Table of contents:

- Features of the roofing profiled sheet: types, tools for work, service life

- Roofing sheet

- Types of professional sheet for the roof

- Methods for cutting roofing profiled sheets

- The service life of the roofing profiled sheet

- Calculation of a profiled sheet for roofing

- Features of operation

- Reviews of corrugated roofing

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

Features of the roofing profiled sheet: types, tools for work, service life

In recent decades, in the construction of private houses and public buildings, metal profiled sheets are increasingly used for roofing. Durability, reliability, aesthetics, economy - this is just a small list of the qualities of corrugated board, which determine its leading position in the rating of roofing.

Content

-

1 Roofing sheet

- 1.1 Advantages of roofing sheeting

- 1.2 The main differences between the roofing profiled sheet and the wall

-

2 Types of profiled sheets for roofs

2.1 Material marking

-

3 Methods for cutting roofing profiled sheets

3.1 Video: what tools to cut a profiled sheet

-

4 Service life of the roofing profiled sheet

- 4.1 Gallery: profiled sheet on the roof of various buildings

- 4.2 Video: how to choose self-tapping screws for fixing corrugated board

-

5 Calculation of the profiled sheet for roofing

5.1 Video: how to choose the right length of a sheet of corrugated board

- 6 Features of operation

- 7 Reviews about corrugated roofing

Roofing sheet

The modern galvanized steel profiled decking is suitable for installation on roofs with a slope of more than 5 °. The bulk of the profiled sheet sold is used by private homeowners when installing the roof. In addition, this material is used in the construction of buildings for various purposes:

- gazebos, awnings and canopies;

- small architectural forms - kiosks, garages, small shops and restaurants;

- large-sized objects - service stations, trade pavilions, hangars, modular buildings.

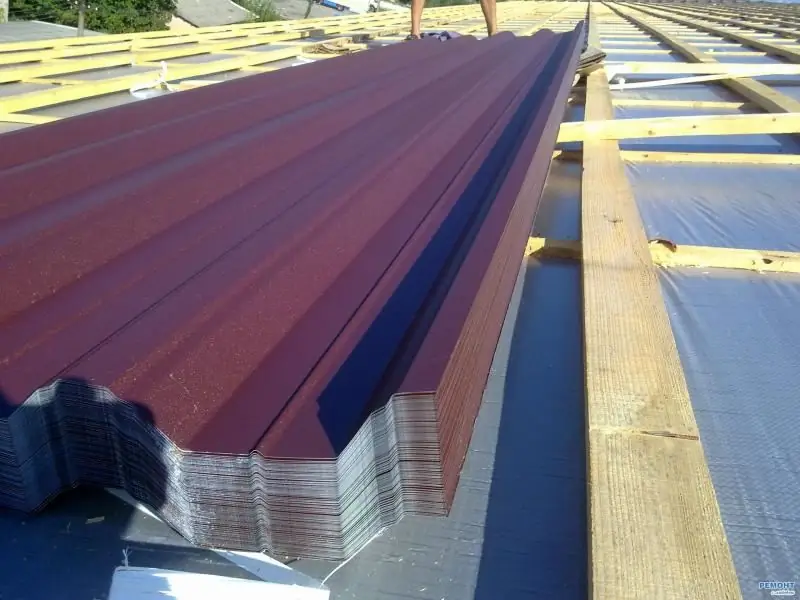

The produced profiled sheet differs in the shape of the wave, its height and color of the coating

The main purpose of the roof covering is to make the roof airtight and reliable. Roofing sheeting differs from other materials in its increased rigidity, wavy relief, thickness used in the production of rolled products and high bearing capacity.

Advantages of roofing sheeting

The main advantages of corrugated board include:

- Ease. Its weight is 4.5-7 kg / m 2, which makes the roof lightweight.

- Strength. Longitudinal stiffening ribs provide high resistance to mechanical damage. Compared to straight sheet, profiled material is at least 3 times stronger.

- Durability. Manufacturers declare operational periods of up to 25 years. In fact, the roofing profiled sheet will last 40-60 years. After this time, it can be used again for other purposes.

- Ease of installation. Flexibility and ease of processing allow you to equip original roofs with configurations of varying complexity. Resistance to low temperatures and humidity makes it possible to install the roof in any season.

- Profitability. The price of the profiled sheet is much lower than that of many other roofing materials. Low weight allows you to save on the foundation and rafter system. Costs for transport, handling and installation work are reduced.

- Aesthetics. The wide color palette of polymer coating and the undulating relief help to give the exterior of the building a finished look or to focus on the unique roof.

- Fire safety, resistance to the destructive effects of corrosion and solar ultraviolet radiation, environmental friendliness.

Professional design and competent choice of material distinguish the building and its roof from a series of monotonous structures

The disadvantages of corrugated board include a low degree of sound insulation and susceptibility to corrosion in the event of mechanical or chemical damage to the protective layers. However, when the roof is insulated with mineral wool, the quality of its sound insulation increases significantly, and regular inspection and timely repair of the roofing significantly prolongs its service life.

The main differences between the roofing profiled sheet and the wall

Profiled metal canvases are used for the arrangement of facades, fences, walls, partitions and roofs. The roofing profiled sheet has some distinctive features:

- To ensure sufficient strength of the roof, sheets with a wave height of at least 20 mm are used to cover it: from 21 mm to 57 mm.

- The roofing profiled sheet has a trapezoidal profile, which ensures the free drainage of large volumes of water during heavy rains and melting snow.

- The height of the profile ridge is taken into account when installing the roof: the smaller the slope angle, the higher the sheet wave. Shallow decking, when installed on a roof with a slight slope, will require a wider overlap when docking. Consequently, the material consumption will increase, increasing the final cost of the coating.

- The edge of the roofing sheet has a capillary groove, which provides additional protection against the flow of sedimentary and condensation water deep into the roofing cake.

In a low-quality profiled sheet, the capillary groove is deformed and becomes useless

Capillary groove provides additional protection against moisture penetration into the roof space

The correct choice of profiled roof covering determines its reliable protection against leaks.

Types of professional sheet for the roof

When classifying profiled flooring, the thickness of the metal, the height of the ribs and the distance between them are taken into account.

According to the rolled metal used in the manufacture, profiled sheets are divided into several types:

- made of steel without a protective coating;

- hot-dip galvanized;

- hot-dip galvanized, covered with a colored protective and decorative layer;

- made of aluminum, chromium-nickel steel, copper;

- special purpose: bent, perforated, textured embossing, etc.

Profiled metal sheeting is stamped with a thickness of 0.3-1 mm.

Different types of profiled sheets can be used for:

- roof coverings;

- installation of permanent formwork for monolithic and interfloor floors;

- installation of walls, partitions and fences.

In terms of geometry, the profile can be wavy and trapezoidal, which, in turn, can have rounded ridges, be reinforced with a groove or have the shape of a traditional trapezoid.

Material marking

On the label of the profiled sheet, the manufacturer indicates the purpose of the material, the height of the ridge, the useful width of the sheet and the thickness of the steel.

The following letter designations are adopted by Russian GOST:

- "N" is the carrier.

- "C" - wall.

- "NS" is universal.

The letter "R" in the designation of the profiled sheet model indicates the presence of a capillary groove, "A" and "B" indicate painting, "AC" or "AK" confirm the coating with aluminum with zinc or silicon. In addition, the type of polymer layer may be indicated in the marking.

The marking of the profiled sheet indicates its purpose, the height of the ridge and the useful width

All types of profiled sheets are used for roofing, since they are made from rolled metal of different thicknesses. Traditionally, roofs are covered with a universal material (HC) made of galvanized steel 0.35-0.7 mm thick with or without a polymer protective layer.

Methods for cutting roofing profiled sheets

The main difficulty when cutting profiled sheets is to maintain the integrity of the decorative and protective layer, the violation of which leads to active corrosion of the metal and shortens the life of the roof. Hot methods, for example, using an autogen, cannot be used, since the polymer coating will deteriorate from exposure to high temperatures. Traditionally, profiled sheets are cut:

- Jigsaw. A feature of the process is the vertical installation of the blade to be cut. Several helpers are needed to hold the cut pieces. Household low-power tools cope with a sheet thickness of no more than 0.2 mm. The torn edge requires additional processing.

- A hacksaw for metal. With a small amount of work - a good choice. Simple and safe, even cuts without notching, but slowly and only in a straight line.

- With an electric saw. Fast, accurate, effortless. The inconvenience lies in the need for a table for work and the ability to cut only straight parts.

- Manual, electric or nibbling shears for metal. Professional expensive tool that cuts profiled sheets up to 1 mm thick quickly and accurately, without burrs, without bending the blade. It is convenient to use when cutting thin strips.

- Grinder. For work, a special cutting aluminum disc with a maximum radius and a thickness of 1-1.6 mm is used. Thanks to the carbide teeth, the cut edges are smooth and clean. An experienced craftsman with a manual angle grinder (grinder) will cut out parts of the required geometric shape or quickly cut a dozen sheets at a time.

Correct cutting of the profiled sheet is possible if the wave height of the material corresponds to the diameter of the grinder's cutting wheel. The use of an abrasive wheel will destroy the protective coating of the roofing sheet.

Professional roofers use cordless drill attachments when cutting corrugated board, which allow you to cut and adjust the canvases during roof installation in hard-to-reach places.

When cutting a profiled sheet, in no case should you use a grinder with an abrasive circle

To protect the edges at the joints, it is recommended to treat the cut points at the end of cutting with anti-corrosion mastic and paint them in the color of the decorative coating.

Video: what tools to cut a profiled sheet

The service life of the roofing profiled sheet

The roof of a building is exposed to continuous environmental influences. Solar ultraviolet light, hail and snow, heavy rains, chemicals, temperature extremes, birds and branches of nearby trees - all these factors negatively affect the roofing. Over time, the roof loses its attractiveness, it requires repair or complete renovation.

Gallery: professional sheet on the roof of various buildings

-

Professional sheet on the roof of the restaurant - Profiled sheet is used to cover the roofs of various public buildings

-

Roof covered with corrugated sheet - Sheds, gazebos and garages are covered with an inexpensive profiled sheet with a thickness of 0.4-0.5 mm with an average wave height

-

Dacha under the roof made of profiled sheet - The decorative colored layer looks aesthetically pleasing and gives the roofing additional protection

-

Galvanized profiled sheet - Galvanized profiled sheet lasts up to 25 years

-

Original roof made of profiled sheet - You can cover a roof with a profiled sheet with a configuration of any complexity

Various factors affect the service life of the profiled blade:

- Protective covering. Hot dip galvanizing will last 15-25 years; aluminum added to zinc will extend this time by 5-10 years. A decorative polymer composition applied over the protective layer increases the service life of the roof up to 50 years.

- The quality of the professional sheet. If defects are found during installation (scratches, chips, creases), such material is not recommended.

- Corrugation height. With heavy snowfall, the ability of the pavement to withstand the load is important. A wave less than 20 mm will bend under the strong pressure of the snow layer. When storm water or melt water flows down, the rib height of 35-70 mm facilitates their unhindered passage and removal.

- Correct installation. Errors in the construction of the roof (wide spacing of the lathing, leaking joints, raw edges after cutting, the use of fasteners inappropriate for the material, etc.) lead to deformations and corrosion, which significantly reduces the operational life of the coating.

- Roof care. Regular inspection and cleaning of the roof from various contaminants helps to timely detect cracks or other defects and carry out repairs.

When choosing a profiled sheet for the roof, you must familiarize yourself with all the technical characteristics of the material and take into account the expected level of load on its surface

Video: how to choose self-tapping screws for fixing corrugated board

Calculation of a profiled sheet for roofing

Before proceeding with the calculations of the required amount of material, you should determine its parameters: sheet thickness, height and waveform, type of protective coating. Further, based on these data and having familiarized themselves with the proposals of the modern construction market, the consumption of the profiled sheet is calculated using the formulas or using a special calculator.

Manufacturers offer profiled sheets with a length of 40 cm to 6 m. If desired, it is possible to order a size corresponding to the length of the roof slope. In width, due to the variety of shapes and heights of the corrugation, the material is produced from 80 cm to 1.05 m. When calculating the amount of material, only the useful width of the profiled sheet is taken into account. That is, the overlap on the next canvas is subtracted from the full size. The width of the overlap depends on the angle of the roof slope, the height of the profile and the thickness of the rolled metal. As a rule, 1 wave is allocated for docking.

For calculations, the useful width of the sheet is usually taken. i.e. its full size reduced by the amount of horizontal overlap

It is not difficult to calculate the material consumption for a single or gable roof. For complex structures (hip, hip, mansard, multi-gable and other forms), it is recommended to resort to a special program or the help of a professional architect. When using the program, it is possible, by changing some parameters, to compare the results obtained. The roof calculator takes into account roof slope, overlap width, castle floors and other components. Moreover, all calculations are made accurately and quickly.

You can calculate the materials yourself or use the help of professionals

When doing the calculations manually, the area of the rectangular zones is first summed up. Then, sections of triangular, trapezoidal and other geometric shapes are added, and the dimensions of the end and eaves overhangs are also taken into account.

In addition to the basic material, it is also necessary to take into account additional elements. For the device of the roof, you will need a ridge, a pediment, an aerator, a valley, a snow holder, a cornice and end strips, as well as plugs for some elements.

The corrugated board is fastened with self-tapping screws with special rubber gaskets. For 1 m 2 of coverage, they need 7-9 pcs.

When carrying out calculations, it is necessary to correctly calculate the number of all required additional elements

With the correct calculation of the number of sheets of corrugated board, additional and fastening elements, waste of materials is minimized, waste of time and money for the purchase of missing parts is excluded.

Video: how to choose the right length of a sheet of corrugated board

Features of operation

The roof of the corrugated board does not require special care. Dust, leaves and small debris are washed off by rain. Large branches in valleys and gutters are removed by hand. In unfavorable conditions (near a production facility that emits processed products into the atmosphere, in areas with salty sea air, etc.), stains and streaks appear on the coating, which can be easily removed with a soft brush and soapy water. Once a year, in the spring after the snow melts or in the fall before the onset of cold weather, the roof must be carefully examined. Found cracks are painted over with paint in the color of the coating or treated with anti-corrosion mastic. In winter, the roof is cleaned of icicles and snow with plastic or wooden tools: shovels, scrapers or special devices.

Reviews of corrugated roofing

Over the past decade, the popularity of roofing profiled sheets has grown significantly. Today, not only the owners of country houses and summer cottages resort to using this material when arranging the roof. In the repair of commercial and public buildings, in the construction of large trade pavilions and various technical structures, a reliable and aesthetic roofing profiled sheet is increasingly used.

Recommended:

Types Of Roofing Materials With A Description And Characteristics And Reviews, Including Roll, As Well As Features Of Their Operation

Types of roofing materials: sheet, soft and tile roofs. Technical characteristics and features of operation of various types of coatings

Roof Membrane, Its Types And Brands With Description, Characteristics And Reviews, As Well As Installation Features

What is a roofing membrane. What types of membranes are used in the construction of various roofs. Membrane brands and features of their installation

Roofing From A Profiled Sheet, Including The Features Of Its Design And Operation, Repair, As Well As How To Avoid Mistakes During Installation

What kind of profiled sheet can be used for the roof. DIY cold and insulated roof device. What mistakes are possible. Features of operation and repair

The Slope Of The Roofing From The Profiled Sheet, Including How To Choose The Right Brand Of This Roofing Material, Depending On The Angle Of The Roof

What is the slope of the roof. The angle of inclination of the roof from the profiled sheet: minimum and permissible. The choice of the brand of corrugated board according to the degree of roof slope

Roof Waterproofing And Its Types, As Well As Features Of Its Design And Installation, Depending On The Roofing Material

What materials can be used to arrange reliable waterproofing of the roof and how to install it