Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-01-23 12:41.

DIY lifting gates

There are several basic designs of overhead gates, each of which has its own operating principles. The definition of "lifting" speaks for itself - it means that the door leaf is lifted with a certain effort, which can be done manually or with the help of automation. In this article, we will provide instructions for making various types of such gates.

Content

- 1 Basic types of overhead gates

-

2 Design and calculation of sectional doors

- 2.1 Selection of materials for the manufacture of doors

- 2.2 Selection of tools

-

3 Instructions for the manufacture and installation of sectional doors

- 3.1 Selection and installation of automation on sectional doors

- 3.2 Video: Installation instructions for sectional doors

-

4 Production of swing gates

- 4.1 Materials and tools required

- 4.2 Instructions for the manufacture and installation of one-piece up-and-over doors

- 4.3 Automatic equipment for up-and-over doors

- 4.4 Video: DIY automatic garage doors

The main types of lifting gates

Overhead doors can be divided into three main classes: roll-up, sectional and solid.

-

Rolling or roller shutter gates are a construction of narrow transverse sections (lamellas). The sections are screwed onto the shaft to open the opening. If the gate is connected to an electric drive, then it can be controlled using a remote control. They are lightweight and can cover fairly wide or high openings. The gates have a modern and very neat appearance that fits into any architectural style of the building. Their main disadvantage is the highest cost in the segment of overhead doors. Self-production of rolling shutters will not save much money, since the main components of the system (canvas, shaft, guides and electric drive) are almost impossible to make at home.

Rolling shutter design Rolling shutters consist of plastic strips (lamellas) connected to each other and forming a leaf, which is screwed onto the drum when opened

-

Sectional doors are very similar in design to roll-up doors, the only difference is in the size of the sections. For such gates, the width of the sections ranges from 30 to 50 cm, and they move upward along special guides. The sections are connected to each other using movable fasteners. Sectional doors require additional space for a raised leaf and are often used to close overall openings. The big advantage of the system is that it can be manufactured by a person without special skills and equipment. To do this, it is important to determine the design, calculate it, determine the required amount of materials and tools.

Sectional overhead gates Sectional doors have a principle of operation similar to roll-up doors, but consist of wider door leaf elements

-

Up-and-over doors are a single piece, fixed to the frame. The frame with the canvas is driven manually or by means of an electric drive. The doors are distinguished by increased strength, burglary resistance and simple design. The blade frame, made of a metal profile, is not subject to distortions and jamming. The door leaf can be made of any material and can decorate a garage or house. Compared to other models, one-piece lifting gates can be very budgetary, while their own production and installation will not cause much trouble. Before starting work, it is necessary to calculate the estimated weight of the canvas and make sure that the lifting mechanism can withstand this load.

Overhead door with solid leaf Up-and-over doors have a solid leaf, which in the open position is located on top in a horizontal position

Design and calculation of sectional doors

The choice of the optimal garage door size depends on the following criteria:

- Number of cars. If the garage is intended for storing several cars, then there may be several door options. The first option is a wide gate designed for simultaneous entry of cars into the garage. The second option is a separate independent gate for each vehicle. The designs of standard and wide gates are no different from each other. The main condition in both cases is sufficient strength and reliability of the lifting mechanism and fasteners to withstand static and dynamic loads from the weight and movement of the web.

-

Vehicle dimensions. The dimensions include the width, length and height of the vehicle. And if the gate is designed for the passage of two cars, then the minimum allowable distance between them is also taken into account. The length of the vehicle does not affect the determination of the door size. Width and height are taken into account. For comfortable and free passage, the width of the garage opening must exceed the width of the car by at least 0.7 m in the case of a perpendicular drive and at least 1 m in the case of an angle drive into the garage. In the manufacture of gates for several cars, the minimum distance between cars is added to the value of 0.7 or 1 m, which is equal to 0.5 m. The height of the opening for the gate is selected with an excess of the vehicle height by at least 0.2 m. In this case, not only the actual the height of the vehicle, but also the dimensions of the attachments that are mounted on the roof. Such equipment includes open trunks, which carry various goods, and closed trunks, intended mainly for the transport of sports equipment.

Car with roof rack The height of the gate should be chosen taking into account the possibility of a vehicle with attachments, for example, with an upper rack

The calculation of the optimal opening for a sectional door for a passenger car looks like this:

- Minimum opening height: 1788 + 200 = 1988 mm.

- The minimum width of the opening for a perpendicular drive: 1942 + 700 = 2642 mm.

- Minimum opening width when driving at an angle: 1942 + 1000 = 2942 mm.

When calculating the width, take into account the overall dimensions together with the side-view mirrors, and when calculating the height, the open tailgate

We have calculated the minimum dimensions for garage doors. When drawing up a sketch or drawing, it is more expedient to round these values to the nearest whole number. We round up the height of the gate to 2 m, and the width to 3 m.

After determining the dimensions of the gate, you can draw up a scheme for their manufacture and a detailed specification of the necessary elements

Selection of materials for the manufacture of gates

All items must be purchased in accordance with the specification. Mostly sandwich or metal panels are used as sections, much less often wooden slats.

The sandwich panel consists of two metal plates coated with protective compounds and a heater between them

The sectional sheet is closed at the bottom with an end profile. From the sides it is covered with side plates, which give additional rigidity and protect the end part of the gate from external factors. Metal channels are used as guide profiles. Metal corners are used as vertical corner profiles. The brackets are also made of a metal profile. For the lifting mechanism you need to purchase:

- shaft;

- spring;

- spring tips;

- drum;

- cable;

- suspension;

- connecting sleeve.

Selection of tools

When manufacturing and installing sectional doors, you will need a standard set of tools:

- Roulette.

- Construction level.

- A hammer.

- Construction knife.

- Pliers.

- Screwdrivers.

- A hammer.

- Drill.

- Bulgarian.

- Drill bits.

- Set of wrenches.

Personal protective equipment is also not worth neglecting - you need to purchase construction gloves and goggles for work. If the gate has a significant height, then you need to take care of the presence of a stepladder.

Instructions for the manufacture and installation of sectional doors

- Before starting work, check the verticality of the walls adjacent to the opening and the geometry of the opening itself. If significant errors are found, then the situation should be corrected if possible, for example, by plastering the surfaces.

-

Before installing the guides, the bottom panel is applied to the opening in such a way that its edges go beyond the opening at the same distance on both sides. These distances are marked with a pencil. Next, proceed to the installation of vertical and horizontal guides, which need to be cut with a grinder into the necessary segments. Holes are drilled in the walls of the opening with a drill and vertical profiles are attached using anchors according to the marking. The horizontal rails are attached to brackets, which in turn are fixed to the ceiling. To prevent skewing of the structure, the profiles are placed strictly vertically or horizontally, their position is checked using a building level.

Installation of guides The horizontal rail is attached to the ceiling through the bracket, and the vertical and horizontal elements are connected to each other by the C-rail

-

Then the sectional sheet itself is mounted directly. At the joints of the sections of the web, track rollers are fixed, which allow the web to move along the guides up and down.

Sectional door installation The track rollers are fixed along the entire height of the web at the joints of its sections

-

They begin to install the lifting mechanism. The gate can be lifted manually or electrically. We will consider all the nuances of the selection and manufacture of an automatic lifting mechanism in more detail below.

Installation of the lifting mechanism The lifting mechanism consists of a shaft, a spring and a drum

-

After all the main elements of the gate are mounted, handles are attached to the leaf on both sides. The lock is usually cut into the bottom section. To increase burglary resistance, two locks are sometimes installed on opposite sides of the canvas.

Sectional door fittings installation A handle is attached to the lower section of the canvas, and a lock is cut into the lower section

- At the end, a catching device is mounted, which allows the curtain to be in a half-open position, and stoppers that limit the movement of the gate when it is lifted.

- The gate is put into operation. Correctly assembled doors must move freely along the guides. In the lowered position, there should be no gaps, the lock should function without additional effort.

Selection and installation of automation for sectional doors

There are two types of automatic mechanisms that are suitable for automating sectional doors.

- Bulk electric drive. It is very powerful and is designed mainly for industrial sectional doors.

- Ceiling type electric drive. This mechanism is more suitable for a garage and is attached to the ceiling in the middle of the opening from the inside. The electric drive sets the door leaf in motion by means of a cable fixed with a traction lever in the upper section of the door leaf.

Almost all electric drives are equipped with a safety system that prevents the web from falling down during a power outage. Various additional functions can also be useful in gate operation:

- remote control;

- the presence of photocells that react to movement;

- the presence of signal lamps.

The electric drive is installed exactly in the middle at a distance of 2-3 m from the opening

Buying automation from well-known European brands, you will never regret your choice, because they really produce high-quality and reliable equipment. Installation of an automatic system is as follows:

- Brackets are fixed to the ceiling with anchors.

- A drive with a chain or torsion mechanism is installed on them.

-

A lever is installed, which on one side is attached to the gate section, and on the other to a chain or cable.

Installation of automation for sectional doors The drive with a torsion mechanism is fixed on brackets to the ceiling and connected to the canvas using a lever

- Electrical wiring is mounted on one side of the opening.

-

The device is configured for operation in a mode convenient for you.

Wiring diagram for sectional door automation The power supply, control and signal cable from the photocells must be connected to the drive mechanism

Video: Installation instructions for sectional doors

Manufacturing of swing gates

The opening for up-and-over doors is calculated similarly to the opening for sectional doors. You need to know the exact dimensions of your car and the angle of approach to the gate in relation to the main road.

The swing gate leaf is a one-piece shield that can be made of any material. The blade can be lifted by hand or electrically. It is set in motion by a lever through a tensioned cable and moves along horizontal guides with the help of sliding rollers attached to its ends. The opening is framed by a steel frame for load distribution. To limit the opening angle, special springs are installed.

When sketching, you need to measure the distance from the gate to the main road. This distance should be sufficient so that a car driving up to the garage does not interfere with the lifting of the canvas, since in any case it will hide a certain space before entering the garage.

Up-and-over doors are retracted under the garage ceiling along special guides, while they require free space in front of the entrance

Required materials and tools

The door leaf is usually made by hand, and the components are bought factory-made.

To calculate the material for the canvas, subtract the thickness of the steel frame from the height and width of the opening. There should be a minimum gap between the canvas and the frame, allowing the canvas to move freely in the opening.

When choosing a material, one should be guided primarily by the desired degree of burglary resistance and thermal insulation, the permissible weight of the canvas and the decorative properties of the coating:

- the cheapest and least time-consuming option is a sheet of profiled sheet fixed to a frame made of a metal profile. This option will not save you from burglary, will not protect against heat loss and will not very much decorate the garage with its appearance, but it will be lightweight;

- the wooden execution of the leaf can allow you to create a very decent appearance, the gate will have good thermal insulation properties, but their weight will also be significant.

To complete the work, you will need the following set of tools:

- Pencil.

- Roulette.

- Level.

- Screwdriver.

- Drill.

- Drills, bits, wrenches.

- Ladder.

- Bulgarian.

- Gloves, goggles and hard hat.

For the manufacture of up-and-over doors, a standard set of tools is used

Instructions for the manufacture and installation of one-piece up-and-over doors

Step-by-step instructions for making a gate from a metal profiled sheet:

-

First, metal profiles of the required dimensions are cut with a grinder to frame the opening. With the help of mounting angles or brackets, the profiles are attached to the opening through anchors, checking their horizontal and verticality.

Frame for the frame of the up-and-over gate A frame made of metal corners is mounted along the perimeter of the garage opening

-

Then proceed directly to the manufacture of the canvas itself. A rectangular frame with braces is welded from a metal rectangular pipe, covered with a protective compound that will protect the metal from rust. A profiled metal sheet is attached on top of the frame.

Tight overhead gate The profiled sheet is fixed on a frame welded from a metal profile

- With the help of metal corners, the lifting mechanism is assembled. On the one hand, two holes are drilled in the corner for attaching the mechanism to the frame, and on the other side, one hole for attaching the bracket on which the spring will rest.

-

Through a metal plate, the spring is attached to the frame on one side, and on the other, it is fastened to the bracket. When the gate is lowered, the spring will be compressed and abut against this bracket.

Manufacturing of a lifting mechanism for overhead gates Spring is attached to the frame of the hoist and to the locking bracket

- The hinge assembly is made from a corner, which must be welded between the center of the slot for the lifting mechanism and the frame.

- A metal plate with a hole is attached to the lever.

-

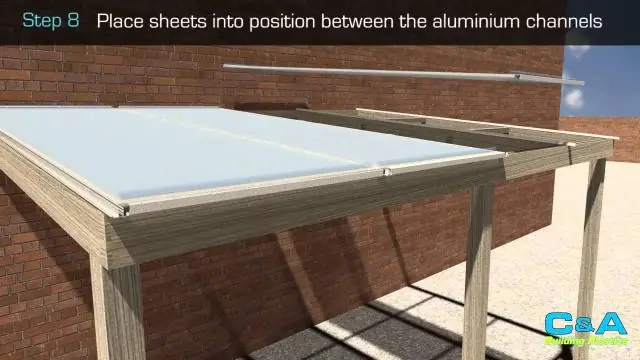

Running rails are made from metal corners.

Running rails The running rails are fixed in a horizontal position through brackets, which are attached, in turn, to the ceiling

- One side of the running rail is welded to the plate. A channel 15 cm long is welded to the other side. Next, this channel is attached to a horizontal frame framing the opening.

Automatic equipment for up-and-over doors

The automatic lifting mechanism significantly increases the comfort of using the doors, it makes it possible to operate them from a remote control. The electric drive for the gate is selected based on the required lift height, area and weight of the door leaf.

The installation process of the electric drive is fully described in the instructions for the device. In general, the installation looks like this:

- Connect the drive and running guides using special brackets.

- First, the carriage is installed on the bus, then the running rail is attached to the ceiling and wall. One bracket is mounted on the wall opposite the middle of the opening at a height of 5 cm from the edge of the canvas. The second bracket is installed on the ceiling at a distance of 15 cm from the wall. First, one edge of the rail is mounted on the bracket, and then the second edge of the rail (electrically operated) is mounted on the ceiling.

- A canvas is attached to the carriage. A traction bracket is attached to the canvas in the closed position.

- The blocking is removed from the carriage, it is moved to the canvas and connected together with the bracket, rod and connector.

-

The automatic lifting mechanism is connected to a power source.

Installation of automatic gate drives Automatic drives are installed on the door leaf and connected to the running guides with telescopic arm-rods

Video: DIY automatic garage doors

Guided by the detailed instructions, you can make and install various types of lifting gates with your own hands. Independent work will save your family budget and bring the most original ideas to life.

Recommended:

How To Make A Bar Stool With Your Own Hands From Wood, Metal And Other Materials + Drawings, Photos And Videos

Bar stools manufacturing options. Required tools, materials used. Step-by-step description of the manufacturing process with a photo

How To Make A Veranda With Your Own Hands To The House - Instructions, Projects, Drawings, Photos And Videos

The article describes how to build a veranda close to the house with your own hands

How To Make A Kite With Your Own Hands At Home: Options With Drawings And Sizes + Photos And Videos

DIY kite: the necessary materials, diagrams, drawings, manufacturing steps. How to make a kite of different shapes. Secrets of a Successful Launch

Installing A Polycarbonate Greenhouse On A Timber, How To Properly Fix The Structure, Instructions With Photos And Videos

Detailed instructions for the manufacture and installation of an arched greenhouse made of wooden beams and sheathing of the frame with polycarbonate

How To Make A Chimney From A Steel Pipe With Your Own Hands: Device, Installation Of A Sandwich Structure, Instructions With Photos And Videos

What is a steel pipe chimney, where is it used, its advantages, disadvantages and its manufacture by hand