Table of contents:

- DIY Russian stove construction: theory and practice

- Russian stove in the house: advantages and disadvantages

- Device and principle of operation of the structure, diagram

- Preparation for construction

- Do-it-yourself step-by-step instructions for building a brick unit: from masonry to a chimney

- Finishing: options, photo

- Putting the furnace into operation: drying and trial furnace

- Video: construction technology

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

DIY Russian stove construction: theory and practice

If you decide to build a Russian stove with your own hands and there is no way to perform work under the guidance of an experienced stove-maker, then it is important to carefully study all the standards and follow them unswervingly. Despite the fact that the traditional Russian stove has a relatively simple design, it is a very important construction. Furnace works and the completed construction must comply with the established requirements of SP 7.13130.2013 and SNiP III-G.11-62.

Content

- 1 Russian stove in the house: advantages and disadvantages

- 2 Device and principle of operation of the structure, diagram

-

3 Preparation for construction

- 3.1 Brick selection

- 3.2 Required tools

- 3.3 Choosing a place for a future project

-

4 Step-by-step instructions for building a brick unit with your own hands: from masonry to a chimney

4.1 Correct chimney

- 5 Finishing: options, photo

-

6 Putting the stove into operation: drying and test furnace

6.1 Cleaning the oven

- 7 Video: construction technology

Russian stove in the house: advantages and disadvantages

The Russian stove is a massive structure that is used mainly for heating and cooking. In addition, it can be equipped with a stove bench, on which they warm up in the cold season, a hob or a fireplace. Before building such a structure in your home, you need to understand well all the nuances of its action, evaluate all the characteristics and scope of the upcoming work. Below we will try to list the advantages and disadvantages of the classic Russian stove.

Traditional Russian stove design

The advantages of the furnace include the following parameters:

- Durability.

- Fire safety.

- Specific heat (slow cooling).

- Cooking food without contact with fire.

- Relatively low cost.

The disadvantages include:

- Relatively low efficiency (no more than 30%).

- Waste fuel consumption.

- Uneven heating of the room (the difference between the temperature of the upper part of the room and the lower one can reach 20 ° C).

- Uneven combustion of fuel (near the mouth, fuel burns much faster due to excess oxygen).

- Inability to observe food during cooking.

Dishes with food are placed on hot coals near an open fire

Device and principle of operation of the structure, diagram

There have been a lot of modifications of the Russian stove for a long time, they differed in shape, size and device. Often in one village it was impossible to find two identical structures, each had its own unique feature. Currently, Russian stoves can be classified according to three main features:

- Small, medium and large in size.

- In terms of functionality - classic and advanced (the stove can be equipped with a fireplace, hob, oven, two-tier stove bench).

- The vaults are domed, barrel-shaped, and three-centered.

The device of a classic Russian stove is shown schematically in the figure. Based on the purpose of individual elements, you can understand the principle of its operation.

The diagram shows the main elements of the Russian stove

The main element of the Russian stove is the crucible, which is a firebox. The crucible consists of a vault at the top and a bottom at the bottom. Firewood is laid directly on the underneath and dishes with food are placed for cooking. The opening in the crucible is called the mouth, and the opening in the front wall of the furnace is called the pole window. These openings form a space between them, called a six, in which the cooked hot food does not cool down for a long time. First, an overtube comes out into the pole, in which smoke collects; above the overtube, there is a hailo, overlapped by a view. The view restricts the ingress of cold air from the street into the oven. The valve closes the overtube, thereby regulating the draft in the chimney during the heating, after the stove is finished, it is completely closed so that the heat does not go into the pipe. There is a cold stove (sub-six) under the six,which is used to store various kitchen utensils. And the space in the lower part of the stove under the firebox is called the sub-stove, firewood is usually stored in it for subsequent heating.

The principle of operation of the oven is as follows - firewood is laid in dense horizontal rows in one or two places of the hearth. Oxygen for combustion enters through the lower part of the mouth, the firewood ignites and heats the stove to high temperatures. Combustion products first accumulate under the vault, then go out through the upper part of the mouth, first enter the hailo, and then go out into the chimney.

Preparation for construction

Brick selection

The materials used in the construction of the furnace must comply with fire safety requirements. For this reason, different materials are used for its individual elements, which are listed in the table:

| Furnace element | Material |

| Masonry oven and chimney | Clay brick |

| Under and roof (lining) |

Refractory bricks Refractory bricks |

| Cladding |

Plaster tiles natural stone |

| Fire retardant insulation |

Clay bricks asbestos cardboard asbestos -cement heat-insulating plates mineral wool plates, etc. |

The composition of the masonry mortar is different for each type of brick.

| Brick type | Solution |

| Clay brick | clayey |

| Refractory brick | refractory clay and sand |

| Refractory brick | refractory clay and chamotte powder |

For the chimney, a solution based on lime and cement or lime and sand is used

The solutions can be mixed independently or you can use ready-made certified mixtures, which are now available on the market in a large assortment. The advantage of using ready-made mixtures for a non-professional is the observance of technologies and proportions in the manufacture and compliance of the solution with the required characteristics.

With the right choice and use of materials, the design of the furnace: firstly, it will meet fire safety standards, which is of great importance in the house, and secondly, the entire structure will be provided with sufficient strength and stability.

Required tools

Before starting furnace work, the following tools must be prepared:

- Ruler.

- Construction pencil.

- Trowel (trowel).

- Pick.

- Rubber mallet.

- Building level.

- Plumb line.

- Bulgarian.

- Solution containers.

- Construction mixer, if the mortar is mixed independently.

- Joining, if no further finishing of the stove is expected.

Choosing a place for a future project

It is advisable to develop measures for the installation of a Russian stove at the time of designing the building. When determining a place in a house, they pay attention primarily to the following factors:

- Foundation. Consideration is being given to building a separate foundation or using an existing one that can withstand the additional load from the furnace. For the construction of the foundation, ready-made concrete foundation blocks are used or a reinforced concrete monolithic slab is poured. Small gaps are left between the main foundation of the building and the foundation of the furnace, which are subsequently covered with sand. The base is not brought to the zero level of the floor to a height of two bricks, while a layer of waterproofing is laid on the first row of bricks.

- Free passage of floors and coverings by the chimney. It is important that the supporting structures (beams, ridge beams, rafter legs, etc.) are not dismantled or damaged during the work. Failure to comply with this condition can lead to an emergency state of the building and an increase in the total cost of building the furnace due to additional work on the construction of additional structures.

- Convenience of location. The oven itself and the chimney can significantly affect the ergonomics of the room. Therefore, you need to carefully work out the placement of the entire structure in relation to windows, doors and furniture for ease of use. If the stove is the main source of heating, then they try to place it in the center of the building, and if it is supposed to cook food in it, then it is necessary to provide it with a neighborhood with the kitchen.

- Fireproof distances to combustible structures. Close attention should be paid to this factor, since fire safety in the house must be organized at the highest level.

To prevent the fire of ceilings and walls near the stove, the following measures should be taken:

- In front of the window of the pole, on the floor, if it has a combustible coating, a metal sheet measuring 700x500 mm is nailed.

- The distance between the oven and the wall or partition to be burned is limited by a distance equal to the height of the oven. Thus, if the height of the structure is 1.2 m, then the nearby combustible wall must be at least 1.2 m away from it. In addition, the wall or partition must be protected from fire by thermal insulation materials (brick, plaster, asbestos-vermiculite plates, etc.).

- The distance from the window of the pole to the opposite wall should be at least 125 cm.

- Metal and reinforced concrete beams passing near the chimney must be at a distance of at least 130 mm from its inner surface.

- Wooden beams passing near the chimney must be at least 13 mm from its outer surface.

Do-it-yourself step-by-step instructions for building a brick unit: from masonry to a chimney

If the decision to build a Russian stove with your own hands is made, then it is necessary to use detailed ordinal diagrams with a description of all the manipulations. Before starting work, you need to prepare the necessary materials and tools. If the work is carried out in the cold season, then it is necessary to control the temperature of the materials, it should not exceed 5 ° C.

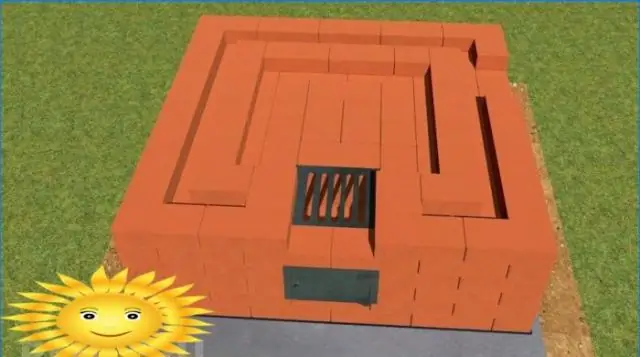

The figure shows the ordinal schemes for the construction of a classic Russian stove with a stove bench (32 rows)

According to the ordinal schemes, we begin to build the furnace in stages:

-

We put two rows of bricks on the foundation with an intermediate layer of waterproofing material.

Foundation preparation Foundation preparation

- Clay brick is pre-moistened with water. The first row starts from the level of the finished floor. It is laid out with solid bricks, providing in the corners a ligation with the second row using three-quarter bricks. Three pieces of such bricks are laid in each corner of the first row. The thickness of the masonry joints in both directions should not exceed 5 mm, the mortar is distributed over the entire surface of the brick. It is very important to keep the masonry horizontal, checking it row by row with a building level.

-

The second row is laid out with solid bricks, leaving a gap for the baking window. If the subsequent finishing of the furnace is not expected, then at the same time, the joints are sewn and the brick is cleaned from the mortar with a damp cloth. Starting from the second row, the verticality of surfaces and corners is checked with a plumb line.

Oven joining With the help of jointing, the masonry takes on a neat look

- Between the third and fourth rows, they provide for dressing in the corners, the fourth row is laid out completely with solid bricks. The bricks that are extreme to the opening are cut off to support the arch of the furnace on them.

- From the fifth row, they begin to lay out the arch of the furnace on the previously prepared wooden formwork. The seams of the arch from one heel to the other should be tied, the bricks should be tightly pressed against each other, almost flush. In the eighth row, the last (closing) row of the vault of hewn bricks is laid out.

-

The walls of the furnace are laid out in one brick with bandaging up to the tenth row, in which they provide a platform for the base. The space above the vault of the furnace is covered to the full height of the walls with sand or broken glass in order for the furnace to produce more heat.

Backfill overlap sub-furnace River washed sand is used

- The eleventh row is laid out similarly to the previous ones, it serves as a cover for the sub-six.

-

In the twelfth row is laid out under. It is laid out with refractory bricks without mortar, the gaps are then covered with sand. In the left part of the hearth, a hole for coal is provided.

Hearth laying Application of refractory bricks

- Next, the laying of the furnace begins, all parts of which are laid out from refractory bricks. The seams for refractory bricks are made no more than 3mm. First, the bricks are placed on the edge along the inner contour of the furnace. The walls of the furnace are recommended to be made of 3/4 bricks with bandaging. For the strength of the masonry, bricks that are located in the two front corners are cut at an angle of 45 °. A wooden formwork is inserted between these corners.

-

From the sixteenth row, they begin to lay out the vault of the furnace, the space between the vault and the walls is covered with sand. The laying of the vault begins at the edges, moving towards the middle. To check the rows of masonry, twine is used, which is fixed to the formwork at the central point of the arch.

Crucible vault The use of wooden formwork when laying the arch

- Next, in the form of an arch, lay out the window of the six.

- When laying the twentieth row, the walls of the furnace are erected, reducing the space above the pole.

- The twenty-fifth row is laid in the same way as the tenth with bandaging the seams, while the space above the six is again reduced, forming an overtube.

- In the twenty-second row, the overtube is reduced even more and the samovar channel is laid.

- In the twenty-third row, a place for the accumulation of soot and an opening for cleaning are provided.

-

From the twenty-fourth row, they begin to overlap the overhead, providing an opening for the view. Opposite the opening, a door is installed through which the view can be opened and closed.

Furnace overtube Installed metal view

- In the twenty-ninth row, the samovar channel is connected to the overtube.

-

In the thirty-second row, the overtube is completely blocked with solid bricks, leaving one hole, which is closed with a valve. After the valve is installed, go to the chimney laying. Wooden formwork is removed 5-6 days after the mortar has gained the required strength.

Gate valve for Russian stove The valve is designed to regulate the degree of fuel combustion in the furnace

Correct chimney

The traditional Russian stove in most cases is equipped with a direct chimney through which the combustion products go directly to the street. The optimal chimney section for a Russian stove is considered to be 260 × 260 mm.

The height of the chimney is determined depending on its horizontal distance to the ridge:

| Chimney distance from the ridge | Chimney height relative to the ridge |

| less than 1.5m | Not less than 0.5 m above the ridge |

| from 1.5 m to 3 m | Not lower than skate level |

| more than 3 m | Not below a line drawn from the ridge down at an angle of 10 ° to the horizon |

The chimney must be sufficiently stable, since, in addition to internal processes (overheating, condensation, freezing, thawing), external factors (wind, snow, foundation sediment) also affect it. Therefore, it is important to take into account all the nuances and the possibility of strengthening the structure even at the design stage.

Requirements that must be taken into account when installing a chimney:

- The density of the walls of the chimney and the chimney should prevent the possibility of smoke and carbon monoxide penetration into the premises, therefore, the masonry joints are performed efficiently, without voids and holes. The thickness of the seams should not exceed 10 mm.

- The surfaces of the chimney must be wiped with a solution and whitewashed;

- The upper part of the chimney, located above the roof, is plastered with cement mortar to protect it from precipitation.

-

A spark arrester made of metal mesh is installed on the chimney located above the combustible roof.

Butchering Distance from the inner surface of the chimney to the ceiling structure

- In places where the chimney touches the ceiling, the chimney expands. This expansion of the brickwork is called cutting. The size of the cut is expressed in the distance from the inner surface of the chimney to the ceiling and depends on the protection of the ceiling from fire. Thus, if the structure is not protected from fire, then the groove is 50 cm, and with a protected structure - 38 cm. The groove must be independent of the overlap, so its structure is not resting directly on it. This is due to the fact that the slump of the furnace may be different from the slump of the entire building, as a result of which there may be a risk of damage to the groove and the floor itself. The groove height is assigned more than the thickness of the overlap by about 10-15 cm above and below it. The material of the ceiling and the floor near the cutting are brought only to it,and the floor directly above it is made of non-combustible materials such as stone, ceramic tiles or concrete.

Finishing: options, photo

The decoration of the stove should be given special attention, because the stove is a very large structure and, undoubtedly, will be the center of attention in any room. When finishing the oven, it is best to strive for smoothness of all surfaces and the ability to keep them clean. Before doing the finishing work on your own, you need, first of all, to assess the scale and complexity of the work, and also to measure the cost of different finishing methods. Before any finishing work, the surfaces of the stove must be cleaned of dirt and dust.

Finishing methods can be very diverse, we will consider the basic and frequently used ones, which can be performed without special professional training:

- Plaster. The plaster gives the stove a neat look, it allows you to correct the defects made during the masonry, and also fills the masonry joints. The plaster solution is selected depending on the required finish quality, purpose and room humidity. Basically, a clay-sand solution is used, and if necessary, lime, alabaster or cement are added to it. It is recommended not to exceed the thickness of the plaster coating by more than 1 cm.

- Mopping the walls with subsequent jointing of the masonry. Work is being carried out to clean the walls of the furnace from the solution protruding from the seams, to more completely fill the seams and give them the desired appearance. When performing work, it is very important to clean the bricks from the mortar in a timely manner with a damp cloth, until it has frozen.

- Furnace with natural stone. Recently this method is gaining great popularity. Before gluing the stone to the stove, it should first be laid out on a horizontal surface in order to perfectly match the size and color, after which the stone is transferred to the walls according to the approved plan. For laying natural stone, ready-made heat-resistant mastics are used.

- Facing with tiles. This method is very time consuming and responsible. Facing the stove with tiles must be carried out in parallel with the execution of brickwork row by row, and first the first row of tiles is laid out, and then a row of brickwork. Tiles should be connected with the main masonry with wire, and between themselves - with staples and pins. The tiles are placed on an earthen solution, which is placed in rumpas (special projections of tiles on the back side). Depending on the desired look, the tiles can be placed one under the other or "in a band". Before the arrangement of the tiles, they are laid out on a horizontal surface in order to choose an ornament and make a hem to the desired size. Between the tiles horizontally, seams are provided with a thickness of 1.5 mm, which are filled with gypsum mortar. Vertical seams are very tight. When installing tiles, it is necessary to strictly observe horizontal, vertical, vertical planes and angles.

-

Fifth finishing option - Painting the oven with paints

-

Third finish option - The use of natural stone in the decoration of the stove

-

Fourth finishing option - Artistic decoration with tiles

-

First finish option - The stove is plastered and whitewashed with lime

-

Second finish option - The stove is neatly built of bricks with jointing

After plastering or mopping the oven surfaces, it can be painted or covered with lime. Paints should be water-based or casein-based. With the help of such paints, which can be multi-colored, you can paint the oven and give it a unique and inimitable design.

Putting the furnace into operation: drying and trial furnace

The oven is dried with shavings, chips and small logs. Initially, no more than 30% of the fuel from the usual volume is laid, then the volume is gradually increased. Drying time depends on the size of the oven and the moisture content of the brickwork. The result of high-quality drying of the oven should be a complete absence of damp spots on its surface and the absence of condensation on the metal elements. The shutter and combustion flap open for the entire drying time. During drying, the surfaces of the oven should have a temperature of about 50 ° C.

After the oven has been dried, a test furnace is carried out. Pre-check the draft and tightness of closing the valves.

The first kindling of the furnace is done in the following sequence:

- With an open valve, they are laid on under dry firewood in very dense rows, filling the crucible as much as possible. The mouth flap closes tightly during firing up.

- Subsequent firewood bookmarks are made after the first firewood burns out to coals. Their volume is already one third less than the first tab.

- The degree of combustion in the furnace should be controlled by a shutter.

- After all the firewood has burned out, they are waiting for all the coals to burn out. The pipe valve can be closed only after the fuel has completely burned out. If there are a few unburned coals left, it is better to extinguish them yourself so that the heat does not go away.

- To prevent cracking, the oven should not be overheated; its temperature should not exceed 90 ° C.

Cleaning the oven

Before the start of the season, the inner surfaces of the stove must be cleaned with a poker from soot and ash. The chimney is cleaned more often as it gets dirty. With the correct design and proper operation of the stove, soot is almost not formed, but to prevent its formation, it is still recommended to periodically heat the stove with aspen or alder wood.

Video: construction technology

If you take into account all the rules and regulations when installing a Russian stove, operate it correctly and carry out periodic inspections, it will serve you for many years, will be a quality source of heat, an assistant in cooking and will create a unique Russian flavor and comfort in the house.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

How To Clean A Stove With Your Own Hands - Repair, Cleaning A Brick Russian, Bath, Round Stove From Soot Without Disassembling Why It Does Not Heat Well, Reasons, Cleaning Wells, G

How to repair and clean the oven with your own hands. Types of repair, when and why you need it. List of necessary tools and nuances to consider

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation