Table of contents:

- How to make a potbelly stove for working off with your own hands

- What is a potbelly stove for mining and where is it used

- Furnace design and principle of operation

- How to make a potbelly stove for working off with your own hands

- Required tools and materials

- Features of operation

- Furnace cleaning and repair

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

How to make a potbelly stove for working off with your own hands

Heating of small rooms, such as a garage or other non-residential premises, can be carried out economically and efficiently. To do this, it is worth considering the option of installing a stove in the room, working on mining. Such a potbelly stove is more economical than solid fuel, but has specific requirements for assembly and installation. But following the instructions, you will be able to understand them and build such a structure with your own hands.

Content

- 1 What is a potbelly stove for mining and where is it used

- 2 Furnace design and principle of operation

- 3 How to make a potbelly stove for working off with your own hands

- 4 Required tools and materials

- 5 Features of operation

- 6 Cleaning and repairing the oven

What is a potbelly stove for mining and where is it used

A potbelly stove for mining is a furnace of a certain design, in which the vapors of waste oil products are burned. Such a potbelly stove is suitable for a garage, but not for living quarters. The fact is that when the mining is burned, a specific smell is released, which is unlikely to be liked by others.

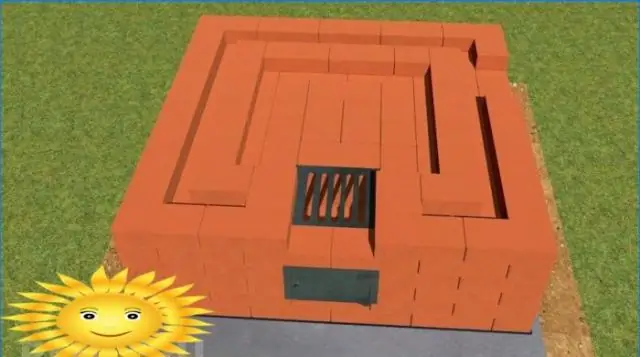

General form

The working furnace has a number of advantages over solid fuel stoves:

- mining of oil products is a relatively cheap resource;

- small costs for the independent manufacture of such a furnace;

- no need for electricity;

- ease of use;

There are also some downsides. In addition to the appearance of an unpleasant odor in a heated room, it will be necessary to equip a sufficiently long chimney, which, in turn, will require careful maintenance. Such a chimney is needed for high-quality removal of harmful volatile combustion products.

Furnace design and principle of operation

Consider the main structural elements of such a furnace, their purpose and the processes that occur in them.

Basic structural elements

This oven has three main structural elements. This is a tank for loading fuel, it is also a primary combustion chamber, a pipe with holes that creates a thrust in the furnace and the second tank is an upper combustion chamber for vapors of oil products. The rest of the elements are the chimney and all kinds of additions, but more on them later.

The fuel tank (firebox) can have different designs. It can be round or square. It doesn't matter. The main thing in this compartment is a fairly wide area (at least 0.25 m 2). This requirement is caused by the need for uniform combustion of fuel and its intensive evaporation.

Such a tank is made of a sufficiently thick sheet steel (at least 4 mm) or a piece of pipe. The thickness of the material is essential for its resistance to combustion.

And also on this tank there is a hole with a removable lid. It is necessary for loading fuel and regulating the intensity of air ingress into the furnace.

This is necessary for several reasons. The fuel evaporates intensively during combustion. And also in the tank there should be a place in which fuel vapors are mixed with air for high-quality combustion.

A mixture of oil vapors and air enters the second tank, where intensive combustion takes place with maximum heat release.

The second tank is made similarly to the first one, from the same material (meaning the thickness of the steel). But it has some peculiarities. The second combustion chamber is equipped with a partition that covers the entire area of the chamber, but is missing to the bottom of the tank. This partition serves as a protection against open fire entering the chimney. If this happens, the chimney will quickly deteriorate.

These two tanks (lower - primary combustion and upper - intensive combustion) are connected by a metal pipe. This pipe must be 100 mm in diameter. Holes with a diameter of 8-10 mm are drilled along the entire length of the pipe.

The ends of the pipe are welded into the tanks. The seam must be of high quality and tight.

A chimney pipe extends from the upper tank. The chimney diameter usually corresponds to the diameter of the pipe between the tanks.

For a clear understanding of the scheme of the device of such a stove, an assembly diagram is given with an indication of all the necessary elements and their sizes.

Assembly diagram

How to make a potbelly stove for working off with your own hands

For clarity, consider the main stages of manufacturing a stove.

1. Formation of combustion chambers. For this, the prepared steel strips are bent into a ring and fixed with clamps. Weld the ring joint. The clamps are released after the welding seam has cooled.

2. Cut out sheet metal circles to the diameter of the rings. Technological holes are made in the circles for the connecting pipe, the chimney pipe and the cover of the fuel loading hole.

3. Prepared rings are welded with circles. Thereby, fuel combustion chambers are formed. It is necessary to check the tightness of the welds. It is better to make the lower combustion chamber (where the mining is loaded) collapsible. This will make it easier to maintain the oven if it needs to be cleaned.

4. In the upper combustion chamber, a technological partition is made of metal of the same thickness as the main structure.

5. For ease of assembly, the upper combustion chamber is first assembled. It is equipped with a flue pipe and a connecting pipe with drilled holes.

6. The lower combustion chamber is welded to the free end of the connecting pipe.

7. The final stage. Legs are welded to the lower combustion chamber, having previously set the oven level on a flat surface. The support bar is welded from the corner. The bar is installed between the combustion chambers. It provides rigidity and stability to the entire structure. If desired, the potbelly stove is painted with heat-resistant paint.

Required tools and materials

For the manufacture of a standard furnace, the following materials will be required:

- sheet steel (at least 4 mm thick, 6 mm thick sheet can be used for the cover);

- pieces of pipe (approximate pipe diameter 100 mm) for connecting tanks and installing a chimney pipe;

- corner or channel for equipping legs or stand. (it is not advisable to install such a stove on the floor, it may be unsafe);

- you will also need electrodes, cutting and grinding wheels for the grinder, a drill for metal 8-10 mm;

- for beauty, you can paint the product with heat-resistant paint.

Tool for making a furnace for testing:

- locksmith tools (hammer, sledgehammer, clamps, etc.);

- power tool (electric drill, grinder) for metal processing;

- welding machine;

- measuring tool (ruler, tape measure, square, level);

Always check that the power tool is working properly before assembling the oven. Before assembly, it is better to clean the workpieces from the burrs left after cutting the metal with a grinder. This should be done to eliminate the possibility of cutting, and it will also ensure a better fit of the workpieces to each other when welding.

If you are going to convert a solid-fuel potbelly stove into a stove that runs on waste oil products, then this is not the best idea. The design features of these bourgeoisie have a number of significant differences, as well as the principle of operation.

It is better to make a potbelly stove on working off "from scratch".

The ideal option would be to equip the room (garage) with two types of stoves: a solid fuel potbelly stove and a working stove. But this is only if there is free space in the room.

Features of operation

During the operation of such a furnace, one should remember about its fire hazard. Do not place flammable substances and materials in the immediate vicinity of the oven.

Walls and floors are best insulated with metal sheets. This is to protect against the ignition of accidentally spilled oil. And also the sheets on the walls will serve as an additional heat reflector inside the room.

Used engine oil, transformer oil is used as fuel in such a stove. It is unsafe to add fuel to the tank while burning; it is better to do this when the previous filling has completely burned out.

Ignite the fuel with a wick. You can also use a rolled-up newspaper.

In the process of combustion, the air supply to the tank is regulated by a damper, thereby regulating the intensity of combustion.

Furnace cleaning and repair

A potbelly stove on working off, like any other furnace, must be cleaned of combustion products.

The soot is also removed from the chimney.

It is also necessary to monitor the metal of the furnace structure. If it burns out, the holes must be welded with metal plates with a thickness not less than the thickness of the metal of the furnace tank.

It is necessary to monitor the tightness of the welding seams of the primary and secondary combustion tanks. The efficient operation of the oven depends on this.

A waste oil oven is an economical and practical heater. With its small minuses (smell, specific fuel), this unit will undoubtedly be useful in any garage.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation

Gazebo With Barbecue And Barbecue With Your Own Hands - Step By Step Instructions With Photos, Drawings And Video

Brazier, grill or barbecue: how to choose an outdoor cooking device and build a suitable gazebo for it on your site