Table of contents:

- A shop from a profile pipe: how to make it yourself

- Metal profile pipes as a material - advantages and disadvantages

- Drawings and dimensions of a metal bench with your own hands

- Recommendations for the choice of material

- Calculated part

- Do-it-yourself shop from a profile pipe - step-by-step instructions for making

- Tips for decorating and designing a metal bench

- Author Bailey Albertson [email protected].

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

A shop from a profile pipe: how to make it yourself

A shaped pipe of rectangular, square, rhombic or oval section is a popular material for industrial purposes, private construction, as well as the manufacture of interior elements for country cottages, private houses and summer cottages. The material of the profile section in terms of resistance to loads is significantly superior to standard round pipes, it is easy to process. The use of profiled pipes allows, at low cost, to create original decorative products - benches, swings, fences, gazebos, characterized by low weight and increased strength. Guided by proven recommendations, it is easy to make and decorate a metal bench with a simple design with your own hands.

Content

-

1 Pipes from a metal profile as a material - advantages and disadvantages

1.1 Photo gallery: benches and benches made of metal profiles

- 2 Drawings and dimensions of a metal bench with your own hands

- 3 Recommendations for the choice of material

-

4 Calculation part

- 4.1 Required materials

- 4.2 Applied tools and equipment

- 5 Do-it-yourself shop from a profile pipe - step-by-step instructions for making

-

6 Tips for decorating and designing a metal bench

6.1 Video: self-production of the original bench

Metal profile pipes as a material - advantages and disadvantages

The metal profile is widely used for the manufacture of benches. The material is made of carbon steel and has a number of positive characteristics:

- easy to process;

- resistant to stress;

- weldable well;

- differs in an affordable price;

- has a small mass.

Despite many advantages, a profiled pipe has some disadvantages:

- to give the pipe blanks a curvilinear shape, special equipment should be used;

- it is necessary to install plugs at the ends to seal the internal cavities of the pipe in order to prevent corrosion.

Photo gallery: benches and benches made of metal profile

-

Bench - The color can be chosen according to the taste of the owners

-

Bench - Bench in a strict classic style

-

Shop - Budget solution for a garden bench

-

Bench option - Good solution for the park

-

Garden bench -

A product with a strict design

-

Bench with forging - Forged elements add lightness to the bench

-

Colored bench - The combination of bright colors pleases the eye

-

Bench with decor - Original decor transforms the bench

-

Bench - Classic garden bench

-

Bench design - The original design of the garden bench

-

Shop -

Bench of strict geometric shape

-

Bench - Warm sunny color improves mood

Drawings and dimensions of a metal bench with your own hands

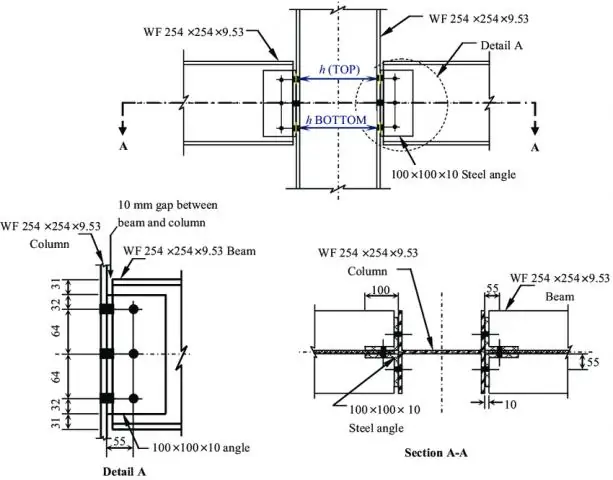

The design features of the product depend on individual requirements and are determined at the design stage. The profiled pipe is quite often used for the manufacture of the metal structure of the shop. The back and seat of the bench are trimmed with wood planks.

At the design stage, it is necessary to think over the features of fastening wooden planks and a scheme for cutting the blanks of a profile pipe. Depending on the relative position of the elements, the ends of the workpieces can be cut at different angles.

When developing a sketch, be guided by the following guidelines:

- the width of the supporting part of the bench should be in the range of 40-60 cm;

- a backrest height of 50 cm above the seat level will provide sufficient support space;

- the distance from the bottom of the bench to the seat support strips should be 40-50 cm.

You can make a bench that has a back.

The drawing contains all the required dimensions

It is more time consuming to manufacture. However, sitting down on such a bench, you can relax as much as possible and enjoy your rest.

The option of self-production of a small shop is possible. The product has a traditional design. The structure of the support frame requires a minimum amount of materials and is simple.

The product is simple in design

Recommendations for the choice of material

When purchasing a metal pipe with a profile section for the construction of a future bench, pay attention to its profile, wall thickness, and the presence of a weld

Pipes have different cross-sectional configurations

Along the cross-sectional profile, the cross-section of the pipe may have the form:

- square;

- rectangle;

- oval of traditional shape;

- oval with flat sides.

An important parameter is the wall thickness of the profile pipe. For example, a 40x20 mm rectangular pipe can have a wall thickness of 1.2 to 3 mm. Wall size affects material cost, finished product weight, and corrosion resistance. In addition, the welding of thin-walled pipes requires a certain qualification of the welding work.

Such a product can be used outdoors painlessly for more than 10-15 years.

The profiled pipe is produced using a seamless or electric welded method. Manufacturing is carried out by hot or cold deformation. The technology for manufacturing shaped pipes is not critical when choosing a material for making a bench.

Calculated part

Based on a pre-developed drawing, you can easily calculate the amount of materials and select the necessary tools for work

Necessary materials

Regardless of the chosen design of the bench, the following materials must be prepared for the manufacture of the product:

-

shaped pipe, the cross-section of which corresponds to the developed documentation. The material is used to make the power frame of the bench;

Pipes The section of the metal profile can be different

-

planks 20-30 mm thick made of coniferous wood. Planks or bars are needed to form the base and back;

Planks It is necessary to prepare workpieces of equal length

-

galvanized screws M6-M8 thread and 80-100 mm long, as well as nuts and washers. Hardware with a semicircular head are used to attach strips to a tubular frame.

Screw Square thrust bearing prevents the screw from turning when tightening the nut

Let's calculate the amount of materials for making a simple shop.

Minimum materials required for manufacturing

To make a bench with a size of 2.3x0.6x0.45, prepare:

- square pipe 30x30 mm with a total length of 10 meters;

- pine boards 30 mm thick and 100 mm wide - 5 pieces 230 cm long;

- bolts with a semicircular head M8x80 with nuts and washers - 10 sets.

The nomenclature of materials used for the manufacture of a bench with a back is slightly different

The need for materials is determined by the design of the bench

For self-construction of a bench 1.5x0.44x0.9 you will need:

- rectangular pipe 40x20 mm - 12 meters in total;

- bars 30x30 mm - 9 pieces of 150 cm;

- countersunk screws М8х100 with nuts and washers - 18 sets;

- steel foot pads 2 mm thick measuring 50x50 mm under the bench legs - 4 pieces.

The profiled pipe must be pre-cut into blanks corresponding to the drawing dimensions

To increase the service life of manufactured products, you will need:

- paint to protect the metal frame of the bench from corrosion;

- material for antiseptic wood processing;

- wood stain or varnish for finishing wood planks.

These materials will increase the resistance of the bench frame to corrosion, and will ensure the safety of the wood when used in high humidity conditions.

Applied tools and equipment

To carry out work on the manufacture of a bench of any level of complexity, you will need the following equipment and tools:

- welding machine complete with electrodes 3 mm in diameter;

- grinder with a cutting wheel for metal;

- electric drill with drills;

- sander (you can use a file and sandpaper);

- roulette;

- building level.

If radius blanks are used in the design of the future bench, then it is necessary to prepare a device for bending shaped pipes

The device allows you to smoothly bend the profile pipe

Do-it-yourself shop from a profile pipe - step-by-step instructions for making

Using the example of an ordinary shop, consider the manufacturing technology

It is quite simple to make such a bench.

The bench shown in the photograph, made of a square steel tube measuring 30x30 mm, is a simple structure of two rectangular supports connected by two bridges.

Carry out the manufacture and assembly of the elements of the bench, observing the following sequence of operations:

-

Mark the prepared material, which will speed up the manufacturing process and avoid mistakes.

Manufacturing stage A special template will make the markup easier

-

Cut the profile pipe into blanks of the required size, ensuring the required angle in the cut zone.

Pipe cutting The use of a grinder significantly speeds up the manufacturing process

-

Lay out the cut parts according to standard sizes, check the compliance with the drawing requirements.

Set of blanks After checking the dimensions, you can start welding

-

Tack the prepared workpieces for two rectangular supports.

Tacking supports A special device will facilitate the welding process

- Check for right angles by matching the diagonals of the rectangle.

-

Finally fix by welding the elements of the rectangular support structure.

Bench support Overlapping pipe welding option

-

Weld the two straps to the supports to match the drawing dimensions.

Manufacturing stage This seam will provide a secure fit.

- Grind the weld seams thoroughly using a sander.

- Cut wooden blocks to fit the size of the supporting metal structure.

-

Mark the attachment points of the wooden blocks, drill holes for their attachment, remove burrs.

Manufacturing stage No burrs on holes after deburring

- Saturate the wooden seating with an antiseptic, after which you can use a stain or varnish.

-

Cover the metal frame with primer followed by a layer of protective enamel.

Coloration You can use a brush to apply the protective coating

- Secure the wooden seat pieces using a hardware kit.

Having mastered the elementary technology of making an ordinary bench, it is not difficult to make a bench with a back. The algorithm for performing the work is completely similar, except for the need for additional fastening of the backrest strips, installation of armrests (if they are provided for by the documentation) and foot pads.

Tips for decorating and designing a metal bench

The traditional finish of the bench involves coating the metal part with paint, and the wood with varnish. Painting is definitely necessary. It increases the service life of the bench, reliably protecting the metal from corrosion. Moisture-sensitive wood should be thoroughly impregnated with compounds that prevent the formation of mold and mildew. After that, you can cover with a clear varnish for outdoor use.

Traditional finishing options - black paint and colorless varnish

Various design options are possible:

-

you can treat the boards of the bench with wood stain or varnish, creating an imitation of valuable varieties of wood;

Bench Dark lacquer imitates hardwood

-

having an artistic taste and using colored paint, you can make an original drawing or intricate patterns on a bench;

Bench finish option The combination of the pattern on the slats with the back design looks harmonious

-

the use of decorative inserts or forging elements allows you to implement non-standard ideas for the design of a garden bench.

Bench with decorative elements Uncomplicated floral ornament transforms an ordinary bench

It is necessary to make the right decision on the decoration and decoration of the shop. Only with a balanced approach and a well-thought-out concept of decoration, an ordinary product will become an original decoration of the recreation area, attracting numerous views.

Video: self-manufacturing of the original bench

The video below shows in detail the manufacturing process of a bench with armrests.

Regardless of the chosen design of a bench for a private house or a summer cottage, the use for the manufacture of shaped pipes reduces the cost of manufacturing a product. The material allows you to create benches with an original design. Self-made shops are difficult to distinguish from industrial designs in appearance. It is important to follow the technology, to carefully consider the concept of the future bench. In this case, she can become a real decoration of the suburban area.

Recommended:

How To Make A Children's Swing In The Country With Your Own Hands (made Of Wood Or Metal, Drawings, Photos And Videos)

Step-by-step instructions for the construction and installation of a swing at a summer cottage. Material selection, tools, model drawings

How To Make A Bar Stool With Your Own Hands From Wood, Metal And Other Materials + Drawings, Photos And Videos

Bar stools manufacturing options. Required tools, materials used. Step-by-step description of the manufacturing process with a photo

How To Make A Veranda With Your Own Hands To The House - Instructions, Projects, Drawings, Photos And Videos

The article describes how to build a veranda close to the house with your own hands

Do-it-yourself Canopy Construction From A Profile Pipe - Drawings, Instructions With Photos And Videos

How to build a canopy from a profile pipe with your own hands: drawings, structural calculations, step-by-step instructions for construction and decoration, photos and videos on the topic

How To Make A Chimney From A Steel Pipe With Your Own Hands: Device, Installation Of A Sandwich Structure, Instructions With Photos And Videos

What is a steel pipe chimney, where is it used, its advantages, disadvantages and its manufacture by hand