Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Features of installing electrical wiring in the kitchen

In order for the electrical wiring in the kitchen to work reliably and for a long time, it must be professionally designed, and then installed in accordance with the developed rules. The peculiarity of the kitchen is that it contains a large number of household electrical appliances, so the load on the network will be maximum here. For each unit of household appliances, it is necessary to provide for a convenient connection to the mains. Only in this case, all kitchen units will work normally, and it will be convenient and comfortable to use them.

Content

-

1 Types of wiring and their features

- 1.1 Open wiring

- 1.2 Concealed wiring

-

2 Features of the electrical wiring in the kitchen

- 2.1 Groups of electrical wiring in the kitchen

-

2.2 Rules for placing sockets in the kitchen

2.2.1 Video: rules for placing outlets in the kitchen

- 2.3 Principles of creating electrical wiring in the kitchen

- 2.4 Additional kitchen equipment

-

3 Preparatory steps for wiring

- 3.1 Checking the old power supply

- 3.2 Determination of the total power of the consumed energy

-

3.3 Cable selection

- 3.3.1 Table: selection of cable cross-section

- 3.3.2 Video: Selecting the Cable Size

- 3.4 What materials are needed for arranging wiring in the kitchen

-

3.5 Necessary equipment and safety precautions

3.5.1 Safety Requirements

-

4 Installation of kitchen wiring

-

4.1 Markup

4.1.1 Video: marking the electrical wiring in the kitchen

-

4.2 Wall chipping

4.2.1 Video: wall chipping

- 4.3 Wiring

-

4.4 Installing sockets and switches, connecting to the network

- 4.4.1 Connecting sockets

- 4.4.2 Video: installation of sockets

- 4.4.3 Connecting switches

- 4.4.4 Video: Connecting a one-button switch

-

Types of wiring and their features

Kitchen wiring can be routed open or closed. Both of these options have both advantages and disadvantages. When choosing a mounting method, consider:

- type of repairs being carried out (cosmetic or major);

- the presence of decorative elements on the walls and ceiling;

- room design;

- owner preferences.

Open wiring

The open way of wiring installation is the simplest and most affordable. In this case, the work can be done quickly, with minimal effort and expense.

Among the advantages of open wiring are the following:

- in the event of a malfunction, the problem can be eliminated very quickly;

- easy to use in wooden houses or on wood-clad walls;

- no need to spoil the walls. Open wiring can be arranged according to the finished finish;

- with the right choice of accessories, you can give your kitchen a stylish and original look.

In order to ensure the necessary level of safety for the installation of surface wiring, special cable channels are used that can be fixed both to the wall and to the ceiling. They consist of a box where the wires are laid and a cover that can be quickly removed or installed. Depending on the cross-section and number of wires, cable channels of the required size are selected. Such products are made of a plastic material that bends well, does not burn and has dielectric properties. If necessary, you can choose the boxes of the desired color or tint them with paint, then they will organically fit into the interior of your kitchen.

Cable ducts and electrical outlets can be stylish accessories for kitchen interiors

Some experts point out that it is undesirable to do open wiring in the kitchen. This is due to the fact that there is high humidity and high temperature, so the wires quickly lose elasticity and overheat, which causes problems. If the design solution requires open wiring in the kitchen, then combined installation can be performed: in the most dangerous places it is made hidden, and in others - open.

Hidden wiring

When creating hidden wiring in the kitchen, all the wires are hidden inside the walls or ceiling. To do this, grooves are made in the bearing surface in which the cable is laid, after which they are closed with a solution and a topcoat is applied. This solution is safer, but its installation will require a hammer drill, there will be a lot of dust and dirt, and it will also take a lot of time and physical labor.

Installation of hidden wiring can be performed both at the stage of building a house and during its renovation. In the first case, it is enough just to fix the wires on the wall, and then plaster it. When carrying out repairs, you will have to gouge the ceiling or walls to create channels for cable routing.

When laying electrical cables in a hidden way, only the faceplates of the sockets remain on the surface

Please note that if a hidden wiring malfunction occurs, you will have to dismantle the finishing of the walls, otherwise you will not be able to get to the cable

Features of the electrical wiring device in the kitchen

For an inexperienced person, it may seem that installing electrical wiring in the kitchen is no different from performing similar work in any other room, but this is not so. The main feature is that a large number of electrical appliances are used in the kitchen. The largest consumers are an oven and an electric stove, and there is also an electric kettle, refrigerator, microwave oven, multicooker, extractor hood, TV and other equipment. If you turn on all or at least most of the devices at the same time, you will need quite a lot of power, which must be taken into account when planning and creating wiring.

Groups of electrical wiring in the kitchen

The electrical wiring in the kitchen must be divided into several groups. This will reduce the load on the cable and ensure reliable network operation.

Groups of electrical wiring in the kitchen:

- Lighting. Here you can use a 2x1.5 mm 2 two-core copper cable.

- Weak household appliances. This includes a refrigerator, extractor hood, coffee maker and others. Usually several devices are combined into one line and connected with a 3x2.5 mm 2 cable.

- Powerful household appliances - oven, washing machine, dishwasher, waste grinder, etc. Most often they are connected to a separate machine. A copper cable 3x4 mm 2 is laid to the oven, a cross-section of 3x2.5 mm 2 is sufficient for all the rest.

-

Kitchen electric stove. Always connected separately, a 3x6 mm 2 cable is used.

Electric wiring diagram in the kitchen When designing an electrical network in the kitchen, consumers need to be divided into groups.

Rules for placing sockets in the kitchen

When planning the placement of outlets in the kitchen, energy consumption and the number of household appliances that will be used here must be taken into account. Separate lines must be laid for energy-intensive units. In addition, there must be sockets for connecting the equipment that is used periodically. The number of equipment simultaneously connected to each line should not exceed the power for which the wiring is designed.

In the kitchen, sockets can be located in the following areas:

- lower - located below the housing of household appliances. It is recommended to use this solution to connect appliances such as a refrigerator, an electric stove, a washing machine and a dishwasher so that the sockets are not visible behind the facades of furniture or behind kitchen appliances;

- middle - located just above the work surface. It is convenient to connect the equipment used for cooking in this zone. The height of the outlet above the floor level must be at least 100 cm;

-

upper - located above the body of the connected device. This is how the hood and lighting of the work surface are usually connected. The socket must be at least 15 cm from the ceiling or 10 cm from the edge of the upper cabinet.

Methods for placing sockets in the kitchen Depending on the type of device to be connected, the socket for it can be placed directly above the floor, on an apron or above wall cabinets

Video: rules for placing outlets in the kitchen

Principles of creating electrical wiring in the kitchen

On average, the total power of electrical equipment used in the kitchen is 12-14 kW. Although all kitchen appliances almost never work at the same time, the calculation of the network power must be carried out taking into account the peak load.

The creation of wiring in the kitchen must be carried out in several stages:

- Development of a wiring diagram. It is impractical to use one junction box in the kitchen. It is necessary to separate lighting and different outlet lines. Each branch must be protected by a separate machine. To connect some devices (washing machine, dishwasher, electric stove, oven), it is additionally necessary to use an RCD, which provides protection against current leaks and the safety of users.

- Choice of cable cross-section. In order for the kitchen equipment to work normally, it is necessary to use a cable with a cross section of 2.5 to 6 mm 2, depending on the total power of the connected appliances.

-

Grounding device. Since the power of the equipment used in the kitchen is large, grounding must be done, and only a three-core cable should be used to connect the equipment (with the exception of lighting fixtures). In urban apartments, the "ground" has already been laid and brought out into the shield on the staircase, the owners of private houses must attend to this on their own.

Grounding in a city apartment In city houses, grounding has already been connected to each apartment.

- Wiring and installation of sockets. When disconnecting the sockets, it is necessary to carefully stretch all the contacts. In a poorly tightened connection, the wire will heat up and burn out over time.

When calculating the number of outlets, you need to take into account how many household appliances you plan to use in the kitchen, and install two more sockets. This will allow you to connect the technique that you may have later.

Lighting in the kitchen usually consists of two zones: top and work. Spotlights are often used here, which can be either stationary or rotating. To create a cozy and light atmosphere, you can use several chandeliers, distributed evenly throughout the kitchen space or installed above certain areas, for example, above the dining table or bar.

Additional kitchen equipment

In order to provide lighting for the kitchen regardless of the presence of power in the network, an additional source can be installed. Typically a 12 V backup power supply is used, which has a built-in battery. LED lamps are connected to such a device, which provide lighting when there is a loss of voltage in the centralized power grid.

To increase safety in the kitchen, it is recommended to additionally install sensors that will warn about the appearance of gas and water leaks. The installation of such an alarm in old buildings is especially relevant, since the communication systems in them are very worn out.

Gas leak sensor signals problems in the gas supply system

The presence of water and gas sensors will help to secure the home and avoid serious accidents. If we talk about the cost of such equipment, then in comparison with their real benefits, it is small - the set will cost 2-3 thousand rubles. Modern systems not only warn owners about leaks, but are also capable of independently shutting off the water or gas supply to the apartment. When problems arise, the sensors inform the owner about it using a cellular connection, turn on the sound alarm and ventilation.

The water leakage sensor will immediately send a message about problems in the water supply system to your mobile phone

Preparatory steps for wiring

Before proceeding with the installation work, you first need to prepare the kitchen. If you will be installing wiring during the construction of the house, then this should be done before completing the wall decoration. If the installation work is carried out in the process of repairing the kitchen, then you will have to gouge the walls, and this is due to the formation of a large amount of dust. To protect doors, windows and what is left in the room from it, it is recommended to close all this with a film.

It is necessary to turn off the power supply to the apartment, and in order for the power tools to work, you need to take care of the presence of a carrier and where you can connect it in advance.

Checking the old electrical network

If you are going to remodel already laid electrical wiring, you need to determine its type. In apartments, the electrical network is most often single-phase, in private residential buildings, you can also find a three-phase connection. The type of network is easiest to find out by the meter - if eight wires come to it, it means that it is three-phase, if four, then it is single-phase. In addition, you need to make sure that you have a functional grounding system.

For a three-phase meter, eight wires are usually suitable

Determination of the total power of the consumed energy

The next step is to calculate the power of the wiring. To do this correctly, it is necessary to add up the capacities of all appliances that will be used in the kitchen. In order to find out the rated power of a particular technique, you need to look at its passport or at a special plate on the case.

After you have summed up the power of all devices, you can proceed to the selection of the cable. As mentioned earlier, the wiring must be calculated taking into account the peak loads, although such a situation when all available devices are turned on at the same time is very rare.

The calculation is performed according to the formula P = P 1 + P 2 + P 3 + … P n, where P (1 - n) is the power of the devices. Since the kitchen equipment is usually divided into several groups, the calculation must be done for each of them separately.

To determine the total power, it is necessary to add up the rated powers of all the equipment used on each line of outlets

Cable selection

According to the wiring rules, when connecting a three-core cable, the phases are connected to the white, black and brown wires, zero to blue, grounding to yellow-green

To connect the phases, white, black and brown wires are used, zero is connected with blue, and "ground" - with a yellow-green wire

When choosing a cable cross-section, it must be borne in mind that:

- to connect the lighting, you will need a two-core wire with a cross section of 1.5 mm 2 each wire;

- for dishwasher and washing machine - 3 × 2.5 mm 2;

- for an electric oven - 3 × 4 mm 2;

- for an electric stove - 3 × 6 mm 2.

To calculate the cable cross-section for connecting other household appliances, you can use a simplified approach: for 1 mm 2 of cable with hidden wiring, up to 8 A should fall, and with open - up to 10 A of operating current.

Table: selection of cable cross-section

| Cable core section, mm 2 | Core diameter, mm | Copper wiring | Aluminum conductor wiring | ||||

| Current, A | Power, kW at mains voltage 220 V | Power, kW at mains voltage 380 V | Current, A | Power, kW at mains voltage 220 V | Power, kW at mains voltage 380 V | ||

| 0.5 | 0.8 | eleven | 2.4 | - | - | - | - |

| 0.75 | 0.98 | 15 | 3.3 | - | - | - | - |

| 1.0 | 1.12 | 17 | 3.7 | 6.4 | - | - | - |

| 1.5 | 1.38 | 23 | 5.0 | 8.7 | - | - | - |

| 2.0 | 1.59 | 26 | 5.7 | 9.8 | 21 | 4.6 | 7.9 |

| 2.5 | 1.78 | thirty | 6.6 | 11.0 | 24 | 5.2 | 9.1 |

| 4.0 | 2.26 | 41 | 9.0 | 15.0 | 32 | 7.0 | 12.0 |

| 6.0 | 2.76 | fifty | 11.0 | 19.0 | 39 | 8.5 | 14.0 |

| 10.0 | 3.57 | 80 | 17.0 | 30.0 | 60 | 13.0 | 22.0 |

| 16.0 | 4.51 | one hundred | 22.0 | 38.0 | 75 | 16.0 | 228.0 |

| 25.0 | 5.64 | 140 | 30.0 | 53.0 | one hundred | 23.0 | 39.0 |

If you take a thicker cable than necessary, then its cost will be unreasonably high and this will negatively affect your budget. If the diameter of the core is less than that necessary for the operation of household appliances, the wire will start to overheat, which can lead to its spontaneous combustion and short circuit.

Video: choosing a cable size

What materials are needed for arranging wiring in the kitchen

After you have determined the total power of consumers and selected the cable, you need to purchase all the necessary components to create wiring in the kitchen. To do the wiring yourself, you will need:

-

cable of the required section;

Cable To connect the sockets, a three-core copper cable of the VVGng type (in non-combustible insulation) is most often used

-

cable channels - they are used when installing open wiring;

Cable channels The size of the cable channels is selected depending on the cross-section of the cables laid in them

-

sockets;

Retractable sockets for the kitchen It is convenient to use retractable sockets in the kitchen

-

switches;

Types of electrical switches Different types of switches can be purchased depending on the desired way of controlling the light.

-

installation boxes (socket boxes);

Socket boxes For the installation of built-in electrical outlets, plastic installation boxes are most often used.

-

junction boxes. They must be made of non-combustible or self-extinguishing materials;

Junction box For in-wall installation, it is necessary to use junction boxes made of non-combustible or self-extinguishing materials

-

protective circuit breakers. For a one- or three-phase network, they are different. Their number is calculated taking into account the fact that it is recommended to install a separate machine for each group of electrical wiring;

Circuit breaker To connect powerful household appliances, it is recommended to install a separate machine

-

residual current device (RCD), which protects users from the possibility of electric shock when touching the case;

RCD and difavtomat RCD protects users from shock when touched, and difavtomat combines RCD and circuit breaker in one case

- alarm against water and gas leakage;

- equipment for providing backup lighting.

When calculating the cable length, it is imperative to take into account the installation allowances:

- in the installation box - 5 cm;

- for a lamp - 10-15 cm;

- to connect to each section of the wire, add 10 cm.

Necessary equipment and safety precautions

In order to be able to perform all the installation work on your own, you will need the following tools:

- set of screwdrivers;

- soldering iron;

- hammer drill with a set of drills and drills;

- multimeter;

- pliers;

- stripper for stripping wires;

- dowel-nails, self-tapping screws or nails for fixing cable channels. The choice of fasteners depends on what the walls in the kitchen are made of;

- gypsum or alabaster. They are necessary to quickly fix the cable in the strobe;

-

extension.

Wiring Tools Both hand and power tools will be needed for wiring

Safety requirements

When self-installing electrical wiring, you must adhere to the general safety rules, as well as follow the following recommendations:

- all work is carried out only when the electricity is off;

- if the electrical panel is located on the staircase, then after a power outage it is imperative to hang up a sign "People are working";

- when laying furrows in concrete and brick walls, it is imperative to work in safety glasses;

- all tools used must have insulated handles;

- to create a through hole in the wall, use a drill 20 cm longer than its thickness;

- you cannot use a faulty hand or power tool;

- it is impossible to work with an electric tool from a ladder; for this they use a ladder or other reliable support;

- the hook for the chandelier must withstand a load 5 times the weight of the lamp plus 80 kg.

Installation of kitchen wiring

After all the preparatory work, the acquisition of the necessary tools and equipment, you can proceed directly to the installation of electrical wiring. All work can be divided into several stages.

Markup

First, you need to take a kitchen plan and apply all the main elements of the wiring on it:

- the point of entry of the supply cable;

- connection points for powerful household appliances;

- installation locations for switches and sockets;

- lamps.

After that, proceed to drawing the scheme on the walls. It is convenient to use the laser level, since it is used to mark the markings strictly in the vertical and horizontal directions.

When marking, you must adhere to vertical and horizontal lines

When performing markup, it must be borne in mind that:

- all cable turns are made only at right angles;

- the horizontal strobe should run at least 20 cm from the ceiling;

- the wire should run at least 10 cm from window and door openings;

- the switches are placed at a height of 80-150 cm, it all depends on the preferences of the owners.

If you do not have a laser level, then the markings on the walls should be applied using a plumb line smeared with charcoal or chalk. So that later you can easily find the wiring, it is recommended to take a picture of the wall markings and save these photos.

Video: marking electrical wiring in the kitchen

Wall slitting

To install hidden wiring in the wall, it is necessary to make grooves in which the cable will be laid. Walls can only be channeled horizontally or vertically, as there is a high risk of injury when working diagonally.

Wall slitting is performed in the following order:

-

Drawing the boundaries of the channel. This is done using a wall chaser or a grinder according to a pre-made marking.

Channel boundaries It is convenient to use a chasing cutter to draw channel boundaries.

-

Creation of grooves. They are made with a hammer drill equipped with a chisel. To make smooth bends, oblique cuts are made inside the corners with a grinder.

Creating grooves A perforator with a chisel is used to create the grooves.

-

Creation of places for sockets. This is done with a hammer drill and core drill. It is quite easy to drill the required hole in the brick wall, you need to work carefully in the reinforced concrete base, since there are reinforcement there. If you suddenly hit it, then you can move a little to the side and make another hole.

Creating places for sockets To create holes for installing an outlet or a switch, a special drill bit is used

It is not recommended to make a double strobe to connect the switch. It is better to make one wide strobe, place a corrugated tube in it and lay two wires in it.

In order to lay wiring on the ceiling, you can use several methods:

- the cable is attached to the ceiling and masked with a stretch fabric;

- a shallow groove for the cable is created, after which it is sealed with plaster;

- voids in floor slabs are used. It is enough to make the entrance and exit from the plate, and then lay the cable in the void.

Video: chipping walls

Wiring

At the next stage, the cable is laid in the previously prepared grooves:

- The wires are laid in the strobe, leaving the necessary margin at both ends. When connecting powerful equipment, twisting cannot be done. In extreme cases, when laying a cable for low-power equipment, the wires can be connected using connectors designed for the required current.

-

In the holes prepared in the grooves, insert and fix the dowel-staples, in which the wire is fixed. For additional protection of the cable from possible damage, it is recommended to lay it in a special corrugated pipe.

Wires in the strobe To fix the wire in the strobe, use special dowel brackets

-

After the cable is laid and secured, the grooves are closed with plaster or alabaster. Before sealing the strobes, it is recommended to ring the laid cables to ensure their integrity.

Sealing the strobe It is best to close up the grooves with plaster or alabaster.

Installation of sockets and switches, connection to the network

Now the moment has come when you need to install the sockets and switches.

Connecting sockets

The sockets are connected in the following sequence:

-

Installation of the socket. The place of installation is slightly moistened with water, after which it is covered with a layer of alabaster 2-3 mm thick. Wires are inserted into the box, after which it is placed in a prepared place and pressed well. You can fix the socket with self-tapping screws or make combined fasteners.

Installation of socket boxes The socket boxes are fixed with alabaster

-

Connecting the socket. The ends of the lead-out cable are stripped by 7-10 mm and fixed to the socket housing.

Connecting the socket The wires are connected in accordance with the established color scheme and marking of the socket contacts

-

Fixing the case in the socket. This is done with the help of two screws, when tightened, the legs of the socket are spread apart and cut into the wall.

Fixing the case in the socket In the socket box, the case is fastened by means of legs, which move apart when the set screws are tightened

-

Edging installation. At this stage, the decorative edging is fixed with a central screw.

Edging installation The edging of the socket is fixed with a screw

Video: installation of sockets

Connecting switches

The process of connecting the switch has some peculiarities, since only two wires are connected to it.

The work is done in this order:

- Determine where the phase and zero are in the junction box.

- The corresponding wire from the lamp is directly connected to the neutral wire.

- The switch input, which is located on top, is connected to the phase in the junction box.

-

The second wire from the luminaire is connected to the lower terminal of the switch.

Circuit breaker connection diagram The switch must open the phase wire, the zero is connected directly to the lamp

In order to save wire and relieve the junction box from a large number of connections, the socket and the switch can be connected side by side.

Make such a connection as follows:

- Connect the socket. All work is carried out in the same way as described above.

- The input of the switch is connected to the phase on the outlet.

- The switch output is connected to the luminaire wire.

-

The neutral and protective wires from the socket are connected directly to the luminaire. If it is far away, then zero and "ground" are taken from the junction box.

Connecting the switch and socket To relieve the junction box from the large number of connections, the socket and switch can be connected side by side

Neutral and earth wires are not connected to the switch, therefore, it will not be possible to connect the outlet from the switch

It remains to connect all the wiring to the network. For this, the cable from sockets, switches and lamps in the junction box is connected to the supply wire. In the switchboard, protective automatics are installed and power is supplied. Then they check the functionality of the created wiring and close the junction box.

Video: connecting a one-button switch

youtube.com/watch?v=McoyH4e14Lo

To do the wiring in the kitchen with your own hands, you have to spend some time and effort. The work must be performed with high quality, accurately and strictly follow the developed technologies and safety rules. Only in this case the electrical wiring will serve reliably and safely for many years.

Recommended:

The Location Of The Sockets In The Kitchen: Placement Height, How Many And Where Needed, Photos, Diagrams

Rules and regulations for the location of outlets in the kitchen. Calculation of the required number of outlets. Drawing up an electrical wiring diagram. Types and installation of sockets

Lighting For The Kitchen Under The Cabinets And Above The Working Area: LED Strip And Surface-mounted Lamps To Illuminate The Surface Of The Kitchen Set

Types of LED backlighting, their pros and cons. Options for placing the backlight of the kitchen set. Installation of LED strip and expert advice

Installation And Connection Of Sockets In The Kitchen - DIY Installation Rules

The layout of the sockets. Marking, drilling holes and installing socket boxes. Wall slitting and wiring. Installing and checking the socket

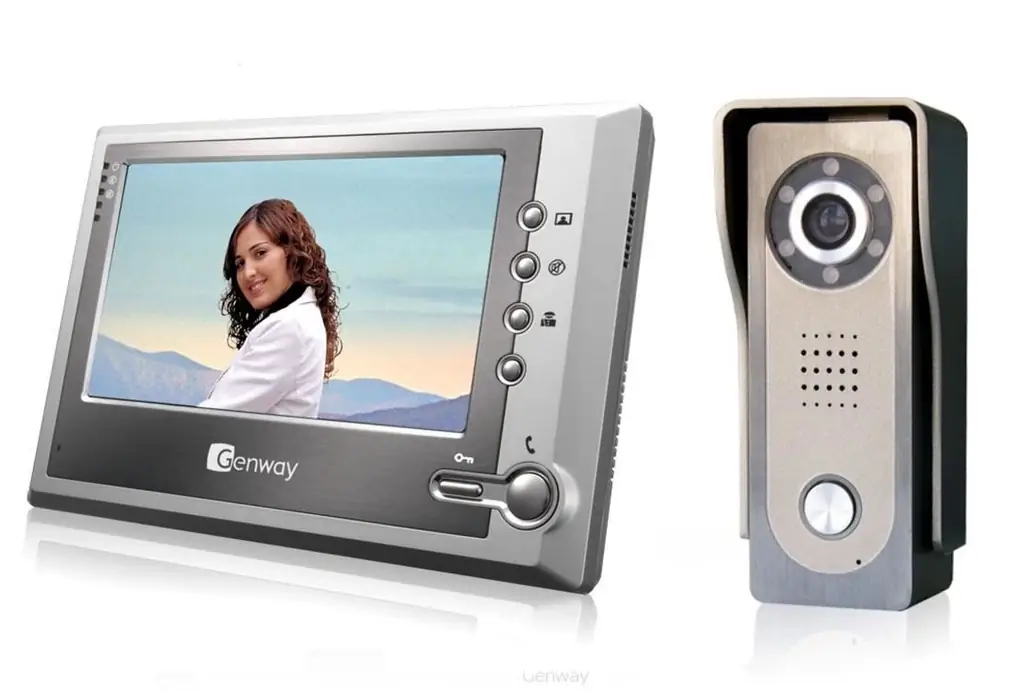

DIY Installation And Intercom: Connection Diagrams And Installation Features, Description Of The Main Stages

Types of intercoms. Sequence and basic installation diagrams. Features of mounting a wireless intercom. Connecting to a TV

DIY Electrical Wiring: Diagram, Tips And Step-by-step Instructions For Installation From Scratch, As Well As Wiring Repair + Video

Practical advice on the installation of electrical wiring in an apartment and a private house. Wiring diagram. Installation of hidden and open wiring