Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Types of roofing and their features during operation

The quality characteristics of any roof structure are directly related to the type of roofing material installed on it. Currently, coatings are widely used, in the manufacture of which modern technologies are used, which make it possible to create multilayer materials with special sprays. Despite the technological innovations in the construction industry, traditional roofing coatings used in the past decades are also very popular. To have an idea of the features of the choice of products for roofing, it is necessary to consider the technical characteristics of each of them.

Content

-

1 Types of roofing materials

1.1 Video: choosing a roof for a house

-

2 Sheet roofing and its varieties

-

2.1 Metal tiles

- 2.1.1 The shape of the relief of metal tiles

- 2.1.2 Protective coatings for metal tiles

- 2.1.3 Glossy polyester (polyester)

- 2.1.4 Matt polyester

- 2.1.5 Pural

- 2.1.6 Plastisol

- 2.1.7 Polydifluorite

- 2.1.8 Video: types of metal tiles

- 2.1.9 Reviews of specialists about metal tiles and types of their coatings

-

2.2 Roofing sheeting

- 2.2.1 Decking Н60

- 2.2.2 Video: professional flooring Н60

- 2.2.3 Professional flooring НС35

- 2.2.4 User reviews about corrugated roofing

- 2.2.5 Video: description of professional flooring НС35

-

2.3 Ondulin

1 Reviews of owners of houses with a roof made of ondulin

-

2.4 Slate

2.4.1 Feedback from owners of slate roofs

-

2.5 Seam roof

- 2.5.1 Steel seam roofing

- 2.5.2 Copper seam roofing

- 2.5.3 Aluminum seam roof

- 2.5.4 Reviews of the advantages and disadvantages of standing seam roofs

- 2.5.5 Video: installation of a seam roof

-

-

3 Materials for soft roofing

- 3.1 Roll roofing

- 3.2 Thermoplastic polyolefin

-

3.3 PVC membranes

3.3.1 Reviews of PVC membrane coating

-

4 Roof tiles and their varieties

- 4.1 Ceramic roof tiles

- 4.2 Cement-sand tiles

-

4.3 Bituminous shingles

4.3.1 Reviews of bituminous shingles

-

5 Real durability of roofing materials

5.1 Video: choosing a roof - the years will show

- 6 Features of the operation of various types of roofing materials

Types of roofing materials

Depending on the design of the rafter system, the angle of inclination of the roof and the region in which the building is located, various types of roofing are used:

- Sheet roofing.

- Metal profile.

- Decking.

- Ondulin.

- Slate.

- Seam roof made of steel, aluminum or copper.

- Soft roof.

- Fused roll materials.

- Flat membrane roof.

- Roof tiles.

Each of the materials presented in the list has technical features, which will be discussed in more detail below.

The most popular roofing materials currently are bituminous and ceramic tiles, seam steel roofing and metal roofing.

Video: choosing a roof for a house

Sheet roofing and its varieties

The name “sheet roofing” means that the roofing is produced in the form of square or rectangular plates with a flat or profiled surface. These roofing materials include:

- metal tiles;

- profiled sheets (corrugated board);

- slate;

- ondulin;

- sheets of steel, copper and aluminum for standing seam roofing.

Metal tile

The material for the manufacture of metal tiles is galvanized steel (alumino-zinc) sheet with a thickness of 0.35 to 0.7 mm, on which several protective coatings are applied.

The metal tile is manufactured using high-tech equipment, with the help of which the material is profiled in order to make it look like ceramic tiles. A layer of zinc, primer and polymer sprays is applied on both sides of the sheet metal. The front side of the coating is painted in different shades, while the inside is usually white or gray.

On sale there are sheets of metal tiles in all basic colors according to the generally accepted RAL catalog

The relief height (stamp depth) affects the stiffness of the sheet of metal. The higher this indicator, the less flexibility of the sheet.

By the type of relief shape, metal tiles are distinguished in two sizes:

- with a small wave, the height of which does not exceed 50 mm;

- high wave - more than 50 mm.

The relief pattern of a metal tile can have a symmetrical or asymmetrical wave.

Metal tile relief shape

Metal tiles differ in the shape of the relief pattern. Most often on the Russian market you can find its variety called "Monterrey", which accounts for up to 80% of all products of this class. It comes in several variations:

- "Standard";

- "Modern";

- "Maxi";

- "Super";

- "Retro";

- "Lux";

- "Classic".

These subspecies of coatings have different shapes and parameters, but the relief pattern for the listed materials is the same - in the form of smooth, rounded waves.

Another, less common type of metal tile, is a modification of the "Cascade" type. Its main difference is that the waves have sharp corners - in appearance, such a coating resembles a bar of chocolate.

The next, even less common type of metal tile is the materials of the Andalusia group. In appearance, they imitate the surface of ceramic tiles. The sheets have an internal fastening, which is hidden at the joints, which makes it possible to mount the coating without visual transitions and height differences. The general view of such a roof resembles one whole surface.

Manufacturers produce several types of metal tiles with different relief shapes and wave heights

Protective coatings for metal tiles

Metal tiles differ in the chemical composition of the protective coating. The thickness of this spraying can be between 0.02 and 0.25 mm. The chemical composition of the coating directly affects the resistance of the material to corrosion, ultraviolet radiation, and weathering. As a protective layer for metal tiles use:

- glossy polyester;

- matte polyester;

- pural;

- plastisol;

-

polydifluorite.

The structure of the sheet of metal The sheet of metal tile has a multilayer structure, and the types of protective and decorative coatings used may differ depending on the class of material and the manufacturer

Glossy polyester (polyester)

Glossy polyester coating has gained the most popularity due to the fact that it has a low price, does not change its chemical and physical properties when exposed to ultraviolet radiation and is practically not subject to corrosive processes. The thickness of the polyester spraying is from 25 to 30 microns. The sprayed layer is a weak point for a sheet of metal tile, since even with a slight impact, scratches appear on it. In this regard, metal tiles coated with glossy polyester are impractical to use in regions where heavy rainfall is frequent.

Glossy polyester coating of metal tiles is not resistant to damage from sharp objects and scratches

Matt polyester

The matte polyester coating is applied in a thicker layer - from 35 mm, which provides greater resistance to mechanical damage. Therefore, the geographical area of application of such a metal tile is more extensive. It should be borne in mind that metal tiles with matte polyester do not differ in a wide variety of shades.

Matte polyester protects the surface of the metal tile better, but has fewer color shades

Pural

Pural spraying is applied to the metal tile with a layer of 50 microns thick. Thanks to the polyurethane, which is part of the pural, such roofing materials have proven themselves well in regions with aggressive weather conditions. The coating is resistant to extreme temperature changes, but it is less durable than plastisol.

Pural applied to metal tiles protects it from large temperature changes and heavy precipitation

Plastisol

The metal tile coated with plastisol has a pronounced texture due to the polyvinyl chloride fibers included in the protective coating. Plastisol is applied in a layer 200 microns thick, which provides the roofing material with the highest resistance to mechanical damage and aggressive weather conditions. However, it has low resistance to direct ultraviolet rays, and the presence of polyvinyl chloride in its composition is recognized in some countries as unsafe for human health.

Plastisol reliably protects metal tiles not only from mechanical damage, but also from negative atmospheric phenomena and provides an attractive appearance of the coating with a pronounced texture

Polydifluorite

Polydifluorite is the most flexible coating, as it is 80% polyvinyl chloride and 20% acrylic. The thickness of the layer for metal tiles is made only up to 30 microns, this is enough to provide reliable protection and resistance to direct impacts. The chemical composition of the coating makes it possible to produce it in a wide range of colors, but the cost of roofing material with such a spraying is quite high.

Polydifluorite (PVDF, PVDF2) is one of the most effective protective coatings for metal tiles, but it greatly increases its cost

Video: types of metal tiles

Reviews of specialists about metal tiles and types of their coatings

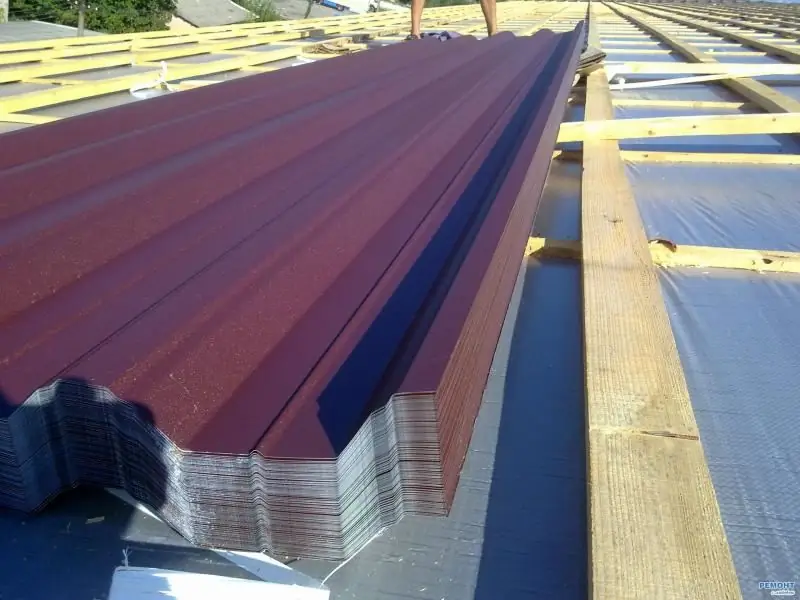

Roofing corrugated board

The corrugated board differs in the dimensions of the sheets and the height of the relief pattern. It should be noted that sheets of corrugated board of different markings are used for the roof and walls. For the roof, corrugated board with the designations H60 and HC35 is used. Roofing sheeting must meet the requirements of GOST 24045-94.

The main difference between roofing and wall coverings is the presence of a special groove designed to drain moisture.

Roofing sheeting has a higher wave height than wall sheeting and a special capillary groove for condensate drainage

Professional flooring Н60

Decking grade H60 is most often used to cover the roofs of residential and industrial buildings. The total width of the sheets of this material is 900 mm, the useful width (minus the overlap with the adjacent sheet) is 845 mm. The figure in the marking of the corrugated board indicates the corresponding relief height in millimeters. For the manufacture of this roofing material, sheets of galvanized or painted steel with a thickness of 0.55 to 1 mm are used. A roof covered with H60 corrugated board can withstand a heavy weight load.

H60 profiled sheeting has a high wave (60 mm) and can withstand heavy loads

Video: professional flooring H60

Professional flooring НС35

Roofing corrugated board HC35 is made of galvanized or painted steel with a thickness of 0.5 to 0.9 mm. Full sheet width 1060 mm, useful width 1000 mm. The height of the embossed pattern of this brand of corrugated board is 35 mm, which is almost half less than that of the previous model.

Profiled sheeting НС35 has a wave height of 35 mm, therefore its bearing capacity is less than that of the Н60 model (with the same sheet thickness)

User reviews about corrugated roofing

Video: description of professional flooring НС35

Ondulin

For the production of ondulin, cellulose fibers are used, which are compressed when heated to 120 o C. In a heated state, the material is given a wavy shape. The frozen sheets are impregnated with concrete mixtures with the addition of polymer materials and painted. As a result of these processes, an environmentally friendly material that is safe for human life is produced.

- Ondulin has a high resistance to getting wet. The cellulose fibers included in its chemical composition, when heated under the influence of sunlight, melt. This process has no negative consequences for the material, as it strengthens it by gluing the fibers together.

-

The material does not change its chemical properties and quality characteristics when exposed to alkalis with acids or products containing oil, such as gasoline.

Ondulin Onduline coating is highly resistant to moisture, harsh chemicals and ultraviolet radiation, and is also lightweight and low cost

- It is convenient to mount an ondulin coating, since the weight of one sheet measuring 200x100 cm does not exceed 7 kg. This is especially noticeable when comparing it with a slate sheet of similar dimensions - the weight of ondulin will be 4 times less.

- The cost of the coating will fit into almost any budget, since the price of ondulin is much less than that of metal tiles and corrugated board.

- As an excellent waterproofing coating, ondulin has a high degree of noiselessness. Given these characteristics, there is no need for additional costs for a soundproof layer.

The combination of these qualities makes ondulin one of the most demanded materials for roofing.

However, despite the large number of positive qualities, ondulin also has disadvantages: it fade in the sun, losing its original color, and easily ignites, since it is an organic material saturated with concrete mixtures.

Reviews of owners of houses with a roof of ondulin

Slate

Not so long ago - several decades ago - asbestos-cement slate was placed on almost all roofs. In our time, it has been replaced by coatings made of bitumen, plastic and metal. However, this does not prevent slate from still enjoying universal popularity. After all, this roof covering, unlike most modern materials, has proven itself well over many years of operation. The service life of slate, without changing its physical and chemical properties, exceeds 50 years.

Slate is produced in the form of flat and wavy rectangular sheets. For the roof, only wave slate must be used.

This coating is molded on the basis of plastic solutions, consisting of:

- Portland cement grades M300-500 (80-90%) - acts as a binder;

- chrysotile asbestos (10-20%) - serves as a reinforcing filler that holds the cement mortar;

- water.

Asbestos-cement slate is produced in accordance with GOST 303403-95. According to these standards, asbestos-cement slate must have 6, 7 or 8 waves.

The roof slate is available in three different shapes and sizes of sheets: for 6, 7 and 8 waves

In fact, the seven and eight wave sheets are more practical. This is due to the fact that the useful and nominal coverage are almost the same:

- the eight-wave slate sheet has a nominal area of 1.98 m², while the usable area is 1.57 m². During installation, a small overlap of the slate coating is made;

- the seven-wave slate has similar parameters. With a nominal area of 1.7 m², it will cover 1.34 m² of the roof;

- wave slate with six waves has a higher consumption compared to previous options. With a total sheet area of 1.97 m², it only covers 1.41 m² of roof surface.

The inconvenience when installing this roofing material is its weight. In accordance with state standards of wave slate and depending on individual parameters, one sheet of this roofing can weigh from 20 to 35 kg.

Since the natural color of slate is gray, it does not decorate the roof. In this regard, some manufacturers apply alkyd polymer or acrylic paint with RAL colors to all products. Coloring is performed when the initial mixture is in a liquid state. At this point, a color pigment is introduced, which, when the mass solidifies, is firmly absorbed into the composition of the material and provides a reliable and durable coating.

The advantages of asbestos-cement slate include:

- fire resistance. Slate resists open fire well, however, with prolonged exposure, it can explode, scattering into sharp fragments of various sizes;

- resistance to decay, corrosion and chemicals;

- high sound absorbing properties.

Despite the large number of positive characteristics of slate, they try not to use this coating in modern buildings. This is due to the fact that slate contains asbestos, which is an environmentally unfriendly and hazardous substance for human life. For living organisms, asbestos fiber is harmful if it is present in the form of dust. To avoid this, it is necessary to cover the slate sheets with linseed oil or paint them.

Slate sheets are heavy and rather brittle, but it resists rotting and corrosion well and dampens noise from falling streams of rain

Despite the hardness of the material, it is quite fragile. Direct blows from, for example, a stone, hammer or large hail can punch a hole in it. The slate sheet can crack if you set it on an uneven lathing or try to bend it when fastening.

Reviews of the owners of slate roofs

Seam roof

A seam roof consists of several strips of metal that are connected using special construction tools or equipment. The result is a specific seam that connects the joints of the sheets by bending metal. Seam roofing materials are usually steel, copper and aluminum.

To create a tight sealed seam on a folded roof, a special tool is required

Steel seam roof

For the manufacture of budget coatings, galvanized, non-galvanized or coated steel with special polymer compositions is used. It is not subject to the harmful effects of corrosion and has a rather long service life, which is up to 50-60 years.

A properly installed seam roof looks very attractive and will serve for 50 years or more

After several years of operation, steel tends to tarnish. In this regard, it is better to select material with a colored multi-layer coating for equipment of a seam roof. However, it should be borne in mind that even in this case, the roof will not retain its original appearance, since exposure to the sun and weather will not save the coating from fading. The sea climate is especially harmful for this type of roofing.

For installation of steel standing seam roofing, both a sparse lathing and a solid base are suitable. For the lathing, you can use both bars and a metal frame. When installing a steel standing seam roof, the pitch width between the rafters should not exceed 250 cm. Otherwise, even strong steel seams may come apart and the roof may bend.

For the installation of metal sheets of standing seam roofing, various connections are used: single, double, standing, recumbent. They create additional ribs for the entire roof.

When joining two sheets, a special seam is arranged along their long side, which is called a fold

Copper seam roof

The use of copper for seam roofing is very popular due to its very beautiful appearance and long service life. Seamed copper roofing is not a favorable breeding ground for biological organisms - using this material, you can forget about the growth of moss. However, copper has significant drawbacks - the metal is soft and quite expensive.

After several years of operation, oxidative processes occur on the copper surface, due to which the roof becomes dark brown. After a few more years, these processes will lead to the fact that the roof will be covered with a noble bloom of gray-green color - a patina - for which true connoisseurs of aesthetics choose this type of coating. Among its other characteristics are the following:

- good thermal conductivity. This fact, however, can create more inconvenience, since in the summer such a roof heats up quickly, and in winter, accordingly, it quickly cools. Given this feature, the insulation layer under the copper roof must have a thickness of at least 20 cm;

- low sound insulation. This disadvantage is eliminated along with the previous one due to good insulation;

- resistance to corrosion and temperature extremes. The performance of copper seam roofing is not lost at temperatures from -70 to +150 o C.

For the manufacture of folded copper roofing, roll and sheet copper is used, the thickness of which is 0.8 mm. The joints of the sheets are fixed with a single or double seam with an edge height of no more than 30 mm. Copper paintings are fixed to the lathing with clamps made of the same material. The distance between the attachment points should be no more than 40 cm.

Standing seam roofing made of copper sheets looks prestigious and expensive, and has served for more than 100 years

Aluminum seam roof

As a roofing coating, aluminum, like copper, is produced by manufacturing plants in sheets or rolls. In the manufacturing process, aluminum can be painted or sputtered from polymer materials. In such conditions, aluminum completely changes its appearance, imitating the surface of wood, stone, tiles or copper.

Only alkali and some chemical compounds can adversely affect aluminum.

It is necessary to use aluminum sheets marked "НС" and "Н" as roofing material. The thickness of these blanks can vary from 0.4 to 1.2 mm.

The main advantages of aluminum seam roofing:

- availability. Compared to copper, this coating is much cheaper;

- environmental friendliness. Aluminum is absolutely harmless to humans;

- long service life - from 100 to 150 years;

- light weight. The mass of the material with an area of 1 m³ is only 2 kg;

- low thermal conductivity. Aluminum has the ability to reflect up to 90% of the sun's rays, acting like a mirror. It will be comfortable under a folded aluminum roof in summer, and in winter, the coating will help melt ice and snow, preventing the formation of ice.

Aluminum roofing helps create comfortable living conditions at any time of the year

Reviews of the advantages and disadvantages of standing seam roofs

Video: installation of a seam roof

Materials for soft roofing

Materials for soft roofs are covered from the outside with stone chips or fine mineral sand. Such spraying plays the role of a protective layer against adverse external environmental influences. An adhesive is applied to the inner side of the soft roof, which holds the material on the batten.

The types of soft roofs include:

- Roll roofing.

- Thermoplastic polyolefin.

- PVC membrane.

- Bituminous shingles.

Roll roofing

Roll roofing is a carpet consisting of several layers of fiberglass, bituminous impregnation, adhesive mixture and small granules of stone or minerals, painted in different shades. The roll material is rolled out on the roof surface, while the reverse side is heated using gas burners.

If it is necessary to replace any section of such a roof, an unnecessary fragment of material is removed, and a new layer is fused in its place with the help of gas burners.

The heated bottom layer of roofing material is glued to the surface with a gas burner

To increase the waterproofing qualities, the soft roof is laid in 2 layers. This material has gained great popularity due to its excellent waterproofing properties, resistance to low temperatures, reasonable price and ease of installation.

Thermoplastic polyolefin

The basis for the manufacture of thermoplastic polyolefins is olefin. It is a synthetic fiber from which clothing is made for those who like to spend time outdoors. The roofing membranes are reinforced with fiberglass to provide rigidity. Installation of this material is carried out using heat sealing. Unlike analogues made of polyvinyl chloride, these membranes do not emit harmful volatile substances.

Olefin-based roofing membranes have good waterproofing properties and do not emit harmful substances

PVC membranes

For all its advantages, polyolefin materials are not endowed with such plasticity as PVC membranes. The peculiarity of this material is its very high strength. In addition, it does not change its physical and chemical characteristics when exposed to critically low temperatures down to -62 o C. Thanks to these properties, this type of coating is used in the northern regions of our country.

PVC membranes withstand critically low temperatures and are therefore used in northern regions

A flat roof is usually covered with canvases made of this material, laid with an overlap of 10 cm. To increase plasticity, special plasticizers with a high degree of volatility are added to the raw materials in the manufacture of PVC membranes. Welding of the joints of this material is carried out using a special apparatus that supplies a stream of hot air. PVC membrane roofing is resistant to open fire, ultraviolet radiation, as well as critical weather conditions and precipitation.

The edges at the junction of two PVC membranes are melted with hot air and additionally pressed by the machine rollers

Reviews of PVC membrane coating

Roof tiles and their varieties

Roof tiles are a piece of roofing material that, when installed, forms a continuous surface. The tiled type of roofing is most convenient for installation on structurally complex roofs. When using it, waste will be minimal.

Roof tiles are made from various materials.

Ceramic tiles

Ceramic tiles are made by molding by firing in a high temperature mode. In such conditions, the material becomes very durable.

The main advantages of ceramic tiles:

- good sound insulation;

- resistance to temperature extremes, precipitation and open fire;

- low thermal conductivity;

- beautiful appearance;

- long service life (over 100 years).

It should be noted that this roof covering is heavy. In this regard, it is necessary to take care of the construction of a strong rafter frame. Moreover, it is quite expensive.

Ceramic tiles are heavy and expensive, but very beautiful roofing material.

Cement-sand tile

Cement-sand tiles are very similar in appearance to ceramic tiles, but the main component for their manufacture is not clay, but a cement mixture. Because of this, this type of roofing has a much lower cost.

Cement-sand tiles are more budgetary than ceramic, but also very high quality and durable roofing material

Bituminous shingles

Bituminous shingles are similar in composition to roll-type coatings, but their layers are slightly thicker. In terms of composition and properties, it belongs to a soft roof, and in terms of design - to tiles, since it is produced in the form of small elements (shingles), which fit with a rather large overlap. The coating is produced in various shapes and colors. The material is not subject to decay, has low thermal conductivity and perfectly seals all joints of bituminous elements.

When installing bituminous shingles, additional sound insulation is not required.

Reviews of bituminous tiles

Real durability of roofing materials

For each type of roofing, there are periods of operation during which their physical and chemical characteristics should not change. As practice shows, the terms declared by manufacturers in real life are not always met:

- Metal tiles with a declared service life of at least 50 years, at best, will last from 30 to 35 years. This is due to the fact that galvanizing of metal in most cases is not done well enough.

- Ondulin, in terms of its chemical composition, is more suitable for temporary roofing, as it contains organic matter. The real life of this material does not exceed 5 years. With a longer service life, this material begins to crack and rot.

- The slate will serve the period specified by the manufacturer. It should be noted that we are talking about Soviet-made slate. Over time, it may lose its original appearance, as it becomes overgrown with moss. Quite often, modern manufacturers produce this roofing material with low quality indicators, which is the reason for the short service life.

- Seam roofing materials will not change their properties within the time specified by the manufacturer. The waterproofing of such a roof can lose its tightness due to poor-quality manufacturing of the folds.

- The service life of roofing materials containing bitumen roughly coincides with the time set by the manufacturer. It should be noted that oxidized bitumen retains the waterproofing properties of the roof longer. In this regard, when buying a soft roof, you should inquire about the chemical composition of bitumen.

- We can say with confidence that ceramic tiles will last 100 years or more. This is easy to verify if you look at European houses with such coverage. Many of these buildings are even more than 150 years old.

Video: choosing a roof - the years will show

Features of the operation of various types of roofing materials

Roofing materials can have different protective layers, be fragile or not resistant to certain influences:

- If the roof is equipped with a metal roof with a hidden valley, it is necessary to periodically (at least 2 times a year) clean the gutters from accumulated debris.

- After heavy precipitation (hail, snow, rain), an unscheduled inspection of the roof must be carried out.

- During roof repairs, you need to wear soft-soled shoes.

- During transportation and installation of metal tiles, the polymer coating of the material must not be damaged. In the future, the top layer in the places of scratches will turn into polymer rags, spoiling the appearance of the roof.

- To extend the life of the ondulin coating, it is necessary to paint it every year.

- The same actions will need to be performed over time if the roof is covered with slate. In addition, there will be a need for periodic cleaning of the slate from the moss.

- Replacement and repair of fragments of the overlaid roof must be carried out using a gas burner.

- In winter, you need to monitor the amount of snow and ice that accumulates on the roof. This is especially important if you have installed heavy roofing elements, such as ceramic tiles. Otherwise, the rafter system may not withstand the total load.

A large number of roofing materials currently produced by different manufacturers makes it possible to make an accurate choice of coverage, taking into account the region, finances, product quality and existing construction skills.

Recommended:

MDF Doors: Entrance And Interior Doors, Their Varieties With A Description And Characteristics, Advantages And Disadvantages, As Well As Installation And Operation Features

Doors from MDF: features, characteristics, varieties. Making and installing MDF doors with your own hands. Door restoration. Reviews, photos, videos

Doors For Restaurants, Bars And Cafes And Their Varieties With A Description And Characteristics, As Well As Features Of The Device And Operation

Features of types of doors for bars and restaurants. Selection and installation of structures, as well as rules for caring for doors in public areas

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size

Roll Roofing Materials: Types With Descriptions, Characteristics And Reviews, Installation Features

What roll material to choose for the roof. How to mount it yourself. Use of self-adhesive materials. Dismantling old roofing

Roll Roofing, Including The Features Of Its Construction, Operation And Repair, As Well As How To Avoid Mistakes During Installation

The difference between roll roofing and modern and Soviet counterparts. Can I use roll roofing on a pitched roof? How to install it and when to repair it