Table of contents:

- How to make a potbelly stove for a garage with your own hands

- Advantages and disadvantages of a potbelly stove for a garage

- Design and working principle

- Calculation of the main parameters (with drawings and dimensions)

- Required materials and tools

- Preparatory work before assembling the furnace: choosing a place

- DIY step-by-step instructions for making a potbelly stove for a garage

- Features of operation

- How to improve oven performance

- How to properly clean a stove

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

How to make a potbelly stove for a garage with your own hands

Very often, it is a stove stove that is used to heat the garage. And you can do it yourself, but you do not need to spend money for this. It is enough to look for unnecessary metal parts in the bins.

Content

- 1 Advantages and disadvantages of a potbelly stove for a garage

- 2 Design and principle of operation

-

3 Calculation of basic parameters (with drawings and dimensions)

- 3.1 Pipe

- 3.2 Screen

- 3.3 Litter

- 3.4 Chimney

- 3.5 Photo gallery: diagrams of a potbelly stove for a garage

- 4 Required materials and tools

- 5 Preparatory work before assembling the oven: choosing a location

-

6 Step-by-step instructions for making a potbelly stove for a garage with your own hands

-

6.1 Classic stove-potbelly stove

6.1.1 Video: do-it-yourself original potbelly stove for a garage

- 6.2 Milk can oven

- 6.3 Video: potbelly stove for a garage from a gas cylinder

-

- 7 Features of operation

- 8 How to improve oven performance

- 9 How to properly clean the stove

Advantages and disadvantages of a potbelly stove for a garage

A stove-stove is considered to be the most practical way of heating in winter. This is a small structure, which is practically portable, capable of heating any room in terms of area, regardless of the temperature outside and other climatic conditions. This is its main advantage. However, in modern conditions, a stove-stove is used exclusively for heating outbuildings, for example, a garage. And this is due to a large number of disadvantages:

- the stove cools down quickly, which means that in order to maintain a constant temperature in the room, it must always burn;

- uneconomical for the same reason;

- is fire hazardous, so when installing it, you need to take care of protecting the nearby wall and floor.

However, its omnivorous nature allows you to save a little on the purchase of fuel, especially considering the almost 100% efficiency of such a device.

The potbelly stove has a special design, thanks to which you can get high efficiency

Design and working principle

The peculiarity of the potbelly stove is that it does not require the construction of a foundation and the arrangement of a capital chimney. In most cases, it is because of this that it is chosen for use in the garage. This room does not always have electricity or a gas pipeline, which means that a stove-stove is the only solution to the heating problem.

Potbelly stove does not require the construction of a foundation

This design is a metal box with a door and a pipe, which is taken outside the heated room.

Calculation of the main parameters (with drawings and dimensions)

The high efficiency of a stove-stove can be obtained only if all the basic parameters of the structure are correctly calculated.

Trumpet

In this case, the diameter of this element is very important. The throughput of the chimney should be less than the capacity of the furnace, which is the main distinguishing feature of the potbelly stove. This will allow warm air not to immediately leave the stove, but to linger in it and heat the surrounding air.

It is very important to make an accurate calculation for it. The diameter should be 2.7 times the volume of the furnace. In this case, the diameter is determined in millimeters, and the volume of the furnace in liters. For example, the volume of the combustion part is 40 liters, which means that the diameter of the chimney should be about 106 mm.

If the installation of grate is provided in the stove, then the height of the firebox is considered without taking into account the volume of this part, that is, from the top of the grate.

It is very important to correctly calculate the diameter of the stove pipe

Screen

It is very important to make the hot gases not cool down, but completely burn out. In addition, the fuel must be combusted by partial pyrolysis, which requires an extremely high temperature. A metal screen, which is located on three sides of the stove, will help to achieve this effect. It should be placed at a distance of 50-70 mm from the walls of the stove, so that most of the heat will return to the stove. This movement of air will give the required high temperature, and will save you from fire.

Red brick stove screen is capable of accumulating heat

Litter

It must be there. There are two reasons for this:

- some of the heat is radiated downward;

- the floor on which the stove is standing heats up, which means there is a risk of fire.

Litter solves these two problems at once. It can be used as a metal sheet with an offset of 350 mm (ideally 600 mm) beyond the contour of the furnace itself. There are also more modern materials that do an excellent job with this task, for example, a sheet of asbestos or kaolin cardboard, at least 6 mm thick.

For litter under the stove, you can use an asbestos sheet

Chimney

Despite all the calculations, gases sometimes go into the chimney not completely burned out. Therefore, it must be done in a special way. The chimney consists of:

- the vertical part (1-1.2 m), which is recommended to be wrapped with heat-insulating material;

- hog (slightly inclined part or completely horizontal), 2.5-4.5 m long, which should be 1.2 m from the ceiling, which is not protected by heat-resistant materials (1.5 m from the wooden surface), from the floor - by 2.2 m.

The chimney must be brought out into the street

Photo gallery: diagrams of a potbelly stove for a garage

-

Circular stove scheme - On the diagram, you need to indicate all the exact measurements

-

Chimney outlet diagram - The chimney must be brought out to the street

-

Drawing of a stove-stove - The potbelly stove can be round or square

-

The scheme for calculating the volume of the furnace - The volume of the firebox depends on the presence of grates

-

Diagram of a homemade potbelly stove - The potbelly stove scheme depends on the material used

Required materials and tools

To make a potbelly stove with your own hands you will need:

- welding equipment (or any other welding machine, if you have relevant experience);

- chisel;

- soft cloth (you can use a rag);

- a hammer;

- sandpaper (fine-grained).

The list of materials depends on which container the stove will be made from. This can be a gas bottle or a milk bottle. If you have some experience with metal, then a potbelly stove can be made from sheet material. However, you definitely need to take care of the availability:

- refractory bricks;

- steel pipes;

- metal wire;

- grate bars (in some cases, you can do without them);

- a branch pipe with a vane;

- door hinges.

Preparatory work before assembling the furnace: choosing a place

Using a potbelly stove in the garage, like any other heating device, requires compliance with safety rules. First of all, this concerns the installation site of the device. The corner of the garage is ideal for this, which is located near the walls opposite to the door of the room.

Remember not to put the stove in the immediate vicinity of the car. The distance between them should be at least 1.5 m. The same distance should be from objects that are easily flammable, for example, from barrels of gasoline.

The walls near the stove must be protected with fireproof material

The distance from the stove to the wall depends on what material the garage is built from. If it is a tree, then there should be at least 1 m from the stove to the wall. Additionally, it is recommended to protect them with asbestos plates.

DIY step-by-step instructions for making a potbelly stove for a garage

The method of making a stove-stove depends on its shape and the material used.

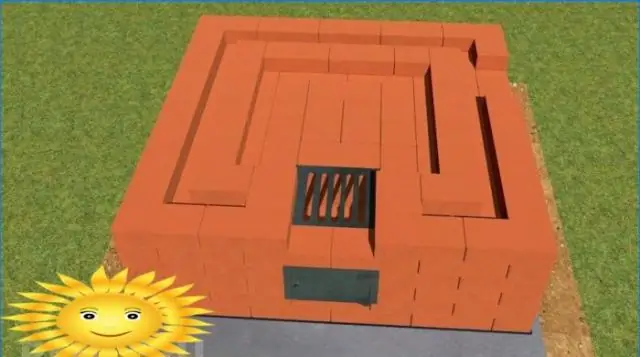

Classic stove-potbelly stove

For the manufacture of such a structure, you must have certain skills in working with a welding machine. All work consists of several steps:

-

Make 5 blanks from sheet metal.

Stove blanks Blanks need to be cut from sheet metal

- Weld the side surfaces to the bottom. Make sure that they are located strictly vertically relative to each other, which will help the use of a level or construction square.

- Weld the back wall.

- The internal space is conditionally divided into three parts: smoke circulation, furnace part and ash pan. Install a grate in the last two. To do this, at a height of 10-15 cm, the corners must be welded to the entire length. For the grating itself, it is recommended to use 25-30 mm thick sheet steel from which strips must be cut. The distance between the plates should be 5 cm. The rods themselves must be welded to two rods, which give rigidity to the grate.

-

From above, it is necessary to weld two metal rods, which are needed to position the reflector (the sheet that separates the firebox and the smoke circulation), the reflector must be positioned in such a way that a channel for smoke is formed.

Grate and reflector The grate and potbelly stove are optional

- Weld the stove cap, not forgetting about the hole for the pipe. Cut and weld the top link. Do the same with a narrower part.

-

Make a door. It is recommended to do it over the entire width of the stove so that the grate and reflector can be removed without any problems during cleaning and repairs. Do not forget that the door must be equipped with a handle, latch and curtains.

Potbelly stove with open door It is recommended to make the door as wide as possible

- Install the structure on the legs, which can be made of a metal pipe with a diameter of 2-3 cm. You should not make them too high. 8-10 cm will be enough. If desired, you can equip them with bolts, which will allow you to adjust the height.

-

Make a chimney from a pipe with a diameter of 15-18 cm. For its outlet, you need to make a hole in the wall of the appropriate size. The pipe consists of three parts, which are interconnected at an angle of 45 °.

Pipe for potbelly stove The pipe must not have horizontal parts

- At the lower end of the chimney, a rotary damper must be made. You can also make it from sheet metal, but the diameter should be slightly smaller than the hole in the pipe. It is also necessary to provide for a handle that would move this damper.

- The pipe must be fixed on a 15-20 cm sleeve, which is welded along the hole to the top cover.

-

Install the stove, adjust its height.

Square stove-potbelly stove When using sheet metal, you can make a stove of any size

Video: do-it-yourself original potbelly stove for a garage

Milk can oven

It is quite easy to make such a furnace, you just need to follow the step-by-step instructions:

- Carefully prepare a container that will serve as a furnace for the furnace. To do this, you need to clean the inner walls of the can from dirt and rust, if any.

- Knock out a hole in the body of the future potbelly stove through which fuel will be loaded. This can be done with a chisel and hammer.

- Fasten the door hinges to the body, then you can install the door. Do not forget to make a hook that will hold the door closed.

- A round hole must be made in the bottom of the container, which will serve for the chimney. The diameter of this hole must be about 10 cm.

- Install a grate made of serpentine wire (in this case, it is recommended to choose just this one). You can make it yourself. Why bend the steel wire several times and put it inside the prepared milk can. First, you need to take care of the supports from the reinforcing bar for the grates, which must be welded to the walls of the container.

-

Weld the chimney.

Potbelly stove from a milk tank Making a potbelly stove from a milk tank is quite easy

- Install the stove in the prepared place. A foundation is not required for this, however, you can make a small support from red brick without using cement mortar.

- Lay a fire-brick screen around the stove. This will increase the efficiency of the potbelly stove.

Video: potbelly stove for a garage from a gas cylinder

Features of operation

During the operation of a homemade stove, it is very important to follow certain rules. This is necessary not only for the safety of its use, but also for a long service life. These rules are:

- it is necessary to maintain a safe distance between the walls of the furnace itself and the walls of the room (a distance of 50 cm is considered ideal);

- the chimney must be brought out to the street, in no case should it be coupled with the garage ventilation system (very often this desire arises when the stove is installed in the basement of the garage), since this is the only way to guarantee sufficient traction for full combustion;

- places where the pipe is taken out into the street must be insulated with asbestos or other non-combustible material;

- it is possible to increase the efficiency of a potbelly stove by insulating the room itself;

- next to the stove, it is necessary to install a box with sand and a fire extinguisher, since this is required by fire safety rules.

How to improve oven performance

Such a furnace has one significant drawback - it cools down very quickly. However, it is very easy to fix this with a brick screen that is installed on three sides of the structure. This will allow you to accumulate heat and give it to the room even after the stove stops burning.

It should be positioned at a distance of 5-7 cm from the walls of the stove, in no case right next to it. In this case, you need to take care of the presence of ventilation holes.

The screen should not be close to the walls of the stove

A structure with a brick screen will weigh much more than an ordinary metal stove-stove, therefore it is recommended to first build an individual foundation.

In some cases, it may be necessary to install an individual foundation. It's very simple to make it:

- Dig a hole about 50 cm deep. All other dimensions depend on the dimensions of the stove itself and the screen.

- Fill the bottom of the pit with sand (usually it takes about 3-4 buckets), after which it must be tamped. Cover the sand with a layer of crushed stone 10-15 cm, also tamp.

- Level the backfill, fill it with the prepared cement mortar. Leave it for a day (it is possible for a few, the foundation will only benefit from this).

- Cover the base with several layers of roofing material.

- Now you can start laying the screen on the brick floor. In this case, the first two rows should be laid out with continuous masonry directly on the roofing material. In rows 3-4, it is necessary to make ventilation gaps. Continue continuous laying.

- It is recommended to make the screen without overlapping.

How to properly clean a stove

The design features of such a stove make it possible to clean it quite rarely.

This is one of the advantages of a potbelly stove. However, from time to time, the chimney must be cleaned of soot residues. For this, you can use a special brush. You can do it yourself. Attach a cylindrical brush to the rope. A plastic or iron bristled brush is recommended. In this case, you need to pick it up in such a way that it squeezes into the narrow chimney pipe without problems.

For a potbelly stove, it is recommended to take a brush with plastic bristles

The cleaning process itself takes place in the following sequence:

- Close the opening of the firebox and plug it with a rag.

- Make several movements with the brush (you need to stop when the brush began to move without resistance). Wait.

- Take out all food that has gone down to the sump.

All this must be done extremely carefully, since the chimney of the stoves is not very strong.

A homemade potbelly stove in the garage can be a reliable and effective assistant in the fight against winter frosts. And if you do it yourself, then the efficiency of the device can be increased many times.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Gazebo Out Of Wood With Your Own Hands - Step-by-step Instructions With Photos, Drawings And Video

A gazebo made of wood, who has not dreamed of having it? Now you have such an opportunity, read and get to work on making the structure yourself

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation