Table of contents:

- How to fold a Dutch oven with your own hands

- What is a Dutch oven and where is it used

- Design and principle of operation

- Calculation of the main parameters of the Dutch woman

- Materials and tools for building a Dutch oven

- Preparatory work before assembling the oven

- One of the options for making a stove with your own hands

- Furnace decor

- Features of operation

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

How to fold a Dutch oven with your own hands

Stove heating, despite its archaism, remains the main type of heating for housing in rural areas. Much attention is paid to the reliability of the design and the efficiency of the unit, since restoration and maintenance are associated with high financial costs. The Dutch stove, which has long been used in Russia, is a time-tested solution to the problem of heating efficiency, a decent interior design of the house and reliable operation for a long time.

Content

-

1 What is a Dutch oven and where is it used

- 1.1 Advantages and disadvantages of the Dutch oven

- 1.2 Types of oven

- 2 Design and principle of operation

-

3 Calculation of the main parameters of the Dutch woman

-

3.1 Determination of power

- 3.1.1 Table: specific calorific value of some types of wood in kW * h / m3

- 3.1.2 Table: Relationship between power and flue size

- 3.2 Determination of the area of a circular pipe

-

- 4 Materials and tools for building a Dutch oven

-

5 Preparatory work before assembling the oven

- 5.1 Pouring the foundation

- 5.2 Preparing openings in ceilings between floors and attic

-

6 One of the options for making a stove with your own hands

6.1 Video: do-it-yourself Dutch oven

- 7 Furnace decor

-

8 Features of operation

8.1 Cleaning and repairing the oven

What is a Dutch oven and where is it used

In Russian, the name of this type of stoves appeared during the reign of Peter I, when the tsar ordered all the boyars to build them on the model of the Dutch, "so that they could please the eye with European beauty." The classic option in the Netherlands is a purely heating facility with hobs and ovens.

The Dutch stove covered with painted tiles fits perfectly into the interior of a country house

The advantages and disadvantages of a Dutch oven

Its main functional advantages are as follows:

- Compact dimensions. The Small Dutch oven has a minimum square size with a side length of 52 cm.

- Relatively simple installation, which even a novice bricklayer can do.

- Consumption of materials in comparison with a similar-sized Russian stove is half as much. For the construction of a small Dutch woman, 700 pieces of bricks are needed, while it will heat the room in the same way as a large Russian stove.

- Light weight. The unit can be installed without additional supports in two - and three-storey buildings. Standard interfloor ceilings, designed for a load of 300 kg / m 2, easily support the weight of the furnace.

- Even significant changes in the design do not have a noticeable effect on the functioning of the furnace. The strength of the case and efficiency are not compromised. The main condition is to avoid gross mistakes in masonry and decoration.

- Thanks to the smooth change in the temperature in the chimney and the simple scheme of gas movement into the oven, it is easy to build in additional devices - a bread maker, a water heater, etc.

- The ability to use any materials during construction, even hollow bricks. High-quality fire-resistant material is needed only for laying out the combustion chamber.

- Easily and without damage to heat transfer, the supra-heating part is increased. The chimney body can be pulled out 2, 3, 4 floors up.

- The thin-walled heat exchanger of the furnace heats up rather quickly and cools slowly.

- Good heat dissipation. Where the Russian stove will heat 40 m 2, a Dutch woman of the same size - 60 m 2.

- No pre-firing is required after long periods of inactivity.

During the construction of a Dutch woman, the consumption of materials is approximately two times less, in comparison with a Russian stove of a similar size

There are also disadvantages:

- The efficiency does not exceed 40%. For comparison, the Russian stove has an efficiency of about 60%, and improved models - up to 80%.

- Some types of fuel cannot be used - straw, brushwood, reeds and other instantly burning materials. A fast oxidation reaction with a large release of energy will not bring heat into the house. The most suitable fuels are coal and wood, which can burn in a smoldering mode.

- To ensure constant heat in the room, it is necessary to heat at least twice a day.

- A layer of soot and carbon deposits quickly forms on the walls of the chimney channels, which ignites from time to time. This could cause a fire in the entire house. If, for example, the door of the firebox is poorly closed, and the soot has caught fire, the blast wave throws out a long tongue of flame through the firebox.

- If, after burning the fuel, the stove damper is not closed in time, all the heat will instantly evaporate.

- The unit does not tolerate overheating. Excessive temperature leads to the rapid appearance of microcracks on the body. This is followed by the flow of carbon monoxide into the dwelling.

The disadvantages are more than offset by the advantages of the Dutch woman. Thanks to this, the stove is very popular among the population. Analyzing its functional qualities, one can come to the following practical conclusions:

- it is optimal for small houses, individual rooms, garages, summer cottages and even baths;

- irreplaceable for floor heating in a building when it is impossible to use a massive Russian stove;

- the design allows the chimney to be led out both through the roof and through the side wall, which makes the stove unique in terms of economy.

The optimum operating temperature of the oven is 60-65 ° C in the middle of the body. It was noticed that the human hand can withstand this temperature, but for the back of the hand such heating is already intolerable. Therefore, the correctness of the firebox can be controlled with your hand.

Furnace varieties

The following characteristics can be used for classification:

- shape and size;

- functions and purpose;

- types of decorative finishes.

The shape was originally rectangular. Today you can find square, round and even triangular ovens. Some models are equipped with a traditional Russian heated bed.

The Dutch oven can also have a stove bench in the "Russian spirit"

The name "Dutch" has become more common than our own. For example, behind the oven known as the "Untermark", invented in the 19th century by the German I. G. Untermark, the name "round Dutch woman" was firmly established. The bell-type furnace Grum-Grzhimailo is called the same, although the principle of its operation is different.

12-pass German Untermark oven is also called Dutch

Depending on the size, Dutch ovens are conventionally divided into large and small, and by purpose - into two classes:

- heating;

- heating and cooking.

For exterior decoration, the following types are distinguished:

- with a metal casing;

- plastered;

- finished with tiles, tiles or other material;

- covered with tiles.

Bell-type stove Grum-Grzhimailo has a rounded shape and is often covered with tiles

Design and principle of operation

The Dutch woman has the following design features:

- Rectangular shape, in which the combustion door is located on the short side, and the chimney ducts on the long elongated side.

- A prerequisite for the combustion chamber is that it consists of high-quality refractory bricks.

- Lack of ash compartment. As a result, the fuel, not fueled by air draft, burns out slowly, with maximum heat transfer to the room.

- The heat exchanger of the furnace consists of several (in the classic version - 6) vertical smoke channels. Hot gases rise up the chimney, transferring heat to the walls. Cooling down, they descend again down to the firebox, heat up and the process is repeated three times. The sixth channel is connected to a pipe through which the smoke goes out.

-

Lack of grate. This feature brings the design closer to the fireplace, but with a high (approximately 2 times) efficiency. If you completely open the door of the combustion chamber, the Dutch stove will turn into a fireplace.

Improved Dutch model The presence of an ash chamber and a grate in a Dutch woman is a new trend

- Thin walls. It is this feature that allows the oven to warm up quickly.

- Heating purpose is the main function, and stove benches, hobs and ovens are improvements to the unit.

The basis of the furnace is the movement of hot gases along the vertical channels of the chimney

Calculation of the main parameters of the Dutch woman

For any stove, you need to determine the power (heat transfer) and the size of the cross-section of the chimney. To calculate the power, you need to know the value of the specific heating value of the fuel. The desired numbers can be found in the tables, which are compiled on the basis of experimental testing of various types of fuel.

Determination of power

If one bookmark vigorous combustion of wood takes one hour, the furnace power can be calculated by the formula: W = V t x E bpm x 0.8x 0.4 x 0.63, where W - power expressed in kW, V t - working the volume of the fuel chamber in m 3, the coefficient 0.8 indicates the amount of fuel burned, the coefficient 0.4 is the efficiency index of the stove and the coefficient 0.63 is the level of the furnace load with combustible material.

For example, you can calculate the heat transfer power for a furnace with a furnace size of 0.4x0.3x0.4 m. The fuel is birch firewood with a moisture content of 25%. We substitute our data into the formula and we get: W = 04x0.3x0.4x2352x0.8x0.4x0.63 = 22.76 kW.

After determining the power indicator, the size of the pipe cross-sectional area is selected.

Table: specific calorific value of certain types of wood in kW * h / m 3

| Wood fuel type | Humidity 12% | Humidity 25% | Humidity 50% |

| Poplar | 1856 | 1448 | 636 |

| Fir | 1902 | 1484 | 652 |

| Spruce | 2088 | 1629 | 715 |

| Birch tree | 3016 | 2352 | 1033 |

| Oak | 3758 | 2932 | 1287 |

| Aspen | 2181 | 1701 | 747 |

Table: ratio of power and chimney size

| Heat transfer power, kW | Linear dimensions of a rectangular chimney, mm |

| Less than 3.5 | 140x140 |

| 3.5 - 5.2 | 140x200 |

| 5.2 - 7.2 | 140x270 |

| 7.2 - 10.5 | 200x200 |

| 10.5 - 14 | 200x270 |

| More than 14 | 270x270 |

Determining the area of a circular pipe

If a circular metal pipe is used, its area is calculated by the formula: S = pR 2, where S is the required area, p is a coefficient equal to 3.14, and R is the radius of the pipe circle. With slow fuel oxidation (in the smoldering mode), heat transfer decreases to 10-30% of the level of the flame phase of combustion. However, the chimney still needs to be calculated at higher power using the data obtained from the above formula.

Materials and tools for building a Dutch oven

For work you will need:

-

bricklayer's trowel, trowel, hammer-pickaxe, jointing, knife;

Stove-maker's tools The basic tools of a bricklayer - trowel, hammer-pickaxe, jointing

-

measuring instruments - tape measure, level, plumb lines, a roll of construction cord;

Construction tape A tape measure is needed to measure the dimensions of the oven.

- containers for mixing solutions, shovel;

-

an electric drill with a stirring attachment (mixer);

Drill with mixer A power tool for kneading masonry mortar will come in handy when building a stove

- a grinder with a diamond disc, with which you can cut bricks;

- ordering - an even wooden lath, marked along brick rows (it is installed strictly vertically and placed along the notches, the tool is easy to make on your own);

- construction stapler.

List of materials for the Dutch stove:

-

full-bodied red bricks;

Red brick Solid red brick is used for brickwork

-

refractory bricks, fireclay;

Fireclay brick Refractory brick brand ШБ-5 is required for laying the combustion chamber

-

a set of furnace casting - firebox and blower doors, chimney valves, views, grate (if a cooking compartment is planned in the furnace, a cast iron stove will be required);

Furnace accessories During the construction of the Dutch women, they use cast iron for the furnace - grate, chimney valves, views

-

materials for the solution - clay, sand and water (you can buy a ready-made mixture);

Clay mixture for brickwork Dry clay mixture is needed for laying the stove

- several meters of tempered steel wire (0.4-0.8 mm in diameter);

-

asbestos sealant in the form of a cord or gasket;

Asbestos cord Seal of metal parts in the form of an asbestos cord is used in the construction of a Dutch woman

-

sheet metal outdoor umbrella (for brick chimney);

Chimney umbrella The umbrella is installed on the head of the stove and serves to protect the masonry from moisture

-

metal reinforcing mesh and several sheets of roofing material or other waterproofing material (for the foundation);

Reinforcement mesh The size of the cell and the thickness of the reinforcement are selected in accordance with the dimensions of the foundation

- formwork boards.

Preparatory work before assembling the oven

Before installing the furnace, the foundation is poured and holes are made in the interfloor and attic floors.

Pouring the foundation

If the installation of the stove is planned at the stage of building a house, then the foundation is poured in the place of its location. According to the rules, it is not associated with the general foundation of the house, but is laid separately. This prevents unwanted distortions that can occur during shrinkage. The erection of the building is carried out simultaneously with the laying of the stove; when placing the load-bearing floor beams, the height of the stove and chimney body is taken into account.

For furnace equipment, a foundation is poured that is not associated with the main foundation of the house

If the decision to install a heating unit has arisen in a finished house, carefully weigh and evaluate the work that will have to be done. The most important are the preparation of the foundation and the laying of the chimney through the attic or interfloor floors. Sometimes it is more expedient to lead the pipe through the wall: the Dutch woman has such an opportunity.

Foundation preparation is carried out in advance. The cement mortar must dry and shrink for at least 30 days. Only then does the installation of the oven begin. Otherwise, deformations are possible during operation, which leads to cracking of the thin walls of the stove and a violation of the tightness of the chimney. To avoid such consequences, the foundation is poured in accordance with the rules:

-

the base of the foundation is dense soil; concrete should not be poured into the soil near groundwater;

Stove foundation The height of the foundation does not reach the level of the clean floor by 2 bricks

- the depth of the pit for filling should not be less than the depth of soil freezing in this region (as a rule, 0.8-0.9 m, with the exception of the regions of the Far North);

-

the concrete solution is placed on an established (within 2 days) sand cushion, which has a depth of 15 to 20 cm and serves as a hydraulic compensator during further operation;

Sectional foundation The foundation is laid in several layers: the bottom - sand, then - stones and bricks, which are covered with rubble and poured with concrete

- inside the concrete, a reinforcing lattice is placed with a metal rod thickness of 5 mm;

- the linear dimensions of the foundation must exceed the dimensions of the furnace base by 15-20 cm;

- the height of the upper plane does not reach the floor level by 2 brick rows.

Several layers of basalt cardboard are laid between the base of the furnace and the waterproofing, which serves as a heat insulator and prevents the heat from leaving the furnace to the foundation.

Basalt cardboard is an inexpensive but effective material for thermal insulation

Preparing openings in ceilings between floors and attic

The holes are cut taking into account the fire-prevention cuts and fluffs, which must be built in the chimney in contact with combustible materials. This is especially true in wooden houses. It is necessary to calculate the location of the pipe so that it does not intersect with the supporting beams and other structural elements of the house. The hole in the roof is made last when the bulk of the masonry has been completed.

The chimney hole is prepared in advance so that plumb lines can be hung

The procedure for removing the chimney to the outside can be as follows:

- Remove the roof at the pipe outlet. If the roof is covered with a continuous layer of material that cannot be separated (for example, corrugated board, slate, etc.), use measurements to determine the exit point and the size of the hole, and then cut it out with a grinder or jigsaw.

- Install jumpers to restore the rigidity of the damaged area. Usually these are additional transverse rafters made of wooden bars.

- Lay and fix a heat-insulating layer between the chimney and the roof. It usually consists of asbestos sheet or mineral panels.

The hole should be made taking into account the fact that an otter must be laid out at the pipe outlet - a horizontal displacement of the masonry that protects the attic space from water penetration.

The otter is located directly at the exit of the pipe from the roof

After that, you can remove the brickwork above the roof.

It is important to comply with the fire safety standards for chimneys when building a Dutch woman

One of the options for making a stove with your own hands

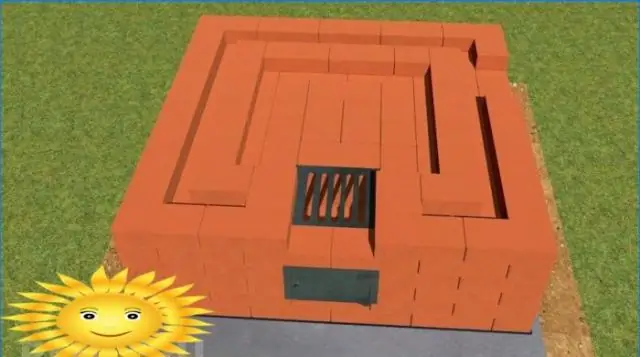

For a heating and cooking stove, as a very practical option for a summer residence or a country house, the order looks like this:

Dutch heating and cooking type - optimal design for a country house

Since a certain precision is required during laying, the craftsmen wet each brick in water. Thanks to this, moisture is not sucked out of the solution. Usually, all bricks for one or two rows are dipped into a trough with liquid. And they add new ones as they are used.

To get the masonry skill, you can initially fold several rows without mortar. If everything works out, you can move on to real masonry.

Particular attention should be paid to the waterproofing between the foundation and the Dutch woman's body. It is made of roofing material in two layers in front of the first row. Some people advise laying out the first row of heat-insulating bricks, since with this type of stove most of the heat can go down.

The insulator is roofing material, roofing felt or other synthetic materials.

Operating procedure:

- The first row is laid out with a solid surface. It is necessary to properly observe the dressing, as indicated in the diagram.

-

The second and third rows are also solid, but the order of the bricks in them is different. The result is a monolithic furnace base over which the load is evenly distributed.

Rows 1- 3 brickwork oven In the first rows, it is necessary to observe the correct layout of bricks

-

In the fourth row, an ash pan door is installed. During installation, it is recommended to use an asbestos cord, which is wound on the end side of the frame with a thickness of 4-5 mm. There are several ways to fix the door, but the best option is using special legs.

Row 4 oven masonry Installation of the blower door is performed on the fourth row of masonry

-

The fifth row is the same as the fourth. Laying is carried out from the right corner with a bandage in half a brick.

Row 5 oven masonry Completion of the ash pan masonry

- On the sixth row, the ash chamber is closed using a steel strip.

-

The seventh row is the beginning of the firebox, which must be laid out with fireclay bricks. They immediately put the firebox door.

Row 7 masonry The installation of the combustion chamber door is carried out on the seventh row of masonry

- Install grate bars with a gap for thermal expansion of 4-5 mm.

- The eighth row completes the overlap of the ash pan, and at 9-14 they form a fuel chamber made of fireclay bricks.

-

In the tenth row, the combustion chamber is blocked and specially made bricks are installed for mounting the hob. The holes on the metal plate are cut with a grinder.

Row 10 Brickwork Kiln On the tenth row, the masonry covers the combustion chamber

- Up to 13 rows form the space above the tiles. Bricks are laid out strictly according to the scheme.

- In row 14, bricks with grooves are mounted, into which a metal corner is inserted to support the weight of the next levels.

-

The fifteenth row covers the recess above the stove, and at 16 and 17 there is a door for cleaning the chimney. The installation is similar to all previous cast iron elements.

Row 15 masonry Installation of the chimney cleaning door is performed on row 15

- From the 18th to the 22nd row, a chimney is made.

-

In the 23rd row, a stove valve is installed on the chimney channel. To do this, the bricks are adjusted so that there is space between the masonry and the metal for an asbestos gasket.

Row 23 oven masonry The chimney valve is installed on the 23rd row

-

In rows 24 and 25, the descending and lifting channels are connected, and in 26 - 28 they form a chimney. In the course of the masonry, the inner surface of the channels is lined. This will improve gas permeability and create a normally functioning traction.

Row 24, 25 Dutch brickwork Chimney ducts are formed on rows 24 and 25

- In the 29th and 30th rows, a valve is installed that regulates the total draft in the chimney.

-

Close the valve and form the chimney outlet.

Dutch oven with stove A Dutch heating and cooking stove of rectangular design is easy to build on your own

If the house has a wooden floor, for fire safety purposes, it is necessary to install a pre-heating apron. It is made of sheet iron with a thickness of 0.5 mm. The size is selected so that the wood is protected from sparks and coals that can fly out of the firebox. An asbestos gasket is additionally laid under the metal.

An asbestos gasket provides additional protection for the floor from fire

After completing the laying, it is necessary to dry the oven properly. This can take anywhere from a week to two, depending on temperature conditions. During this time, you need to leave all the latches and doors open. You can put a switched on electric lamp in the firebox to speed up the process.

Video: do-it-yourself Dutch oven

Furnace decor

Brickwork made from quality bricks can look spectacular in itself. But Dutch women often decorate - they are covered with tiles, tiles and other finishing materials. In the right hands, an ordinary stove turns into a work of art. For finishing use:

-

majolica;

Dutch majolica trim A plot panel on majolica will decorate a Dutch oven

- various "imitators" - marble, wood, tiles, etc.;

-

a natural stone;

Furnace finishing with natural stone A Dutch woman faced with natural stone looks beautiful

-

normal and textured paintable plaster.

Dutch stove plaster A country-style plaster stove is a great option for a summer residence or a country cottage

If clinker bricks are used for the construction of the furnace, the appearance will acquire an exquisite gloss and monumentality. Additional finishing is not required in this case.

Cleverly folded clinker bricks are an excellent facing material

When choosing a coating for a stove, pay attention not only to price, but also to technical characteristics, especially environmental suitability. We must not forget that the operation will take place in an elevated temperature environment.

Features of operation

A characteristic feature of Dutch ovens is the increased length of the chimney ducts. It is because of this that the furnace works so well for heat transfer. But at the same time, with such a flue arrangement, the likelihood of carbon monoxide gases entering the dwelling increases. To avoid this, it is important to observe the correct firing mode: the body, the heating temperature should not exceed 60 to Celsius.

Furnace cleaning and repair

In order for the Dutch woman to work without surprises, it is necessary to monitor her technical condition:

- clean the furnace and blower from ash daily;

- perform preventive cleaning of the chimney once a year;

- once every 4-5 years, carry out an audit of the internal and external walls, and if cracks are found, eliminate them.

Each person can build a Dutch stove on their own without outside help. Observing the described recommendations and following the ordering diagrams, the heating unit can be easily folded down in 1 week.

Recommended:

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Installing A Boiler (water Heater) With Your Own Hands: Connection Diagram To The Water Supply System, Rules, Etc

What is a boiler, how does it work. How to independently install and connect an instantaneous and storage water heater. Safety regulations

How To Repair A Boiler With Your Own Hands (including Draining The Water): Malfunctions, Their Causes, Etc. + Video

The device and principle of operation of water heating devices. How to find the causes of a water heater breakdown. DIY instructions for eliminating major breakdowns

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation

How To Make A Kuznetsov Oven With Your Own Hands: Diagram, Ordering With Photos And Videos, Etc

Step-by-step instructions for installing a heating furnace-blacksmithing. Selection of materials and necessary tools. Rules for effective operation of the unit