Table of contents:

- Author Bailey Albertson [email protected].

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Sauna door: material selection, manufacturing steps and installation procedure

The sauna door that closes the entrance to the steam room works in difficult conditions. Therefore, when making and installing it yourself, you must comply with a number of requirements, otherwise the service life will be short-lived.

Content

-

1 Features of the device of sauna doors

1.1 The door to the steam room

-

2 Materials

- 2.1 Glass

-

2.2 Tree

- 2.2.1 Thick tongue-and-groove boards

- 2.2.2 Lining

- 2.2.3 Shaped inserts

- 2.2.4 Video: the secret of assembling a tsar paneled door for a bath

-

3 Required tools, material and accessories

- 3.1 Tools

- 3.2 Accessories

-

4 Making a door

4.1 Video: restoration of the bath door

-

5 Installation

-

5.1 Installation of a bath door into a log wall

- 5.1.1 Video: how to properly cut an opening in a log wall (part 1)

- 5.1.2 Video: how to cut a groove and install a door frame (part 2)

-

-

6 Thermal insulation of the sauna door

6.1 Video: how cheap and easy it is to insulate the door in the bath

Features of the device of sauna doors

To ensure the appropriate temperature regime, at least two doors are installed in the bath:

-

outdoor - at the entrance from the street into the extension itself (or a separate building);

External bath door The entrance street door to the bath is usually insulated, made more massive and decorated with metal fittings

-

internal - between the dressing room and the steam room.

Internal sauna doors The steam room can be equipped with a door made of durable glass or wood

If the layout of the bath provides premises for other purposes (recreation room, bathroom, washing room), then the number of doors increases accordingly.

The doors inside the bath for different rooms are best made of wood to keep warm in winter

The door to the bath can be completely wooden or metal, but sheathed with wood

The door to the steam room

Requirements for the door to the steam room:

- if the bath is Russian, then tightness is ensured, if the sauna - a gap of 1-2 cm is left below for ventilation. In the presence of cracks in the Russian bath, steam escapes from the steam room, and full acceptance of the procedure becomes impossible. In a sauna without a gap under the door, the distribution of steam is uneven;

- the door leaf should not deform from high temperatures, significant temperature fluctuations and high humidity;

- materials that do not burn on contact are used: wood and glass. Plastic cannot be used - with a sharp increase in temperature, harmful substances are released from it;

- the door should open easily outward and be without locks. Sometimes simple latches are installed - ball, roller or magnetic.

But roller and ball latches begin to seize in conditions of high temperature and high humidity, so it is better to give preference to magnetic ones

The door to the steam room can be made of sheet fireproof glass

In the old days, they tried to reduce the opening leading to the steam room to reduce heat leakage. The door was placed very low: about 1.5 m high. Nowadays, good thermal insulation materials are used, so the door can be made in the usual size, taking into account the following factors:

- Concentrated steam collects under the ceiling in a layer of 60-80 cm, and the upper edge of the door should be below this layer. Therefore, with a ceiling height of 2.5 m, the door should be about 1.7-1.9 m. To make the entrance comfortable for a tall person, you will have to increase the height of the steam room;

-

in the opening of the Russian steam room, a threshold of 10-20 cm in height is set to contain the cold air from the dressing room. This means that the length of the door leaf will be no more than 1.8 m. The threshold is not required in the sauna.

Door thresholds in the Russian bath Door sills in the Russian bath help to keep the heat inside the steam room

The door can be any width - from 60 to 80 cm

Materials

Inside the bath, only wooden and glass doors are used, and metal and plastic doors are also used for the entrance.

At the entrance to the bath, you can put a door made of plastic and double-glazed windows to provide the dressing room with additional natural light

Glass

A glass door looks impressive, especially if a drawing is made on its surface, but it is impossible to make it at home: this requires tempered glass with a thickness of 8 mm or more.

Solid glass bathroom doors usually use frosted or tinted glass

The only thing you can do with your own hands is to install a finished door.

A glass door with a magnetic lock can be installed at the entrance to the sauna

Safer and more reliable when used in a steam room, a glass door inserted into a wooden frame

Wood

It is possible to completely independently make a bath door in a home workshop only from wood: the material is available and easily processed. You should choose those types of wood that are most resistant to decay and least of all absorb water. These are oak, ash, larch, pine and spruce.

The resin of coniferous trees does not cause trouble - it is released in small quantities and is easily removed.

Using coniferous wood, in the future you will not have to fear the curvature of the door

You can use different lumber to make a door.

Thick grooved boards

The easiest way is to make a door from grooved boards: they are easily assembled into a shield, around the perimeter of which a strapping is made from a bar.

The canvas, assembled from grooved boards, is strengthened with crossbars, then the surface is processed

Crossbars are usually attached to such a bath door - keys that prevent deformation of the canvas.

Two cross-members are cut and slightly recessed into the door leaf, then glued

Also, to strengthen the structure, fastening boards are diagonally nailed.

There can be several fastening diagonal boards: they are laid out in a pattern along the entire door leaf

For a Russian bath with wet steam, a massive door is best suited

Lining

It is used in two cases:

-

For the manufacture of a frame door, the frame is assembled from bars, and the lining is used as a cladding. The cavity of such a door is filled with a heat insulator, so it turns out to be very warm.

Scheme of a multilayer frame door The door frame is filled with insulation and sheathed with clapboard on both sides

-

For decorative cladding of doors made of low-grade timber. This makes it possible to reduce the cost of manufacturing a door: the door leaf is assembled from boards of cheap wood, and resistance to temperature and humidity is provided by clapboard cladding, for example, from oak.

The door to the bath, lined with clapboard The clapboard door enhances the appearance of the bath

Curly inserts

Doors assembled from such elements are called paneled doors. But paneled doors:

- rather difficult to manufacture;

- are more likely to deform with temperature changes.

Therefore, they should be taken up only if you have sufficient experience in carpentry work, and installed at the entrance to the bath or relaxation room, but not to the steam room.

The paneled door is beautiful, but difficult to do it yourself

Video: the secret of assembling a tsar paneled door for a bath

Required tools, material and accessories

Consider the manufacture of a wooden bath door with a size of 2000x800 mm. To do this, you will need to purchase:

- grooved board with a section of 200x30 mm;

- bars with a section of 30x20 mm (to strengthen the canvas);

- bars with a section of 30x30 mm (for strapping);

- timber with a section of 110x60 mm (for a door frame);

- feigned strips;

- platbands.

Tools

In the process of making doors you will need:

- jigsaw (or a set of saws with different tooth heights);

- clamps: 2-3 pieces;

- hammers: regular and rubber;

- plane;

- drill with a set of wood drills;

- screwdriver;

- coarse and fine sandpaper (or grinder with grinding wheels);

- vernier caliper (depth gauge);

- chisel;

- rack building level with a bubble ampoule;

- manual router or milling machine;

-

roulette.

Carpentry tools Before you start making the door, you need to acquire a set of carpentry tools

Components

You will also need basic components:

-

door hinges - it is better to take brass, as steel due to high humidity will begin to rust. Since the door will turn out to be heavy, it is better to fasten it on three hinges;

Brass door hinges Brass tolerates high humidity well

- latch - magnetic will work flawlessly;

-

wooden handles - 2 pieces;

Wooden door handles for a bath A carved wooden handle will decorate the interior of the bath and protect the visitor's hands from burns

- screws and nails.

Making a door

The manufacturing process consists of the following steps:

-

Cut the grooved board into blanks of the required length. Since the length of the canvas is 2000 mm, and the strapping around the perimeter is performed with a bar 30 mm wide, the length of the blanks is calculated by the formula: 2000 - 2x30 = 1940 mm.

Sawed blanks from grooved boards You can also arrange the boards in horizontal rows, rather than vertical ones, then you don't have to cut them along the edge.

- Treat all blanks with an antiseptic.

- Cut 60 mm from one board with a jigsaw along the edge to fit the board to the required width (800 mm). Therefore, it should be reduced by the thickness of the side bars: 800 - 2x30 = 740 mm.

- If the door leaf is assembled from a whole number of boards (narrower), then a spike must be cut off from the outermost one so that the butt end turns out to be even, without a protrusion.

- Assemble a shield from the boards, but so far without glue - make sure all sizes are correct.

- Cut the timber prepared for the role of strapping into blanks: two with a length of 2000 mm and two with a length of 740 mm.

-

Smear all the grooves of the boards with white glue and join. Tap with a mallet for a tight connection.

Gluing a board from boards For gluing the board from the boards, only high-quality furniture glue is taken, which does not turn yellow and does not emit harmful chemical fumes into the air

- Fix the shield in the corners with clamps. Allow the glue to dry for several days.

-

Cut the canvas with a plane: set it up for fine processing to simply smooth the surface.

Plane processing Using a planer, the surfaces of the assembled shield are given the necessary smoothness

-

Screw the harness to the ends of the shield with self-tapping screws. With a bar width of 30 mm, self-tapping screws of 50-60 mm are suitable. Better to connect the bars with grooves.

Corner connection of bars with grooves The corner connection of the bars with grooves is more reliable, but requires skill in the manufacture of such fasteners

-

Attach two crossbars to the outer side of the leaf at the top and bottom, which will give the door rigidity. They can be screwed onto self-tapping screws or cut into the shield body in the form of dowels.

The scheme of making a door with cutting of dowels Pre-assembly of prepared door elements is carried out without the use of glue

- Screw on the hinges so that the door opens outward, put the handles.

-

The inner side can be additionally treated with an antiseptic, and the outer side can be covered with transparent varnish.

Impregnation of a wooden door with an antiseptic Impregnation of a wooden door with an antiseptic allows you to protect the wood from rotting in wet conditions

- Assemble a box from a bar with a section of 110x60 mm. In depth, it should exceed the thickness of the door by 60-70 mm and be perfectly rectangular. Choose the dimensions so that there is a gap of 4 mm between the frame and the door - in the expectation that the wood will swell from moisture.

-

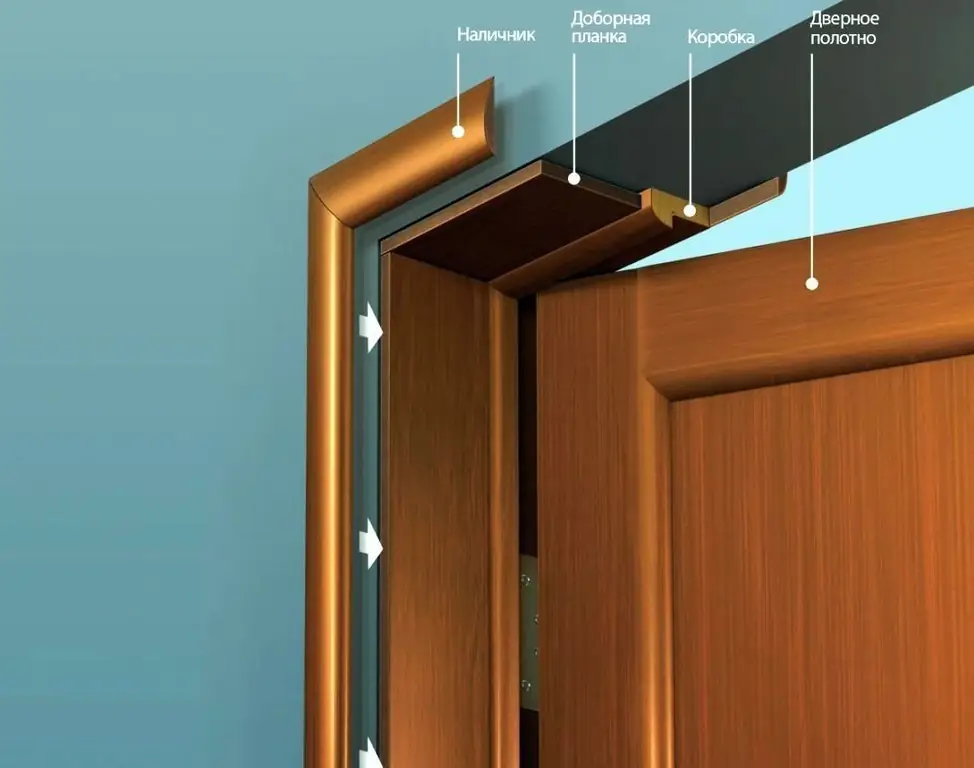

Install the box in the opening and equip it with a rebate: either select a groove along the edge with a router, or nail in the pretend strips (expanders). Put platbands.

Door frame fixing scheme It is necessary to install and mount the door frame strictly according to the level, maintaining vertical and horizontal

Video: bathroom door restoration

Installation

The door is installed in the usual way:

-

Place the box on a level in the opening and secure it with bars that are driven in between it and the wall.

Installing the door frame in the opening Installation of a door frame in the opening requires special accuracy, because the functioning of the door will depend on it

- Hang in the door and check its free play.

- After eliminating the defects, screw the box to the wall with anchor bolts, drilling holes through the bars.

- Close the gap between the box and the wall with polyurethane foam or clog it with a rag, as polyurethane foam emits harmful substances under the influence of high temperature.

-

Install platbands.

Installation of platbands The installation of platbands completes the installation and decorates the appearance of the bath door

- Screw the parts of the magnetic catch to the door and frame.

Installing a bath door into a log wall

If the bath is done in a log house, then it is important to learn about the features of installing a door into the wall of such a structure. There are two things to consider:

- Put the door six months after the completion of construction. Shrinkage of a log house is an unpredictable process, therefore, the size of the opening should exceed the parameters of the door by 100 mm in each direction.

- After that, the walls of the opening must be strengthened by connecting the ends of the logs on each side with an additional element.

Reinforcement of the opening is performed as follows:

- at the ends of the wall on each side of the opening to the full height, a milling cutter selects a groove 50 mm wide and 30 mm deep;

-

a bar with a section of 50x60 mm is laid in the groove so that it is not clamped by the walls, but freely moves up and down;

Reinforcement of the opening in the log wall To exclude the weakening of the connections between the logs in the opening, their ends must be fastened together

-

in the door frame on the sides, a milling cutter cuts a groove with a width of 50 mm, with which it is put on a beam installed in the logs.

Mounting the door frame in a log bath It is necessary to mount the door frame in a log bath on an additional beam built into the opening

Video: how to properly cut an opening in a log wall (part 1)

Video: how to cut a groove and install a door frame (part 2)

Bath door insulation

Insulation is attached to the outside of the door leaf, between the crossbars. The thickness of the material must be such that it is flush with the keys. Basalt wool, glass wool or izolon are usually used.

The entire soft surface is sheathed with leatherette (leatherette, eco-leather) - it does not allow steam to pass through, so the insulation will last a long time. For a canvas with dimensions of 2000x800 mm, a leatherette cut of about 2120x920 mm will be required, so that there is a margin of 60 mm on each side.

If you need to insulate the bath door, then it is better to use a dense insulation, and then sheathe it with leatherette

To make the door appear convex from the side of the insulation, batting is spread over the heat insulator

The leatherette lining is nailed to the door leaf with carnations with large caps. On the front side, a wire or fishing line is pulled between them, which makes it possible to obtain a volumetric diamond-shaped pattern on the surface.

Video: how cheap and easy to insulate the door in the bath

The process of making a bath door is not difficult. Assembling the door yourself, you can make every effort and get a high-quality and durable product, while expensive branded doors often do not withstand difficult operating conditions and warp. You just need to carefully study all the recommendations again and boldly take up the tools.

Recommended:

How And How To Insulate The Ceiling In The Bath With Your Own Hands Outside And Inside

Insulation of the ceiling in the bath outside and inside. The materials used, the methods used, their advantages and disadvantages. Step by step description of the process

Bath Installation, How To Install The Bath Correctly

Do-it-yourself bath installation. How to install a bathtub, collect a drain and connect it to the sewer system. Installing a bathtub in a bathroom without specialists

Door Handles: Varieties And Characteristics, Pros And Cons, And How To Install Correctly

Purpose and design of door handles. Types of door handles, their pros and cons. Features of installation and repair of different types of door handles

Door Frame: Varieties And Material, Pros And Cons, As Well As How To Make It Correctly

What is a door frame. Types of door frames, their main dimensions. Manufacturing and installation of a door frame in the opening

How To Make A Door With Your Own Hands, What Material And Tools Are Best To Use, And Also How To Correctly Calculate

Features of self-production of doors of various types. Calculation of the structure. What are the best materials and tools to use