, veranda, bathhouse or loggia. This option is an excellent addition to the main heating of the home using radiators. Electric floors are used in homes and apartments where high efficiency hot water heating is not possible.

The installation of such heating is quite simple, and many options are available for sale. This makes it possible to assemble a warm floor with your own hands easily and without problems.

Content

- 1 The most common methods of installing an electric underfloor heating

- 2 Tools and materials necessary for the installation of a warm floor with your own hands

- 3 We distribute heating units and control elements

- 4 Surface preparation before installing the warm floor

- 5 Do-it-yourself electric underfloor heating installation

- 6 Video about laying a warm cable floor

The most common methods of installing an electric underfloor heating

There are several options for how to install a warm floor, and they can differ significantly from each other:

- The heating element is mounted inside the screed layer, and then the floor covering is laid;

- The warm floor is laid on top of the screed under the ceramic tiles;

- The installation is carried out directly under the floor covering (this applies to foil floors).

The first option is optimal for heating living rooms, loggia, kitchen and bathroom. In this case, we mean the installation of a cable underfloor heating.

Let's say you have a pre-insulated room on the floor below. Then you can install an electric underfloor heating directly under the tiles, without laying an additional layer of thermal insulation and without installing a screed. Ceramic tiles and a layer of special adhesive insulate the heating elements by themselves.

Installation of a film underfloor heating (also called infrared) is a good option if you want to install a warm floor under a layer of linoleum or laminate, but do not have the desire or ability to do major repairs. In this case, the insulation is laid in the form of a layer of foamed polyethylene foam on the existing screed. Electrical elements are mounted on top, if necessary, a layer of waterproofing, and only then the floor covering itself.

Tools and materials necessary for installing a warm floor with your own hands

Before starting directly to work, stock up on everything you need so as not to be distracted and have everything you need at hand. You will need:

- Underfloor heating system (this includes a heating cable, sometimes with a pre-reinforced mesh);

- Mounts;

- Copper cable for grounding;

- Connecting wires;

- RCD protection system;

- Regulator;

- Thermal sensor.

The basic principle is to calculate the heat loss of a room, after which we select the required wire laying step and the required length for the entire room.

The calculation for film systems is much simpler: you need to select such a number of elements so that they cover the entire area of the room. The calculations also include a wire for connecting the warm floor and the regulator from the meter and to the system elements from the regulator. Direct connection of an electric underfloor heating to an outlet is prohibited.

According to the calculations and the received power of the entire surface of the warm floors, check the total electrical input for its ability to withstand the load. If the existing bushing is not sufficient, it must be replaced and suitable automatic fuses fitted.

We distribute heating units and control elements

First of all, create a detailed plan for installing a warm floor with your own hands on paper. Keep in mind that you should not install heating cables or foil where you are going to put large household appliances and massive pieces of furniture. Also, an area free from heating elements must be provided where heating pipes and other heat sources pass.

If the heat output is limited, for example, by furniture, or additional heating is applied from the outside, the elements will overheat and fail. Plus, furniture can be damaged too. This can become a significant disadvantage of a warm floor: it is undesirable to rearrange the room.

As a result of creating the plan, you will get an irregular shape inscribed in the rectangle of the room. It is inside this circuit that the electric floor heating will be laid.

The most optimal option would be to form separate circuits for different rooms, even if symbolically separated, with a separate power supply and regulators. If you are pouring a screed, then lay a damper tape between these areas along the floor surface.

Once the plan is on paper, transfer it to the floor surface. Mark the position of the regulator on the wall in a convenient location. Here, make a hole for the mounting box and lower the strobe to the floor. Since we have already calculated the amount of materials, we can get to work.

Surface preparation before installing the warm floor

If necessary, completely dismantle the old screed to the ground. Clean the surface thoroughly.

Now lay the waterproofing layer with a margin of about 10 cm on the wall. Immediately on the wall surface, fix the damper tape around the perimeter: it compensates for the thermal expansion of the floor when heated. Excess tape and waterproofing can then be trimmed.

The type of insulation must be chosen depending on how the room is located, what type of surface, and at the same time keep in mind the target orientation of the heating system.

- If the warm floor is a means of complementing the main heating system, then it will be enough to use penofol - foamed polyethylene - as a substrate;

- If there is a well-heated insulated room under your apartment, one floor below, use any durable insulation with a thickness of 20 to 50 mm, for example, sheets of extruded polystyrene foam;

- By installing a warm floor with your own hands on a veranda or loggia that has not been heated before, form a denser and more solid insulation layer. Use mineral wool or expanded polystyrene up to 10 cm thick.

Lay a reinforced mesh on top of the insulating layer. This may not be necessary, since for a thin layer of screed, it is enough to add microfiber and a plasticizer to the solution.

DIY electric underfloor heating installation

Before laying the wire, check its resistance and check it with the passport. The take-off run can be no more than 10% of the data declared in the documentation.

If you install such a floor in a bath or bathroom, be sure to ground the reinforcing mesh, and connect the ground to the regulator. Use tinned copper wire for this.

- Installation of a warm film floor is simple: the elements are spread on top of the insulating layer. If the manufacturer offers a certain laying technology, then you may need to fasten it with a special tape or by the ears on the element.

- In those places where the wire is located above the line dividing the floor slabs, hide it in a piece of corrugated pipe to avoid cable breakage during thermal expansion of the slabs.

- The connection points should be marked on the apartment plan. Subsequently, this will be needed if you have to make repairs to your warm floor.

- After all the elements are in place, check the resistance of the wire again. It is possible to turn on the warm floor only if the resistance differs slightly from the preliminary measurements.

- Next, lower the corrugated pipe along the strobe from the regulator, place its other end between the nearest cable strips exactly in the middle. Inside the corrugated pipe, you need to place a temperature sensor: with its help you will regulate the operation of the electric floor.

- Some experts recommend using a tube with a larger diameter for the temperature sensor than the one that comes with the cable. For example, place the temperature sensor inside the tube before flooding the floor and do not pull it out again. Since the heat is transferred to the surrounding screed, the cable does not reach its maximum temperature.

- If everything is within normal limits, then de-energize the system and remove the regulator until the finishing work is completely finished. Form a screed, after it is dry, check the operation of the entire system. With a positive result, you can install the floor covering.

In the case of installing a film floor, there is no need for a screed, so you can lay linoleum or laminate immediately.

Video about laying a warm cable floor

You have probably noticed that self-installation of a warm electric floor is not a difficult task, and it is certainly easier to do than to mount a hydraulic heating system. Using our advice and recommendations, you will cope with this work, and your home will always be warm and comfortable. We ask you to ask your questions and make suggestions in the comments, we will be happy to take part in your repair, and your advice can help readers. Easy repair!

Recommended:

How To Clean A Coat At Home Using Different Methods, Without Washing, Care Features For Different Materials, Can It Be Washed

How often to clean your coat and when is it best to trust dry cleaning. Description of ways to remove dust, stains and other defects from different materials. Reviews

Warm Floor In The Kitchen Under The Tiles: Features, Advantages And Disadvantages, Installation, Photo

What is underfloor heating and its types. Recommendations for choosing a coating for underfloor heating. The sequence of work on the installation of a warm floor

Floor Covering For The Kitchen: Types, Pros And Cons, Which Floor Is Better To Do, Professional Advice, Photos

What materials are suitable for the kitchen floor. How to choose a material for your kitchen floor: designer tips

Tiling The Bathroom Floor - How To Lay Tiles On The Floor When Renovating A Bathroom

Laying tiles on the bathroom floor professionally with your own hands | Step-by-step instructions on how to lay tiles on the floor when renovating a bathroom

Spouses Sleep Under Different Blankets

Explanation of signs about sleep under different blankets from the point of view of folk wisdom and modern psychology