Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

The choice of material for finishing the floor in the kitchen: ceramic tiles or porcelain stoneware

The existing types of tiles (ceramic and porcelain stoneware) are characterized by their durability, but to a different degree. In addition, materials differ in other characteristics, which determines the cost. However, it cannot be said that any of these varieties are not suitable for laying in the kitchen, since the coating can be used in different conditions, and this will affect the service life. To make the final choice, it is necessary to compare the main parameters of the products, take into account the recommendations of specialists, as well as the intensity of the mechanical load and the effect of other external factors.

Content

-

1 Porcelain stoneware or ceramic tiles - which is better?

- 1.1 Features of ceramic tiles

- 1.2 Features of porcelain stoneware

- 1.3 Table: properties of the main parameters of porcelain stoneware and ceramic tiles

- 1.4 The difference in manufacturing technology

- 1.5 Hardness and strength of materials

- 1.6 Frost resistance

- 1.7 Material cost

- 1.8 Difficulty laying

- 1.9 Durability and service life

-

2 Expert recommendations

2.1 Video: experts in more detail about the characteristics of porcelain stoneware and ceramic tiles

Porcelain stoneware or ceramic tiles - which is better?

For the kitchen, it is recommended to choose materials that will not lose their properties during long-term use in rather aggressive conditions. So, in this room, tiles of any type will be exposed to temperature extremes, ultraviolet radiation, and mechanical stress. It must be resistant to abrasion, since you have to spend a lot of time in the kitchen every day preparing food. The most common options are: ceramic tiles, porcelain stoneware.

Features of ceramic tiles

The advantages of tiles include:

- weak sorption properties (within acceptable limits), i.e. the tile practically does not absorb water;

- easy care;

- versatility: ceramic tiles can be used in premises for various purposes (private houses, administrative, commercial organizations, etc.) and on various surfaces, for example, on the floor, walls, stairs, basement;

- a large selection of models that are different in shade, texture;

- acceptable price.

There are also disadvantages to such a tile, for example, instability to mechanical stress. With a point effect, ceramic products can deform, which will lead to the formation of chips and cracks. In most cases it is no longer possible to restore the tiles. If finishing in the kitchen with such material is performed, it is necessary to avoid situations where a weighty object may fall on the floor.

Another disadvantage of ceramics is their instability to UV radiation. So, after a certain period of service, the coating fades. As a result, its attractiveness can be significantly reduced. However, for this to happen, the coating must be used long enough. Such changes in material properties in most cases occur in areas exposed to sunlight.

Ceramic tiles have many advantages, but they are not resistant to mechanical stress and ultraviolet light.

Features of porcelain stoneware

According to a number of parameters, porcelain stoneware is more preferable when laying on the floor. Its advantages:

- long period of operation;

- non-hygroscopic (does not absorb water);

- resistance to abrasion and the influence of external factors: UV radiation, moisture, mechanical stress, temperature changes;

- appearance similar to natural stone.

Porcelain stoneware does not scratch, does not fade with prolonged use, which means, after a while, the floor in the working area in the kitchen will not differ in shade from the coating in the rest of the room

There are practically no drawbacks to porcelain stoneware, only a higher cost is noted compared to ceramic tiles and a smaller number of options that are different in shade

Table: properties of the main parameters of porcelain stoneware and ceramic tiles

| Ceramic tile | Porcelain stoneware | |

| Weight | 10-25 kg / m 2 | 20-70 kg / m 2 |

| Appearance | It gets worse over time | The coating does not lose its attractiveness |

| Resistance to high temperatures in a domestic environment | Differs in stability | Resilient |

| Water absorption | up to 4.5% | 0.05% |

| Porosity | Yes | No |

| Resistant to chemicals | Only materials of class AA, products of classes A, B, C, D lose their attractiveness to varying degrees | Appearance does not deteriorate, properties do not change |

| Wear resistance | Products of groups III-V only | All types of tiles |

The difference in manufacturing technology

The technology for the production of ceramic tiles is based on the use of various materials: clay, carbonates, quartz sand. Additives are used: feldspar, dyes. Next, the mixture is prepared. The components are connected in different ways: dry or wet. In the first case, water is not used, it is added separately. Ceramic tiles are produced using different technologies: pressing and extrusion. The first of them involves the compaction of the mixture under the influence of special equipment (hydraulic press), while significant pressure is exerted on the material.

The extrusion method is based on the use of an extruder. The mass formed from the above components passes through it. It is squeezed out through a small hole under strong pressure. The resulting strip is cut in accordance with the required dimensions. Then moisture is removed from the tile, for which a drying method is used. Finished products can be coated with glaze. For this purpose, various equipment is used: sprayers, dispensers, airbrushes. In the last step, ceramic tiles are exposed to high temperatures. It is firing that provides strength to products of this type.

Porcelain stoneware is obtained by combining components: kaolin, white clay, feldspars, quartz. To change the color of the products, mineral pigments are added. At the next stage, the mixture is subjected to pressure (up to 600 kg / cm 2). Due to this, no voids remain in the structure of the mixture, the density of the finished material increases, and the porosity decreases. Further, the plates are fired at a temperature of + 1300 ° C. This ensures the recrystallization of the components, which makes it possible to obtain a monolithic material with increased strength.

Due to the composition and production technology, porcelain stoneware withstands intense loads

Porcelain stoneware is sanded with diamond paste. The result is tiles with varying degrees of roughness: from 20 to 80%. Such products are not covered with glaze, as is the case with ceramic products. However, certain types of porcelain stoneware are protected with special compounds that do not provide a glossy surface, but prevent the appearance of oil stains on the surface. At the same time, tiles of this type do not lose their roughness.

Hardness and strength of materials

Thanks to the production technology, porcelain stoneware surpasses ceramic tiles in terms of resistance to mechanical stress. Such material will not deform if a heavy object falls to the floor. This is due to impact strength, resistance to deformation loads (breaking, compression). Even when used in the most difficult conditions and in rooms with high traffic, such tiles retain their properties and attractiveness.

In comparison, ceramics are much less durable. They can serve for a long period in areas that are not exposed to mechanical stress (for example, on walls), but when laying such material on the floor, the risk of chips and cracks increases. This is due to the fact that this type of coating is characterized by higher porosity and lower density. The flexural strength of ceramic tiles is 360-450 kg / cm, and that of porcelain stoneware is 470-600 kg / cm. Surface hardness on the Mohs scale for ceramic tiles: from 3 to 5. Porcelain stoneware index for this parameter: from 6 to 8.

Ceramic tiles are inferior to porcelain stoneware in strength and hardness

Frost resistance

At low temperatures, ceramic tiles do not last long: they withstand 25-100 freeze / thaw cycles. With similar initial data, porcelain stoneware lasts much longer. The number of cycles of freezing / defrosting of this material is 100-300.

Such properties of porcelain stoneware are due to its higher density, lower porosity and low water absorption. This material does not absorb water upon contact with liquids. This means that under the influence of low temperatures followed by heating the tile, its properties will not change. Porcelain stoneware is not subject to freezing, does not expand when temperatures change. Thanks to this, the tile does not deform, which means that the coating can serve for a long time.

Material cost

Due to the production technology and improved properties, the price of porcelain stoneware is higher compared to most artificial analogues. So, you can buy material of this type for 90-25000 rubles. (1 m 2). This range of prices is due to a wide selection of tile options with excellent properties. At a higher price, we offer porcelain stoneware of substantial thickness with a limiting index of frost resistance, intended for laying on the street in places with high traffic. For finishing the floor in the kitchen, a material that is offered at the minimum or average price from the specified range is suitable.

The price is formed taking into account the dimensions of the product, its wear resistance, the type of surface (polished, matte, rough)

The cost of ceramic tiles is much less. So, products of this type are offered at prices ranging from 200 to 1500 rubles. (1 m 2). The price is formed taking into account the production method, type of surface, degree of wear resistance. More expensive varieties are used to decorate objects with high traffic. For installation on the kitchen floor, it is recommended to purchase tiles of the middle or high price category. The cost is also influenced by the brand of products, the country of origin.

Complexity of styling

The technology of finishing a horizontal surface with porcelain stoneware and ceramic tiles is not much different. In this case, marking is performed, glue is applied, products are fixed. At the last stage, grouting of seam joints is performed. However, it is necessary to take into account the significant weight of porcelain stoneware, which requires the use of special mixtures for fixing on the surface. The high hardness of this material is also noted, which will require more effort to fit the tiles in accordance with the dimensions in areas where it is impossible to place whole products.

Wear resistance and service life

When choosing the right material between porcelain stoneware and ceramic tiles, wear resistance should be considered. The service life of the coating will depend on this. Wear resistance of ceramic tiles and porcelain stoneware:

- PEI I - suitable for wall decoration, since it does not have increased resistance to mechanical stress;

- PEI II - allowed to be installed in private houses and apartments where residents wear soft shoes;

- PEI III - used for floor mounting in residential rooms and small offices, provided that the traffic is low in these areas and the entrance is not from the street;

- PEI IV - can be used in private houses and apartments, as well as small public facilities with low traffic;

- PEI V - it is permissible to lay the material of this group in any premises without restrictions on the degree of passability.

In terms of service life, these types of materials are also slightly different. Modern ceramic tiles can be used for 20 to 50 years or more. Porcelain stoneware retains its properties for 50 years and longer. In theory, such a coating has no life limits. The service life of any of these materials can be reduced or, conversely, increased, which is affected by operating conditions.

Expert recommendations

The best option today is porcelain stoneware. It is the undisputed leader in appearance and properties among artificial materials. It is similar to granite in both texture and strength. Such material will serve for decades without losing its attractiveness. For this reason, it is best used for kitchen flooring. It is recommended to consider products characterized by III degree of wear resistance. A more durable material for the premises of this purpose should not be used, since at the same time there are no increased loads on the floor, and the price of such a tile is much higher.

Porcelain stoneware by its external properties resembles natural stone (granite)

Ceramic material for kitchen installation should be characterized by a higher strength than products for installation on the walls of this room. Options that differ in the degree of wear resistance are suitable: PEI III, IV.

Ceramic tiles can be identified by the variety of patterns, shades

In addition, ceramic tiles should be used in cases where the kitchen windows face the north-east side. In this case, the coating will be less exposed to ultraviolet radiation. According to its characteristics, such a material is suitable for laying in a kitchen that is used only for the purpose of cooking, but not as a dining room. Moreover, the permeability of the room should be low or medium.

Porcelain stoneware should be installed on the floor when a large family lives in the house and the kitchen is used frequently. In addition, this type of material can be stacked on a horizontal surface even in cases where there is no separate dining room in the house. In this case, family members eat several times a day in the kitchen. Then the load on the coating will be high, which will require the use of a material with improved characteristics, which is precisely porcelain stoneware.

Video: experts in more detail about the characteristics of porcelain stoneware and ceramic tiles

Given the significant cost of porcelain stoneware, such material should be used if the budget for repair work in the kitchen allows it. It is characterized by higher strength, will serve in conditions of high humidity, low temperatures (in poorly heated rooms). Ceramic tiles are inferior in properties to this coating. However, its advantage is a reasonable price and a wide selection of shades and patterns. If you choose the right material in terms of density, degree of wear resistance, you can count on a long service life of the finishing layer.

Recommended:

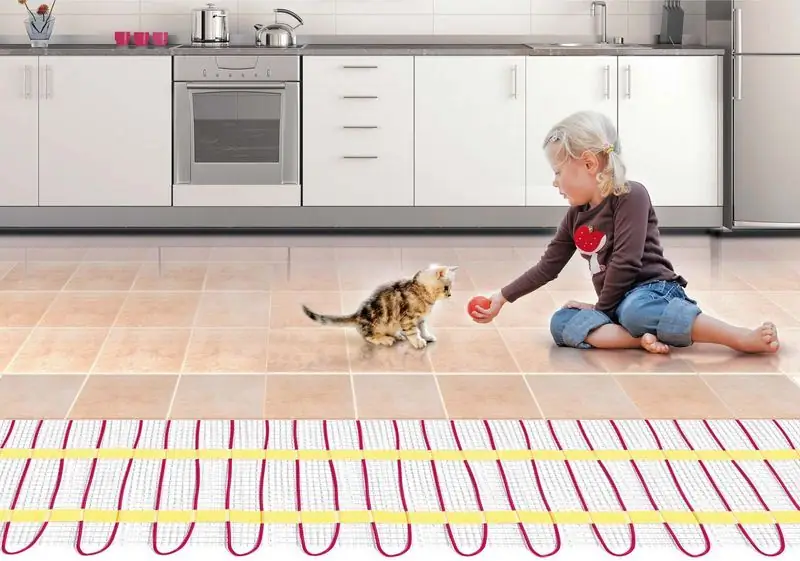

Warm Floor In The Kitchen Under The Tiles: Features, Advantages And Disadvantages, Installation, Photo

What is underfloor heating and its types. Recommendations for choosing a coating for underfloor heating. The sequence of work on the installation of a warm floor

Kitchen Sinks From Porcelain Stoneware: Pros And Cons, Features, Care

What is a porcelain stoneware sink, features, advantages and minutes. Recommendations for choosing a granite sink. Care tips for your porcelain stoneware sink

Ceramic Tiles 10x10 For The Kitchen: Features, Advantages And Disadvantages, Main Application, Examples With Photos

10x10 cm tiles: features, advantages and disadvantages. Selection recommendations. Kitchen design options with square tiles. Styling tips

Types And Brands Of Metal Tiles With Descriptions, Characteristics And Reviews, As Well As Recommendations In The Choice Of Material

Description of the types of metal roofing tiles and their characteristics. An overview of the main grades of material and tips for choosing a coating

Tiling The Bathroom Floor - How To Lay Tiles On The Floor When Renovating A Bathroom

Laying tiles on the bathroom floor professionally with your own hands | Step-by-step instructions on how to lay tiles on the floor when renovating a bathroom