Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Building a foundation for a greenhouse: step by step instructions

In the construction of a greenhouse, the structure of the aboveground part is of paramount importance. But we must not forget about the foundation either. Otherwise, the work can go to dust. The base for the greenhouse can be built with your own hands from different materials.

Content

- 1 Greenhouse foundation: purpose

- 2 Types of foundations for greenhouses

-

3 Material selection

- 3.1 Wood

- 3.2 Concrete

- 3.3 Foundation blocks

- 3.4 Brick

- 3.5 Natural stone

-

4 Calculation of the base

- 4.1 Ground pressure

- 4.2 Laying depth

- 5 Tools

-

6 Step-by-step instructions for building a foundation

-

6.1 Wooden base

6.1.1 Video: construction of a wooden foundation for a polycarbonate greenhouse

-

6.2 Monolithic strip foundation

1 Video: pouring the strip foundation under the greenhouse

- 6.3 Foundation of bored piles

-

- 7 Insulation of the foundation

- 8 Finishing the foundation

Greenhouse foundation: purpose

In everyday life, a greenhouse is often called any structure that allows you to create a zone with an artificial climate on a garden plot. This is not entirely correct, since temporary objects of this type, consisting only of enclosing structures and being used only for several months, are not, in the full sense of the word, greenhouses. These are greenhouses and cold nurseries, including arched ones that are popular today, which can easily do without a foundation. For stability, it is enough to attach them to pins driven into the ground and a heavy plank frame, laid directly on the ground.

For a greenhouse of light construction, the foundation is not necessary

A real greenhouse is also used in winter under much more severe conditions. The foundation is very desirable for her and here's why:

- Provides support on stable ground. Everyone has seen how the top layer of the soil, which seems so reliable and solid in summer, turns into mush in the off-season due to rains or melting snow. It would be extremely unreasonable to install a greenhouse on such a treacherous base, burdened with insulation, heating and lighting. To prevent the structure from sagging, it is better to lean on the underlying soil layers, which are not affected by weather factors.

- Securely fixes the building on the ground. Equipped with the already mentioned equipment, a capital greenhouse, by definition, cannot be squat and streamlined, like, for example, an arched greenhouse, so the wind acts on it with much greater force. The consequences of the accident are also different: if the polyethylene "shell" of the cold nursery is carried away, nothing terrible will happen; if the greenhouse is overturned, then literally thousands of costs will fly away to the wind.

- Reduces heat loss significantly. In winter conditions, when the temperature difference inside and outside is large enough, any gap becomes the cause of colossal heat loss. If the greenhouse is simply placed on the ground, it will blow under the walls. If you equip the structure with a base, the walls are as if buried, which eliminates blowing. Additionally, the foundation prevents heat leakage through the ground, which accounts for 10% of the total heat loss.

- Protects the interior from the penetration of pests living in the ground - a mole and a bear. And also excludes the penetration of rhizomes growing around the weeds.

- Improves the operating conditions of the lower part of the greenhouse. Thanks to the foundation, it is raised above the ground, which means that it is less exposed to the moisture that impregnates the top layer of the soil.

Capital greenhouse needs foundation

Varieties of foundations for greenhouses

Foundations of the following types are erected under greenhouses:

-

Strip foundation. It is a frame on the crossbars (strips) of the greenhouse walls resting along the entire length. Such a foundation fulfills all the functions that were listed in the previous section.

Greenhouse strip foundation The strip foundation is a reinforced concrete monolithic strip

-

Plate. Such a foundation has to be erected in special conditions, when the soil is too weak or too saturated with water (marshland). A monolithic reinforced concrete slab is poured under the entire structure, so that the bearing area becomes maximum, and the specific pressure on the ground, respectively, minimum. A significant drawback of the base is its high cost.

Greenhouse slab foundation Foundation slab is a material-intensive and expensive structure

-

Columnar or pile. This foundation is also called point. Instead of one continuous tape, several pillars are erected under the wall. Protection against heat loss and shrews is not provided with such a base, but it costs much less than a tape one. It is quite suitable for greenhouses that are operated only in the warm season - they do not need soil insulation.

Scheme of a columnar foundation for a greenhouse The columnar foundation consists of concrete supports

A columnar foundation differs from a pile foundation in a way of construction:

- in the first case, the support is erected in a pre-dug recess like a wall - it is laid out from blocks or made by pouring concrete into the formwork;

-

in the second, a metal, wooden (very rarely) or concrete rod, called a pile, is hammered into the ground or screwed into it.

Pile foundation Piles, like pillars, are linked together into a single structure

The device of the pile foundation is unlikely to be within the reach of an ordinary summer resident, since this requires special equipment - a diesel hammer (also called a pile driver). Another thing is the construction of bored piles. In fact, this is the same columnar foundation, but it is arranged in a much simpler way than the classic version. This explains its demand for individual construction.

A bored pile is arranged by drilling a well into which a reinforcing cage is laid and concrete is poured

Material selection

Foundations can be built from different materials: wood, concrete, brick, etc.

Wood

To some, perhaps, the idea of building a foundation from a wooden beam will seem somewhat wild. Nevertheless, this option is resorted to quite often. There are reasons for this:

- such a base is extremely cheap;

- is built very quickly;

- It can be easily dismantled and reused, which is convenient if it is necessary to move the greenhouse to a new place (this is done if the soil in the old place has already been depleted).

Wooden beams can be used to build a foundation for a greenhouse

A wooden foundation will be especially appropriate for a greenhouse, which is supposed to be in operation for only a few years. Under such conditions, the main disadvantage of wood - a short service life - ceases to be of any importance.

The greenhouse on a timber foundation is easy to move to another place

Concrete

It is more correct to say - reinforced concrete. The fact is that artificial stone, as concrete is also called, extremely poorly holds tensile forces. Therefore, it is never used in its pure form, but only with reinforcement from steel rods.

The construction of reinforced concrete structures is a very time consuming process. But on the other hand, for any size and shape, they turn out to be monolithic, which means that they are as strong as possible.

Foundation blocks

These are ready-made reinforced concrete modules, from which it is much easier to build a foundation than from concrete in the form of a solution. In contrast to the monolithic, such a foundation is called precast.

Block foundation suitable for wet soils

The strip foundation does not have to be made in a monolithic design, pouring directly on the construction site. It is faster and easier to fold it from reinforced concrete foundation blocks produced by various companies. Before buying blocks, read the rules for their selection:

- Only give preference to those suppliers whose reputation is beyond doubt. Today, unscrupulous businessmen often undertake the manufacture of reinforced concrete products, unknowingly or deliberately (in order to save money) violate the production technology. Quality blocks are supplied with a certificate, which the seller must present to the buyer at the request of the latter.

- It is better to purchase blocks as long as possible (as far as the available freight transport and lifting equipment allows). The fewer the seams, the more solid the foundation will be. You just need to carefully calculate everything, since it is extremely difficult to cut the foundation block in order to shorten it.

-

In the absence of lifting equipment, it is possible to purchase small-sized foundation blocks intended for manual laying.

Manual foundation blocks Manual laying foundation blocks are used for the construction of precast concrete foundations without lifting equipment

- You should not overpay by purchasing blocks of expensive concrete with high frost resistance and water resistance. The foundation, unlike, for example, a blind area or a concrete path, is always covered with waterproofing, so that for normal conditions the frost resistance grade F150 and the waterproofness W2 will be sufficient.

- If engineering communications are planned through the foundation, look for special blocks with holes.

- The strength of the concrete from which the blocks are made should be selected taking into account the weight of the structure.

The last parameter is indicated by two characteristics:

- strength grade: denoted by the letter "M" and a number indicating the ultimate load in kg / cm 2 (for example, M150);

- class: denoted by the letter "B" and a number indicating the ultimate load in MPa (megapascals).

Strength grade is a kind of "theoretical strength", which is determined based on the cement grade and the properties of other ingredients. The class is determined by testing an already cast sample. It characterizes the strength of concrete more objectively: concretes of the same grade and composition under different hardening conditions can acquire different strength classes.

Brick

Quite often, the columnar foundation is laid out from this material. You should use solid red fired brick: it has good moisture resistance, and therefore high frost resistance. Silicate and hollow bricks are not suitable for such tasks.

Ceramic solid fired brick is required for the construction of the foundation

The disadvantage of brickwork is that, unlike reinforced concrete structures, it is not monolithic.

Natural stone

The advantage of the material lies in the combination of cheapness and such necessary qualities in construction as strength and moisture resistance. From pieces of stone with layers of cement-sand mortar, a strip foundation is assembled, which is called rubble concrete (but it is precisely called pieces of stone).

A large stone of natural origin is used in the construction of rubble concrete foundations

Base calculation

When designing a foundation, attention should be paid to two parameters - the specific pressure on the ground and the depth.

Specific ground pressure

Specific pressure is calculated using the following formula: P = M / S, where: M is the mass of the entire structure, including the foundation itself, kg; S is the support area of the foundation, cm 2.

The P value should not exceed the P max value - the bearing capacity of the soil at the construction site. The latter, ideally, should be calculated by a licensed company based on geological surveys, but such a study is expensive and is usually ordered for the construction of large industrial greenhouses.

An ordinary summer resident who intends to build a greenhouse for his own needs can be guided by the experience of neighbors who once ordered a similar study when building a house

Another way is to set the specific pressure P, which is guaranteed to be able to withstand any soil. This value is 1 kg / cm 2.

Depth of laying

In principle, to lean on a stable soil and securely fix the building, it is enough to deepen the foundation by 50 cm. But there is an important circumstance: if the temperature of the soil below the base of the foundation in extreme cold will drop below 0 ° C, and the soil will be saturated with water, then on the structure from below will be affected by the so-called frost heaving forces. They are due to the property of water to increase its volume when it freezes. Even a heavy construction, the heaving forces will be squeezed out without difficulty.

The forces of frost heaving are distributed unevenly, which can lead to cracking and even breaking of the foundation tape

Soils with well-defined drainage properties - sandy and stony - usually do not contain a lot of moisture (unless the groundwater is under the surface itself), so the owners of such plots during construction can safely deepen to the same 0.5 m. Another thing is clayey soils and loams, exhibiting waterproof properties and therefore retaining moisture: for them the forces of frost heaving are very characteristic. The owner of a plot with a similar soil should choose one of three options:

- To deepen the base of the foundation to the depth of freezing of the soil, typical for a given geographical latitude (preferably with a small margin of 15-20 cm).

- Surround the building with a semblance of a blind area made of insulation, thereby reducing the depth of soil freezing in this zone. Then the depth of the foundation can be reduced.

- Take the laying depth equal to 0.5 m, but remove the rest of the soil to the depth of freezing and replace it with well-compacted sandy one. The width of the sand backfill should slightly exceed the width of the foundation.

Tools

The builder must have:

- roulette;

- a set for marking: pegs or metal pins (often reinforcing rods are used) with a coil of cord or fishing line;

- shovels of two types: bayonet and shovel;

- plumb line and level;

- a hacksaw and an ax;

- a hammer;

- grinder with a cutting disc for metal (for cutting reinforcement);

- hook for knitting a reinforcing cage;

- construction vibrator (for vibrating concrete).

If a decision is made to prepare concrete for the foundation on your own, you will need a concrete mixer with a drive (the solution mixed in the trough with a shovel will turn out to be half as strong).

Step-by-step instructions for building a foundation

Any construction begins with the marking of the territory. Pegs are driven into the ground, between which a cord is pulled, outlining the contours of the future greenhouse. In this process, there is only one subtlety: it is necessary to achieve equality of the diagonals of the marked 4-gon - this is a sign that all of its corners are right.

Now let's take a closer look at the process of building some types of foundations.

Wooden base

A foundation from a bar is constructed in the following sequence:

-

It is necessary to prepare a dried (moisture - 20-25%) timber with a section of 100x150 mm or 150x150 mm. Of the species, larch is the most preferred.

Axonometric projection of the foundation from a bar with an indication of the executive dimensions For the foundation, a beam with a section of 100x150 or 150x150 mm is used

-

The timber is twice treated with an antiseptic, after which it is wrapped with glassine. The latter can be shot with a construction stapler.

Fixing glassine on the surface of the timber Glassine provides waterproofing of the timber

-

A trench is dug along the entire perimeter of the future greenhouse, somewhat larger in width than the timber.

Foundation trench The trench should be slightly wider than the timber to be laid

- The bottom and walls of the recess are covered with rolled waterproofing material - roofing felt or tar paper.

-

The beams are laid in the trench. Between themselves, both in the corners and in straight sections, they are connected in half a tree or in a thorn with fixation with long nails.

Timber connection Half-tree connection is the easiest way

- For greater reliability in a wooden foundation, you can drill through vertical holes and "sew" it to the ground with long metal pins (reinforcing bars are suitable).

- The space between the side edges of the timber and the walls of the trench is covered with sand.

The greenhouse frame is fastened to this base using corners and self-tapping screws.

Discarded railway sleepers are an excellent material for a wooden foundation. The construction of them is assembled in the same way as from a regular bar. Only during work should you be careful: the sleepers are impregnated with creosote, which, when it comes into contact with the skin of the hands, causes a burning sensation.

Video: construction of a wooden foundation for a polycarbonate greenhouse

Monolithic strip foundation

For the device of the tape base, you need to do the following:

- Dig a trench around the perimeter of a slightly wider width than the future foundation. The optimum width of the concrete tape is 35-40 cm.

- At the bottom of the excavation, arrange a sand backfill, which must be well compacted (for this, it must be watered). The thickness of the backfill after compaction should be approximately 10 cm.

-

Lay a layer of crushed stone or gravel of the same thickness on top, followed by tamping.

Sand and crushed stone pillow under the tape Sand and crushed stone are poured in layers with compulsory compaction

-

From boards, thick plywood or chipboard, build a formwork - a form for a concrete tape. All elements are fastened securely, since the concrete solution is quite heavy. Between the walls of the trench and the formwork, you need to install supporting bars that will not allow it to disperse. Above ground level, the formwork should rise by about 20 cm. It is advisable to set its upper edges strictly horizontally with the help of a level, in order to then use them as beacons when leveling concrete. It is better to wrap the formwork elements with polyethylene - then they will not be spoiled by the moisture present in the solution and can be used later for other purposes.

Plywood formwork Plywood sheets along the top must be tied with bars

-

Install reinforcement and embedded parts in the formwork for fixing the greenhouse frame. For small buildings (up to 10 m 2), the reinforcement can be simplified: steel pins 60-70 cm long are driven into the ground at regular intervals. They need to be driven in half the length. The pins are tied with thick wire. The segments should be used as long as possible so that the reinforcement is solid).

Rebar knitting Reinforcing bars are tied with soft wire

- If the size of the greenhouse is larger, but its area does not exceed 15 m 2, you can apply the same reinforcement scheme, only the wire is tied in two rows.

-

For larger buildings, a full-fledged frame is laid in the foundation: above and below - working belts of three longitudinal rows of reinforcing rods with a diameter of 10-12 mm, all this is connected by vertical and horizontal transverse reinforcement with a diameter of 6 mm. It is impossible to connect the elements of the frame by welding - the reinforcement in the zone of the welded seam loses its strength. They must be tied with annealed wire.

Reinforcement cage for strip foundations It is convenient to knit the reinforcement frame on the surface, and then lower it into the formwork

- The concrete cover on all sides of the frame must be 40 mm thick. To ensure the presence of such a layer from below, the frame is laid on special plastic bosses or suspended from a wire.

- Embedments should also be attached to the reinforcement, which will protrude from the concrete and be used to fasten the greenhouse frame.

-

Pour concrete.

Pouring concrete into a trench It is advisable to use a technique or a construction hose for pouring concrete mixture

- Wait for the concrete to mature. This usually takes about 28 days. Concrete requires water to mature, so when it dries, it will not be able to gain sufficient strength. In hot weather, the structure must be kept under plastic wrap and periodically watered. The formwork can be dismantled 10 days after pouring.

-

Perform foundation waterproofing works. The structure is pasted over with roofing material, bitumen mastic is used as an adhesive.

Foundation waterproofing Roll material (roofing material), glued to the reinforced concrete tape by means of bitumen mastic

- Backfill the trench.

Concrete can be prepared independently according to the following recipe:

- cement grade M300 or M400: 1 mass part;

- sand: 3 parts;

- crushed stone: 4-5 pieces;

- water: 4-4.5 parts.

For self-preparation of the mixture, it is better to rent a small concrete mixer. An easier way is to order concrete from the factory, from where it will be delivered by an auto mixer.

It is very important when pouring concrete to ensure that air is released, otherwise voids will form in the body of the foundation

The best effect is given by a special tool - a vibrating plate. In its absence, a freshly poured solution can be pierced with a reinforcing bar or a shovel.

Video: pouring a strip foundation under a greenhouse

Bored pile foundation

As already mentioned, this is a type of columnar foundation, the piles of which are made in a very simple way:

- In the corners of the future building, as well as along its walls with a step of 1.5-2 m, wells are made with a garden drill to the depth of freezing.

-

At the bottom of each well, a sand and gravel pad is placed as described above.

Well marking for bored piles Civil engineers call a pile placement drawing a pile field

- Next, large-diameter plastic pipes are inserted into the wells. They will simultaneously play the role of formwork for concrete and its waterproofing. The pipes should rise somewhat above the ground, while their tops should lie in the same horizontal plane.

-

In each pipe, a reinforcing cage is suspended in the form of a triangular parallelepiped, the vertical edges of which are represented by rods with a diameter of 10-12 mm (this is the working part of the frame), and the cross ties are thinner, with a diameter of 6 mm. Mortgages are attached to the frames.

Construction of a bored pile The number of vertical rods depends on the pipe diameter

-

It remains to pour concrete into each pipe.

Pouring bored piles with concrete Pouring the pile with concrete is done in one step

The heads of the bored piles must be tied into a single structure with a horizontal frame called a grillage. It can be assembled from rolled metal or timber, which are attached to the mortgages protruding from the posts.

The following guidelines may be helpful:

- Instead of a plastic pipe, a casing sewn from roofing material can be used as a formwork.

- If it is necessary to increase the support area of the column, the hole for it should be drilled with a TISE drill. It has a folding knife, which forms a spherical widening in the lower part of the well.

Insulation of the foundation

It is advisable to insulate the strip foundation. The heat insulator will not only help to save heat inside the greenhouse, but also protect the waterproofing from mechanical damage.

The insulation, as in the case of brick walls, should be placed outside, if possible. Otherwise, the structure will be isolated from the warm inner space, which means that it will freeze harder. As mentioned above, due to the pressure of the freezing soil, extruded polystyrene foam or other durable material must be used as insulation. Expanded polystyrene sheets are best used with specially cut ends, which exclude the presence of through seams. If ordinary sheets are used, the seams between them should be blown out with polyurethane foam (polyurethane foam). Expanded polystyrene is mounted as follows:

-

The sheet is coated with glue, after which it is pressed against the foundation with force.

Insulation of the foundation with expanded polystyrene Expanded polystyrene boards are attached to the concrete surface with glue

-

After that, in the corners and in the center, the sheet must be screwed to the concrete with special dowels with an enlarged head (they are called "umbrellas" or disc-shaped).

Umbrellas for attaching expanded polystyrene to concrete With the help of umbrellas, additional fastening of polystyrene foam to concrete is performed

Foundation finishing

If the greenhouse owner wishes to veneer the aboveground part of the foundation, then basement siding can be used for this. In comparison with the wall, it is more durable.

The cheapest is vinyl plinth siding. Its advantage lies in a wide variety of colors and textures: you can find varieties that imitate brickwork, natural stone (including marble), wood, etc. Metal siding is more durable and reliable, but also more expensive.

Siding panels are attached to the crate from a special metal profile, but if you want to save money, you can also make it from wooden bars.

The crate for the panels can be made of wood or metal

Also, the cladding of the foundation can be made with slabs of natural stone (quite an expensive option) or its artificial analogue. These materials are laid on mortar or glue.

There are a lot of varieties of foundations for a greenhouse. But none of them suggests insurmountable difficulties in construction. When choosing a foundation, it is necessary to take into account the material from which the greenhouse is made, its weight, as well as the type of soil. Follow the recommendations, and the design will be reliable and durable.

Recommended:

How To Clean White Shoes At Home Made Of Natural, Artificial Leather And Other Materials + Photos And Videos

Features of cleaning white shoes. How to clean shoes made from natural or artificial materials. The subtleties of caring for sports white shoes, practical advice

How To Soften Shoes (made Of Leather, Suede And Other Materials), Including Softening The Backing So That It Does Not Rub + Photos And Videos

What to do if your shoes rub your feet. Proven ways to soften shoes made from different materials. Using professional products and folk recipes

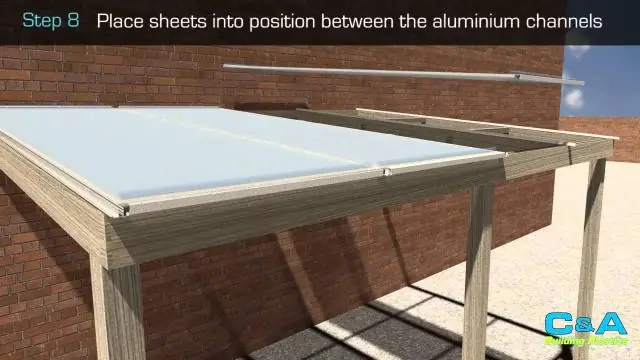

Installing A Polycarbonate Greenhouse On A Timber, How To Properly Fix The Structure, Instructions With Photos And Videos

Detailed instructions for the manufacture and installation of an arched greenhouse made of wooden beams and sheathing of the frame with polycarbonate

How To Choose And Build A Foundation For A Bath With Your Own Hands - 4x6, 3x4 And Other Sizes, Tips, Instructions, Photos And Videos

How to make a foundation for a bath with your own hands. Types and features of foundations. The choice of materials and technology, installation rules and step-by-step instructions

DIY Children's Slide Made Of Wood And Other Materials - Instructions With Photos And Videos

Types of children's slides. Wood slide construction technology. Installation instructions for a metal children's slide