Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-01-23 12:41.

DIY chimney: from words to deeds

A properly made chimney perfectly removes smoke, supports wood burning, and creates good draft. And every home craftsman can make a chimney for a stove.

Purpose of the chimney

The chimney is designed to discharge combustion products into the atmosphere. They are removed, allowing air to flow into the furnace and supporting combustion. Therefore, any solid fuel heating device must be equipped with a chimney.

Chimney device and pipe diameter calculation

For a small portable stove structure, a lightweight collapsible chimney system is required. At the entrance to the chimney, a damper is located and opens during the furnace. The part of the pipe located inside the furnace serves as a heat exchanger. Leaving the premises should be done short. The pipe consists of two or more elements, so that it is convenient to replace burnt-out areas. Its diameter should be calculated in a ratio to the volume of the firebox 1: 2.7. For example, if the combustion chamber is 60 liters, the pipe should be 160 mm in diameter.

Preparatory work and necessary materials and tools

First of all, you need to determine where the chimney will exit from the room. Then make a hole in the ceiling (wall). It is possible to withdraw the pipeline through the window. It all depends on the room, the location of the stove and the amount of material used. The pipe must not come into contact with the ceiling, as insulating elements will be used. It is worth removing flammable substances from the cracks.

Materials and tools used

For work, you should prepare tools:

- welding machine;

- a hammer;

- mallet;

- roulette;

- Bulgarian;

-

scissors for tin.

Chimney elements For the successful assembly of the chimney, you need to prepare all the elements and the necessary tools

The material should also be lightweight and heat resistant. Usually metal is used. You can take a pipe made of asbestos cement, but only at the top of the system, because it does not withstand temperatures above 280 degrees. To install a standard chimney you need:

- metal pipes with a diameter of 160 mm (two or more);

- metal tee with a diameter of 160 mm;

- knee with a diameter of 100 mm, a length of 1200 mm;

- elbow for joints with a diameter of 160 mm (the number depends on the constituent elements);

- means for sealing joints;

- thermal insulation elements (asbestos cord, mineral wool, heat-resistant sealant);

- bitumen;

- umbrella to protect the outer pipe outlet.

Chimney installation

-

First of all, it is necessary to determine the junction of the inner and outer parts of the pipe. Better to do this in the attic or just under the roof.

Chimney installation To install the chimney, it is best to use the diagram

- To extend the life of the chimney, a cast iron knee can be installed at the exit from the stove. It's good if its height is about a meter.

- Then install the next part of the metal pipe, another one, there should be as many as the sections of the chimney we planned.

- Lead out and connect the internal and external parts of the chimney through the passage glass. The chimney must be higher than the roof.

- Equip the pipe exit point from the roof with a passage nozzle. Remember to remove flammable insulation materials to avoid fire.

- It is recommended to use sheet metal to fix the chimney.

- The outer part of the chimney must be covered with bitumen.

-

An umbrella should be installed at the outer end to protect the chimney from rain and debris.

Do-it-yourself chimney installation The chimney can be fixed in the ceiling

For the construction of a stove chimney in a garage, the same principles are needed - light and heat-resistant materials are used, thermal insulation is used. It is necessary to remember about fire safety. The room should be well ventilated. Gasoline, fuel and other flammable substances should be stored in a specially designated place.

You can lead the pipeline through the wall. Installation principle:

- Make a hole in the wall.

- Clear from flammable materials.

- Lead the pipe outside through the through glass.

- Fix it with sheets of tin.

-

Install a support on the outside of the bracket, fix the chimney parts to it.

DIY chimney construction The chimney is allowed through the wall

- The final stage of the assembly of the structure is sealing. Thoroughly coat all seams and joints with heat-resistant sealant.

- After complete drying, you need to check the quality of work. To do this, you should flood the stove. If the smoke does not seep in and out of the firebox, everything is done correctly.

Another option for the outlet of the chimney: through the window. It is convenient to use a window. Take out the glass and fix the pipe with a sheet of sheet metal, securely fix it on the support installed outside.

We use the window to output the pipe

Chimney operation and cleaning rules

Approximately every six months, you must carefully inspect the structure. The safety of people and buildings depends on this. If areas of burnt, rusty, or cracked metal are found, they should be replaced. This is the advantage of the prefabricated structure.

Chimney cleaning features

Remember to clean your chimney once or twice a year or as needed. A build-up of soot and ash impairs traction and interferes with the normal emission of smoke, making the structure heavy. There are mechanical, chemical and folk cleaning methods. But it is impossible to clean the chimney of a potbelly stove by means of mechanical cleaning of stationary stoves. It is best to use ready-made chemicals by adding them to the wood during the fire. You can buy similar compositions in specialized stores. If you prefer traditional methods, heat with aspen logs. The high combustion temperature will burn out the soot.

Video: chimney for a long burning oven

Now it is clear that making a chimney for a stove with your own hands is not difficult. Stick to technology, be smart, get the right materials. Make sure that it is working properly and use the system for many years.

Recommended:

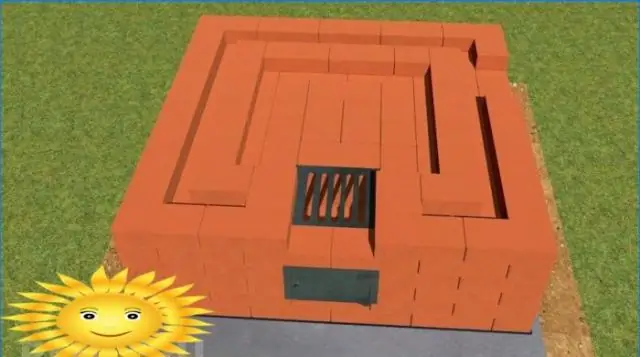

How To Make A Brick Chimney With Your Own Hands: Diagram, Device, Etc

Brick chimneys - design features, advantages and disadvantages, calculation of parameters. Step-by-step instructions for making it yourself

How To Make A Deflector (weather Vane) For A Chimney With Your Own Hands: Calculation, Drawings, Etc

How to make a deflector for a chimney with your own hands: design features, principle of operation and choice of materials, step-by-step instructions for manufacturing and operation

How To Make A Chimney In A Bath With Your Own Hands: Scheme, Device And Calculation, Output Through The Ceiling, Insulation, Step-by-step Guide With Photos And Videos

The chimney in the bath: what is it, why is it needed, what kind of structure it has and how it is made by hand

How To Make A Potbelly Stove From A Gas Cylinder With Your Own Hands: Photos And Drawings, Videos And Secrets

Making furnaces of vertical and horizontal types from a gas cylinder with your own hands. Recommendations for the operation and repair of such stoves

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces