Table of contents:

- How to make a metal, stationary and folding brazier yourself

- Pros and cons of a metal barbecue. Its features

- Preparation for construction: drawings, diagrams, what should be the optimal dimensions and device

- Making a stationary barbecue from metal with your own hands: step by step instructions

- How to decorate an iron barbecue, and can it be painted?

- Projects, sketches and manufacturing features of a collapsible and folding barbecue

- Video: brazier in the form of a suitcase

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-01-23 12:41.

How to make a metal, stationary and folding brazier yourself

With the onset of warm spring days, many people think about going out into nature or to their country house in order to relax after the winter cold and eat delicious kebabs with a real aroma of a haze of pine, cherry, apricot or apple twigs. And for this you need a metal brazier. Naturally, you can buy it in the store, but if you are not too lazy to spend a few hours of your time, you can make an excellent brazier made of metal with your own hands, which will delight you and your loved ones with delicious barbecue for many years.

Content

-

1 Pros and cons of a metal barbecue. Its features

1.1 Photo: varieties of design of metal structures

-

2 Preparation for construction: drawings, diagrams, what should be the optimal dimensions and device

- 2.1 What material to choose for the construction of the cauldron: stainless steel, iron, etc.

- 2.2 Required tools and materials

- 3 Making a stationary barbecue from metal with your own hands: step by step instructions

-

4 How to decorate an iron grill, and can it be painted?

- 4.1 Video: building a steel barbecue oven

- 4.2 Video: homemade design option

-

5 Projects, sketches and features of making a collapsible and folding barbecue

-

5.1 Collapsible grill for giving

5.1.1 How to do

-

5.2 Folding brazier

5.2.1 How to weld

-

- 6 Video: brazier in the form of a suitcase

Pros and cons of a metal barbecue. Its features

If you decide to make a brazier out of metal (steel) on your own, then first of all you need to decide what size will be optimal in order to satisfy the needs of your whole family, as well as which metal will serve your purposes the longest.

Today there are a large number of varieties of barbecues that can be made from a wide variety of materials, but metal is the most popular among them, since it has many undeniable advantages, such as:

- Mobility. Even if the brazier is not folding, it can still be easily transferred to any utility room (basement, closet, garage, storage room), where it will stand until its next use, safely hidden from the effects of various atmospheric precipitations.

- Fire safety. Even with an accidental strong fire of wood or coal, the dimensions and metal of the barbecue can prevent a fire hazardous situation. The metal can be very hot, but since it does not burn, the fire cannot start.

- Affordable price. Metal is currently the most affordable and inexpensive material for the manufacture of any type of barbecue compared to refractory bricks, natural stone or other expensive materials.

- Manufacturing speed. With the availability of material and a welding machine, such a brazier can be made in just a few hours and immediately operated, while a brick structure will have to be made for at least a month and it will not be possible to operate it for several more days.

- The convenience of use. The metal brazier is easy to clean, washable and, if necessary, disassembled or folded (if it is collapsible or folding).

- Fast food preparation. Since the metal holds heat well, meat, vegetables and other foods will cook on it quickly enough and bake evenly.

The only drawback of this design can be called an unaesthetic appearance. But if you are a jack of all trades, then you can make metal not just a brazier, but a real work of art. The metal is also susceptible to corrosion, but if you treat it with special anti-corrosion agents and take care of the product from it, then it will serve you for more than a dozen years.

Photo: varieties of metal structures design

Let's see what unusual and beautiful braziers can be made of iron, steel and improvised means, if there is at least a little imagination and "golden hands" of the master.

-

Stationary metal brazier - Here is what a beautiful brazier you can make with your own hands for your home

-

Stationary metal brazier - Stationary brazier in a strict classic style made of stainless steel, which will decorate any personal plot

-

Stationary metal brazier - Stationary metal brazier with skillful decoration

-

brazier - machine -

This brazier in the form of a car will look great in the yard of a motorist

-

Brazier - ship - This brazier in the form of a ship will allow you to sail into the sea of pleasure from the aroma of barbecue

-

Brazier - pig - such a brazier - your children will definitely like the pig and they will be happy to help you fry kebabs

-

Mangals from cans - Such magnificent barbecues from cans simply cannot be distinguished from factory ones.

Preparation for construction: drawings, diagrams, what should be the optimal dimensions and device

The size of the barbecue that you are going to make must meet your requirements and take into account all the conditions of its operation.

- If your family consists of three or four people, then a product measuring 50x30 cm will suit you.

- The width of an ordinary barbecue is 30 cm. This distance is calculated for one skewer, which will fit eight or nine small pieces of pork or veal per serving.

- The length of the barbecue can be different based on the number of skewers that will need to be stacked next to each other. The distance between the skewers should be about 10 cm, so for 8 pieces it is necessary to measure 80 cm of the leaf length, for 10-1 meter, etc. But you should not make a brazier too long, as it will be simply inconvenient and it will be too bulky and awkward.

- The depth should be about 15 - 20 cm. This volume will be quite enough for a person to be able to place logs or coals in the grill, as well as meat, so that it does not come into contact with burning coals and does not burn later during frying.

- The height of the "box" from the bottom to the legs should be such that a person can stand upright, hold a skewer in a bent hand and turn it over while frying a kebab.

- For the manufacture of legs, you can take corners (25 - 30 mm shelves) or four pieces of ordinary reinforcement (diameter 8 - 10 mm).

Stationary grill and its drawing

What material to choose for the construction of the cauldron: stainless steel, iron, etc

For welding the barbecue, ordinary sheet metal is best suited, from which the bottom and walls of the product are cut. The thicker you take the metal, the stronger and more reliable the grill will be, as well as more stable. Usually a sheet with a thickness of more than 4 mm is taken.

The sheet size should be:

- width - 80 cm - 90 cm;

- length - 80 cm - 100 cm.

Stationary models should be thick-walled as they will have a longer service life. To make a brazier box, you can take stainless steel, regular ferrous metal, or heat-resistant steel. Naturally, stainless and heat-resistant steel is the most optimal option for the manufacture of a stationary reliable barbecue, but also more expensive.

If you look from the point of view of economy, then it is best to buy a good steel sheet and metal profiles (corners or fittings) once, than to repair the brazier later, which will burn out due to low-quality metal. The black metal can rust over time, and the bottom of the brazier can simply burn out with frequent use of the barbecue. Therefore, it is necessary to choose the material taking into account the intensity of the operation of the future product.

Required tools and materials

- Sheet metal (stainless steel or heat-resistant steel, common ferrous rolled metal).

- Iron corners or regular pieces of reinforcement (individual length).

- Angle grinder (grinder), hacksaw or electric jigsaw.

- Powerful drill.

- Welding machine.

Making a stationary barbecue from metal with your own hands: step by step instructions

On the iron sheet, it is necessary to make chalk markings in accordance with the developed drawing plan

Marking a metal sheet for a future barbecue box

- Cut out the sides and bottom of the structure with an angle grinder, hacksaw or electric jigsaw.

- In the lower part of all four walls of the barbecue, it is necessary to drill symmetrical holes around the entire perimeter, which will facilitate the flow of air from the outside to speed up the process of lighting logs or coals. Also, at the bottom of the brazier box, you can make a special perforation with a grinder for constant air circulation.

Barbecue bottom perforation for better air circulation

- On the upper part, along the entire length of the walls, it is necessary to make holes for laying skewers. This can be done with a grinder. The distances between them must be strictly symmetrical with respect to the opposite side and have equal distances between them.

- Further, the walls and bottom of the barbecue must be welded into a kind of rectangular box, which will form the main part of the barbecue. All welded seams must be well grinded so that they are smooth and attractive.

Brazier with recesses for laying skewers

To make the legs, you need to take corners or fittings and weld to all four corners of the walls. If desired, you can make the legs unscrewed. You just need to weld four nuts to the bottom of the barbecue, and cut a thread on the fittings to screw the legs to the base of the brazier. Nuts must match the diameter of the fittings. Then the legs can be easily unscrewed for more convenient storage of the barbecue at the end of the season

Brazier with bottom perforation

How to decorate an iron barbecue, and can it be painted?

Let's see if it is necessary to paint the barbecue box and why is it necessary to do it? It is not advisable to use paint and other chemically active dyes, since in the process of burning coal or firewood, the paint will begin to peel off, emit an unpleasant odor, and the meat can absorb chemical emissions hazardous to health.

But at present, modern manufacturers can offer special means for coloring the entire structure of the barbecue that are completely safe for people nearby and for meat, vegetables and other products cooked on it.

The only problem is that the temperature inside the frypot is so high that any coating (even very tough ones) can simply burn off and crumble quickly.

Heat-resistant paints for coloring the barbecue

Today there are such heat-resistant paints as:

- Organosilicon enamels that can withstand heating temperatures up to +600 degrees Celsius.

- Heat-resistant powder paints are great for coloring the brazier, but they are quite difficult to use, since they must be fired at very high temperatures.

- The oxidation process is quite complicated, but if desired, it can also be carried out in a homemade way. To do this, the barbecue box must be treated with five percent sulfuric acid. Then boil in a thick solution of alkaline soap and cook for about one and a half or two hours in sodium solution. After these "water" procedures, the metal will be covered with a black non-stick coating, which will keep it from corrosion. But this method is very unsafe, since working with a chemical such as sulfuric acid requires great care.

Video: building a steel barbecue oven

Video: homemade design option

Projects, sketches and manufacturing features of a collapsible and folding barbecue

Collapsible grill for giving

Such a grill is very easy to decompose into separate elements that will not take up much space during storage.

The design of the brazier does not provide for the welding of all its parts, so a welding machine may not be needed here. And in order for the sidewalls and legs of the barbecue to be removed, we only need bolts and nuts.

Collapsible barbecue drawing

How to make

- First, you need to mark all the details of the product on an iron sheet. On the sides and bottom, add about 4 cm to the joints as indicated in the diagram.

- Then all the details must be cut.

- In order to be able to bend the sheets, it is necessary to make small cuts on the sides of the cut out sides. Then it will be possible to dock the corners and the bottom can be easily laid inside the frame.

- To prevent the entire structure of the "box" of the brazier from falling apart during the preparation of kebabs, holes must be made at the ends of the walls and firmly fixed with bolts.

- On the top of the sides of the brazier, you need to make recesses at the same distance for stacking skewers.

- The legs must be made of 4 iron corners, in which holes must also be made for the bolts, as well as in the corners of the adjacent walls to which they will be attached.

- For better air access at the very bottom of the box walls, you need to make small holes with a drill or grinder.

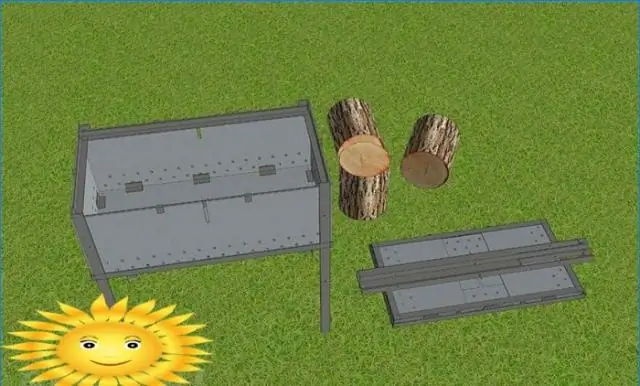

View of the finished collapsible barbecue

Folding brazier

Such a camping grill can also be made in the courtyard of your house and it will be an excellent option for out-of-town picnics. When folded, it is a small iron suitcase with a portable device. The thickness of this "suitcase" is only 40 mm, and the length is from 65 to 85 cm. You can put skewers or a grill rack in it.

Folding brazier in the form of a suitcase

How to cook

It is necessary to cut out the bottom of the barbecue from a sheet of iron and drill round holes on the sides with a drill with a diameter of about 10 mm for air flow. Then bend the sidewalls along the line shown in the drawing

Drawing of the bottom of a folding barbecue

- Cut out the sides (size 62x20.5 cm).

- In order for them to easily fold into the "suitcase", two small loops (canopy) must be fixed between the bottom and the walls. This can be done with screws or welding.

- Next, you need to cut out the end removable walls. When assembled, they will be inserted into the sides and bottom. For this, rectangular thin cuts must be made along all the edges of the side walls.

Drawing of the walls of the folding barbecue

- To the bottom of the bottom, four nuts must be welded, which are necessary for the screw-on legs.

- To make them, you need to take four rods of reinforcement, 60 cm long, and on each of them you need to make a thread (1 cm M8). During assembly, the legs can be screwed onto the welded nuts.

Folding brazier - assembled view

- For ease of portability, the barbecue structure is complemented by a special metal handle, which can be simply welded or screwed on with bolts and nuts.

- In order for the grill to close like a "suitcase", it is necessary to fasten a latch or a hook on one of the walls.

Folding brazier - folded view

Video: brazier in the form of a suitcase

Whatever type of barbecue you choose (stationary, collapsible or folding), each of them has its undeniable advantages, which you will immediately see as soon as you want to make a barbecue in your personal plot or go out into nature with the whole family. A brazier made with your own hands will delight you for many years, and you can be proud of your work.

Recommended:

Diy Brick Brazier: How To Make, Drawings, Photos And Videos

How to make a brick brazier yourself. A step-by-step description of the work, advice on choosing the type of barbecue and the necessary materials

How To Make A Kite With Your Own Hands At Home: Options With Drawings And Sizes + Photos And Videos

DIY kite: the necessary materials, diagrams, drawings, manufacturing steps. How to make a kite of different shapes. Secrets of a Successful Launch

How To Choose And Build A Foundation For A Bath With Your Own Hands - 4x6, 3x4 And Other Sizes, Tips, Instructions, Photos And Videos

How to make a foundation for a bath with your own hands. Types and features of foundations. The choice of materials and technology, installation rules and step-by-step instructions

The Best Blenders 2018: Rating Of Models By Reliability With Price And Photo, Including Submersible And Stationary

How to choose a good blender: an overview of the characteristics, what is important to consider. Rating of blenders 2018 for reliability and quality with price and photo

How To Make A Birdhouse Out Of Wood With Your Own Hands: Options With Drawings And Diagrams + Photos And Videos

How to make a wooden birdhouse with your own hands. The right tree, the necessary materials and tools, drawings, step-by-step manufacturing instructions. Video