Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-01-23 12:41.

We make a long burning stove with our own hands

When the budget allows, you can purchase a long-burning furnace produced at the enterprise. This option has an elegant look, it can last a very long time. In addition, the unit is definitely safe in operation. However, not everyone can afford such a purchase. And then the question arises about the independent manufacture of such a stove. It is also called pyrolysis. The creation process is relatively complex, it requires strict adherence to all the necessary technologies and algorithms. First, you need to thoroughly study how this apparatus functions. You must have experience with metal and other turning skills.

Content

-

1 Main characteristics and advantages of long burning ovens

- 1.1 What is a long burning oven

- 1.2 Pros and cons of long burning stoves

- 1.3 Design features of pyrolysis ovens

-

2 Making a long burning stove with your own hands

-

2.1 Calculation of furnace parameters according to drawings

2.1.1 Table: workpiece thickness and duct rib heights for different furnace base diameters

- 2.2 Required tools and materials

- 2.3 Selecting the installation site

-

2.4 Step-by-step instructions for self-assembly of a long-burning furnace

- 2.4.1 Video: do-it-yourself bubafony from a gas cylinder

- 2.4.2 Features of making a furnace from sheet metal

-

-

3 Furnace modernization, efficiency increase

- 3.1 Optimization of the chimney design

-

3.2 Which fuel is best used in long burning stoves

3.2.1 Table: Specific Filling Factor and Specific Heat Transfer of Various Fuels

-

4 Operation of long burning stoves

-

4.1 Cleaning and repairing long-burning stoves

4.1.1 Video: long burning oven - cleaning and checking

-

Main characteristics and advantages of long burning furnaces

Self-created long-burning stoves can operate on the following types of solid fuel:

- firewood;

- coal;

- sawdust.

The cost of fuel cells is low. For this reason, they are very widespread. It is the long-burning wood-burning stove that has gained great popularity among homeowners. It is created at home, called "bubafonei".

What is a long burning oven

There may be slight differences in the designs of long-burning furnaces. But the principle of their functioning is similar - it is the production of heat energy during pyrolysis (not by the open flame method), when the wood is exposed to an impressive temperature with a limited amount of oxygen. And the fuel smolders, forming a hot gas. It includes:

- methane;

- hydrogen;

- carbon monoxide;

-

other elements.

Long burning oven In a long-burning furnace, a lack of oxygen is specially created, as a result of which the wood does not burn, but smolders, giving off maximum heat to the room

Pros and cons of long burning stoves

The use of solid fuel long-burning stoves in the heating system of premises helps to eliminate almost all the shortcomings inherent in standard designs on similar fuel:

- Pyrolysis units are characterized by a higher efficiency when compared with classical modifications.

- Long burning stoves do not need to be constantly loaded with wood or coal.

- The pyrolysis system can be automated.

There is a small caveat to the latter advantage. When a home-made apparatus that generates heat is used, the need for automation usually disappears, since even one load of fuel cells guarantees uninterrupted operation for 20 hours.

Design features of pyrolysis ovens

Combustion in a pyrolysis oven is characterized by low dynamics and high efficiency. It is supplied with air by means of a regulator. When the fuel cells are burning properly (approximately 20 minutes after loading), close the air supply hole. This minimizes the passage of oxygen.

The main contribution to the generation of heat in the pyrolysis furnace is made by flue gases, which are located in a special sealed compartment.

The fuel smolders and is almost completely converted to gas. And the flue gases are concentrated in the ignition compartment. When they burn out, a lot of heat is generated. If you try to implement this method of combustion in a conventional furnace, directing its operation to the smoldering mode, you can seriously damage your own safety. In the best case, the gases will rush into the chimney. At worst, they will find themselves in the room, bypassing the doors with weak tightness.

Making a long burning stove with your own hands

Before starting installation and assembly work, it is necessary to correctly calculate the operating mode of the furnace and its design, and then prepare all the necessary materials and tools. We will consider the manufacturing process of the furnace in steps, starting with the creation of a detailed diagram of the thermal unit.

Calculation of furnace parameters according to drawings

For a preliminary assessment of the upcoming volume of work and the configuration of the main elements of the pyrolysis furnace, it is necessary to study the general scheme of its device.

According to the general scheme, you can carry out preparatory calculations and understand the structure of the furnace.

You can calculate the parameters according to the drawing, which reflects the internal structure of the furnace with all dimensions and designations.

The main overall dimensions of the furnace are its diameter D and height H

For reference, we present a table of dependence of the main parameters of the furnace on the diameter of its base

Table: workpiece thickness and duct rib heights for different furnace base diameters

| Furnace cylinder inner diameter (D), mm |

Pancake blank thickness (q), mm |

Air duct rib height (H), mm |

| 300 | 8 ÷ 10 | 40 |

| 400 | 6 ÷ 8 | fifty |

| 600 | 4 ÷ 6 | 60 |

| 800 | 2.5 ÷ 4 | 80 |

When the cylinder diameter does not fit the values indicated in the table, the thickness is calculated in proportions, focusing on the standard of the metal sheet (its thickness).

For an arbitrary cylinder diameter, the thickness of the metal sheet and the height of the ribs are calculated in proportion to the standard values

The air ducts must be rounded and arranged in a spiral. This will ensure the optimal movement of the flue gases.

The ribs of the ducts should be smoothly rounded and arranged in a spiral

Required tools and materials

A very important stage of preparation is the selection of the necessary materials and tools. The key component is a cast iron barrel with a capacity of 200 liters. It is possible to work with a barrel made of steel. The main thing is that it does not have defects and rust. If a suitable barrel is not available, you can use:

- very thick pipe element;

- sheet steel;

- massive fire extinguisher;

- unused gas bottle.

The main requirement is wall thickness. It determines the operating life of the furnace

Other materials:

- Metal products for making legs. Fittings, elements of small-sized pipes or channels are suitable.

- Steel 5 mm thick. You need two circles that have the same diameter as the barrel.

- Ready-made or self-made door.

- The pipe is 10 cm in diameter and 15 cm longer than the barrel itself.

- A pipe with a diameter of 15 cm and a length of about 5 m. It is necessary for the chimney.

Tools:

- Bulgarian. Instead, you can apply autogen.

- Ax and hammer.

- Measuring instruments: level, plumb line, tape measure.

Selecting a place for installation

After installing the furnace, a reflector is made, but they plan this before measurements and welding. It helps to optimally direct heat fluxes so that the room warms up evenly. In addition, the reflector significantly increases the safety level during heating.

The site intended for the installation of the stove must not violate any of the fire safety criteria, since a red-hot stove body is a potential source of fire. And so it becomes when the user violates the operating rules of this unit, incorrectly calculating the amount of sawdust or firewood.

The stove should not be placed against walls or any flammable objects. Adequate space must be maintained around it. For example, the distance to wooden walls cannot be less than 25 cm.

Even before the assembly process, you need to select a workspace. All stages of production will take place there. The premises are subject to the following criteria:

- availability of power supply;

- availability of the required space;

- powerful sound insulation;

- protection from precipitation;

- the ability to store blanks.

Soundproofing is needed in order not to cause discomfort to neighbors. After all, the work turns out to be quite noisy. This insulation can be dispensed with when the work area is far from residential buildings.

Step-by-step instructions for self-assembly of a long-burning furnace

The sequence of actions is as follows:

-

Suppose that what is in private garages or workshops goes into work. These are old gas cylinders. They are prepared for work as follows: the upper side of the structure is carefully cut off. The formed element will become the basis. For cutting, a grinder or autogen is used here.

Preparing a gas cylinder for making a furnace The upper part of the gas cylinder is cut off and a window is made for loading firewood

- After cutting off the top side, a side hole is made in the cylinder body. It is needed to load fuel into the furnace during its operation. Based on the parameters of the hole, you need to make a door, and then put it in place. The door should cover this hole very tightly.

-

Below the indicated hole, another smaller one is made. Ash will be removed through this compartment. It also serves as a blower.

Combustion process in a pyrolysis oven To ensure the required firewood burning mode, a blower with an adjustable level of air supply should be arranged from the bottom of the furnace

-

When the balloon is ready, the next stage begins: the preparation of the starting material. Here, a pipe with a diameter of 10 cm and a metal sheet are taken. A circle of slightly smaller diameter than the balloon is prepared from it. A hole for the working pipe is created in its center. The circle is put on and welded onto it.

Furnace cover making A pipe is welded onto a circle slightly smaller than that of a cylinder, and a lid is obtained, which covers the burning firewood

- 2-3 channels are welded to the lower side of the circle. Their role is to increase the mass of the cover.

- Then the circle is lowered into the prepared (cut) gas cylinder. After that, holes for the pipe are created in the cover. After that, the lid is put into position and welded.

Video: do-it-yourself bubafony from a gas cylinder

Features of making a furnace from sheet metal

Consider working with a sheet metal base. In the work, the master must precisely:

- Calculate the parameters of all structural components.

- Lay out sheet material.

- Process all elements of the apparatus.

- Carry out welding operations.

Mandatory conditions:

- A furnace made of sheet material can have different shapes. It is set both by the master himself and the amount of free space for installing the oven.

- Just necessary parts in the work - special rolls. They allow you to define the shape of the metal sheet. If they are not there, the oven will turn out only in the form of a rectangle.

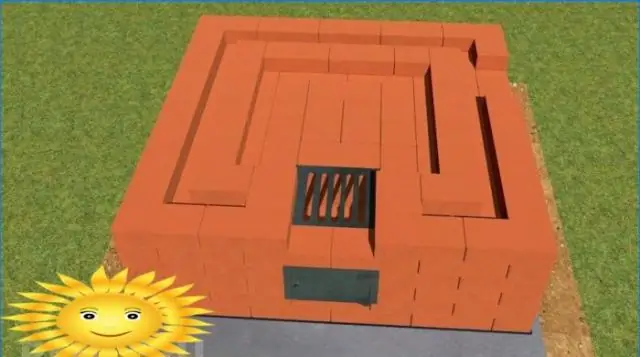

- A prerequisite for safe operation is the foundation. The unit is installed on it.

-

The foundation must be highly reliable, constructed of fire-resistant material. The oven itself weighs a little, so it does not have a strong impact on the ground. High temperatures are generated during operation. It can severely damage the base. To avoid this, you need to use fire-resistant materials when creating the foundation. Fire-resistant bricks are often used. Its laying goes on a pre-prepared concrete base.

Bubafoni stove foundation The foundation for the stove must be made of non-combustible material, for example, brick or concrete

- A metal pipe of the required diameter is quite suitable as a chimney. During installation, the chimney is welded to the top cover of the stove.

- When a rectangular stove is created, the chimney can only be connected to the side of the stove.

- When the chimney is mounted to the stove, it is important to take into account that it should be located only vertically. When creating a chimney, use as few bends and elbows as possible, since a lot of soot is produced after burning solid fuel. It can settle in hard-to-reach areas. Therefore, it is better to make the chimney composite. This will make it easier to disassemble the structure for periodic cleaning.

Furnace modernization, efficiency increase

There are three main ways to increase the efficiency of the stove: one of them is associated with the chimney, the second is with fuel, and the third is with operating conditions

Chimney design optimization

For the chimney, as already noted, a pipe with a diameter of 15 cm and a length of 5 m is used. If you put a pipe of smaller dimensions, especially in diameter, then it will not cope with the resulting loads. And the furnace itself will operate at a reduced efficiency. To adjust the draft, a valve is arranged in the pipe. A door is created at the bottom of the chimney for easy cleaning.

Condensate forms and accumulates in all pipes. And in pipes during pyrolysis it turns out even more, since the gases, having parted with all their heat, at the exit have negative temperatures. This trend becomes the reason for high-quality pipe insulation. The sandwich technology perfectly copes with this task. Its essence: the second is introduced into one pipe, and a layer of heat protection is made between them.

A sandwich pipe can also be made by hand by wrapping the chimney with insulation material and protecting the structure with an outer pipe

In areas where pipes pass through the roof, it is necessary to perform thermal insulation using a metal box filled with insulation. A deflector is placed on the pipe head. It prevents precipitation from entering the system and also protects against the effects of wind.

If the place of installation of the stove is a stoker, there is no need for a reflector. When the stove is located in a room, the masonry surrounding it performs two functions:

- Protective screen for walls and things.

- Heat accumulator.

Since the body is made of metal, the furnace heats up and cools down rapidly. Cooling occurs immediately after the fuel burns out. Therefore, a brick screen, created on three sides of the oven, stores heat and releases it over time. As a reflector, you can use corrugated board or a smooth metal sheet.

What fuel is best used in long burning stoves

The efficiency of the furnace also depends on the fuel used. It is best to use dry logs. But since the stove is homemade, you can also save on fuel. The device can work even with natural debris.

Experts recommend using pellets (granular fuel) created by dry pressing in such stoves. The basis for pellets can be:

- cones;

- chips;

- sawdust;

- nutshell;

- straw.

Coal gives a good combustion temperature. But its use is justified when the stove is made only of materials with a decent thickness. Otherwise, such a unit will quickly burn out. A table showing the specific heat transfer of various materials can serve as a guideline.

Table: specific filling factor and specific heat transfer of various types of fuel

| Solid fuel type | Specific bookmarking factor, kg / dm 3 | Specific heat transfer, kW / h |

| Aspen standard size | 0.143 | 2.82 |

| Coniferous shavings or sawdust | 0.137 | 3.2 |

| Alder pellets | 0.285 | 3.5 |

| Coal grade DPK | 0,4 | 4.85 |

| Coal grade SSOM | 0.403 | 5.59 |

| Large fraction anthracite | 0.5 | 5.72 |

| Peat briquettes | 0.34 | 2.36 |

Operation of long burning stoves

At first glance, it may seem that to fire a pyrolysis oven, you just need to throw firewood into the combustion compartment. This is only a superficial impression. Here it is important to do the following:

- Remove the cover, take out the pressure plate and the pipe. Place fuel on the bottom of the stove. The filling limit is the opening of the flue pipe. The fuel cells are stacked as tightly as possible to each other. Light small twigs are thrown over them. And they are covered with a rag soaked in kerosene. You can also put paper.

- Then the clamping circle must be returned to its place, and the lid must be closed. When the unit fires up, it is required to close the damper that conducts air flows. And she will be in this position for a long time.

When creating a chimney, be sure to provide convenient ways to clean it. It is best if the structure can be quickly disassembled. When a composite chimney is made, its parts are connected so that the joints are located in the opposite direction compared to the moving gases.

Cleaning and repair of long burning stoves

Improper operation of the furnace may result in deterioration of its characteristics and decrease in efficiency. Therefore, check the device periodically for cracks and other defects. It is especially necessary to study the areas around the perimeter of the combustion chamber door and stove. If serious cracks are found, the defective parts must be replaced. Small gaps can be filled with sealant.

All burnt and cracked parts of the furnace must be replaced promptly

Video: long burning oven - cleaning and checking

If you have a small house, garage, or just need to heat the utility room with high quality, a long burning stove is the best option. With a certain experience of working with metal and the skills of a welder, such a device can be built in 1-2 days. If the result is successful, you can save finances and get satisfaction from the process of making a useful thing with your own hands.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Gazebo Out Of Wood With Your Own Hands - Step-by-step Instructions With Photos, Drawings And Video

A gazebo made of wood, who has not dreamed of having it? Now you have such an opportunity, read and get to work on making the structure yourself

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Do-it-yourself Wood Stove - How To Make Economical Wood-fired Stove Heating, Device, Diagram, Drawing, Design With A Water Circuit, Reactive, Iron, Metal, For A Greenhouse + Video

Features and types of wood-burning stoves. Sizing and finding a place to install the oven. Do-it-yourself wood stove installation. Operating a wood-fired oven

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation