Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

How to make a frame pool with your own hands: instructions, tips, recommendations

Many people want to have a pool on their site, where they can swim in the summer heat. Not everyone has the opportunity to build an expensive, permanent tiled concrete structure. But everyone can build an inexpensive and convenient frame pool for the whole family on their own.

Content

-

1 Features of an outdoor frame pool

- 1.1 Table: advantages and disadvantages of frame pools

- 1.2 Varieties of frame pools

-

1.3 Comparison of the frame pool with other types

1.3.1 Video: installing a frame pool

- 1.4 Photo gallery: types of frame pools

-

2 We build a frame pool with our own hands

- 2.1 Selecting the size and location of the structure

- 2.2 The choice of material for the manufacture of the pool bowl

- 2.3 Stages of construction of a frame pool

- 2.4 Video: how to make an inexpensive frame pool

Features of an outdoor frame pool

The main feature of a frame pool is the presence of a frame frame, which can be made in the form of wooden, plastic or metal elements. The pool bowl is usually made of durable waterproof awning material or reinforced PVC film, inside which there is a thin nylon mesh, which provides it with a high degree of strength.

PVC film for swimming pools can have a wide variety of designs: both ordinary blue and custom-made, with complex patterns and applications in the form of various signs and shapes

Table: advantages and disadvantages of frame pools

| Pool advantages: | Pool disadvantages: |

| Comes in various shapes and sizes | The fragility of the structure (service life no more than 12 years) |

| Quickly assembled and dismantled | Imperfect filtration system |

| Has high performance characteristics | Low degree of resistance to various atmospheric phenomena |

| Can be installed in any convenient place | The complexity of the selection of an individual design |

| Does not require a foundation | Seasonality of use (in most cases) |

| Resistant to temperature changes | |

| Easy to clean | |

| Does not require a water supply system | |

| Affordable | |

| UV resistant | |

| Can be used as a skating rink in winter |

Varieties of frame pools

Frame pools are:

-

Leafy. The base of the frame is made of metal, plastic or wood sheets, which are attached with special supports.

Sheet frame pool The sheet frame pool is strong and solid, since the sheet frame gives rigidity and strength to the entire area of the walls

-

Rod. The frame is made of metal or plastic pipes, wooden beams.

Rod pool The rod structure is very quickly assembled and disassembled, and is also quite strong

In both versions, the bowl is made mainly from a special high-strength PVC film.

Pools can have an automatic filtration system, disinfection, water heating, LED lighting and other additional devices.

The frame pool bowl can be rectangular, oval, round and trapezoidal. A frame of any geometric shape can be made from metal sheets.

The film is attached to the frame using fittings supplied with the frame pool itself

Frost-resistant constructions can be used at temperatures down to -20 ° C. The PVC film and the frame of such reservoirs can "hold" even frozen water in the pool.

The frost-resistant pool can easily replace your traditional winter ice hole after a bath or serve as a small home ice rink

Seasonal frame pools are intended only for use during the warm season. For the winter, such structures must be dismantled and removed indoors.

Comparison of a frame pool with other types

Frame pools have a much shorter service life than concrete stationary structures. There is no need for them to dig a pit and build a foundation. The installation time of such reservoirs is much less than that of concrete ones.

A concrete pool is more durable and durable, but its construction will take more time and money

Most inflatable pools cannot be left over the winter as the materials from which they are made may not withstand too low temperatures. In comparison with inflatable pools, frame ones are more durable and reliable. They have a long service life, are less susceptible to physical and mechanical damage. For an inflatable pool, it is imperative to arrange a flat platform so that its frame does not have distortions and rolls, as a result of which water can pour over the sides.

The advantage of installing inflatable pools in the country is that they can be freely moved around the site, installing in any suitable place

Therefore, frame outdoor pools are the most profitable option for people who want to have an inexpensive, but durable and reliable reservoir on their site, which is quickly and easily assembled without the use of expensive materials and tools.

Video: installing a frame pool

Photo gallery: types of frame pools

-

Frame pool polygonal - Frame pools are compact, convenient and mobile

-

Oval frame pool - If there is no centralized water supply on the site, you can purchase a pumping station that will ensure uninterrupted operation

-

Recessed timber frame pool - Frame pools can be installed on the surface or at some depth in the ground. Thus, the bowl can be placed in different places depending on the landscape.

-

Frame pool under the awning - The frost-resistant pool does not need to be dismantled on the eve of winter. In order for it to "survive" the winter season without any problems, it must be filled with clean water, covered with an awning to protect it from debris and left to freeze

-

Wooden frame pool - Swimming pool maintenance does not take too long

-

Large frame rectangular pool - Frame pools are adapted for the installation of additional equipment

-

Frame pool with ladder and filtration system - A frame pool with imitation stone sides will fit well into the landscape of the cottage

-

Collapsible frame pool - A collapsible frame pool can be taken with you to nature, since it does not take up a lot of space in the trunk and this structure is quite light in weight

We build a frame pool with our own hands

A frame pool is considered one of the simplest and most common designs. It can be assembled in one day and alone. This work is creative, extremely creative and very interesting.

Choosing the size and location of the structure

We will build a rectangular frame wooden pool, 4.5x2 meters in size and 1 meter deep, from waterproof awning fabric. The displacement of the pool is about 8 tons. This is the optimal design of the reservoir, in which both adults and children can swim freely.

Since usually the standard sizes of personal summer cottages vary from 6 to 10 acres, such a structure can be installed in any convenient place. It does not require large-scale earthworks and complex ground planning.

The rectangular shape of the pool is optimal for a small area

The rectangular shape of the pool does not take up much space, which will make it possible to use most of the area for planting vegetables, flowers and other plants. In addition, water from such a pool can be used for irrigation. Due to what the water consumption in the country will be saved and controlled.

The choice of material for making the pool bowl

For the manufacture of the bowl, we will use a waterproof high-tech PVC material that has a high degree of strength, is practically not subject to stretching and does not allow water to pass through. It is best to use a canvas made in Belgium with a width of 2.5 meters. Its average specific gravity of 650 g / m 2, so it can withstand high water pressure.

One of the sides of such a fabric is smoother, and we will use it as the inside of the pool.

Tools needed to build a pool:

- construction hot air gun with a special nozzle - operating temperature range 20-700 ° С;

- chipboard or fiberboard plates;

- rolling roller;

- eyelets about 260 pieces;

- ropes or strong ropes;

- sand and crushed stone;

- bitumen sheets;

- rule and building level;

- pine timber - 100x50 mm;

- board - 25 mm thick;

- antiseptic agents;

- Sander;

- hand drill;

- self-tapping screws - length 45-50 mm;

- self-tapping screws with a press washer - length 35 mm.

Stages of construction of a frame pool

- We put fiberboard or chipboard on a flat surface for the convenience of working with the cloth for the bowl.

-

We take a PVC sheet and cut it out depending on the size of the structure, not forgetting about 20-30 mm allowances for gluing. We select the required welding temperature depending on the manufacturer's recommendations. We lay out the fabric with an overlap and warm up the joints with a hot hairdryer until it melts slightly so that it does not burn.

We cut and glue the canvas When cutting the canvas, remember about the allowances for gluing

-

Press the softened fabric tightly with a special roller and go over the entire surface of the product to be glued. We carefully monitor the tightness of the seam, since the strength of the bowl and its waterproof characteristics depend on this. Before starting work, you can practice on a small piece of material.

Ready canvas for the pool It is necessary to carefully monitor the tightness of the seams.

-

After the whole bowl is glued together, bend the edges along the perimeter of the product by about 50-70 mm and also boil them with a hairdryer. We attach eyelets along the entire edge of the resulting side using a special tool. We place eyelets (metal rings) every 50 cm of the pool bowl.

Fixed eyelets We fix the eyelets at a distance of at least 50 cm from each other

-

Then we prepare a site for installing a wooden frame. To do this, choose a suitable place on the site and remove the top layer of the earth, remove excess plants and debris.

Foundation preparation It is important to carefully clean the area for the pool from debris.

-

The surface must be flat and clean enough so that the frame is straight and straight. Pour sand on the ground, about 5-10 cm thick and level it. For the convenience of work, we install beacons and level the sand with a rule or an ordinary board.

We level the sand with the rule For the correct installation of the pool, it is necessary to carefully level the area

- Assembling the frame structure of the pool. For this we take a bar, unedged and semi-edged boards. All wooden elements are treated with antiseptic agents before assembly. The lumber must be well dried so that it will not be "led" in the future. We mark the corners of the future frame and check their diagonal evenness.

-

Then we drill holes (holes) about 50-70 cm deep with a drill. On the long side we install two supports, except for the corner ones. We should have gaps of about 1.4 meters. We set one support in width on both sides. We put the pillars vertically, following the line. To do this, we take a special construction cord that can be pulled along the entire perimeter of the base. We install the racks in the dug holes and fill them with rubble, and then tamp them well. Before digging in, we wrap the lower part of the bar with pieces of bitumen to extend its service life.

Installing racks We install the frame racks to a depth of 50-70 cm

-

After the timber has been installed, we begin to tie it with a board. From above, at a height of about 1 meter from the base horizontally, we fasten a half-edged board. We carry out the lower strapping of the perimeter of the fence with a shawl. We maintain a height of about 20-40 cm from the ground. We fasten all the boards to the timber through the supports with self-tapping screws (45-50 mm).

Making the top harness We make the upper frame strapping at a height of 20-40 cm

-

The intermediate support legs must have strong struts, as a large amount of water will "press" on them. Therefore, from the top of the supports, using special braces from a bar, we make triangular structures that will hold the entire frame. Thus, we will ensure the strength and reliability of the entire pool structure. After strapping, the excess parts of the racks can be cut off, or you can leave them so that in the future you can attach a canopy or awning to them to cover the pool.

Triangular frame structures Triangular stabilizing braces are essential for the strength of the frame

-

After the frame is made, you need to install the ladder. For this, at a distance of about 60 cm from the corner of the frame, we install an additional sturdy rack. We take an unedged board and cut out two wide bowstrings, which we attach from below to the support platform. We fasten them to the supports from above and rest on the upper part of the strapping.

We fasten the bowstring We fasten the string for the stairs at a distance of 60 cm from the corner of the frame

-

According to the level, we mark the future placement of the steps with a step of about 25 cm. We fasten support bars in these places opposite each other. We cut out the feet from a wide board and put them on the supports. We should have 4 steps, and attach the upper one to the harness so that we get a small platform at the very edge of the pool.

Ladder installation There must be at least four steps by the stairs

-

We level the sand bed. Then horizontally through the eyelets we attach the sides of the bowl with self-tapping screws and press washers.

We attach the bowl to the frame All fasteners must be made of galvanized

-

We carefully stretch the canvas so as not to tear the fabric, and press it with self-tapping screws.

We stretch the canvas onto the frame The fabric stretches neatly and tightly

As a result, we got a convenient and inexpensive outdoor frame pool, which can be improved over time: install a filtration system, water supply and drainage, LED lighting, etc. Since our pool turned out to be collapsible, if necessary, it can be rearranged from one place to another. The frame can be left for the winter by simply covering it with an awning, and the PVC film can be removed for winter storage by unscrewing all the screws.

The frame pool can be prefabricated or collapsible

Video: how to make an inexpensive frame pool

A collapsible frame pool is one of the simplest, most convenient and inexpensive suburban structures. It can be easily and quickly assembled on your site using a minimum of materials and tools. On hot summer days, the whole family can enjoy water treatments, and before and after the season, the water from the pool can be used to water the plants.

Recommended:

Making A Pool From Polypropylene With Your Own Hands + Photos And Videos

A step-by-step description of building a pool and making a polypropylene bowl with your own hands. Features of the material, calculations, the necessary tools. Video

Do-it-yourself Pool Cleaning And Repair - How To Remove Greens, Small Particles And Rust, Seal The Film With Your Own Hands, Get Rid Of The Nematode, Clean Without A Vacuum Cleaner

Do-it-yourself pool repair and cleaning. Methods for plastering and painting the structure. How to seal an inflatable pool. Water treatment methods

Rice Vinegar: What Can Be Substituted At Home For Sushi, Rolls And More; Apple, Regular And Other Options + Photo And Video

Features of rice vinegar. How to cook it yourself at home. What vinegars and acids can you replace it with? Proportions for different dishes

How To Purify Pool Water With Your Own Hands - Filters, Chlorination And Other Options With Photos And Videos

Pool cleaning methods and means. Recommendations for making a filter device at home. Chlorinating Water Tips

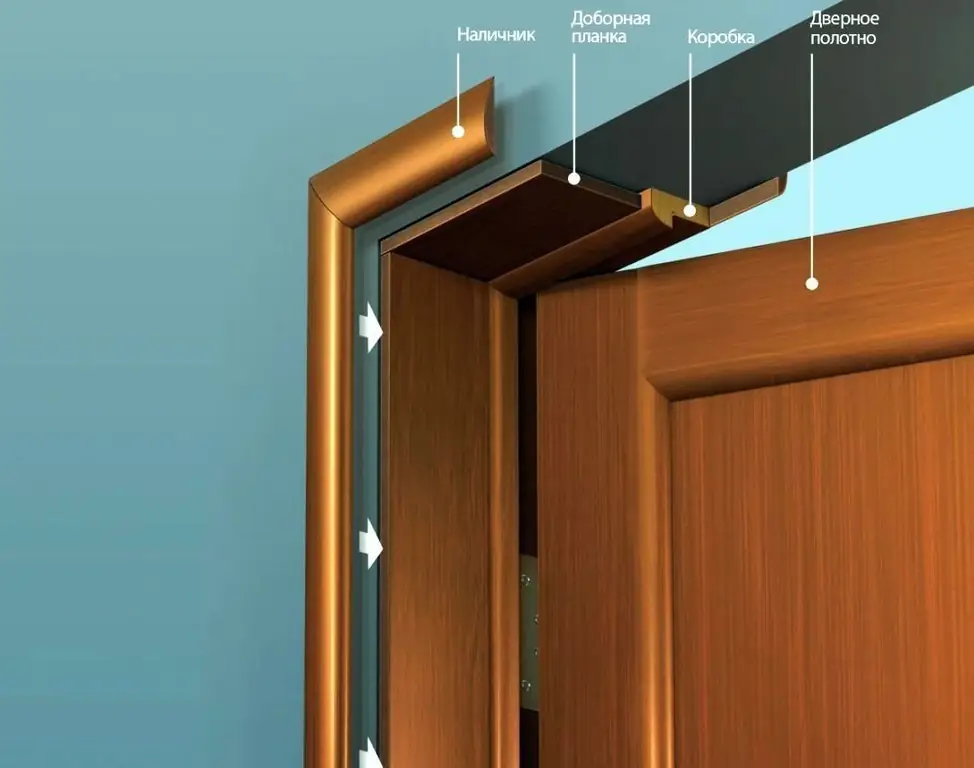

Door Frame: Varieties And Material, Pros And Cons, As Well As How To Make It Correctly

What is a door frame. Types of door frames, their main dimensions. Manufacturing and installation of a door frame in the opening