Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

How to make a reliable and practical do-it-yourself ping-pong table

Amateur sports can not only diversify leisure, but also benefit health. Nowadays, the passion for ping-pong is very popular among children and adults. Wanting to master this game, you need to take care of the availability of a specialized tennis table, the manufacture of which with your own hands will help you save a decent amount of money.

Content

-

1 How you can make a ping-pong table with your own hands

-

1.0.1 Tabletop dimensions

-

-

2 What materials can be used for making

- 2.1 Plywood

- 2.2 Chipboard

- 2.3 Film faced plywood

- 2.4 Fiberglass

- 2.5 Composite aluminum

-

3 Drawings and step-by-step instructions for making DIY ping-pong tables

-

3.0.1 Indoor table model

-

-

4 Video: technology for making a tennis table for the street

-

4.0.1 Disassembled tennis table model

- 4.1 Assembly

-

4.2 Painting

- 4.2.1 Drawing of a folding table tennis table

- 4.2.2 Features to consider when making tennis table legs

-

How to make a ping pong table with your own hands

Currently, there is a wide range of ping-pong table models on the market, however, a hand-made table can compete with most of them. The designs of such products are simple and do not require the use of complex technological methods. And the preliminary purchase of high-quality materials will make it possible to manufacture a product suitable for use both at home and outdoors.

Ping pong table

Before starting the manufacture of such a table, you need to decide which design will become more acceptable for you. Ping-pong tables can be folding or stationary. The latter option is best suited for outdoor installation.

Stationary table

And foldable models save usable space when the game becomes irrelevant. When deciding in advance on the place where the table will be installed, it should be remembered that there must be enough space around it for the players to move freely. The area of such a space should be 5x8 m.

Folding table

The floor covering deserves special attention. It is desirable to give the advantage to the firm and even anti-slip version. For this purpose, a floor made of bitumen or concrete is perfect. Wood flooring installed on a flat and hard surface is no less effective.

Tabletop dimensions

According to the standards accepted all over the world, a classic ping-pong table should be 2740 mm long and 1525 mm wide, with a standard height from the floor of 760 mm. However, it is possible to make a table with other dimensional characteristics, taking into account individual requirements and the area of space intended for its installation. For teenagers, the height of such a product can be from 600 to 700 mm. The dimensions of the mini-table are equal to 2440x12200 mm, and in some cases even 110x61 mm. The thickness of the tabletop of such a product used within the club, according to generally accepted standards, should be 22 mm, while for a professional game, a tabletop with a thickness of 25 to 28 mm is required. And for amateur tennis, a plate with a thickness of 16-19 mm is quite suitable.

Tabletop dimensions and table height for ping-pong

What materials can be used for manufacturing

When choosing materials for a do-it-yourself table, you can focus on sheet plywood, OSB and chipboard. Each of them will be able to provide the required rebound height of a standard ball dropped from a height of 30 cm, equal to 23 cm, as specified in the generally accepted standards.

Plywood

A wide range of plywood sheets is currently on the market in the following dimensions:

- 1525 x 1525 mm;

- 1525 x 1300 mm;

- 1525 x 1475 mm;

- 1475 x 1474 mm.

From this material, you can make a folding tabletop consisting of two halves by cutting to a given size on only one side. In addition, the surface of the plywood does not require additional processing, which will save time and money. However, when buying plywood sheets, it is advisable to give preference to goods of I and II grade marked "Ш1", indicating the presence of a sanded surface and sufficient moisture resistance.

A tabletop made of plywood has a number of disadvantages, one of which is its sagging. It is for this reason that this material is best used in the manufacture of non-separable tables, on a rigid box-shaped base equipped with struts. For the manufacture of such a support, boards are perfect. Self-tapping screws installed along the contour of the product with a pitch of 100-150 mm can be used to fasten the plywood tabletop to the base. In this case, it is advisable to putty their heads.

Another drawback of the plywood table is the sluggish, albeit correct, ball rebound. To correct the situation, painting the surface of the countertop with water-based acrylic paint, applied in 2-3 layers, will help. Such processing will simultaneously increase the moisture resistance of the product. However, before applying a layer of paint, it is necessary to impregnate the plywood sheets with a water-polymer emulsion on both sides.

plywood

Chipboard

Choosing a chipboard for the manufacture of a ping-pong table, pay attention to its following dimensions, which are optimal for such a product:

- 2750 x 1830 mm;

- 2750 x 1750 mm;

- 2750 x 1500 mm

The quality of this material largely depends on the brand of the manufacturer, but in general it is quite capable of satisfying the existing requirements. By purchasing a sheet with dimensional characteristics of 2750x1500 m, you are buying an almost ready-made worktop suitable for a stationary structure. In this case, you can choose a laminated sheet of blue or green, which eliminates the need for painting.

Such material, with a thickness of 16 mm and more, is very heavy, which is ideal for making a strong and massive tennis table. If you need to adjust the dimensional characteristics of the chipboard sheet, you can use the services of material sellers who can trim, in accordance with the dimensions you specified, as well as trim. The purchase of chipboard will cost more than purchasing plywood sheets, however, the durability of this material is higher.

Chipboard

Laminated plywood

When creating do-it-yourself ping-pong tables, you can also use laminated plywood, which eliminates the possibility of deformation during operation. This material, made on the basis of waterproof birch plywood, is not flammable, and is also resistant to a number of mechanical damage. Melamine with subsequent processing is used as a laminate in the production of such products. In addition, film faced plywood is available in a wide range of colors, which will also help to save on painting costs. Standard sheet sizes allow you to make both solid and folding tabletops.

High-quality plastic is used as an edge for this material, however, the material itself is not at all tiny. The edge line of the field can be drawn with masking tape, and the demarcation lines are best done with acrylic paint, which will not wear off for a long period of time. A tennis table made of laminated plywood can be outdoors. During the game, the bounce of the ball from the surface of such a table will be ideal. The cost of this material cannot be classified as cheap, however, the money spent will correspond to the high quality level of your future table.

samples of film faced plywood of various colors

Fiberglass

Another versatile material that can be useful in the production of ping-pong tabletops is fiberglass, sheets of which can be purchased at specialized hardware stores. When choosing, it is desirable to give preference to sheets with a thickness of 10 mm, the color of which can be any. Created on the basis of the use of modern technologies, fiberglass has enviable strength and low weight. A table equipped with such a tabletop will become all-weather, since the material is designed to be used in a wide temperature range. Products made from it are insured against decay processes, and are also distinguished by an enviable resistance to mechanical damage and deformation. Among the features of this material can also be attributed to its incombustibility. The cost of fiberglass is quite high,but it is completely justified taking into account the listed qualities.

fiberglass

Composite aluminum

In some cases, aluminum is used to make ping pong tables. Such tabletops correspond to the characteristics of semi-professional tables, the plate thickness of which is 22 mm. Outwardly, such a material resembles a pressed chipboard and can be used outdoors without fear of deformation and mechanical damage. There is a myth that the volume level of bounce from aluminum tables is quite high. However, this is a misconception. These all-weather tables are very practical and can fully satisfy the expectations of their owners. The cost of the material in this case is very acceptable, however, such a table will still cost more than a product equipped with a plywood tabletop.

aluminum

Stationary Outdoor Ping Pong Tables are best constructed from all-weather materials that can withstand changes in weather conditions. However, as a protection against precipitation, preventing the surface of the table top from getting wet, you can use an awning moisture-repellent material or durable roll polyethylene.

various samples of awning material

rolls of rolled polyethylene

DIY drawings and step-by-step instructions for making ping-pong tables

Indoor table model

To make a wooden tennis table with your own hands, the model of which is best suited for indoor installation, you will need the following materials:

- board 25 x 100, length 1050 mm - 6 pcs.;

- board 30 x 100, length 2200 mm - 2 pcs.;

- timber 50 x 50, length 750 mm (for legs) - 6 pcs.;

- bar 30 x 50, length 850 mm (for the underframe) - 4 pcs.;

- adjustable furniture leg - 4 pcs.;

- studs or bolts М8, length 120-125 mm - 12 pcs.;

- nuts and washers М8 - 24 sets;

- self-tapping screws for wood;

- sandpaper.

In this case, it will be advisable to prepare in advance such tools as:

- hacksaw;

- chisel;

- screwdrivers;

- drill or screwdriver;

- drill with a diameter of 8 mm;

- open-end wrenches 12 x 13 mm;

- marking tool (pencil, tape measure, carpenter's square).

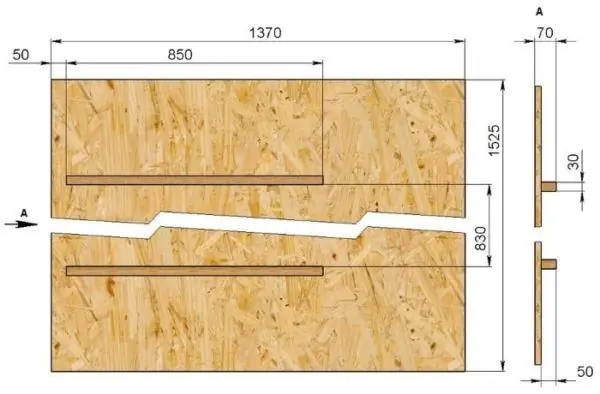

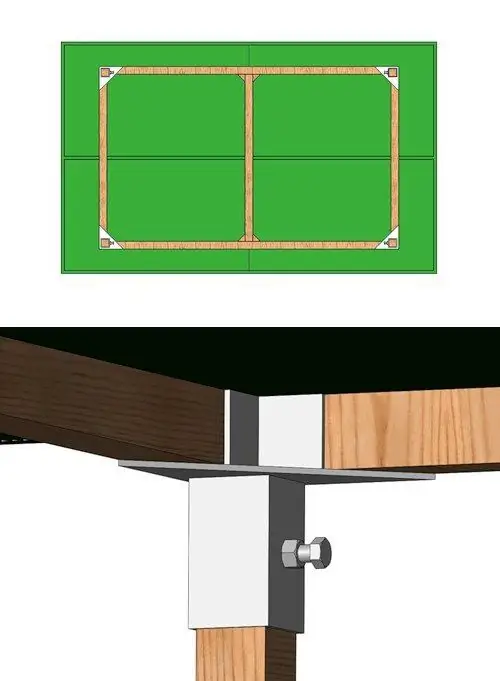

The proposed version of the ping-pong table design consists of a table top made according to the specified dimensions,

table top drawing

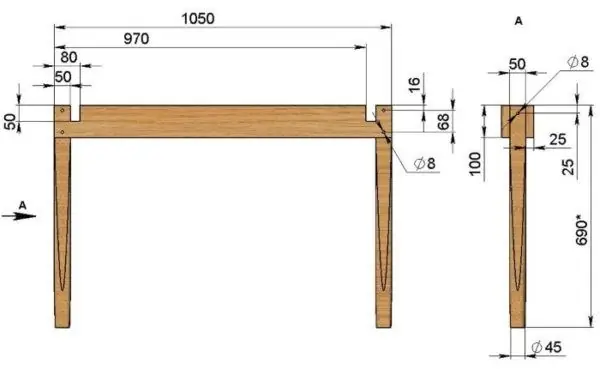

three support legs

drawing of support legs

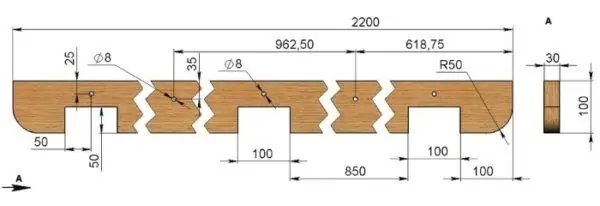

and two longitudinal bars.

drawing of longitudinal bars

The parameters of each of the parts are similarly indicated in the drawings.

-

Initially, you need to prepare the tabletop canvases, as well as create all the necessary details, relying on the information specified in the drawings. In this case, the grooves located on the longitudinal beam and having a section of 50x100 mm should fit as tightly as possible into the mating grooves located on the support legs.

countertop preparation countertop preparation

-

Then you should assemble the support legs. To do this, furniture legs with adjustment should be attached to the bars with a cross section of 50x50 mm, specially designed for them, using nuts and studs.

furniture leg attached to the bar furniture leg attached to the bar

-

After that, it is necessary to assemble the frame, which involves inserting the longitudinal beams into the grooves of the legs from above.

ping pong table frame assembly of the table frame

- After completing this stage, it is necessary to securely attach the bars with a section of 30x50 mm to the tabletop using self-tapping screws.

-

We install the tabletop on the resulting frame, fixing its position relative to the longitudinal bars. As fasteners, you can use bolts, having previously drilled longitudinal bars together with bars with a section of 30x50, or self-tapping screws.

fastening the tabletop to the table frame fastening the tabletop to the table frame

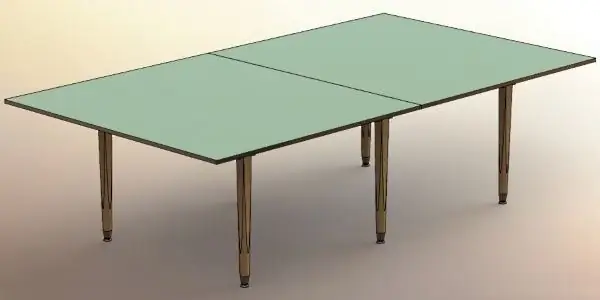

After completing the work, you will receive something like this finished product.

DIY ready-made ping-pong table

Video: technology for making a tennis table for the street

Dismountable tennis table model

To create another version of a collapsible model of a tennis table with your own hands, you need:

- Sanded plywood 1525x1525x12 mm - 2 pcs.

- Edged timber 50x50x3000 mm - 5 pcs.

- Metal brackets for attaching legs - 4 pcs.

- Self-tapping screws 5x89 - 38 pcs.

- Self-tapping screws 3.5x49 - 45 pcs.

- Bolts for attaching brackets to legs - 4 pcs.

- Antiseptic for wood.

- Putty for wood, enamel for painting the table top (matt green, or blue, black).

-

Enamel aerosol white

And the following tools:

- Hacksaw.

- Welding machine.

- Drill, drill on iron.

-

Spatula, roller, paint brush.

In this case, the manufactured table will correspond to the following dimensional characteristics:

- The height of the table from the floor covering to the mesh is 760 mm.

- Table top length - 2740 mm.

- Table cover width - 1525 mm.

And in the presented drawing, you can also familiarize yourself with the parameters of the installed grid.

This design presupposes the presence of an easily removable tabletop, for which special brackets are required, which provide the possibility of quick disassembly of the table, and will act as reliable fasteners. For people far from working with metal, similar products can be ordered from locksmiths.

sketch of countertops and homemade brackets

- The table top of such a table is made of plywood. In this case, you will need two sheets of 1525x1525 size. To create a tabletop that meets the European standard, you have to saw off 155 mm from each sheet. In this case, the joint between the two plywood boards will be located clearly under the mesh.

-

Then the timber should be cut, after which the resulting elements should be treated with an antiseptic and dried properly.

beams and plywood preparation of beams and plywood

- Then it is necessary to weld the brackets. This operation will create secure mounts for the four legs.

-

The manufactured brackets must be equipped with holes into which self-tapping screws will be inserted during the assembly of the structure.

brackets homemade table brackets

Assembly

-

After marking the bars, it is necessary to assemble the support frame, fixing it with self-tapping screws.

support frame table support frame

-

Then we mount brackets to the corners of the frame, which can stretch and hold the corners of the frame.

installation of brackets installation of brackets at the corners of the frame

-

Now you need to adjust the existing legs to the mounts, by removing excess wood. However, it is necessary to create conditions for inserting an additional plate, whose task will be to distribute and strengthen the tension from the bolt. Since the brackets will be made by hand, each of them will have slight differences. For this reason, each of the supports used will have to exactly match the parameters of its nest. To avoid confusion, it is advisable to number the legs and brackets.

inserting legs into mountings inserting numbered feet into the mountings

-

Then the timber should be installed in the nests and bolted to the brackets. After that, you can put the resulting platform on the legs, which are tightly screwed to the frame.

installation of the table platform on the legs installation of the platform on the legs

- Create holes that are sized to fit the hardware heads flush with the slab surface.

-

We disassemble the resulting structure, after which we fasten the cover equipped with ready-made holes for self-tapping screws to the frame located on the floor.

fixing the tabletop with self-tapping screws fastening the tabletop to the base using self-tapping screws

Painting

-

To prepare the countertop for painting, it is advisable to wipe it with a hard cloth or blow it off with a powerful jet of air from the compressor. Then we start applying the putty, the layers of which are allowed to dry completely.

table top putty putty applied to the surface of the countertop

- We apply paint in 2-3 layers, thoroughly drying each of them.

- Using masking tape, we create boundary stripes and mark the playing field using an aerosol can or a brush.

-

After completing the design of the table, install the grid.

ready table ready ping pong table

Drawing of a folding table tennis table

Folding table models are especially popular among table tennis fans, allowing them to start playing even in the absence of a partner. You can make such a table with your own hands, based on the drawing below.

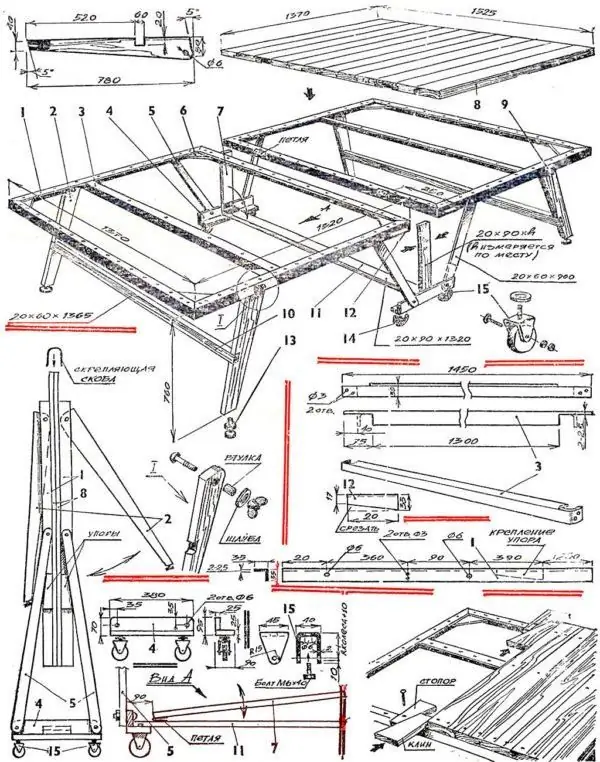

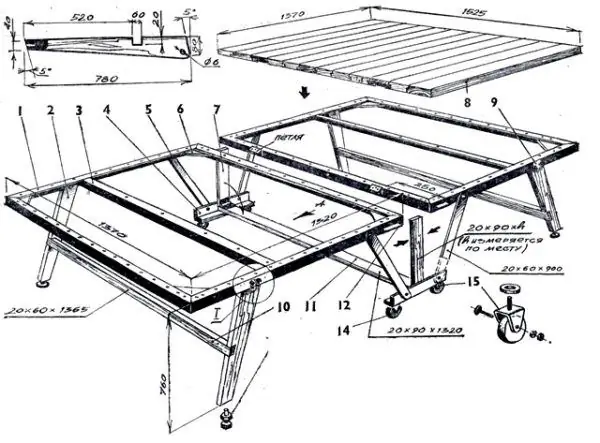

drawing of a folding model of a ping-pong table with exact indication of the dimensional characteristics of each part

However, in this drawing, the type-setting tabletop is made of boards, which is not a very successful and practical option. As a material for its manufacture, you can use plywood or any other option described in this article. This will eliminate the need to install additional fastener lines, without compromising the strength of the structure.

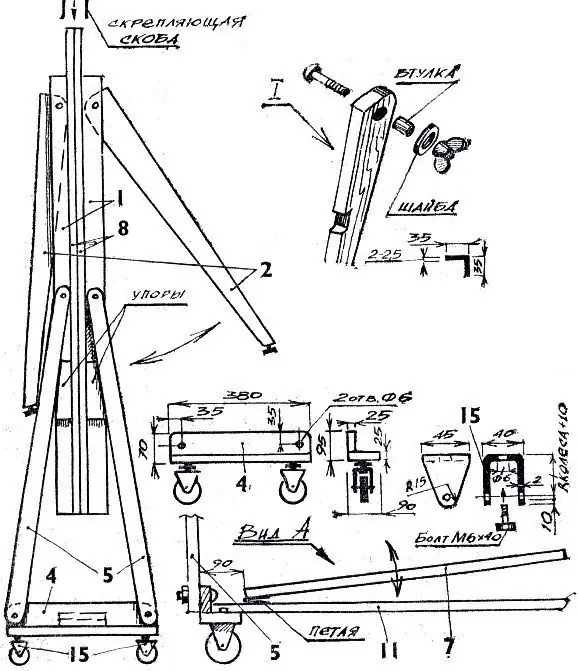

Wooden elements can be used to create such a model of a ping pong table. However, an easier solution would be to create a frame using corners made of steel or duralumin. In this case, it is better to weld the steel corners, and to fasten the duralumin elements use screws with triangular gussets made of metal, the thickness of which ranges from 2 to 2.5 mm.

folding model dimensions

To provide the frames with the required rigidity, it is advisable to strengthen them with the help of transverse corners. To connect the frames, you can use piano or ordinary hinges, which should be sunk into the shields. Holes must be made in the side surfaces of the frames for fastening the table legs and platform struts.

The platform is based on:

- four braces,

- four furniture casters,

- two supports,

- two carts.

The trolleys are made of boards with a thickness of 20 to 25 mm. To create struts, you need boards 60 mm wide and 20 mm thick. And the base should be made of boards 90 mm wide and 20 mm thick. Furniture casters can be selected and purchased in specialized stores.

For the legs, you will need boards 80x20 mm. Their attachment to the frame should be hinged, made on the basis of the use of bolts with wing nuts. This will allow you to fold them as needed.

detailed ping pong table layout

- On the legs, mark the bolt holes, drawing center lines along each of them.

- It is advisable to strengthen the upper parts of the legs with metal plates, and equip the holes with bushings for more reliable fixation.

- To level the playing field, it is recommended to install foot pads on each of the legs. To do this, use an M-10 or M12 nut and carve a bolt under it.

- Then you need to press it into the leg of the structure and screw in the bolt.

- The legs must be fastened in pairs with 60x20 mm strips.

- And then proceed with the installation of a tabletop made of the material of your choice. Self-tapping screws or long screws can be used as fasteners.

- Paint the tabletop in the desired color, and then mark the playing field.

Features to consider when making tennis table legs

Outdoor tennis tables are best made without the use of adjustable furniture legs. When installed on the ground, such legs will bog down in it, and when installed on a paved surface, they lack the adjustment limit. The best material for making the support structure in this case is metal. A structure equipped with such feet will stand firmly on the ground and can be leveled by simply pressing the feet into the ground. This is the best option for a folding table.

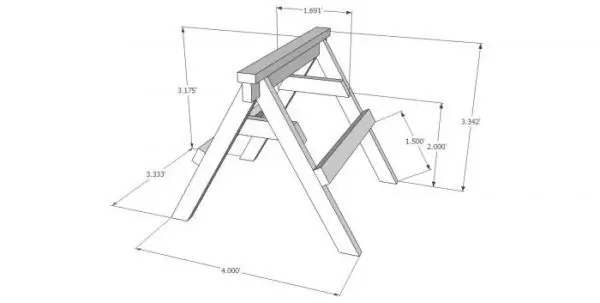

In some cases, it is very advisable to make the base of the table in the form of a "goat" made of a wooden beam, with the additional installation of two beams or boards from above, which excludes the occurrence of a deflection of the table top.

"Goats" designed to install countertops

trestle table

The design of the supporting "goats"

The sizes of the goats can be any, provided that their overall width should be less than the width of the tabletop by about 300 m.

To calculate the height of the "goat", a formula is used, according to which the thickness of the countertop slab should be subtracted from 760 mm, and then the height of the timber placed under it should be subtracted.

The construction of a wooden "goat"

drawing "goat"

Other types of bases are also used for outdoor tennis tables.

outdoor tennis table on a stationary stand made of natural stone

stationary tennis table

Making a table yourself is not too difficult a task. The right materials and tools will help you make your dream come true, eliminating the need for large investments. Exciting ping-pong lessons will help to maintain excellent physical shape and bring a lot of positive emotions to people of all ages.

Recommended:

How To Make A Hanging Chair With Your Own Hands: Step By Step Instructions And More + Photos And Videos

How to create attractive do-it-yourself hanging chair models using materials at hand. Types of hanging chairs, tips, diagrams and step-by-step instructions

How To Make A Rocking Chair (including Plywood) With Your Own Hands: Types, Step-by-step Instructions, Drawings, Etc. + Photos And Videos

How to make a rocking chair with your own hands. Different types of chairs, materials, step-by-step instructions for making simple models

How To Make A Bench-table (transformer) With Your Own Hands: Step-by-step Instructions For Making A Folding Bench With Photos, Videos And Drawings

Description of the design of the transformer bench and the principle of its operation. DIY step-by-step instructions for making. Recommendations for the choice of material and finish

How To Make A Street Horizontal Bar With Your Own Hands - Step By Step Instructions With Drawings, Photos And Videos

How to arrange a sports corner on the site with your own hands. Choice of location and materials. Necessary drawings, calculations, dimensions. Features of children's designs

How To Make A Slime At Home With Your Own Hands - Without Sodium Tetraborate And Glue, From Hand Cream, Shaving Foam And Other Ingredients, Recipes With Photos And Videos

Is it possible to make a slime at home. Types of slimes and recipes for their manufacture, depending on the desired properties. Toy care features