Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

How to choose corrugated board for the roof: characteristics of brands and tips for choosing

Profiled metal sheets are widely used in construction. Among the assortment of this material, the roofing sheeting, presented by several brands, stands out. The choice of a particular option is based on the characteristics and features of each brand, and for this it is important to know the properties of the material.

Content

-

1 Roof decking

1.1 Video: replacing the gable roof cover with corrugated board (accelerated shooting)

-

2 Types of profiled sheets

- 2.1 Video: the main types of corrugated board

- 2.2 Photo gallery: options for roofs made of corrugated board

-

3 Grades of roofing sheeting

-

3.1 Benefits of using corrugated board

3.1.1 Video: the advantages of corrugated board, features of its production and use

- 3.2 Service life

-

-

4 How to calculate the material consumption for the roof

4.1 Video: error when choosing the length of metal sheets

- 5 Reviews about corrugated roofing

Roof decking

It is possible to create a metal roofing not only with the help of metal tiles, but also corrugated board. This material is steel sheets with a certain thickness, wavy surface and equipped with a protective colored polymer coating.

The roof made of corrugated board is easy to maintain and looks solid

Also, corrugated board is used for wall cladding and installation of partitions in non-residential premises, strengthening fences and even inside fire doors.

Sheathing with corrugated board is inexpensive, but it perfectly decorates the appearance of various buildings

A common feature of all types of corrugated board is the type of coverage.

The use of corrugated board allows you to get an inexpensive and durable roof. Manufacturing technology of profiled sheets does not require high costs, but at the same time provides high material characteristics. Its advantages also include: simple installation on the crate and a smooth surface that facilitates snow melting in winter.

Pitched roofs covered with corrugated board are easy and quick to repair if necessary

All grades of profiled sheets intended for the roof have common characteristics. These include:

- simple fastening technology;

- the possibility of partial replacement of the coating;

- service life more than 15-20 years;

- a variety of shades and UV resistance of the polymer coating;

- smooth structure;

- resistance to moisture.

The corrugated board is suitable for roofs with different slope angles, however, there are certain installation requirements. For the construction of each type, these rules are individual, therefore, before starting installation, the features of the device of a particular roof are taken into account.

Video: replacing the gable roof covering with corrugated board (accelerated shooting)

Types of profiled sheets

Profiled sheeting is presented in a wide variety, where all types are classified according to many characteristics. The main parameter is the purpose of the material. Option marked "C" means that the material is intended for walls, partitions, fences, sandwich panels. The thickness of this type of sheet is from 0.5 to 0.7 mm, and the profile height can be from 8 to 44 mm.

Wall corrugated board is easy to install and has a lower cost

The most durable material is marked "H", which means "bearing". Such sheets are designed to create strong, stable and durable structures: floor slabs, fixed formwork, steel fences, etc.

In the case of the load-bearing type, the steel thickness ranges from 0.6 to 1 mm. The weight of one sheet depends on the dimensions, and the coating is often colored. The sheets can withstand significant loads and temperature changes, are resistant to humidity and ultraviolet radiation, and are also equipped with an additional stiffening rib on the bottom of the corrugation.

The main parameters of the sheet are its thickness, profile height and dimensions.

The variant marked "HC" is considered universal: it is suitable for fences, floor slabs and formwork, partitions and wall decoration. All sheet profiles are equipped with additional stiffening ribs that increase its strength. The thickness of the elements is from 0.4 mm, and the coating is made of zinc or polymer. The profile is trapezoidal.

Grade НС44 has a profile height of 44 mm and additional stiffening ribs along the lower and upper rows

This material classification allows you to quickly determine the desired option.

Video: the main types of corrugated board

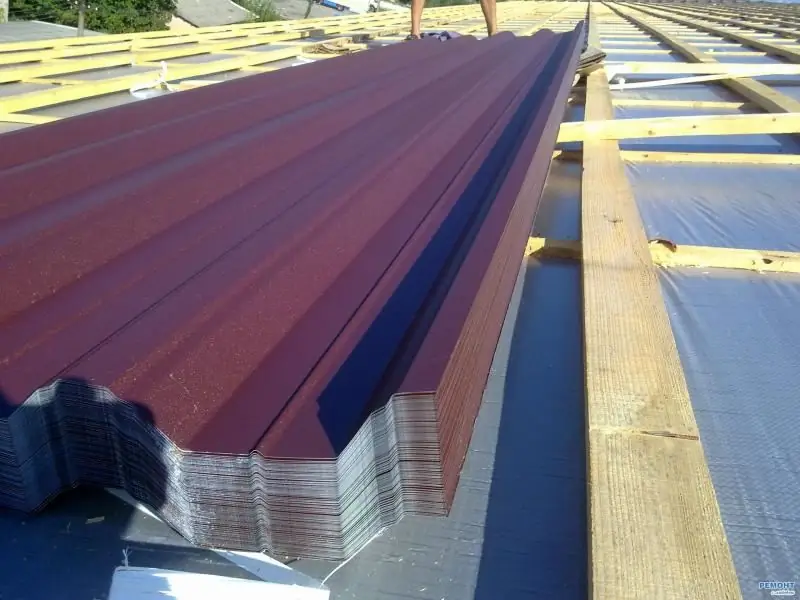

Photo gallery: options for roofs made of corrugated board

-

Gable roof made of colored corrugated board - Profiled sheeting is the ideal solution for a large gable roof: it is covered during the day

-

Composite half-hip roof made of brown corrugated board - Profiled sheets are suitable for complex roof options: hip and semi-hip

-

Garage fully covered with corrugated board - A freestanding garage can be completely sheathed with corrugated board: both walls and roof

-

Roof option with ledge - It is easy to supplement the corrugated board with accessories, covering all joints with them

-

Corrugated bunk roof - A two-tiered roof can be covered with corrugated board of different colors, visually separating one tier from another

-

Bright roof with corrugated pipe trim - Profiled sheets go well with brickwork

-

Long roof slope made of corrugated board - Sheets are available in different lengths, so it is easy to find the right option for any design

Roofing sheeting brands

Of all the existing grades of sheets, there are options that are best suited for external roofing. Here are their features:

- profile height over 20 mm - does not allow moisture to accumulate under the sheets;

- trapezoidal profile - for better drainage of precipitation;

- the presence of a capillary groove (additional stiffening rib);

- polymer coating made of pural, plastisol.

In this case, attention is required for the height of the profile, which depends on the angle of inclination of the slopes. The smaller the slope, the higher the wave height should be.

Profiled sheeting is used for pitched roofs, but it is important to choose the right coating model

The following grades of metal sheets have the necessary properties for roofing:

-

C21 - wave height 21 mm, profiled sheet width 1051 mm, working width 1000 mm. Sheet thickness: 0.35 mm or 0.7 mm or 0.8 mm. There is no capillary groove on the profile. The material is good for roofs with slopes over 45 °. The polymer coating protects the metal from corrosion and ultraviolet radiation;

Diagram of the device of corrugated board C21 C21 corrugated board is suitable for roofs in regions with low snow load

-

Н57 - wave height 57 mm, working width of the profiled sheet 750 mm, steel thickness 0.6-0.9 mm. The corrugation pitch is 187.5 mm, and the weight of 1 m 2 of 0.8 mm thick material is 9.19 kg. The lower part of the wave is supplemented with a stiffening rib. The brand is used for flat roofs or in regions with a large amount of precipitation;

Construction and parameters of corrugated board Н57 H57 sheets have a high profile, so they are good for different types of roofs

-

Н60 - wave height 60 mm. The profiled sheet is made from rolled steel with a width of 1250 mm, and after forming it acquires a width of 902 mm. There is a stiffening rib at the bottom. During manufacture, the galvanized material is covered with a polymer colored component;

Form and parameters of corrugated board H60 Stiffening ribs are present in almost all grades of sheets that are best suited for the roof

-

Н75 - wave height 75 mm, steel thickness 0.65-1 mm, sheet length 0.5-14.5 m, working width 750 mm. The trapezoid pitch is 187.5 mm, and the weight of 1 m 2 with a thickness of 1 mm is 12.87 kg. The corrugation has a complex shape and stiffening ribs in the lower part, which makes the material as strong and resistant to mechanical stress as possible;

Parameters of corrugated board H75 Polymer coating protects the material from moisture and damage

-

Н114-600 - total width 646 mm, working width 600 mm, steel thickness 0.8-1 mm. The length of the sheet is from 0.5 to 13 m, the trapezoid pitch is 200 mm, the ribs on all parts of the corrugation. Polymer coating.

Scheme of corrugated board Н114-600 with parameters The Н114-600 grade is in demand for structures with increased reliability

Before choosing a brand of corrugated board, it is necessary to take into account the angle of inclination of the slopes and the installation features.

Benefits of using corrugated board

Affordable price and variety of brands make profiled sheets in demand. This roofing material has the following advantages:

- elements are easy to assemble yourself;

- the total cost of the coating is much lower than that of roofs made of other materials;

- variety of shades and aesthetic appearance of the building;

- application on roofs with any slope of slopes, as well as on flat ones;

- environmental friendliness and fire safety;

- light weight and resistance to mechanical stress.

The corrugated sheathing allows you to set the direction of rainwater on the roof. To do this, during the installation of sheets, the corrugations are directed to the desired zone, and the water flows down them into a special trough.

Video: pluses of corrugated board, features of its production and use

Life time

The durability of the material is largely dependent on the outer coating.

A simpler option is zinc: the maximum thickness of this layer can be 25-30 microns. Such a roof will last more than 30 years without serious damage.

Galvanized corrugated board serves more than 25-30 years without changing the appearance

A composition of 55% aluminum, 1.6% silicon and 43.4% zinc forms an aluzinc coating. Material with such a layer can last up to 40 years in a moderately aggressive environment: central Russia without extremely low or high temperatures.

Zinc or aluzinc sheets are suitable for warehouses and industrial buildings. For residential buildings, it is necessary to use elements with a durable polymer coating.

Buildings made of galvanized sheet are not distinguished by high performance characteristics and are used as "temporary enclosures"

Polymer compositions are more diverse and include organic and synthetic components. Depending on the ingredients, polymer layers are divided into the following types:

- polyester (PE) - inexpensive, common, versatile. It is used for different designs. A material with a matte or glossy polyester layer 25 microns thick will last about 30-35 years;

- plastisol (PI) - is applied to metal sheets with a layer of 180-200 microns, resistant to operation in an aggressive environment (in the chemical industry). It fades slightly in the sun, but the structure is not disturbed. Plastisol allows using corrugated board for more than 40-45 years;

- pural (based on polyurethane) - layer thickness of about 50 kmk, maximally resistant to chemical, climatic and mechanical influences. The service life is over 50 years.

The choice of colored roof sheeting is also based on the type of coating, because each of them has its own properties and makes the material differently durable.

How to calculate roof material consumption

After determining a suitable grade, the required amount of material for a quality roofing should be calculated.

The roof covered with corrugated board retains its appearance for several decades

The length of the sheets should correspond to the length of the slope. If it is difficult to execute for some reason, then during installation the profiled sheets are laid with an overlap. For covering the ridge, cornice and valley, additional parts will be required, which must have the same characteristics as the corrugated board used.

Video: error when choosing the length of metal sheets

Reviews of corrugated roofing

Polymer coated metal sheets are the best and most affordable option for roofing. This material is varied, so it is easy to select sheets with suitable characteristics. And even a non-professional can do the installation.

Recommended:

Composite Tiles, Advantages And Disadvantages, Review Of Popular Brands With Descriptions, Characteristics And Reviews, As Well As Installation Features

Composite shingles: history of use, characteristics, pros and cons. Features of installation. Review of popular brands. Reviews of builders and home owners

Types Of Roofing Materials With A Description And Characteristics And Reviews, Including Roll, As Well As Features Of Their Operation

Types of roofing materials: sheet, soft and tile roofs. Technical characteristics and features of operation of various types of coatings

Types And Brands Of Metal Tiles With Descriptions, Characteristics And Reviews, As Well As Recommendations In The Choice Of Material

Description of the types of metal roofing tiles and their characteristics. An overview of the main grades of material and tips for choosing a coating

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size

Roll Roofing Materials: Types With Descriptions, Characteristics And Reviews, Installation Features

What roll material to choose for the roof. How to mount it yourself. Use of self-adhesive materials. Dismantling old roofing