Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Furnace on liquid fuel or do it yourself working off

Often for a car enthusiast there is a problematic situation with the correct disposal of used engine oil, diesel fuel and other combustible elements from vehicle units and assemblies. So why not use mining to heat your own garage, especially since you can get it for nothing, and pollution to the environment is minimal. It remains only to make a stove that consumes this type of fuel with your own hands. Among car owners, this type of garage stove is quite well known and widely used.

Content

-

1 Oil-fired stoves

-

1.1 Advantages and disadvantages

- 1.1.1 Pros

- 1.1.2 Cons

-

- 2 Types

- 3 Furnace design

-

4 Drawing preparation and calculation of parameters

- 4.1 Materials

- 4.2 Tools

- 5 Choosing an installation location

-

6 Making a waste oil oven with your own hands

6.1 A good video on the manufacture and installation of a sheet metal furnace

-

7 Features of the operation of the stove during testing

-

7.1 Firing up the furnace

7.1.1 Video instruction for use

- 7.2 Security

- 7.3 Cleaning and repair

-

Oil fired stoves

The use of such stoves is typical for garages, utility rooms, country houses and other premises, mostly of a technical and economic nature, which do not require any special cleanliness and aesthetics.

Advantages and disadvantages

In general, stoves operating on liquid fuel perfectly fulfill their purpose, but just like other types of stoves, they have their own characteristics, including advantages and disadvantages.

pros

- Simple and cheap construction.

- Stoves heat up well small spaces such as garages, utility rooms and small country houses.

- A stove made according to the rules does not smoke and almost does not burn.

- Compact and mobile due to the lack of installation work.

- Fireproof, subject to the relevant safety rules. The oil is very difficult to ignite, only vapors are highly flammable.

Minuses

- Used engine oil should only be used filtered, free of impurities, as an explosive situation may arise.

- Presence of oil odor.

- The characteristic hum of the oven.

Views

Furnaces that use liquid fuels are fueled by diesel fuel or used engine oil. Furnaces using diesel fuel are produced mainly in an industrial way, although there are quite good home-made samples, while those working on mining are made handicraft in ordinary garage conditions. For self-production, a furnace using testing is best suited, due to the simplicity of manufacturing the structure and the cheapness of materials, since pipe sections of various diameters or metal sheets in the case of rectangular tanks can act as materials for the furnace. It is also possible to use out-of-date propane cylinders.

Industrial and handicraft ovens

Furnace design

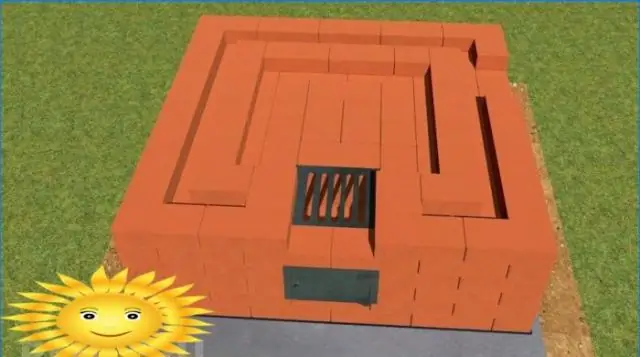

The design consists of two tanks connected by a perforated pipe. The upper tank has an offset relative to the vertical axis of the lower one. It is best to use the cylindrical shape of the tanks used, but in practice rectangular tanks are very often used and performance does not suffer from this at all. To give a working vertical position on the floor of the room, the structure provides for legs. Schematic diagram of the furnace in the figure below:

Furnace device for working out

The fuel combustion system in the stove works on the principle of pyrolysis - combustion of fuel vapors. Since the ignition point of engine oil is relatively high, its full combustion requires heating it with the formation of vapors, which subsequently burn in the furnace. To achieve this result, filtered waste is poured into the lower tank through the filling hole, filling it halfway and igniting. To quickly ignite the oil, add a few grams of gasoline or thinner to the filling hole.

In the process of gasoline combustion, the oil heats up and begins to evaporate from the surface, then the vapors ignite in the afterburner, and the furnace temperature goes into the pyrolysis combustion operating mode. In the fuel tank, which also serves as a firebox, oil is directly burned. The air required for the primary combustion is taken through the filler hole. An air damper is provided to regulate the combustion process. With the throttle fully open, the oil consumption will be approximately 2 liters. per hour, while in the slow combustion mode to maintain the operating temperature of about 0.5-0.7 liters. in hour.

The self-made working furnace is equipped with a vertical perforated pipe for the intake of air, which is necessary for the pyrolysis combustion process. Oil vapor trapped in the pipe, mixed with the incoming air, burns in it, and also partially in the upper tank. Further, the combustion products bypass the partition and are removed from the room through the chimney.

Drawing preparation and calculation of parameters

We will focus on the finished drawing of the furnace from pipe sections, since this material is the most accessible. The first step is to study the finished drawing and calculate the amount of material needed to make an oil stove. If the exact diameters are not available, which are indicated in the drawing, this is not critical, the main thing is the approximate size ratio. I advise you to print the drawing so that it is always at hand during the assembly of the oven.

Furnace drawing for working out

Materials

In this example, a propane cylinder is used as a material for the cylinders, but pieces of metal pipes of other diameters are quite suitable.

- Sections of the propane cylinder (pipe) according to the drawing.

- Afterburner pipe. Dimensions in the drawing.

- Sheet steel.

- Tubes for legs with a diameter of 20 mm or an angle.

Tools

To complete the work, you will need the following tools:

- Welding machine mask and electrodes, propane cutter (if available).

- Grinder with cutting and grinding wheels.

- Drill and drill with a diameter of 9 mm.

- A hammer, tape measure, pencil or marker.

- Protection for eyes and hands.

Choosing an installation location

The place of installation should be selected based on the location of windows, doors and the stove should be placed in the opposite corner from them. It is also worth paying attention to the convenience of removing the chimney outside. Taken together, these parameters for selecting a place for the furnace play a major role. On the walls, it is recommended to make reflectors of sheet metal or galvanized steel to improve heat transfer to the room and ensure fire safety. Do not forget about fire safety. When installing the stove in a room with a wooden floor, lay a sheet of tin on the installation site. For a concrete floor, it is also worth making such a bedding, since filling oil into the tank is highly likely to spill it, and such traces can no longer be removed on the concrete floor. It is in this case that a sheet of tin helps us out, because it will not be difficult to wipe off the spilled working off with an unnecessary rag from it.

Heat shield device on the walls

Making a waste oil oven with your own hands

Welding the elements together should be done as follows - first we go through the entire length of the joint with point tacks with a step of 3-4 cm, then we just weld the joint completely. Be sure to monitor the high-quality welding of the seam, otherwise oil will seep even into a microscopic crack

- We cut off pieces of pipes according to the dimensions from the drawing.

-

Using a cutter, cut out circles from pieces of sheet metal according to the dimensions of the drawing. In the absence of a propane cutter, you can burn metal with electrodes. You can also do this with a grinder, but this is quite long and unsafe, so it is better to use one of the other two options.

Blanks Stove blanks

-

After cutting out the bottom for the oil tank, cut off the same pieces of tubes for the legs and weld to it, this will simplify the subsequent assembly of the furnace. Square pieces of steel 5 * 5 cm can be welded onto the base of the legs for better stability.

Legs Welding the legs

-

We weld a piece of pipe to the bottom to form a fuel tank. First we cook with tacks every 3-4 cm and then we boil the joint completely.

Tank Fuel tank

-

The tank is collapsible and consists of two parts for easy cleaning of carbon deposits. Next, we assemble the lid of the tank from a piece of pipe and a cut-out circle of metal with two holes for a filling hole and an afterburner. The outer diameter of the pipe section for the lid should be slightly less than the inner diameter of the tank, thanks to which the lid will freely close it.

Cap Tank lid

-

The next step is to weld to the cover of the pyrolysis afterburner with pre-drilled holes in the body according to the diagram in the drawing.

Afterburner Afterburner welding

-

We weld the base and wall of the upper part of the oven. Here we repeat the steps described in point 4.

Top part Welding the top of the furnace

-

The next stage is the partition. In fact, this is just a strip of sheet steel 33 * 7 cm and 4 mm thick, but depending on your specific dimensions, its size may also vary. It is welded closer to the stove chimney hole.

Partition Welding the partition

-

We weld the lid by placing it on the top of the oven.

Cap Cover on top

- It remains to weld the chimney outlet. A pipe section with a diameter of 10-12 cm and a length of 13 cm is perfect for its role. At the end of the entire structure, a steel bar must be welded between the upper and lower tanks, thus providing additional rigidity of the structure. After completing all welding work, the welded seams must be cleaned with a grinder with a cleaning disc, from burrs and sharp edges, so as not to injure themselves during further operation of the furnace. The upper part can also be made collapsible by making it by analogy with an oil tank.

At the end of the assembly, it is imperative to check all welds for leaks using a soap solution and supplying compressed air to the cavity of the stove

By analogy, you can make a furnace from sheet steel with the only difference that the number of parts and welded operations will slightly increase, therefore, it does not make practical sense to describe it separately. Below is a drawing for a sheet steel furnace:

Drawing of the second version of the furnace

A good video on the manufacture and installation of a sheet metal stove

Features of operating the stove during mining

Kiln ignition

Before firing up the furnace, you first need to fill it with working off at least half a tank and top up with a few grams of gasoline or solvent on top. It usually takes no more than five minutes to warm up to operating temperature. On a piece of long wire, you need to wind a piece of paper, making a kind of wick, set it on fire, and carefully ignite gasoline through the hole for refueling the mining. Gasoline heats the oil to the temperature of evaporation of combustible substances, where they are further ignited. A stable combustion of oil vapors is formed in the perforated pipe. The intensity of combustion is regulated by covering or opening the filling hole, from where the air is blown directly.

Video instruction for use

Safety

No matter how reliable your stove may seem, you should not forget and always follow the basic fire safety rules:

- Do not leave a burning hearth unattended for a long time.

- Do not install the oven near flammable objects and materials.

- Do not place any objects closer than 0.5 meters from the oven.

- Check the chimney regularly for leaks.

- Use only pre-filtered waste as fuel without the slightest presence of water.

Cleaning and repair

In our case, only the lower tank will undergo regular cleaning, since unburnt components and soot are deposited there. To clean the tank, it is enough to remove the upper part from it and access is open. The walls are best cleaned with a hard metal object like a putty knife or a metal brush. After cleaning, the walls can be rinsed with a little gasoline and then dried. We put the entire structure in its place and you can use the oven again.

A stove on liquid fuel, in particular on used engine oil, is no more difficult to manufacture than an ordinary wood stove, and in some ways it is even simpler. Anyone with the skills of welding and working with metal is able to collect it in his garage, one might say, on his knee. In the cold season, such a stove will always be a lifesaver in the garage or in the country.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces

How To Make A Comfortable Computer Desk With Your Own Hands: Drawings, Diagram, Detailed Instructions + Video

Practical advice and recommendations for making a computer desk. Required materials and tools, step by step instructions

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation