Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

We close the seams between the sheets of drywall ourselves

When you are finishing a room with drywall, before proceeding with its finishing, you should process the seams at the joints of the sheets. These are the most sensitive zones to damage and destruction. In the absence of a high-quality finish, cracks may appear at the seams, which will negate the results of both already done and subsequent work. Sealing the seams between drywall sheets is not difficult, but painstaking. It requires attention both in the process itself and in the selection of materials and tools.

Content

- 1 What materials and tools will be required

-

2 Embedding process from start to finish

- 2.1 Nuances of work

- 2.2 Sewing joints

- 2.3 Primer

- 2.4 Kneading the putty

- 2.5 Putting on seams and using serpyanka

- 3 Putty on the corners

- 4 Video about sealing joints between drywall sheets

What materials and tools will be required

A standard set of sealing tools looks like this:

- several spatulas (at least two): wide - 15 mm, narrow - 10 mm;

- special corner spatulas for finishing corners;

- building level;

- falcon - a special plate with a handle for a set of putty;

- primer brush;

- trowel with sandpaper or abrasive mesh;

- painting knife;

- edge planer for drywall.

Sealing tools for drywall sheets

When choosing materials, pay attention to the list of the essentials:

- starting gypsum putty such as Fugenfüller or Uniflot (the second type is somewhat more expensive, but has a higher density);

- acrylic primer mix;

- perforated masking tape - serpyanka;

- metal corners that reinforce the outer or inner corners.

When you choose a mixture for sealing joints and seams, be sure to consider what the surfaces will be finished with. For example, you can use cheaper materials for wallpaper or decorative plaster. Cracks that appear over time will not be visible. Fugenfüller-type mixes work well for this. When using them, it is recommended to use serpyanka.

But if you plan to paint the surface, it is better to purchase high-quality finishing mixtures. Uniflot mixes are used without a reinforcing tape if they are used for grouting. Paired with serpyanka, they give additional strength and stability to the plasterboard structure.

Embedding process from start to finish

So, you have prepared everything you need, now you can get to work. How to close up the seams between drywall sheets? First of all, you need to putty them at the joints. Above, we have already told how it is better to seal the seams in drywall and which putty mixture is more suitable for subsequent surface finishing.

Nuances of work

- Observe the temperature conditions in the room when working. The optimum temperature is not higher than +10 degrees.

- About two days after the end of the work, there should be no sudden temperature changes in the room.

- Avoid drafts in the room while grouting.

- Plasterboard installation refers to the final stages of work. Therefore, in front of him you need to do all the wet work (plastering and installation of the floor screed).

- Keep an eye on the humidity in the room so that the filling work is carried out efficiently and there are no problems with the joints.

- After plastering the surface, allow it to dry well before working on drywall.

- Check if the plasterboard sheets are well fixed to the base. A loose sheet will eventually destroy the putty layer.

- Thoroughly tighten the heads of the fastening screws so that they do not bump under the layer of putty.

After completing the preparatory work, proceed to the next stage.

Joining seams

Before moving on to processing the joints between the sheets with putty, make the edges of the drywall as suitable for work as possible. This is achieved with the help of jointing, that is, processing the edges of the sheets with a painting knife and a special plane.

- First of all, the cut edges are processed with a plane on drywall. GLA should fit as closely as possible to each other.

- Now chamfer the sheet at an angle of about 40 degrees. Between the sheets, when they are joined, a wedge in the shape of the letter V should form inward. Its depth is from 5 to 10 mm.

- Now hang the sheets and screw them on with self-tapping screws.

If the sheets have already been installed, you can simply chamfer with a paint knife.

Plasterboard jointing

Some manufacturers produce prepared gypsum boards with a thinned edge forming the necessary recess. Such sheets will free you from the need for joining

Primer

Often the priming process is considered optional, especially when working with drywall, which already has a high level of adhesion (adhesion), due to which the putty adheres well. But we insist that a primer is a must, especially if you plan to paint the surface after processing. Otherwise, even a paint applied in two layers runs the risk of cracking over time and peeling off.

Seams are also subject to priming, like the entire surface. To do this, choose acrylic-based primers: they penetrate deeply into the structure of the gypsum plasterboard. This material dries quickly enough - 1-3 hours - depending on the level of humidity and temperature in the room.

We knead the putty

A properly prepared putty mixture is one of the main conditions for high-quality work. The solution is usually prepared from a special mixture and water, in the proportions indicated by the manufacturer in the instructions. Stir it until the consistency of thick sour cream. For this, use a construction mixer or a drill with a special attachment, operating at a speed of 600 rpm.

After thoroughly mixing, leave the putty for 5 minutes so that it is finally infused and softened, and mix again.

Putty seams and use of serpyanka

When the putty mixture is ready, take a small amount of it on the tip of the putty knife and apply to the joint surface in longitudinal movements so that the width of the layer is wider than the gap between the sheets of drywall. Press the mixture thoroughly into the seam.

If the joint length is more than three meters, it will be more convenient for you if you divide the surface into several sections.

Cut a piece of reinforcing mesh - serpyanka, equal to the length of the seam to be processed, and attach it to the junction of the drywall sheets. You need to glue so that the seam runs along the center of the tape.

Usually, the serpyanka needs to be glued at the beginning of work - the base allows you to do this. But if the first layer of putty has already been applied, you can press the tape into it. The sequence is not important.

Use a scythe to seal drywall joints

Place the putty on the falcon, so it will be more convenient for you to take it in small portions.

Remove excess mortar and cover the tape with another layer of the mixture. Carefully level all layers with a spatula. When they are dry, apply a final coat and let it dry throughout the day.

Make sure the seams are even and match the level of the drywall sheets. The building level will help you check this.

You can use a special paper tape instead of a serpyanka. It is not easy to glue, but in quality it surpasses the reinforcing mesh.

- Cut the required number of strips of the required length from the tape, put them in a bowl, pour boiling water over and leave for several hours. While the paper is swelling, apply the first layer of mortar to the drywall joints.

- When the solution hardens, sand it so that no unevenness remains. Prepare the paper tape for gluing: remove several strips from the water, squeeze out excess water, passing them between your fingers one by one.

- Apply a layer of PVA glue to each strip with a brush and fold in half so that the glue does not dry out. When the strips are ready, glue one joint with glue and immediately press the paper tape to it in the center of the seam. Do the same for all joints. Smooth the tapes with a spatula without pressing hard.

- After drying, the tape becomes thin, taking the form of a seam. In addition, it is tightly glued to drywall, penetrating into its structure.

When all the puttying work is over, wait until the surface is completely dry and sand the seams with sandpaper or an abrasive mesh. This will help to thoroughly level the surface, eliminating protrusions, excess mortar and roughness.

Putty on corners

Fillet welds may seem daunting at first. But you can easily cope with it if you were able to close up simple seams. The principle of operation is the same, but you need metal corners for reinforcement and a corner trowel.

Angle spatula

Apply one layer of plaster and fix the metal corners on it by pressing them into the mortar. Remove excess and apply a few more coats of putty.

You can also cover the seams at the corners using a serpyanka. Take a single-sided putty knife and spread the putty on one side of the corner, and then on the other. This way you will avoid over-consumption of the putty.

Cut a piece of tape to the required length, fold in half, attach to the corner. Apply the putty alternately on both sides of the tape, stretch with a spatula.

In the same way, you can seal the interior corners along the ceiling.

Video about sealing joints between drywall sheets

Now you know that it is not at all difficult to putty the seams between drywall sheets with your own hands. All that is required from you is attention and accuracy, and experience and skill will come in the process. We also revealed a couple of professional secrets. We hope this will help you in your work. Share with us and our readers in the comments your experience in working with drywall. Good luck and comfort to your home!

Recommended:

How And What To Paint A Drywall Ceiling With Your Own Hands + Video

Features of painting a plasterboard ceiling with your own hands. Choosing the right paint. step by step process

Do-it-yourself Pool Cleaning And Repair - How To Remove Greens, Small Particles And Rust, Seal The Film With Your Own Hands, Get Rid Of The Nematode, Clean Without A Vacuum Cleaner

Do-it-yourself pool repair and cleaning. Methods for plastering and painting the structure. How to seal an inflatable pool. Water treatment methods

How To Choose And Build A Foundation For A Bath With Your Own Hands - 4x6, 3x4 And Other Sizes, Tips, Instructions, Photos And Videos

How to make a foundation for a bath with your own hands. Types and features of foundations. The choice of materials and technology, installation rules and step-by-step instructions

How To Make A Fence With Your Own Hands From Scrap Materials: Step-by-step Instructions For Making And Decorating From Plastic Bottles, Tires And Other Things, With Photos And Vide

How to make a hedge with your own hands. Choice of material, pros and cons. Required instructions and tools. Tips for finishing. Video and photo

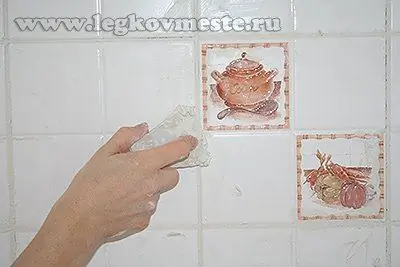

Grouting Tiles. We Rub The Seams Between The Tiles Without Problems

Do-it-yourself grout tile joints. How to rub seams on tiles and seams between tiles with your own hands