Table of contents:

- Making a potbelly stove from a gas cylinder with your own hands

- Potbelly stove from a gas cylinder: advantages and disadvantages

- The design of the stove and its principle of operation

- Calculation of basic parameters: drawing and recommendations

- Required materials and tools

- Preparatory work before assembling the oven

- Making a potbelly stove from a gas (propane) cylinder with your own hands

- Features of operation, cleaning and repair

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

Making a potbelly stove from a gas cylinder with your own hands

For small-sized premises for economic or industrial purposes, it is more expedient to use a stove-stove as heating than to equip such premises with a stationary heating system with expensive communications and a boiler. A do-it-yourself potbelly stove from a gas cylinder holds the palm in popularity among such units, especially in garages of motorists.

Content

-

1 Potbelly stove from a gas cylinder: advantages and disadvantages

1.1 Examples of homemade products in the photo

- 2 The design of the stove and its principle of operation

- 3 Calculation of basic parameters: drawing and recommendations

- 4 Required materials and tools

-

5 Preparatory work before assembling the oven

5.1 Preparing the gas cylinder for safe handling with a power tool: video

- 6 Making a potbelly stove from a gas (propane) cylinder with your own hands

- 7 Features of operation, cleaning and repair

Potbelly stove from a gas cylinder: advantages and disadvantages

The potbelly stove made of a gas (mainly propane) cylinder has two fundamentally different types: vertical and horizontal. Although the manufacturing process does not limit the designer's imagination. Combined options are not excluded.

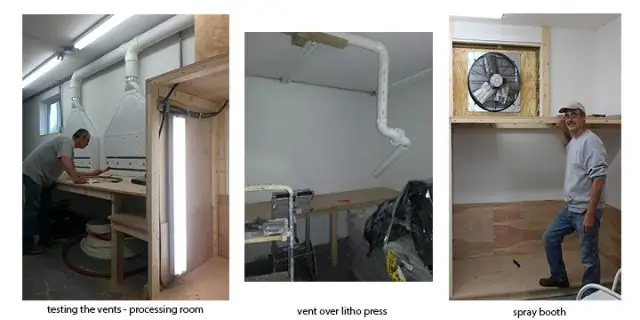

Examples of homemade products in the photo

-

Potbelly stove from a cylinder -

Horizontal execution

-

Potbelly stove from a cylinder - Vertical execution

-

Potbelly stove from a cylinder - Combined execution

In such a stove stove, solid fuels are used: wood, coal, fuel briquettes.

The advantages of such a stove include the following:

- good thermal conductivity due to the thickness of the metal of the cylinder wall (4 mm);

- optimal size / efficiency ratio;

- with vertical design takes up very little space in the room;

- ease of manufacture and availability of the necessary materials;

- the possibility of equipping such a stove with a sheet of metal for heating and cooking.

The disadvantages of such a potbelly stove:

- using only solid fuels;

- with vertical design, it is necessary to adjust the firewood to the optimal size;

As you can see, such a stove has definitely more advantages.

The design of the stove and its principle of operation

Like any solid fuel stove, a potbelly stove from a gas cylinder has two main structural compartments: a firebox and an ash pan (blower).

A working process takes place in the furnace - fuel combustion. The ash pan is located under the firebox, directly connected to it through the grate and serves to remove non-volatile combustion products from the firebox.

Horizontal and vertical design

Combustion products are formed during combustion. Volatiles are eliminated through the chimney under the action of natural draft, and loose ones through the openings in the grate into the ash pan. The subsequent removal of bulk combustion products from the ash pan is performed manually using a poker or a shovel.

And also the ash pan serves to supply air to the combustion chamber (firebox). Therefore, it should be cleaned in a timely manner. Without a normal air supply, the efficiency of fuel combustion is significantly reduced.

The heat from the potbelly stove enters the room directly from the hot walls of the firebox.

Calculation of basic parameters: drawing and recommendations

For the manufacture of an optimally efficient potbelly stove, an all-metal cylinder with a volume of 50 liters is suitable.

A standard 50 liter bottle will suffice

Finding such a balloon is usually not difficult. They are often used in the household and industry.

To equip such a stove with a chimney, a pipe with a diameter of 100-125 mm and a thickness of at least 3 mm is used to make a chimney pipe. The chimney itself should be placed vertically, but deviation from the axis is also allowed (a slope of no more than 30 degrees). The slope is made for greater efficiency of heat transfer from the chimney pipe. Although the location of the pipe directly depends on the local conditions for installing the stove.

For ease of use, the sections of the firebox and ash pan are equipped with doors with a locking mechanism. When the doors are closed, the combustion process is improved and the risk of fire-hazardous particles falling into the room is reduced. And also by adjusting the gap with the ash pan door, you can adjust the intensity of air supply to the furnace.

Doors are made of any shape. The main thing is to take into account the standard size of firewood and the convenience of loading them.

An important part of the potbelly stove is the grate. The grate serves to support the fuel (firewood) and at the same time helps to separate loose combustion products. The grate is undergoing a combustion process. Therefore, the metal from which the grate is made must be strong enough and resistant to high temperatures. It is better to make a grate from reinforcement rods with a diameter of at least 12 mm. Such rods are cut according to the dimensions of the inner part of the cylinder (width) and assembled into a lattice with a gap width of 10-15 mm. The rods are connected by welding.

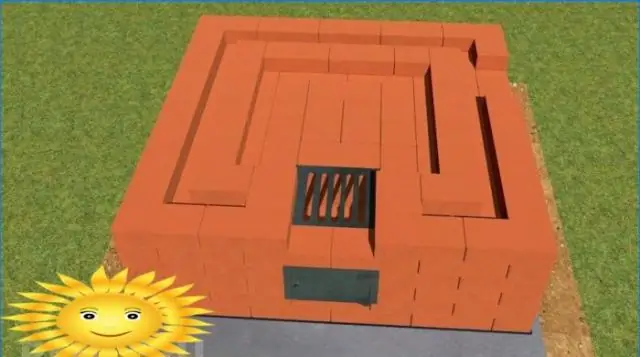

Potbelly stove from a cylinder

An approximate assembly diagram of a horizontal solid fuel stove is applicable to a gas cylinder.

The diagram is applicable for a gas cylinder

Required materials and tools

Naturally, for the manufacture of such a potbelly stove, you will need a gas (propane) cylinder. And you will also need a metal pipe for the manufacture of a chimney, a rod of fittings for a grate, a corner or channel for the manufacture of legs, metal hinges for the doors of the furnace and ash pan, as well as sheet metal with a thickness of at least 3 mm for the manufacture of an ash pan placed outside the cylinder body (removal is optional but preferred).

And you will also need consumables: cutting and sharpening (one sharpening is enough) wheels for the grinder, 3 mm electrodes (one package). If the product is to be painted with heat-resistant paint, then you will need a metal brush to prepare the oven surfaces.

Required tool:

- locksmith tools (open-end wrench for unscrewing the cylinder vent, hammer, chisel, file, clamp, etc.);

- grinder for cutting holes in a cylinder and other work;

- welding machine;

- measuring tool (ruler, tape measure, square, level);

Preparatory work before assembling the oven

Preparatory work includes a very important stage - the removal of gas residues from the cylinder. This stage should be considered in detail, since without its correct implementation, further work is extremely dangerous.

First of all, it is necessary to unscrew the cylinder valve to remove the gas under the residual pressure in the cylinder. The valve is completely dismantled from the body. After removing the gas, the cylinder is inverted to remove the condensate.

Turning the balloon over, we eliminate moisture in a natural way. It is better to collect condensate in a disposable container. Condensate often has a specific unpleasant odor. Therefore, it is better to immediately discard the container with the collected condensate.

Then the balloon is turned over again - set in a vertical position. For complete cleaning of gas residues, water must be drawn into it. The water drawn up to the edges of the cylinder will completely displace the remaining gas from it. Thereafter, the container is emptied of water and is considered cuttable.

For greater clarity, a video of preparing the cylinder for cutting is shown.

The video is taken from Youtube. Used for informational purposes only and does not constitute advertising.

Preparing a gas cylinder for safe handling with a power tool: video

Preparation of the tool (power tool) includes its examination for damage, establishing the degree of its suitability for safe work.

Making a potbelly stove from a gas (propane) cylinder with your own hands

After preparing the tool and materials, you can start making the furnace.

Manufacturing a potbelly stove of a vertical type includes the following stages:

-

On the prepared cylinder, the marking of the future openings of the furnace chambers and ash pan is performed. The distance between these cutouts should be 80-100 mm;

Marking a gas cylinder for making a potbelly stove with your own hands We mark the balloon

-

With the help of a grinder, holes are cut along the marking. The cut segments do not need to be discarded; they will be used to make doors.

Sawing a gas cylinder with a grinder for the manufacture of a potbelly stove Make cuts, but do not throw away the remaining parts after work

-

The cut segments are hinged to the cylinder by welding. A grate is welded into the cylinder from the reinforcement rod.

Diy potbelly stove from a gas cylinder Option for fastening the stove door

-

The final stage. A chimney pipe is welded into the upper part of the cylinder. A chimney pipe is connected to this branch pipe at the place where the furnace is installed.

Do-it-yourself chimney for a stove stove from a gas cylinder Carry out welding work carefully or entrust them to a professional

-

Potbelly stove from a gas cylinder, assembled.

Vertical stove from a gas cylinder, assembled The finished product must be checked for correct functioning!

Features of operation, cleaning and repair

To increase the efficiency of the stove, there are several recommendations:

- The potbelly stove should be installed at a height of at least 20 cm from the floor. This way the heat coming from the stove is better distributed.

- The speed of fuel burning can be adjusted by installing a damper in the chimney pipe. The damper regulates the air flow, which creates a natural draft in the firebox.

- To improve heat transfer through the stove body, you can weld on sheet metal plates. This creates a kind of radiator. The plates are welded at a distance of 4-7 mm from each other.

- To give the potbelly stove an aesthetic look, it can be painted with heat-resistant paint.

- It is necessary to install the stove on a non-combustible base (sheet of metal, concrete block). This is to reduce the risk of fire from spilled smoldering particles.

There is advice on improving the process of heating the room by directing a fan to the stove. Thus, air circulation increases, and therefore the speed of heating the room.

The ash pan compartment should be promptly cleaned of ash and solid particles. Waste is removed manually, so be careful.

It is also necessary to clean the chimney from combustion products. This can be done once a year, before the start of the heating season. For better operation of the chimney, it can be insulated.

The main repair process for a potbelly stove is metal welding. The burned-out places of the firebox are welded using prepared metal plates.

It is necessary to monitor the tightness of the welding seams of the chimney and the chimney itself. Leaks can lead to a decrease in draft, as well as to the ingress of harmful combustion products into the room.

Making a potbelly stove from a gas cylinder is a job that everyone can do. The simplicity of design and operation make this stove an indispensable assistant in the cold season.

Recommended:

How To Make A Bar Stool With Your Own Hands From Wood, Metal And Other Materials + Drawings, Photos And Videos

Bar stools manufacturing options. Required tools, materials used. Step-by-step description of the manufacturing process with a photo

How To Make A Kite With Your Own Hands At Home: Options With Drawings And Sizes + Photos And Videos

DIY kite: the necessary materials, diagrams, drawings, manufacturing steps. How to make a kite of different shapes. Secrets of a Successful Launch

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation

How To Make A Brazier From A Gas Cylinder With Your Own Hands + Photos And Videos

What kind of grill can be made from a gas cylinder. Preparatory work Step-by-step instructions for making a brazier with your own hands with a photo. Video