Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Application and features of liquid roofing rubber

One of the universal waterproofing materials for roofs is liquid rubber. Such a composition has high efficiency and a number of other advantages, but it requires proper application for good protection of the roof from moisture.

The history of liquid roofing rubber

A material such as liquid rubber appeared in Russia relatively recently. In 2005, manufacturers gradually introduced this compound to the market, actively promoting it as a durable seamless waterproofing for roofs. For several years, the composition has been supplied from abroad, for example, from Canada. Later we got brands of goods from Israel. By 2011, Russian manufacturers have mastered the technology of manufacturing liquid rubber for the production and application of the product.

Liquid formulation forms an even, durable, wear-resistant coating

Currently, domestic companies have fully mastered the technology for the production of liquid rubber, and its composition is constantly being improved. This takes into account the climatic conditions of different regions of the country, the method of application, service life and other parameters. Thus, liquid rubber from Russian manufacturers is a waterproofing agent that best suits the country's climate and consumer needs.

Features and characteristics of liquid rubber

Liquid rubber is a product based on polymer bitumen dispersed (crushed to a powdery state and dissolved) in water. The composition has the following properties:

- high level of elasticity;

- environmental friendliness of the finished coating;

- resistance to mechanical stress;

- service life from 10 years;

- preservation of properties at low temperatures;

- easy application and simple technology.

Liquid rubber is applied by spraying and forms a thin layer on the roof surface

One of the main features of liquid rubber is the high adhesion of the compound. The mass is easily and carefully fixed on any surfaces. After curing, a durable coating is formed that is resistant to stretching and other influences. Liquid rubber is versatile and can be used both for roofs of residential buildings and for industrial structures.

Types of liquid rubber

The classification of liquid rubber is carried out depending on the method of application of this product:

- the bulk composition is applied by pouring, after which the mastic is leveled manually using special rules or other suitable tools;

- the sprayed material is applied using special spray equipment mechanically;

- painting technique of application involves the use of a brush, roller or spatula.

The filling layer of liquid rubber is leveled using the rule

The cost of liquid rubber is determined by various factors, but the main one is the type of product, which can be one- or two-component. The first option is optimal for sealing and waterproofing roofs and foundations; it is an elastic, thin and durable coating. Two-component products are used to equip a mastic membrane.

Equipment for applying liquid waterproofing

The treatment of large surfaces with liquid rubber is most often done by spraying, which allows the agent to be applied evenly over the entire surface. Regardless of the method of treatment, the roof must be cleaned, leveled and dried. Cracks, surface defects are repaired with a cement screed or other suitable materials, depending on the type of roof.

In order to obtain a flat roof surface, it must be thoroughly cleaned and dried before processing with liquid rubber.

To apply the liquid composition, special equipment is used, the principle of operation of which is similar to that of a conventional spray gun. In this case, two containers are used, one of which contains a bitumen-polymer emulsion, and the other contains a hardener with a calcium chloride base. The composition is fed from these reservoirs using a two-channel gun, in which the components are mixed.

Liquid rubber coating is carried out using special equipment in which the components of the composition are mixed

The average thickness of the sprayed coating is 2-4 mm. If necessary, liquid rubber is laid in several layers, applying each next layer after the previous one has dried.

Video: applying liquid rubber to the roof

Application rules

There are certain rules for each method of applying liquid rubber. It is important that the surface to be treated must be clean, dry, free of dust and debris. The painting technique involves a simple application of the composition to the surface. When pouring funds, use a special tool called a rule. The device allows you to create a flat surface. When painting and filling equipment, the following features of the work are taken into account:

- the bulk method is often only one layer of rubber. If it is necessary to install a coating of greater thickness, you need to wait until the previous layers dry;

- liquid rubber for the painting method is applied with a wide brush or roller, carefully distributing the composition over the surface;

- seams, joints and other complex areas are especially carefully processed;

- areas that do not need processing (ventilation holes, windows, etc.) should be protected with a film, attaching it with tape.

Video: an example of using Elastomix liquid paint

Spraying technique

It is always important to observe the general requirements for work. The spraying technique is the most difficult, since it requires a mobile spray gun and containers for automatic mixing of components. In the case of a filling or painting technique, it is enough to prepare tools with which the mixture will be leveled on the surface. For this purpose, a rule is suitable, a brush, a spatula.

Liquid rubber can be applied with a brush on vertical surfaces

The main stages of applying liquid rubber by spraying:

- Cleaning and leveling the roof surface.

- Preparing containers with components, connecting the system to the mains.

- Surface treatment starting from the corners of the roof.

- Application of the next coats after drying the first one (if necessary).

Before starting work, you should determine the application method depending on the type of product. Spraying is optimal for two-part compound, and one-part rubber can be applied with a roller, brush or trowel. This is due to the fact that the double composition dries very quickly and manual application does not allow for a high-quality surface treatment.

Video: processing a metal roof with liquid rubber

Liquid rubber is a practical and effective compound that is optimal for waterproofing different types of roofs. Knowledge of the technology of its application and the correct choice of a suitable product allow creating a durable protective coating without defects.

Recommended:

Apricot Red-cheeked: Description And Characteristics Of The Variety, Advantages And Disadvantages, Planting And Care Features + Photos And Reviews

Rules for growing apricot varieties Krasnoshekiy: planting, plant care. Pest and disease control

Pear Chizhovskaya: Description And Characteristics Of The Variety, Advantages And Disadvantages, Planting And Care Features + Photos And Reviews

Features of the Chizhovskaya pear variety. Rules for growing and caring for the crop. Gardeners reviews

Pear Lada: Description And Characteristics Of The Variety, Advantages And Disadvantages, Planting And Care Features + Photos And Reviews

Pear Lada belongs to the early summer varieties. Differs in juicy fruits for universal use. The tree is unpretentious in care, gives stable high yields

Apple-tree Melba: Description And Characteristics Of The Variety, Advantages And Disadvantages, Planting And Care Features + Photos And Reviews

The Melba apple tree has been popular all over the world for almost a hundred years. And success is not only due to the taste of the fruit. How to care for a tree to get a consistent harvest?

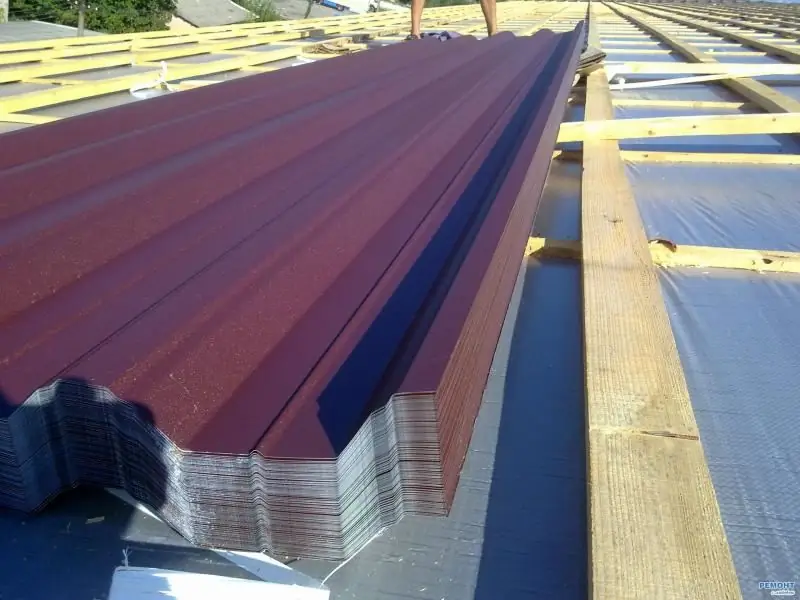

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size