Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Wood burning stove

The stove personifies a home that warms all those close to you. Therefore, for the house, they choose such a device with a firebox that would warm up the room well and would not fail during operation. The wood-fired stove is characterized by special strength and reliability. If desired, you can build it yourself.

Content

- 1 Advantages and disadvantages of a wood-burning stove

- 2 Types of wood stoves

-

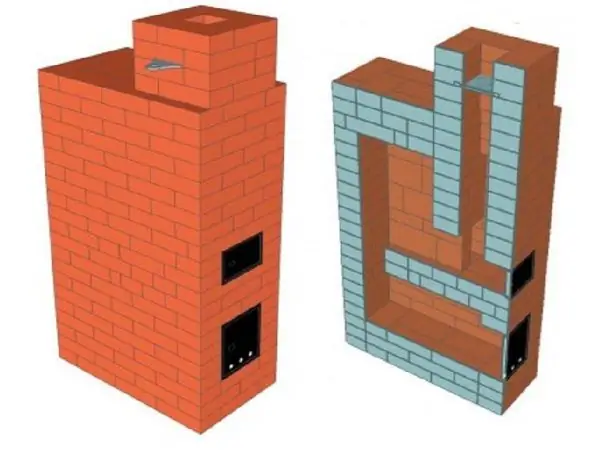

3 Design and principle of operation of a brick wood stove

3.1 Video: all about the brick oven

-

4 Making a brick wood-burning stove with your own hands

-

4.1 Calculation of the parameters of the wood-burning stove

4.1.1 Table: Recommended oven surface depending on its location

- 4.2 List of materials and tools

- 4.3 Finding a place to install the oven

-

4.4 Variants and schemes for making a wood-burning stove

4.4.1 Video: DIY oven laying for the house

-

-

5 Operating the wood-burning stove

5.1 Video: how to properly heat the stove

Advantages and disadvantages of a wood-burning stove

If firewood is taken as fuel, then a stove in a house, garage or in the country must meet a number of requirements. Both the firebox and the chimney of the device are constructed so that they do not collapse during operation.

Brick wood-burning stoves are laid according to a special scheme that ensures structural strength and maximum heat transfer to the surface

Thanks to the special manufacturing technology, the wood-burning stove has many advantages:

- Efficiency. The stove, in the firebox of which firewood is placed, easily heats the air into a room with an area of at least 4 m².

- A pleasant aroma emanating from the wood enveloped in flames.

- The ability to use not only firewood, but also coal.

- Long service life with timely repairs.

- Low cost of buying fuel.

However, it is worth paying attention to some of the disadvantages of a wood-burning stove:

- The need to control the fuel combustion process every 15 minutes, adding new batches on time.

- The requirement to remove ash from the oven, the accumulation of which impairs traction.

Types of wood stoves

Stoves in which firewood is burned are classified into the following types:

-

A cast iron wood stove is a room heating device used as an additional source of heat. Smoke and gases are removed from it through a corrugated chimney or hose. The cast iron stove heats the air in the house very quickly and is installed in any area of the house. Equipped with an air blower, it keeps the room temperature comfortable for long hours.

Cast iron wood stove A cast iron stove heats up very quickly, but it cannot keep heat as long as a brick

-

A metal wood-burning stove is a structure that can heat the air in a room in an amazingly short time, since it is made of steel that retains heat. But the effect of the work of a metal furnace disappears quickly, because its walls are made of thin material. Therefore, in order to avoid an instant drop in the temperature in the house, the stove should be built from stainless steel sheets, creating thick seams that will protect the structure from cracking.

Metal wood stove The metal oven heats up quickly, but cools down just as quickly

-

A brick wood-burning stove is the most reliable device for heating a room, requiring high construction costs. The brick stove is equipped with a serpentine chimney, due to which the received heat does not leave the house for a long time. True, this device takes a long time to create a comfortable temperature, which distinguishes it from a metal oven. But the room, heated by a brick structure, does not cool down for a long time, and the oven itself can be used for cooking.

Brick wood stove A brick oven is the most difficult to build, but it keeps heat better than anyone.

In a wooden house, it is wiser to put a compact oven made of bricks of the heating and cooking type. And the heat capacity of the device should be medium.

The design and principle of operation of a brick wood stove

Each stove in which firewood is laid has the following structural elements:

- chamber where firewood is laid;

-

a cast iron grate on which they are located;

Furnace of a brick oven The bottom of the furnace, made of a thick cast iron plate with longitudinal holes, is called a grate

- ash pan, where the incombustible fuel residue gets through the holes in the grate;

- chimney for removing gases emanating from firewood during combustion.

Burning wood in the firebox leads to the formation of gases heated to a high temperature. These substances pass through the pipe, making the walls of the furnace hot. As a result, heat is transferred to the indoor air. How quickly the air temperature rises in the house depends on the thickness of the material of the walls of the stove. Usually it takes about 5 hours to heat the rooms of a private house.

To maintain the fire in the furnace, it is necessary to regulate the thrust force. To do this, open less or more the blower door and the smoke valve located in the chimney. At the same time, it is important to prevent excess or lack of oxygen in the firewood chamber. An excess amount of air lowers the temperature in the furnace, and an insufficient amount of air causes the formation of incomplete combustion products. Because of this, the heat transfer of the stove is significantly impaired, and an accelerated formation of soot occurs in the chimney.

Video: all about the brick oven

Making a brick wood stove with your own hands

Before starting work, it is necessary to calculate the dimensions of the furnace based on the amount of heat that it should emit into the surrounding space. Next, you need to purchase materials and carry out the masonry according to the selected sequential scheme.

Calculating the parameters of a wood-burning stove

To determine which furnace dimensions you need to build, you should take into account the area of the room. The square of the building is obtained by multiplying the outer perimeter by 21 (the amount of heat required to heat 1 m³ of the area to 18 degrees).

You can find out what a wood-burning stove should be using a table reflecting the dimensions of the equipment surface, depending on its location and room parameters. The presented data should be used if the height of the house is 3 meters, and the temperature outside the window is at least 25 degrees below zero.

Table: Recommended oven surface depending on its location

| Room area, m2 | Surface area for different types of premises, m 2 | |||

| non-angular | with one corner | with two corners | hallway | |

| 8 | 1, 25 | 1, 95 | 2, 10 | 3¸40 |

| ten | 1, 50 | 2, 40 | 2, 60 | 4, 50 |

| 15 | 2, 30 | 3, 40 | 3, 90 | 6 |

| twenty | 3, 20 | 4, 60 | 5, 20 | - |

| thirty | 4, 60 | 6, 90 | 7, 80 | - |

Let's say they are going to build a stove between the kitchen and the hallway. When calculating the area of equipment, proceed as follows:

- Add the volume of the kitchen to the volume of the hallway (let, for example, it be 54.39 m³ + 18.87 m³ = 73.26 m³).

- Find out the value of the return of thermal energy - 73.26 x 21 = 1538 kcal / h.

- Determine the heating area of the furnace, taking into account that a square meter of the furnace gives off 300 kcal / h - 1,538 kcal / h: 300 = 5.1 m².

- Divide the heating area of the furnace by its active height (heated height) and obtain the perimeter of the active surface - 5.1: 2.2 = 2.3 m.

- Determine the sum of the two sides of the furnace - 2.3: 2 = 1.15 m.

- Set some width and find the length (for example, if the oven is 510 mm wide, the length will be 640 mm).

List of materials and tools

When starting to build a brick oven on wood, you need to prepare the following construction raw materials:

-

fireclay bricks brand Ш8 (for the furnace), since they easily tolerate high temperatures, retain heat and do not collapse for a long time;

Fireclay brick Fireclay bricks withstand temperatures over 1,000 degrees, so it is used to lay out the furnace part of the furnace

-

red fire bricks, which are immune to extreme heat, but are fragile and therefore require extreme care when laying;

Red brick Red refractory brick has a high heat transfer, therefore, the main parts of the furnace are constructed from it, which give off heat to the room and remove combustion products

- mastic used as an adhesive for brickwork;

- furnace door;

- blower flap;

- cast iron hob;

-

cast iron grates mounted between the firewood combustion chamber and the blower;

Grate The cast iron grate is installed between the firebox and the blower

- chimney valve.

The construction of a brick kiln is performed using the following tools:

- an electric saw with a metal disc;

- sharpener, eliminating the unevenness of bricks;

- hammer;

- spatulas with plates of various widths and lengths;

- level and plumb line to control construction;

- drill operating from the mains.

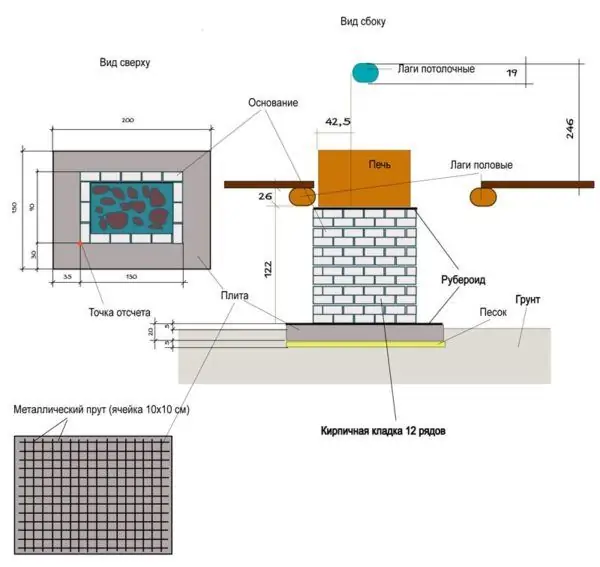

Finding a place to install the oven

A brick structure for heating a house is supposed to be installed so that it does not cause a fire in the house. For furnace equipment, you need to find a place that would allow you to use its power to the maximum.

The installation of a brick oven should be done in one of the following areas:

- the center of the room, where the air heating equipment will divide the room into sectors;

- a niche in the wall located between two or three rooms;

- a place against the wall (further by about 30 cm) if you want to raise the air temperature in only one room.

Having decided on the site for the oven, markup is performed. The lines that define the contours of the furnace equipment to be manufactured start from the ceiling. In this case, they use a plumb line, since it is very important to make sure that the chimney passes through the attic ceilings at a distance of 15 cm from the rafter legs.

When looking for a suitable site for a furnace, one must bear in mind that a lot of space is needed to build a foundation. Therefore, the area where the oven will stand in the future needs to be increased by 10 or 15 cm on each side.

When looking for a place to install a stove, it is necessary to find a reasonable compromise between the distances from the walls and rafter joists and the availability of free space for a strong foundation

Before laying the bricks, a stand is placed on the floor, which will protect the area under the oven from the pressure of a heavy structure and overheating. The device should be multilayer, that is, it should consist of plywood covered with a composition that protects the material from decay, dense basalt cardboard, 8 mm thick aceite and galvanized.

A sheet is also nailed to the wall, which will be next to the stove, to protect against strong heat. It is customary to create this heat shield from pieces of basalt cardboard and aceite coated with molten zinc.

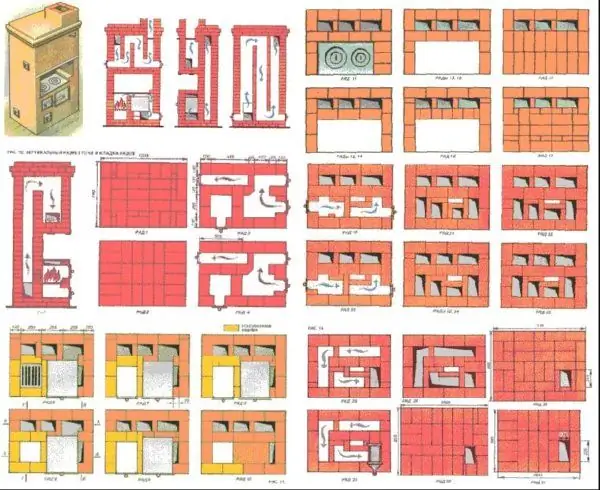

Options and schemes for making a wood-burning stove

According to which scheme a furnace should be built from bricks, depends on the type of equipment. For example, a Swedish oven is laid out as follows:

-

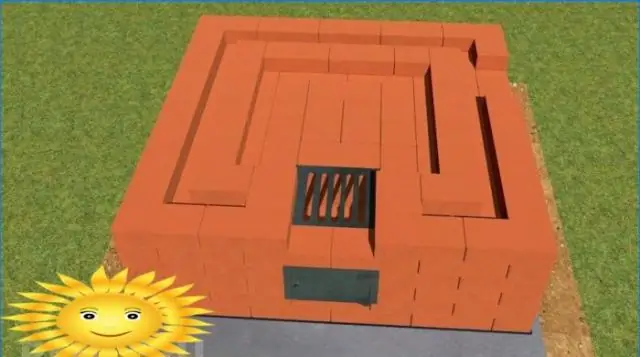

1 row - a piece of roofing material is placed on the bottom of the future furnace, which is sprinkled with sand, forming a layer of 1 cm. At the same time, the horizontalness of the base is kept under control, otherwise the furnace will turn out to be a curve. Having created a platform, the first row of bricks is laid out, thereby obtaining the corners of the structure.

First row of oven masonry The first row of masonry sets the corners of the future structure

- 2nd row - with the help of wire and cement composition, the blower door is mounted.

- 3rd row - placing a line of bricks, make sure that the blocks of the next row overlap the joints of the bricks laid out earlier. A metal strip 4 cm wide, 40 cm long and 4 mm thick is placed on the right.

-

4th row - several metal corners are mounted with vertical elements facing down and brought into the joints of the bricks. Then put a cast iron grate in place.

Installation of the grate The grate is laid on metal corners, walled in the masonry

- 5 row - the corners of the brick blocks are leveled, eliminating roughness. We are talking about those bricks that are adjacent to the grate. Chewing is supposed to be 7-8 cm.

-

6 row - put cast iron doors for the combustion chamber. The element is fixed in place using steel wire and cement mortar. To prevent the brick structure from becoming fragile due to the strong heating of the cast iron, the area around the door is wrapped with an asbestos cord.

Installation of the combustion chamber door The firebox door is fastened with steel wire

- Rows 7, 8 and 9 are formed by enclosing the door of the combustion chamber. In this case, the seams horizontally are made thin (no more than 5 mm). This will allow you to lay out the ninth row at the level of the upper edge of the frame from the fire door.

- 10th row - with a new line of bricks, they cover the joints of previously built blocks.

- 11th row - two steel plates 4.5 cm wide, more than 4 cm long and about 4 mm thick are placed on the laid out line of bricks.

-

12 row - strips of steel are placed on the left side of the structure, and whole bricks are placed on it. After that, they work on the right side of the structure, put two bricks, reduced by ¼. Laying out whole bricks, it will not be possible to make an opening corresponding to the size of the hob with one burner. An asbestos cord soaked in water and cement mortar is laid along the edge of the created window. The hob is fixed using steel wire and a level that allows you to evaluate the horizontal structure.

Hob A hob or heating panel without burners is mounted on the twelfth row of masonry

- Row 13 - a line of bricks is laid out behind the hob, leaving a space of 1 cm for heat to pass. Later, this gap is covered with sand.

- Rows 14-17 are created as required by the ordering scheme. The height of the wall to the left of the hob is adjusted based on the size of the entire masonry. To mount the floors above the hob, the 17th line of bricks is supplemented with three corners 60 cm long and three strips of dense steel 30 cm long.

-

18 row - they carry out the installation of the overlap of the cooking chamber, taking care of the complete filling of the joints with solution.

Overlap over the hob The first row of overlap above the hob is laid on metal corners and plates

- 19 row - on the right side of the brickwork, a half-brick void is left. This space will later serve as an opening for cleaning the oven.

- 20 row - laying out the next line, a brick is laid in the opening left earlier, which can be easily pulled out. A steel strip is mounted on the laid bricks, the length and width of which is 1.4 cm. The plate will provide a zigzag movement of gases along the chimney, which means it will contribute to uniform heating of all zones of the furnace.

- 21st row - create partitions that will separate the lowering and lifting channels for the removal of combustion products from each other.

- Row 22 - during the laying of the next line of bricks, another steel plate is installed.

- 23 row - act according to the ordering scheme.

- 24 row - having laid out a new line of bricks, lay the last steel strip, the task of which is to make the smoke move along the pipe in a zigzag manner.

- 25 row - a piece of sheet steel with an even hole in the place where the chimney passes is attached to the laid bricks with steel strips.

-

26 row - continue to create brickwork, focusing on the ordering scheme, and install a valve for the chimney.

Gate valve The gate valve allows you to regulate the draft of the chimney and block the smoke channel after the coal has completely died out

- 27 row - lay out a solid line of bricks with a gap for holding the pipe.

- 28 row - the walls of the furnace are supplemented with the last line of bricks, after which they check how well all the seams are sealed.

- 29 row - lay out the structure of the pipe going through the roof.

Each row of a brick oven has a clear masonry pattern

If you want to build a small stove that will consume little firewood, despite the high heat transfer, then you should give preference to the following option for assembling a brick structure:

-

1st row or base for the oven. A blower door with a gap and an asbestos-cement cord is also installed here.

First row Bricks are laid close to each other

- 2-3 rows. The walls of the ash chamber and one cleaning are laid out, which is closed with half a brick dry.

- 4th row. It partially overlaps the ash chamber and begins to form smoke channels.

- 5th row. It involves the installation of a grate. The holes are located along the fuel chamber. The laying of the canal walls continues.

- 6-8 row. The furnace is formed. Here, at the same time, the firebox door is installed with a gap (3-5 mm), into which the asbestos cord is placed.

-

9 row. Forms the walls of the furnace and channels according to the orders.

Ninth row Warm air exhaust ducts pass next to the furnace

- 10 row. Continues the construction of the walls of the furnace and channels in accordance with the orders.

- 11th row. A single-burner stove is installed, the niche frame is laid and the laying of the furnace wall and channels continues.

- 12-18 row. The cooking niche and channels are laid out. On the thirteenth row, a latch for kindling is installed.

-

19th row. On the metal frame of the cooking niche and on the bricks, the second half of the stove with a valve is installed and the nineteenth row is laid out.

Nineteenth row In the first row, after overlapping the hob, it is necessary to make triangular cutouts in the bricks

- 20th row. It involves the installation of an oven and further laying of channels according to the orders.

- Row 21-22. Continue laying around the oven and laying channels.

- 23rd row. Supports are installed to overlap the oven chamber.

-

24-26 row. The canals are laid according to the orders.

Rows twenty-fourth to twenty-six In the twenty-sixth row, a gate valve is installed

- 27-28 row. The channels are overlapped, leaving one channel of the pipe 140x140 mm according to the orders.

- Next, the chimney pipe is being laid.

Video: DIY oven laying for the house

Operating a wood-burning stove

To keep the oven safe, you need to take care of the following:

- nail a sheet of steel 30 cm long and 2 mm thick on the floor from the side of the combustion chamber, which would extend beyond the brick structure by 15 cm;

- use a chimney (if it is not brick) made of acid-resistant material that can diffuse smoke well.

The firebox of the stove will not create problems if, during its operation, the rule is followed - to put in the chamber only those firewood that is stored in a covered woodpile that protects the fuel from dampness.

Operating a wood stove is a real craft. To make it enjoyable and beneficial, you should heed some advice:

- firewood is laid in the firebox more tightly, with gaps that were left in the woodpile;

- it is wiser to put thick firewood on top, and thin firewood on the bottom;

- under the arch of the firebox it is supposed to leave a gap of 1/5 of its height;

- after laying the first batch of firewood, the firebox door must not be opened for an hour.

Video: how to properly heat the stove

At the end of the work, it will become clear that building a wood-burning stove is not as burdensome as it seems at first. Although it takes a lot of effort and hours to complete this task, the result will not make you regret what you have done.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces

Diy Solar Water Heater: Diagram, Device, Etc. + Video

Solar collectors: structure, characteristics of different types, tips for choosing. Step by step instructions for assembling a solar water heater. Video

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation