Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

DIY brick chimney in a private house

The efficiency and safety of a heating device that generates heat by burning one or another fuel largely depends on the parameters and condition of the chimney. Today, many companies are engaged in the production of insulated steel models, but not all users are ready to put up with their high cost and relatively short service life. Often, homeowners make the decision to build a chimney using traditional technology, that is, from brick, with their own hands. To do this, you need to adhere to some rules and know which materials are best to use.

Content

- 1 Strengths and weaknesses of a brick chimney

- 2 Elements of a brick chimney

-

3 Calculation of basic parameters

- 3.1 Height

- 3.2 Section dimensions

-

4 Materials and tools

-

4.1 Types of bricks

- 4.1.1 Class I

- 4.1.2 Class II

- 4.1.3 Class III

- 4.2 What solution is needed

- 4.3 Tools

-

- 5 Preparatory work

-

6 How to lay out a chimney with your own hands: step by step instructions

- 6.1 Formation of an otter

- 6.2 Insulation of a brick chimney

- 6.3 Fitting the sleeve

- 7 Chimney cleaning

- 8 Video: laying a brick pipe

Strengths and weaknesses of a brick chimney

Brick chimneys can be used at any facility, be it a boiler room or a private house. With the advent of prefabricated steel sandwiches, they have become less in demand, but are still widely used. This is due to their following advantages:

- a brick chimney is cheaper than a "sandwich";

- lasts longer: about 30 years;

- is an important architectural element and is ideally combined visually with some types of roofing, for example, tiles.

But this design has a lot of disadvantages:

- In terms of complexity and duration, the construction of such a chimney is inferior to the installation of a "sandwich", and special transport will be required to deliver materials.

- The brick chimney has a significant weight, so it has to be provided with a reliable base.

- It is rectangular in cross-section, although a circular cross-section is most suitable. Eddies are formed in the corners, preventing the normal outflow of gases and thus impairing traction.

- The inner surface of a brick chimney, even when finished with plaster, remains rough, as a result of which it becomes covered with soot faster.

Elements of a brick chimney

The chimney design is very simple.

Schematic diagram of a brick pipe, which should be followed

The flue duct is protected from above by a cone-shaped piece - an umbrella or a cap (1), which prevents precipitation, dust and small debris from getting inside. The upper element of the pipe - the head (2) - is wider than its main part. Thanks to this, it is possible to reduce the amount of moisture that gets into the lower area during rain - the neck (3).

There is another widening above the roof - an otter (5). Thanks to it, atmospheric moisture does not enter the gap between the chimney and the roofing (6). A slope (4) is formed on the otter with the help of cement mortar, along which water that has fallen onto the pipe runs. To prevent the rafters (7) and lathing (8) from igniting from contact with the hot surface of the chimney, they are wrapped in heat-insulating material.

The section of the chimney that crosses the attic is called the riser (9). In its lower part, just at the level of the attic floor, there is another widening - fluff (10).

Brick chimney is more reliable than metal

The thick walls of the fluff protect the wooden floor elements (11) from excessive heat, which could cause them to catch fire.

The chimney can be made without fluff. Then, in the zone of passage of the ceiling around the pipe, a steel box is mounted, which is subsequently filled with a bulk heat insulator - expanded clay, sand or vermiculite. The thickness of this layer should be 100-150 mm. But experienced users do not recommend using such a cutting option: the insulating filler pours through the cracks.

The fluff is additionally lined with an effective non-combustible heat insulator (12). Previously, asbestos was used everywhere in this capacity, but after revealing its carcinogenic properties, they try not to use this material. A harmless but more expensive alternative is basalt cardboard.

The lowest section of the chimney is also called the neck (14). It has a latch (13) by means of which the draft can be adjusted.

Depending on the method of construction, the chimney may be one of the following types:

-

Nasadnaya. The furnace itself acts as the basis for this design. To withstand the impressive weight of the chimney, its walls must be two bricks thick.

Stacked chimney The stacked chimney is part of the oven

-

Root. Such a chimney stands on a separate foundation and is not part of any heat generating installation. The flue pipe of the furnace or boiler is connected to it by means of a horizontal tunnel - a crossover sleeve.

Root chimney Such a chimney needs a separate foundation.

-

Wall. Chimneys of this type are channels in load-bearing walls. In order to save heat, internal walls are usually used, on both sides of which there are heated rooms.

Wall chimney Wall-mounted chimney is easy to confuse with a regular wall

In a vertical brick chimney, the draft is formed naturally, that is, due to convection. A prerequisite for the formation of an upward flow is the temperature difference between the ambient air and the exhaust gases: the larger it is, the stronger the thrust is generated in the pipe. Therefore, for the normal functioning of the chimney, it is very important to take care of its insulation.

Calculation of basic parameters

At the design stage, it is necessary to determine the height of the chimney and the dimensions of the cross-section of the flue duct. The task of the calculation is to ensure the optimal traction force. It must be sufficient to ensure that the required amount of air enters the furnace and all combustion products are discharged in full, and at the same time not too large so that the hot gases have time to give off their heat.

Height

The height of the chimney must be selected taking into account the following requirements:

- The minimum height difference between the grate and the top of the canopy is 5 m.

- If the roof is covered with a combustible material, for example, shingles, the chimney head must rise above it by at least 1.5 m.

- For non-combustible roofs, the minimum distance to the top is 0.5 m.

The ridge of a pitched roof or a parapet of a flat in windy weather should not create a support over the chimney. To do this, you need to adhere to the following rules:

- if the pipe is located closer than 1.5 m in relation to the ridge or parapet, then it must rise above this element by at least 0.5 m;

- at a distance of 1.5 to 3 m from the ridge or parapet, the pipe head can be at the same height with this element;

- at a distance of more than 3 m, the top of the head can be placed below the ridge, at a height drawn through it, an inclined line with an angle of 10 degrees with respect to the horizontal.

If there is a higher building near the house, then the chimney should be erected 0.5 m above its roof.

The brick chimney is very neat and fits into any exterior

Section dimensions

If a stove or a boiler is connected to the chimney, then the cross-sectional dimensions should be determined depending on the power of the heat generator:

- up to 3.5 kW: the channel is made in the size of half a brick - 140x140 mm;

- from 3.5 to 5.2 kW: 140x200 mm;

- from 5.2 to 7 kW: 200x270 mm;

- over 7 kW: in two bricks - 270x270 mm.

The power of prefabricated heat generators is indicated in the passport. If the stove or boiler is homemade, this parameter has to be determined independently. The calculation is carried out according to the formula:

W = VT * 0.63 * * 0.8 * E / t, Where:

- W is the power of the heat generator, kW;

- Vт - volume of the furnace, m 3;

- 0.63 - average load factor of the furnace;

- 0.8 - averaged coefficient showing what part of the fuel burns in full;

- E is the calorific value of the fuel, kW * h / m 3;

- T is the burning time of one fuel load, h.

The chimney, if desired, can always be decorated

The calorific value E depends on the type of wood and its moisture content. Average values are:

- for poplar: with a moisture content of 12% E - 1856 kW * h / cu. m, with a humidity of 25 and 50% - respectively 1448 and 636 kW * h / m 3;

- for spruce: at a moisture content of 12, 25 and 50%, respectively, 2088, 1629 and 715 kW * h / m 3;

- for pine: respectively, 2413, 1882 and 826 kW * h / m 3;

- for birch: respectively, 3016, 2352 and 1033 kW * h / m 3;

- for oak: respectively, 3758, 2932 and 1287 kW * h / m 3.

For fireplaces, the calculation is somewhat different. Here the cross-sectional area of the chimney depends on the dimensions of the furnace window: F = k * A.

Where:

- F - cross-sectional area of the flue duct, cm 2;

- K - coefficient of proportionality, depending on the height of the chimney and the shape of its cross-section;

- A is the area of the furnace window, cm 2.

The coefficient K is equal to the following values:

- with a chimney height of 5 m: for a round section - 0.112, for a square section - 0.124, for a rectangular section - 0.132;

- 6 m: 0.105, 0.116, 0.123;

- 7 m: 0.1, 0.11, 0.117;

- 8 m: 0.095, 0.105, 0.112;

- 9 m: 0.091, 0.101, 0.106;

- 10 m: 0.087, 0.097, 0.102;

- 11 m: 0.089, 0.094, 0.098.

For intermediate values of the height, the coefficient K can be determined according to a special schedule.

This graph allows you to determine the coefficient K at intermediate values of the pipe height

They tend to make the real dimensions of the flue duct close to the calculated ones. But they are selected taking into account the standard sizes of bricks, blocks or cylindrical parts.

Materials and tools

A brick chimney is operated in conditions of significant temperature changes, therefore it should be erected from the highest quality bricks. Compliance with this rule will also determine how safe the structure will be: if the brick does not crack, then poisonous gases and sparks that can cause a fire will not enter the room.

Brick types

The pipe is erected from solid ceramic bricks with refractory properties of grades from M150 to M200. Depending on the quality, this material is divided into three grades.

First grade

When making such bricks, the temperature and holding time during firing are ideally matched to the type of clay. You can find it out by the following features:

- blocks are bright red, yellowish tint is possible;

- the body of the brick does not have pores and inclusions visible to the eye;

- all faces are even and smooth, there are no chipped areas on the edges;

- tapping with a light hammer or other metal object gives a clear and clear sound.

It is recommended to choose a brick depending on its properties.

Second grade

Such a brick is unfired. Here are the signs that are characteristic of him:

- the blocks are pale orange, weakly saturated;

- numerous pores are visible on the surface;

- the sound when tapped is dull and short;

- on the edges and edges there may be defects in the form of scoring and crumbling areas.

For bricks of the 2nd grade, low heat capacity, frost resistance and density are characteristic.

Third grade

Bricks in this category are burnt. They are recognized by the following features:

- the blocks have a deep dark red color, there are almost brown ones;

- when tapped, they give a too sonorous sound;

- edges and edges contain defects in the form of chips and scuffs;

- the structure is porous.

Such a brick is not frost-resistant, does not hold heat and is too fragile.

The chimney should be built of first grade brick. Second-rate should not be used at all, and third-rate can be used to make foundations for free-standing pipes.

What solution is needed

The requirements for the quality of the mortar are as high as for the brick. Under any temperature, weather and mechanical influences, it must ensure the tightness of the masonry throughout its entire service life. Since individual sections of the chimney work in different conditions, different solutions are used when laying it.

This scheme will help you choose the right mortar for brickwork

If the pipe being erected is a root pipe, then the first two rows of it (zone No. 3), located under the floor, should be laid on a cement-sand mortar (for 1 part of cement, 3-4 parts of sand). To make the mixture more plastic, 0.5 parts of lime can be added to it.

The upstream sections of the chimney, up to and including fluff, have an internal temperature of 355 to 400 degrees, so a clay-sand mortar is used for their construction. If the fluff ends at the ceiling (zone No. 8), and the cutting is made of bulk material (zone No. 9), then the use of this mixture extends to the rows in the cutting.

The riser, otter and chimney neck (zone 10), which do not get very hot, but are subject to wind loads, should be laid with a lime mortar. The same composition can be used for the construction of the head (zone number 11), but the usual cement-sand mixture is also suitable for this area.

The composition of the solution depends on which part of the chimney is being built

Clay for mortar should be taken medium-fat. It should not have a strong odor, as this is a sign of the presence of organic impurities that cause cracks in the solution.

In addition to these materials, you will need special purchased items - a cleaning door, a latch and a hood. The gaps between the brickwork and the metal products mounted in it are sealed with asbestos cord or basalt cardboard.

Tools

The most common tools will be used:

- Master OK;

- hammer pick;

- plumb line.

You can't do without a building level.

Preparatory work

If a main chimney is being built, then construction work should begin with the construction of a reinforced concrete foundation. Its minimum height is 30 cm, while the sole must be located below the freezing depth of the soil. The foundation of the chimney should not have a rigid connection with the foundation of the building, since both objects give different shrinkage.

The sand must be thoroughly cleaned of impurities by sifting through a sieve with a mesh of 1x1 mm, and then rinsed. It is better to wipe the clay through a sieve after soaking. The lime used must be slaked.

Solutions are prepared according to the following recipe:

- Clay-sand: mix sand, fireclay and ordinary clay in a ratio of 4: 1: 1.

- Lime: sand, lime and cement of the M400 brand are combined in a ratio of 2.5: 1: 0.5.

- Cement-sand: mix sand and cement of the M400 brand in a ratio of 3: 1 or 4: 1.

The mortar for the brick must be of sufficient density

The clay is soaked for 12-14 hours, stirring from time to time and adding, if necessary, water. Then sand is added to it. The recipe given is designed for clay of medium fat content, but it is advisable to check this parameter in advance in the following way:

- Take 5 small portions of clay of the same mass.

- Sand is added to 4 portions in the amount of 10, 25, 75 and 100% of the clay volume, and one is left in its pure form. For known to be oily clay, the amount of sand in portions is 50, 100, 150 and 200%. Each of the test pieces should be mixed until uniform, and then, by gradually adding water, turn into a solution with the consistency of a thick dough. A properly prepared mixture should not stick to your hands.

- Several balls with a diameter of 4-5 cm and the same number of plates with a thickness of 2 to 3 cm are made from each portion.

- Then they are dried for 10-12 days in a room with a constant room temperature and without drafts.

Determine the result, considering the solution suitable for work that satisfies two requirements:

- products made from it did not crack after drying (this happens with high fat content);

- balls dropped from a height of 1 m do not crumble (this would indicate insufficient fat content).

The solution that has passed the test is prepared in a sufficient volume (2-3 buckets are required for 100 bricks), while so much water is added so that the mixture easily slides off the trowel.

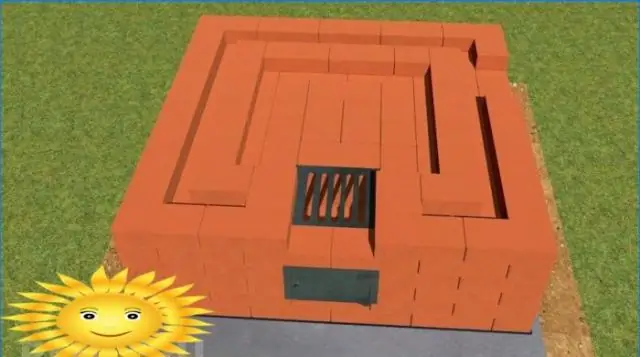

How to lay out a chimney with your own hands: step by step instructions

If materials and tools are prepared, construction work can begin:

- About two rows before the ceiling, they begin to spread the fluff. If there are several channels in the chimney, then the bricks that block them must be partially recessed in one of the outer walls.

-

The first two rows are laid out especially carefully. They set the tone for the entire structure, so they should be perfectly even and strictly horizontal. If a packed pipe is placed, then it is erected from the first rows on a clay-sand mortar, which is applied with a layer of 8-9 mm thick, and when the block is installed in place, it is compressed to a thickness of 6-7 mm.

Laying of the first and second rows of the chimney At this stage, you need to carefully monitor that the level remains both vertically and horizontally

- Following the order, the chimney neck is erected. The seams must be tied up so that the masonry does not crack into separate layers.

- From the inside, the seams are rubbed with a solution (so that the inner surface of the chimney is as smooth as possible).

-

The duration of the fluff is determined taking into account the expected settlement of the structures:

- if the building is expected to settle more strongly than the stove or main chimney, fluff is made with a margin from below;

-

if it is expected that the pipe will give the draft (suppose the house was built a long time ago and has already completely settled), then the fluff is done with a margin on top.

Laying fluff The dimensions of the fluff depend on the draft of the chimney

-

With each row, the wall thickness in the fluff is increased by 30-35 mm. For this, plates of different thicknesses are cut from bricks. So, for example, in the 1st row of fluff, in addition to whole blocks, the number of which has increased from 5 to 6, longitudinal and transverse halves (2 pieces each) and several quarters are used. Cut bricks must be laid so that the rough cut looks inside the masonry, and not into the flue duct. The row of fluff, which will be flush with the overlap, must be isolated from the wooden elements with strips of asbestos or basalt cardboard. Then they return to the original dimensions of the chimney - this will be the first row of the riser. At this stage, using a plumb line, you need to determine the projection of the chimney onto the roof and make a hole in it for it. In waterproofing and vapor barrier films, not a hole is made, but a cruciform incision. After that, the resulting petals are folded in such a way that the functionality of this element is not compromised. A riser is laid out row by row, trying to make it absolutely vertical (controlled by a plumb line).

Brick chimney First row of riser

Otter formation

The riser ends side by side, protruding halfway above the lower edge of the roof opening. Those that are at the level of wooden rafters and battens must be insulated with asbestos or basalt strips.

When building an otter, you need to use asbestos or basalt strips

The otter begins next. Like the fluff, it gradually expands, but unevenly, and taking into account the different heights of the edges of the hole in the roof. Further, the dimensions of the chimney return to their original values - the neck of the furnace begins.

This is what a well-formed otter looks like.

The last stage is the device of the head from two rows. The first row is made with a broadening of 30-40 mm in all directions. The second row - according to the usual scheme, while on the ledge of the lower row an inclined surface is laid out using concrete mortar.

In the future, you will have to fix the umbrella on the head.

An umbrella is attached to the ledge of the head. The clearance between its bottom and the top of the head should be 150-200 mm.

The gap between the pipe and the roof must be sealed.

The gap between the roof and the pipe is sealed

The otter's "steps" are smoothed out with a solution so that an inclined surface is formed, after which the entire outer part of the chimney must be treated with a waterproofing compound.

Insulation of a brick chimney

The cheapest way to insulate a chimney is to coat its surface with a solution based on lime and slag. First, a reinforcing mesh is attached to the chimney, then a solution is applied layer by layer, making the mixture more and more thick each time. The number of layers is from 3 to 5. As a result, the coating has a thickness of 40 mm.

Thermal insulation of a pipe with mineral wool is the most economical option

After the plaster dries, cracks may appear on it, which must be covered. Next, the chimney is whitewashed with a solution of chalk or lime.

A more expensive, but more effective version of insulation is associated with the use of basalt wool with a density of 30-50 kg / m 3. Since the walls of the chimney are flat, it is most advisable to use this insulation in the form of hard plates, and not soft panels (mats).

To install basalt wool on the chimney, you need to fix the metal profile frame with dowels. The insulation is placed in the frame, after which it can be fixed with a stretched nylon cord or screwed to the brickwork with special disc dowels with a large-diameter cap (to prevent the material from being pushed through).

A vapor-impermeable film is laid on top of the basalt wool (this heat insulator absorbs water well), and then it is plastered with an ordinary cement-sand mortar on a reinforcing mesh or sheathed with tin (it can be galvanized).

Installing the sleeve

The stacking of the chimney is carried out in the following sequence:

- In the connection area of the boiler or stove, the chimney masonry is dismantled to a height sufficient for mounting the longest part of the steel liner. This is usually a condensate trap.

- All elements of the liner (liner) are sequentially installed, starting from the topmost one. As the installation progresses, the parts to be installed are fed upward, freeing up space for subsequent ones. Each element has hooks on which you can catch a rope passed through the upper hole.

- After installing the liner, the space between it and the walls of the chimney is filled with a non-combustible heat insulator.

Flexible sleeve will allow you to correctly form the chimney

At the end, the opening in the chimney is again bricked.

Chimney cleaning

A layer of soot deposited inside the chimney not only reduces its cross section, but also increases the likelihood of a fire, since it can ignite. Sometimes it is even specially burned out, but this method of cleaning is very dangerous. It is more correct to remove soot by a combination of two methods:

- Mechanical implies the use of brushes and scrapers on long stackable holders, as well as weights on a strong cord, which are passed into the chimney from above.

- Chemical: in the firebox, along with ordinary fuel, a special agent is burned, for example, "Log chimney sweep" (sold in hardware stores). It contains many substances - coal wax, ammonium sulfate, zinc chloride, etc. The gas released during the combustion of this agent forms a coating on the walls of the chimney that prevents soot from sticking to them later.

The second method is used as a prophylactic one.

"Log chimney sweep" will clean the chimney in two weeks

Video: laying a brick pipe

At first glance, the chimney seems to be an extremely simple design. However, at every stage of its construction - from the choice of materials to the installation of thermal insulation - a balanced and deliberate approach is required. By following the recommendations of experts, you can build a solid and safe structure that will last for many years.

Recommended:

How To Make A Deflector (weather Vane) For A Chimney With Your Own Hands: Calculation, Drawings, Etc

How to make a deflector for a chimney with your own hands: design features, principle of operation and choice of materials, step-by-step instructions for manufacturing and operation

How To Make A Chimney In A Bath With Your Own Hands: Scheme, Device And Calculation, Output Through The Ceiling, Insulation, Step-by-step Guide With Photos And Videos

The chimney in the bath: what is it, why is it needed, what kind of structure it has and how it is made by hand

How To Make A Chimney From A Steel Pipe With Your Own Hands: Device, Installation Of A Sandwich Structure, Instructions With Photos And Videos

What is a steel pipe chimney, where is it used, its advantages, disadvantages and its manufacture by hand

How To Make A Coaxial Chimney With Your Own Hands: Installation Requirements, Installation, Operation, Etc

Types of coaxial chimneys. Features and conditions of installation. Step-by-step installation instructions and tips for operating a coaxial chimney

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation