Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

How to Choose the Best 3D Printer for Small Business or Home Use

Volumetric 3D printing of a material object based on its three-dimensional computer model is a unique technology of our time, which has great prospects in the future. Until recently, devices using it seemed fantastic, but today they have become reality, and have already become available even for home use. Although the cost of 3D printers is still high, and exceeds the price of other computer devices, they are finding increasing practical use not only for applied creativity, but also for various areas of business. Continuous development and improvement of this technology has already led to the creation of industrial devices. Which one should you choose?

Content

-

1 What is a 3D printer, its purpose

1.1 Video: how the mechanism works

- 2 How to choose: parameters you need to pay attention to

- 3 Most Suitable 3D Printers for Small Businesses

- 4 What device to choose for home

- 5 Rating of the best 3D printers

What is a 3D printer, its purpose

A peripheral computer device that, using a digital volumetric model, creates a material object by layer-by-layer application of a rapidly solidifying material, is called a 3D printer. For the operation of such a device, a computer three-dimensional model is required, made in any of the 3D editors or obtained on a 3D scanner. Today there are several varieties, depending on the technology used:

-

FDM and DIW 3D printers using the extrusion method based on forcing molten material through a thin hole in a special device called an extruder (in printers of the first type, a thermoplastic heated to the melting limit is layer-by-layer applied to the cooled surface of the platform, and in the second - ceramic sludge, which called ink, thick ceramic slurry can be used in large architectural models);

How does an FDM 3D printer work? Extrusion technology 3D printers (FDM) make a layout by stacking molten plastic layer by layer, extruded through an extruder. The print head moves in the X and Y axes and the print bed moves down the Z axis

-

printers of the SLA-DLP type, using the photopolymerization method, in which a liquid photopolymer is used, and the hardening of each of its layers is carried out by means of exposure to an ultraviolet laser;

How a 3D printer works using SLA technology In 3D printers based on SLA technology, the product is formed in a bath filled with photopolymer resin. Under the action of UV laser radiation acting on a thin layer of resin, it hardens and the base goes down to the thickness of the next layer

-

printers in which an aligned layer of powder is used to create a three-dimensional material object, which is bonded in layers by different methods, by applying glue using inkjet printing (3DP printers) or melting it with an electron beam in a vacuum (EBM), laser radiation (SLS or DMLS, depending on powder type) and heating head (SHS);

How 3D SLS Printer Works When using SLS technology, a thin layer of powder in the right place is sintered with a laser, and the printing platform is lowered to the thickness of the layer, and the entire space of the table is filled with a new portion of powder.

- EBF 3D printers, which use a wire that melts under the influence of electron radiation to obtain a material model;

-

printers based on the principle of lamination, or layer-by-layer application of a film, in each layer of which the contour of the part is cut with a special cutter or laser;

The principle of operation of a device for three-dimensional printing, built on lamination technology 3D printers based on lamination technology use thin film stacking followed by laser cutting of the layer

- printers with a point supply of powder melted by laser or electronic radiation;

- devices working using the method of multi-jet modeling (MJM), when the method of inkjet printing is applied to a rapidly solidifying material;

- bioprinters are innovative peripheral computer devices that are just beginning to be introduced, they use cells of a living organism to form internal organs, and in the future will be able to create a full-fledged material for transplantology (there are already cases of successful manufacture and transplantation of a jaw for humans and a thyroid gland for a laboratory mouse) …

Video: how the mechanism works

The possibilities of such a unique peripheral computer device are practically unlimited. Today it is already being used for the following purposes:

-

rapid creation of accurate models in architectural design, the design of various mechanisms and machines, as well as in interior and landscape design in order to finalize the project and present it to the customer;

Architectural layout built by 3D printer Architectural layouts created by 3D printing devices are used for project presentations to the customer or for its revision

-

manufacturing of any complex-shaped parts for single or small-scale production, as well as spare parts for the repair of various devices;

Using 3D printing to make parts One of the uses of 3D printing is the manufacture of spare parts for repair

-

making models and molds for casting, including when creating jewelry;

The use of 3D printing in jewelry The plastic is 3D printed into a mold into which the jewelry is cast. In this way, products of the most complex configuration can be produced.

-

construction of buildings and structures of any complexity, for which they use special devices resembling a tower crane, instead of cables, which have highways for supplying liquid concrete (such a device allows you to build 1 floor in 10 hours, which significantly reduces the construction time);

Volumetric printing when building a house They are already building houses with the help of a 3D printer, feeding concrete instead of plastic

-

creation of prostheses and internal organs for transplantation in medicine;

3D-printed prosthesis 3D printing is used to create prostheses, and the first tests on the manufacture of internal organs from bio-ink DNA are underway

-

production of layouts of complex devices for educational aids;

Making visual aids with a 3D printer 3D printed visual aid for the undercarriage design

-

creation of geographic information systems, which are a three-dimensional map of the area in color, with an accurate display of the relief;

Volumetric map of the area obtained on a 3D printer Creation of geoinformation models of the terrain is one of the directions of using 3D printers

-

production of household items, various accessories and items for interior decoration;

3D printed table Using 3D printers, you can create interior decoration items

-

development of layouts of packages and containers for marketing purposes;

Original bottle mock-up made on a 3D printer By means of volumetric printing, you can create layouts of packaging of goods and various containers

-

manufacturing of experimental equipment cases - cars, automation systems and various electronic devices;

3D printed electronic device housing Devices for three-dimensional printing can produce cases of various household and electronic devices

-

manufacturing of advertising and souvenir products;

New Year's souvenirs, printed on a 3D printer Souvenirs and promotional items are created using 3D printing

-

production of exclusive clothing and footwear according to the figure and size of a specific client, obtained by 3D scanning.

Making footwear in devices for 3D printing 3D printers can make exclusive shoe models

This list clearly demonstrates the prospects for the use of 3D printers and their relevance in various fields of human activity.

How to choose: parameters to pay attention to

When buying any complex device, you need to clearly define for yourself the purposes for which you are going to use it. This will determine what operating parameters it suits you best. Considering that such a peripheral device is not cheap, you should select it most carefully, taking into account all the operating parameters, so that you do not regret the purchase later.

First of all, you need to decide on the type of printer for the 3D printing technology used. The most popular and affordable models today for home use or small business are:

-

FDM printers, which use various types of polymer filament as a material, and have a fairly good print quality and the lowest price;

FDM printer 3D printing device with extruder using FDM technology

-

SLA devices on photopolymer with higher print quality and price, ideal for jewelry production;

SLA technology in 3D printing Printer working on liquid photopolymers using SLA technology

- the most expensive of the peripheral devices of this group are SLS-type devices that melt the powder with a laser, it is impractical to buy them for the home, and they can only be suitable for business, due to their high cost (up to 30 thousand dollars).

Among the main selection criteria are the following:

-

The type of media used for printing. When choosing a 3D printer, you need to take into account that consumables for FMD devices will cost less than for SLA printers. For those who decide to purchase an FDM printer, there is a large selection of plastics of different colors and types (PLA, ABS, HIPS, PVA and others), but PLA plastic filament will be ideal for beginners, since this material is easier to use, and products from it are perfectly flat and smooth. Those who choose the SLA 3D printer will have to purchase more expensive material in the form of photopolymer resins. For non-professional printers, it is best to buy a photopolymer of the Vera, Somos or Tanga series, which are distinguished by transparency, high strength, heat resistance and plastic stability.

The cheapest and most affordable material for 3D printing is filament ABS filament for 3D printing with FDM technology

-

Accuracy of printing. It is higher for SLA printers. The accuracy of the model reproduction in devices of the extrusion type largely depends on the thickness of the layer that is laid by the printer during printing. This means that the thinner the hole of the extruder nozzle, the higher the clarity of reproduction of the digital model in the material object. Today there are models of printers with different nozzle hole diameters from 0.1 to 0.4 mm. It should be understood that the smaller the hole of the extruder nozzle, the longer it will take to make the model. Here everyone has to choose for himself what is more important for him - the accuracy of the 3D model display or the printing speed.

This is how the same model looks like, made on a 3D printer with different printing accuracy The top photo shows a detail made on a 3D printer with an accuracy of 0.1 mm, and the bottom one - 0.025. With greater print accuracy, the product is smoother, without visible plastic layers

-

Printable area, which determines the maximum size of an object that can be printed by this printer. There is, of course, the ability to make larger objects, but only in parts, gluing them together with a special glue. To do this, using the 123D Make program, the digital model is split into separate parts. But, if you do not want to engage in gluing, then when choosing a printer, compare the desired dimensions of the manufactured layouts with the printable area of a particular model.

3D printer print area The maximum space that a layout can take on a 3D printer is its printable area

-

Design features. Here it matters whether it is open or closed, and from what materials the body and bearing elements are made. These factors most of all affect the rigidity of the entire structure, on which the speed of movement of the print head depends, as well as the ability of the bearing parts of the device to damp vibrations and vibrations from several electric motors responsible for moving the printer head along all three axes (X, Y and Z) and its table along the Z axis. The case, made of wood, may seem too budgetary to some, but it perfectly absorbs vibrations. Bearing structures made of aluminum or steel will be stronger and more durable. It is better to buy SLA printers with a well-ventilated working chamber, which will facilitate faster curing of the photopolymer. And for FDM type devices,especially when working with ABS plastic or nylon, which have a high degree of shrinkage during rapid cooling, it is better to purchase a 3D printer with a closed case and lining of the working area.

Open and Closed Design 3D Printers Closed printers (photo on the right) are more rigid and can achieve faster print speeds.

- The presence of auxiliary software. 3D printers are high-tech computer devices that require special software to operate. First of all, a 3D printer must recognize and be able to read all 3D editors and various data entry formats. The latter include the STL and X3D languages, as well as the VRML standard. There are many auxiliary programs that allow you to perform a wide variety of actions for preparing for printing and creating a material model. These are, for example, slicer programs that allow you to cut an object into parts for printing in parts (Kissslicer or Cura) or 123D Catch program designed to work with a cloud service, and allows you to get a three-dimensional digital model of an object from its photographs taken from different angles. Availability of auxiliary programs,supplied by the printer manufacturer, greatly facilitates the handling of such technically complex devices. And this fact should also be paid attention to when choosing them.

The most suitable 3D printers for small businesses

Bulk printing using 3D printers is the most promising direction for small businesses today. With the help of these computer devices, which do not require too large financial investments, as for industrial printers, it is possible to establish small-scale production of various goods.

Of the large variety of printers on the market for these purposes, models that meet the following criteria are most suitable:

- print quality must be high enough to create unique and realistic models that are interesting for sale, which immediately excludes relatively cheap printers from the choice, costing up to $ 1000;

- it is desirable that the printer be adapted for color printing (FDM, DIW, 3DP or EBF printers), which will save time for coloring the product in small-scale production;

- the device must support work with at least two main types of plastics (PLA and ABS), which will expand the possibilities of its use, and will make it possible to produce products for children (PLA plastic is intended specifically for children's goods);

- the price of consumables used by a 3D printer should provide an acceptable cost of finished products, sufficient for a normal level of business profitability;

- the size of the working chamber should correspond to the dimensions of the models provided for production, while it should be borne in mind that printers with a larger print area will cost more.

In any case, the choice of printer will depend on what kind of business you intend to do. For the production of small crafts, devices of the extrusion type are suitable, and for the manufacture of jewelry or dentures - more expensive printers on photopolymers. Among the most suitable for small businesses are the following models:

-

Flashforge Creator Dual, with a working chamber volume of 5.2 liters and two extruders, the printer supports work with three types of plastics - ABS, PLA, PVA and has a printing accuracy of 0.1 mm;

3D PRINTER FLASHFORGE CREATOR DUAL Ideal printer for small business Flashforge Creator DUAL with two extruders and support for three types of plastic

-

3Dison pro AER from the Korean company Rokit, with a working space of 15.3 liters, capable of working with 50 materials, having a high printing speed (up to 1000 mm / s) and a layer thickness of 0.025 mm;

3D Printer 3DISON PRO AER The 3DISON AER printer model is designed to work with 50 types of materials, has a high printing speed and an accuracy of 0.025 mm

-

stereolithographic 3D printer, type SLA model

Asiga Pico 2 3D Printer The Asiga Pico 2 printer model works on liquid photopolymers. It is the perfect choice for jewelers and dentists

The Pico 2 from Asiga, the perfect choice for jewelry or dental professionals, is powered by a solid-state LED UV source.

Which device to choose for home

Considering the still high cost of peripheral computer devices for 3D printing, it would hardly be advisable to buy an overly expensive and sophisticated 3D printer for home use, costing 5-10 thousand dollars and more. A device priced from $ 500 to $ 3,000 will be enough. It all depends on the customer's exactingness to print quality and his financial capabilities.

It is best if a 3D printer for home has simple and intuitive operation, user-friendly interface and ideal value for money. All printers in demand today for home use can be divided into the following groups by price categories:

- budget models, the most affordable of this type of device, priced from 300 to 1,000 dollars;

- middle class printers ($ 1-1.5 thousand);

- fairly high-end devices at a reasonable price from 1.5 to 3 thousand dollars.

Among the most popular printers for 3D printing, the following models can be noted:

-

Printrbot Simple, worth $ 300, which belongs to extrusion printers (FMD), and is sold disassembled - self-assembly of the device will help you better understand its design and understand the principle of operation of this equipment;

3D Printer Printrbot Simple Printrbot Simple is sold disassembled and is the most affordable and popular peripheral computer device for the home.

-

Kino XYZ printing da Vinci 1.0 is a new printer from the Taiwanese company XYZ printing, which has a high print resolution comparable to more expensive devices - 0.1 mm, its cost is about $ 500 (the technology of layering molten plastic - FDM is used in the work);

3D printer Kino XYZ printing da Vinci 1.0 The Kino XYZ printing da Vinci 1.0 model has a closed design and high print resolution up to 0.1 mm

-

Cubify CubeX, belonging to the mid-price segment, with a cost of $ 1,300, and characterized by high print quality and speed of creating a model with large dimensions, this printer is available in three designs - with 1, 2 and 3 extruders, which allows you to get color layouts of computer models, can be connected to a computer via USB connection or Wi-Fi module.

Cubify CubeX 3D Printer The Cubify CubeX 3D printing device is available in three variations with one, two and three extruders to produce color products

-

Afinia H-Series H479, which has high printing accuracy (0.15 - 0.4 mm), convenient software that works with inexpensive ABS filament of decent quality, costs such a device 1.5 thousand dollars.

Afinia H-Series H479 3D Printer $ 1.5K Afinia H-Series H479 Printer with 0.15-0.4mm Print Accuracy

Rating of the best 3D printers

The world's most famous expert in the field of volumetric printing is the foreign portal 3D Hubs, which regularly lists the best models of printing peripherals in various nominations. According to this Internet resource, the following models of 3D printers were named the best in 2017:

-

Original Prusa i3 MK2 manufactured by the Czech company Prusa Research. This printer is intended for electronics hobbyists who are new to 3D printing, who will be able to independently assemble it from components, since it is sold disassembled. The device belongs to the extrusion models of the FDM type, and supports work with 15 types of plastic, including ABS and PLA, Carbon and Nylon, HIPS and FilaFlex, Bamboofill, Laybrick and others. This model can work simultaneously up to 4 different materials. It has an integrated Z-axis and a heating table with a PEI type plastic printed surface. A printer of this model has a fairly large print area with dimensions of 250 x 210 x 200 mm, a minimum thickness of a stacked plastic layer of 0.05 mm and a printing speed of 40 - 60 mm per second.

# 1 3D printer in 2017 Original Prusa i3 mk2 The Original Prusa i3 mk2 printer supports 15 types of plastics, and is capable of simultaneously working with 4 different materials

-

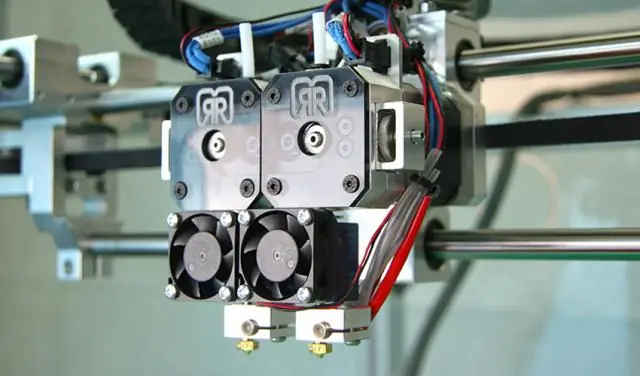

BCN3D Sigma R17 (Release 2017). This 3D printer model, released by the Spanish company BCN3D Technologies, is a continuation of the worldwide popular Sigma line of 3D printing devices. The new model uses an independent double extruder, which allows to avoid deformations when changing the color of products, as well as to simultaneously print two identical layouts. The upgraded device adopts a new cooling system and upgrades the technology of microchips that control power. All this allowed to make the printer more silent. Sigma R17 has a high printing accuracy of 0.125 mm and a layout area of 297 x 210 x 210 mm. We use filament from the following polymers ABS, PLA, HIPS, PET and Exotics, which the extruder extrudes with a minimum layer thickness of 0.05 mm.

BCN3D Sigma R17 Printer The model BCN3D Sigma R17 has a dual independent extruder that allows you to print two identical products at the same time

-

Formlabs Form 2 is a stereolithography (SLA) 3D printer manufactured by the American company Formlabs, equipped with a powerful laser, touch screen and Wi-Fi module. The device has a printable area of 145 x 145 x 175 mm and a layer thickness of 0.025 - 0.1 mm. This printer uses liquid photopolymers and can be used with resins from other manufacturers. It is equipped with a heated platform and built-in control panel.

Formlabs Form 2 Printer The Formlabs Form 2 3D printer is equipped with a powerful laser, touchscreen display and Wi-Fi module. The device uses SLA technology, with the use of photopolymer resins

-

PowerSpec 3D Pro. This model is made in China and belongs to the price category of budget 3D printers. Its distinctive features are durability, high printing speed and the presence of a double extruder in the design, which is a rarity for inexpensive models. 3D Pro supports three types of plastics (PLA, ABS and PVA) and has high printing precision. The thickness of the layer to be laid is 0.1 - 0.3 mm.

PowerSpec 3D Pro 3D Printer The PowerSpec 3D Pro printer model has high durability and printing speed. It is equipped with a dual extruder, which is quite unusual for a budget printer.

-

OrdBot Hadron. This printer is manufactured by ORD Solutions, Canada. The model is a mechanical 3D printing platform made of aluminum. It has high rigidity, reliability and printing speed (400 mm / s). The principle of its operation is based on FDM technology. The device supports work with two types of plastics - ABS and PLA, and has a printable area of 190 x 190 x 150 mm. The design of this printer provides the ability to connect a second extruder, a servo drive, an LCD screen and other equipment, which will be able to significantly upgrade the device after its purchase.

ORD Bot Hadron 3D Printer The model of the device for three-dimensional printing ORD Bot Hadron is made of aluminum, and due to the high rigidity of the structure, has a good printing speed - 400 mm / s

3D printing technologies are just beginning to conquer the computer market, and the cost of printers for translating a digital model into a material object is still quite high. But these technologies are the future, and for sure 3D printers will soon appear in every home, becoming a common addition to the computer. Already today, many models have become available for people with an average income level, and are widely used not only in small businesses, but also in everyday life. Using the above recommendations, you can easily find the right printer for home use or small business of your own.

Recommended:

Which Toothpaste Is Best For Sensitive Teeth, For Whitening, For Sore Gums, For A Child And How To Choose It Correctly

Choosing a toothpaste is a responsible business. However, not everyone knows the basic rules that must be followed when choosing a good toothpaste

How To Choose A Kitchen Knife: Which Company Is Better And From Which Material

Rules for choosing knives for work in the kitchen. Types of knives, their distinctive qualities. Selection criteria, best manufacturers

Which Automatic Blood Pressure Monitor To Choose: A Review Of The Best Models + How To Measure Pressure Correctly And On Which Hand

What is the best tonometer to choose - rating, reviews. How to correctly measure blood pressure with an automatic tonometer, on which hand

Dogs For An Apartment: Best Breeds, Small And Medium, Photo

Criteria to consider when choosing a dog for an apartment. An overview of the 15 most common "apartment" breeds

Which Antenna Is Best For Digital TV: Selection Criteria And Review Of The Best

What types of digital antennas are: indoor, outdoor, active, passive, etc. Which type is right for you. Review of 5 popular models