Table of contents:

- Author Bailey Albertson [email protected].

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

Cement-sand tile: characteristics and application

Cement-sand shingles can not only decorate the roof beautifully, but also create a durable and practical roof covering. However, the characteristics of the material do not allow it to be used in certain climatic conditions, which should be taken into account when choosing.

Content

-

1 Characteristics of cement-sand tiles

- 1.1 Video: composition of tiles, manufacturing process and strength testing

- 1.2 Service life

- 1.3 Resistance to external influences

- 1.4 Frost resistance

- 1.5 Dimensions and shape of tiles

- 1.6 Weight of cement-sand tiles

- 1.7 Advantages and disadvantages

- 1.8 Video: features of cement-sand tiles

-

2 Rules for the installation of tiles

- 2.1 How to make a sheathing for tiles

- 2.2 Basics of installation

- 2.3 Video instruction: installation of lathing and laying of tiles - in detail, with calculations and measurements

-

3 Operation of tiled roofs

- 3.1 Photo gallery: roofs with cement-sand tiles

- 3.2 Reviews of cement-sand tiles

Characteristics of cement-sand tiles

This type of tile consists of quartz sand, dyes, cement, binders and water-repellent additives.

Shades of cement-sand tiles are obtained by using dyes

In the manufacture of tiles, the dye is used both for external application and in the composition of the mass itself. This makes the coating practical, as small chips are invisible on the roof surface.

Video: composition of shingles, manufacturing process and strength testing

Life time

All components in a natural tile are selected for a successful interaction with each other, so its service life is more than 50 years. Elements created without breaking technology and correctly mounted on the roof surface will last up to 100 years. Manufacturers provide a 30-year warranty for their products.

Correct installation ensures long-term and efficient operation of the cement-sand pavement

For the longest possible operation, it is important to adhere to certain conditions for laying the tiles:

- the optimal angle of inclination of the roof is from 23 to 66 °;

-

a waterproofing film must be laid and the lathing is attached with a step of 31-34.5 cm;

Roof lathing for shingles It is important to correctly lay the wooden lathing under the tiles.

- the overlap of the elements is maintained from 7.5 to 10.8 cm along the entire length of the roof.

Compliance with the installation rules provides a reliable base under the natural tile and contributes to its resistance to climatic and mechanical influences.

Resistance to external influences

Cement-sand tiles are resistant to climatic influences. The coating of such elements practically does not fade under ultraviolet rays, it tolerates heavy rains and snowfalls well.

All colors are UV resistant

The material easily withstands such influences as:

- frequent precipitation in the form of rain and snow;

- mechanical loads: snow cap layer or roof repairs;

- exposure to hail, strong wind.

A tile made of a cement-sand mixture has a high level of strength, so minor repairs can be carried out directly on it without the risk of damage. But you should avoid sharp blows and the impact of sharp objects on the tiles.

The shingle calmly withstands the weight of a person, without giving in to deformation

Frost resistance

The cost of cement-sand tiles is lower than ceramic. Moreover, the characteristics of both practically do not differ in either water retention or frost resistance. They can easily withstand sudden changes in temperature within 10 degrees and retain their shape down to -45 ° C.

Installation of tiles can be carried out at temperatures down to -10 ° C

This material is optimal for use in regions where the air temperature does not drop below 30-35 ° C in winter. This allows you to ensure maximum durability of the roof covering and reduce the risk of accidents that may arise from a harsh winter.

The size and shape of the tiles

Cement-sand tiles are manufactured in various shapes and sizes: each type has a specific purpose and is mounted in different places on the roof. Therefore, all shingles are divided into basic and additional elements: the roof surface is covered with the main ones, and the joints are closed with additional ones.

Shingles differ in shape: each type is intended to decorate different places on the roof

The following types of natural tiles are produced:

-

in-line (ordinary) - for laying on a flat surface of slopes, where the material is easily distributed in the form of straight rows. Has a wavy shape, and in the complex creates a beautiful coating;

Laying of row shingles Row shingles fit faster and have a convenient locking fastening

-

lateral (pediment) - curved L-shaped, mounted along the edge of the roof gable. Left-sided elements are placed on the left end of the roof, right-sided - on the right, and universal - along the entire end;

Decoration of frontal parts of roofs with cement-sand tiles Curved elements are placed along the edges to ensure the neatness of the front of the roof

-

half - for those areas where in-line elements are cut at an angle, but it is possible to add small details. This allows you not to waste a full-fledged ordinary tile, cutting it into pieces. Usually half-tiles are produced in the size 420x180 mm;

Half CPU Roof Tile Half shingles are convenient for installation in difficult areas

-

checkpoint - for installing additional pipes on the roof;

Walk-through tile Passage tiles are installed in a specific place where the pipe will be installed

-

footboard - for fixing the gratings that allow you to move safely for roof maintenance. Their location is determined in advance;

Roof shingles For ease of movement, tiled footrests are installed on the roof

-

ventilation - for air circulation in the valley area, on the ridge or in the cornice area;

Ventilation tiles Installation of ventilation tiles avoids condensation

- support - for places where snow-retaining ladders are installed. Has greater strength than in-line: allows you to reliably fix the ladders and avoid a sharp descent of ice;

-

ridge (initial and final), end - to close all joints and complete the overall picture of the roofing.

Types of natural tiles and additional elements Additional elements help to harmoniously arrange all the edges and joints on the roof made of natural tiles

The most common tiles are standard sizes - 420x330 mm. The average consumption of such parts is 10 pieces per 1 m 2.

Weight of cement-sand tile

Tile from a cement-sand mixture is a material similar to fine concrete, but with better characteristics. The weight of the elements for the roof is from 45 to 50 kg / 1 m 2.

When designing, the weight of the roof and the load that it will withstand must be calculated

Knowing the average weight of the tiles and the area of the roof, it is easy to determine the weight of the coating.

Advantages and disadvantages

Tiles made of a cement-sand mixture have been used for roofing for only about 160 years. But she was already able to gain popularity due to a number of advantages:

- looks like ceramic, it is made in different colors;

- environmentally friendly, does not rot and deformation, resistant to various natural influences (except for large hail);

- leaves a minimum amount of waste during installation (about 5%);

- has high sound and thermal insulation, as well as ventilation qualities;

- easy to operate and repair;

- affordable, durable with high-quality styling.

Cement-sand shingles are especially suitable for buildings made of brick or timber

However, this material is not without its drawbacks, which must be taken into account:

- heavy weight - suitable only for a reliable stable building, requires the use of equipment for transportation and lifting to the roof;

- a small variety of forms of the main elements;

- weak strength to mechanical stress - requires care during transportation, laying and during operation. Broken elements must be immediately replaced with new ones in order to protect the building from leaks;

- small piece material - takes a lot of time for installation;

- roughness of the surface - delays the convergence of snow, therefore it is important to strengthen the roof rafter system in advance.

Video: features of cement-sand tiles

Tile installation rules

During installation, it is important to take into account the characteristics of each type of tile and adhere to the fastening technology. Cement-sand tile consists of the following elements:

- the main lock is triple, double or single. Protects the roof from blowing out and snow ingress, increases the strength of the coating;

- side locks - lock the tiles together and prevent leakage. Allow parts to shift relative to each other up to 8 cm;

- reinforcement ribs - to reinforce the tiles. Provide strength and stability of each part to various loads;

- rounded edges - allow you to effectively drain precipitation;

- bottom hooks - fix the tiles to the lathing, help to evenly distribute the weight.

Tiled tiles are varied and have a well thought-out structure

Each tile is equipped with mounting holes for easy installation work.

How to make a crate for a tile

For the lathing, coniferous wood bars with a moisture content of no more than 25% are used, which protects the base from deformation and decay

The step of the lathing should not be more than the length of the tiles

The step of the lathing depends on the slope of the roof.

When constructing multi-slope roofs, the distance between the lathing bars is calculated for each sloped surface separately.

Installation Basics

Before starting construction, an antiseptic should be applied to all wooden parts of the roof from a sprayer, and an anti-corrosion agent should be applied to metal parts. After filling the crate, the chimney is sealed: a tape with a reinforcing mesh is attached to it. If a valley is provided in the roof structure, then a sealing tape is laid in this area. Then the process of laying the tiles begins:

- The first row is placed from the bottom right corner. The tiles should hang over the edge of the roof by no more than 7 cm. The tiles are fixed to the crate with galvanized screws.

- Further along the edge of the roof end, a row is mounted in the vertical direction. Before laying the next strip, pull a cord between the opposite edges of the roof to ensure that the rows are laid horizontally.

- Observing the markings and starting from the fixed end pieces, horizontal rows are formed.

- In difficult corners and valleys, a covering of pre-cut elements is laid out.

- The ridge, connecting and other additional parts are attached last.

Installation of cement-sand tiles in the valley area requires precision in cutting the tiles and correct fastening

Installation can be carried out along the perimeter of the slope or vertically, but the presented method is the simplest and allows you to get even rows.

Video instruction: installation of lathing and laying of tiles - in detail, with calculations and measurements

Tiled roof operation

It is possible to increase the service life of the cement-sand coating if you follow the operating rules:

- replace damaged elements with new ones in time, carefully removing them;

- remove snow from the roof with a special tool that cannot damage the surface of the tile;

- if a leak occurs inside a building, it is important to immediately identify the cause and eliminate it;

- annually clean the ventilation gaps in the tile and ridge from dust and dirt.

The valley area is most susceptible to leaks and needs regular inspection

If during operation a problem arose in a certain place of the coating, then it is imperative to inspect the entire roof to identify the cause. Only then can the damaged tiles be replaced or other necessary work can be carried out.

Photo gallery: roofs covered with cement-sand tiles

-

Hip roof of a building with tiles - Dark colored roof tiles are practical and make the exterior of the building stylish

-

Gable roof of the house - Red roof - a popular classic for private houses

-

Roof of complex shape made of cement-sand tiles - Bright tiles always decorate the roof of the house

-

Original roof made of cement-sand tiles - Cement-sand tiles are suitable for complex roofs

-

Beautiful roof covered with cement-sand tiles - A multi-slope roof covered with cement-sand tiles does not look different from a ceramic coating

-

Tiled roof of a two-story building - For two-story buildings, the tiles are optimal and make the roof practical to use

-

Modern tile roofing on the roof of a private house - Ridge elements decorate the roof and make it look complete

Reviews of cement-sand tiles

A cement-sand coating in the form of unusual colored scales, affordable and easy to install, will help to make your roof beautiful and practical. And the guarantee of the durability of such a roof will be the quality of the tiles and compliance with the rules of installation.

Recommended:

MDF Doors: Entrance And Interior Doors, Their Varieties With A Description And Characteristics, Advantages And Disadvantages, As Well As Installation And Operation Features

Doors from MDF: features, characteristics, varieties. Making and installing MDF doors with your own hands. Door restoration. Reviews, photos, videos

Estet Doors: Types And Models, Their Advantages And Disadvantages, As Well As Installation Features And Customer Reviews

What are the features of the Estet doors. How they might look and what is the production technology. Feedback from real users about Estet doors

Torex Doors: Entrance And Interior Models, Their Advantages And Disadvantages, As Well As Installation Features And Customer Reviews

Doors "Torex": production features, advantages and disadvantages. Model range, fittings and components. Features of installation, tips for use

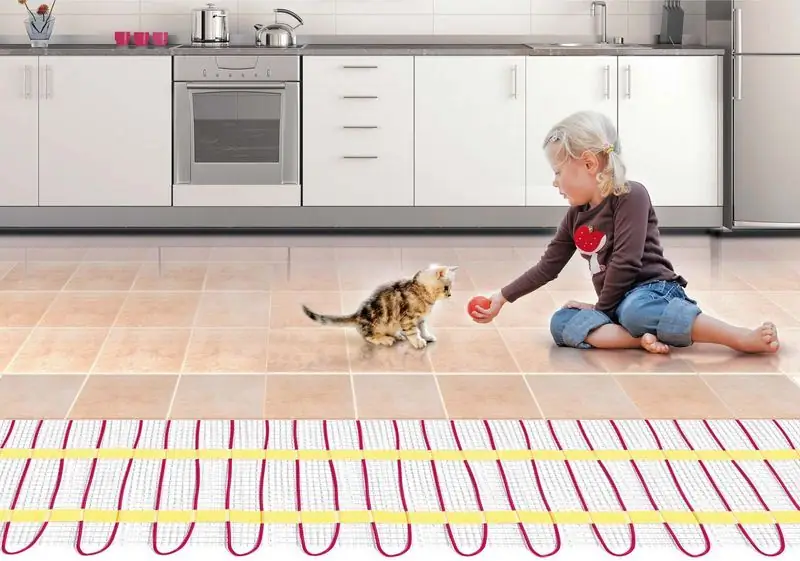

Warm Floor In The Kitchen Under The Tiles: Features, Advantages And Disadvantages, Installation, Photo

What is underfloor heating and its types. Recommendations for choosing a coating for underfloor heating. The sequence of work on the installation of a warm floor

Composite Tiles, Advantages And Disadvantages, Review Of Popular Brands With Descriptions, Characteristics And Reviews, As Well As Installation Features

Composite shingles: history of use, characteristics, pros and cons. Features of installation. Review of popular brands. Reviews of builders and home owners