Table of contents:

- Author Bailey Albertson [email protected].

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

Types and characteristics of roofing materials

The roof should protect the building from precipitation, cold and other natural influences, and also provide an aesthetic appearance of the house. When arranging a roof, it is important to choose the right coating from materials that are presented in a wide variety and differ in their properties and characteristics.

Content

-

1 Kinds of materials for roofing

1.1 Photo gallery: types of roofs with different coatings

-

2 Characteristics of modern roofing materials

-

2.1 Galvanized steel sheets

2.1.1 Video: why you shouldn't cover the roof with galvanized metal

- 2.2 Copper roof

- 2.3 Coating of polyurea or polyurea

- 2.4 Roof covering made of piece materials

-

2.5 Asbestos-cement corrugated sheets for roofs

2.5.1 Video: Slate is an excellent roofing material

- 2.6 Plastic roof coverings

- 2.7 Timber roof

- 2.8 Zinc-titanium roofing

-

2.9 Slate roofing

2.9.1 Video: slate roof

-

-

3 Comparison of popular roofing materials

3.1 Table: Comparison of roof materials

-

4 How to choose the best roofing material for a private house

- 4.1 Video: the pros and cons of various roofing materials

- 4.2 Reviews of different materials for the roof

Varieties of materials for the roof

Among all the variety of roofing materials, it is important to choose a coating that best suits the operating conditions, safety and aesthetics requirements. To do this, you need to familiarize yourself with the assortment of materials that are produced by well-known manufacturers.

The most common roofing materials are various types of tiles: ceramic, cement-sand, metal and bituminous.

Roofing coverings are made from different types of metals, bitumen and fiberglass, cellulose or plastic. In many cases, a protective polymer coating is applied to the base, which makes the material durable and aesthetic. The structure of the coatings is also different. Roofing materials can be of the following types:

- piece in the form of separate small elements, during installation, forming a solid coating;

- folded, in which sheets of metal are connected to each other by a sealed seam;

- sheet, the installation of which involves the fastening of large sheets of coating to the roof with an overlap;

- self-leveling or mastic structures with a liquid consistency and suitable for flat surfaces;

- soft roofs - bituminous tiles and other similar materials.

Modern technologies make it possible to manufacture traditional types of coatings not only from natural materials, but also from polymer composites, providing new options for colors and shapes

When choosing, you need to take into account the brand and manufacturer of the material. High-quality and durable products cannot be too low cost in comparison with products of the same type from well-known factories.

Photo gallery: types of roofs with different coatings

-

Pitched roof tile - Polymer shingles are practical, durable and varied in color.

-

Complex roof of a residential building - Bituminous shingles can be easily mounted on any roof shape

-

The original soft roof of the building - It is very convenient to arrange cone-shaped roofs with bituminous tiles.

-

Bright roof of the house -

Metal roofing can be selected in any desired color scheme

-

Natural tile roof - Clay tiles are a classic natural finish

-

Hip roof with ledges - Sand-polymer shingles allow you to create an airtight coating on roofs of complex shapes

-

Gable roof with attic window - Metal tiles can have waves of different shapes

Characteristics of modern roofing materials

Roofing manufacturers produce many materials that differ in appearance and other characteristics. The main parameters that you should pay attention to when choosing are the following:

- service life during which the material retains its properties and appearance;

- resistance to humidity, ultraviolet rays, temperature extremes, mechanical stress;

- installation technology and the necessary conditions for the correct laying of this or that material;

- the level of sound insulation that characterizes the coating.

Polymer-sand tiles have a long service life and provide a reliable roof covering with a high level of hydro and sound insulation

The main thing when choosing is the compliance of the characteristics of the coating with the operating conditions. After selecting the types of material suitable for these parameters, you should pay attention to the design, color and shape. When arranging roofing, you can combine materials of different colors, creating a unique decorative design of the building.

Galvanized steel sheets

One of the simplest and most inexpensive coating options is galvanized steel. Flat or profiled sheets with different wave heights are produced from it. Flat elements are used for constructing a seam roof, profiled ones - overlapping without the formation of complex locks. Galvanized sheets have a silver color, ideal for gable roofs with an angle of 18-30 o. If the slope of the slopes is less, then sediments will accumulate on the surface, which contributes to metal corrosion.

Flat galvanized sheets have special shelves on the long side, which are folded with a special tool and form a strong and durable connection

Installation of galvanized steel sheets is carried out on the crate, laid on top of the waterproofing film and rafters. Insulation can be located from the inside of the roof, which is important for mansard roofs with a living attic space. For the organization of roofing, galvanized steel sheets with the following characteristics are suitable:

- sheet length from 710 to 3000 mm, width - from 510 to 1250 mm, thickness - from 0.8 mm;

- the thickness of the zinc layer is not less than 0.02 mm;

- no defects in the zinc coating - the presence of scratches can lead to metal corrosion.

Galvanized steel is rarely used for roofs of residential buildings, as it has poor resistance to corrosion, mechanical stress and does not meet modern design requirements. Typically, such coatings are chosen for farm buildings, baths and other auxiliary buildings.

Video: why you shouldn't cover the roof with galvanized metal

Copper roof

Copper is one of the most durable and reliable materials. From this metal, manufacturers produce tiles and sheet roofing materials that provide roof protection and an attractive building appearance. Copper coatings have a service life of up to 200 years and a low specific weight - 6-7.5 kg / m 2.

The copper roof initially has a reddish color, and over time it becomes covered with a noble greenish coating, for which it is appreciated by true lovers of prestige and comfort

Copper roofs can be tiled or folded. In the first case, small elements in the form of squares or semicircles are laid on the prepared roof area. Each option allows you to get an effective finish, but it is important to carefully fix the piece parts. If a seam roof is equipped, then copper sheets with a lock fastening - a seam are used. It can be single or double, and the second option is much more durable and airtight, but requires the use of additional tools. The thickness of the copper sheets for the seam cover device must be at least 0.8 mm.

Polyurea or polyurea coating

Polyurea or polyuria is a thick and elastic film that forms a monolithic coating. The material is applied to the surface in liquid form by spraying, and then solidifies. It contains two main components: resin and isocyanite. The polyurea coating has no seams, is durable and resistant to climatic and mechanical influences.

Polyurea is applied by spraying on the prepared surface

Polyurea has good waterproofing properties and is widely used in construction. The tensile strength of the film is about 38.5 MPa, it can be applied at temperatures above -20 o C, while the surface moisture does not affect the strength of the film, but negatively affects the adhesion of the composition to the base. It is also worth considering that there are two types of polyurea: hybrids and pure formulations. The first option has only a part of those properties that are inherent in expensive pure options.

Roof covering made of piece materials

The piece roofing materials usually include ceramic or sand-cement tiles. The elements of the cover are fixed on slopes with a slope of 25 to 60 o. Pre-create a crate with a step slightly smaller than the width of the elements.

Ceramic tiles are attached to the base with roofing nails or self-tapping screws, so the pitch of the lathing should be slightly less than the length of the covering element

Clay elements have a protective coating that prevents the negative effects of moisture and ultraviolet radiation. The material is manufactured by the method of forming from a special mass with further pressing and firing. The average weight of 1 m 2 of material ranges from 20 to 40 kg and depends on the type of tile, therefore, the rafter system for such a coating must have sufficient bearing capacity.

Asbestos-cement corrugated sheets for roofs

Slate or asbestos-cement sheets are made from a mixture of asbestos, Portland cement and binders. One sheet of such material weighs 10-15 kg, its length is 1750 mm, and its width varies from 980 to 1130 mm. The number of waves on one sheet can be from 6 to 8. The elements are fastened on slopes with a slope of 12-60 o with an overlap in one wave. As a base, a lathing of 5x5 cm bars is used, the step between which is 50-55 cm.

The slate is fixed with special nails with sealing washers, which protect the attachment points from leaks

Asbestos-cement sheets are characterized by low cost and fragility, because their service life does not exceed 40 years. Therefore, slate is often used to equip the roofs of outbuildings. Over time, the material loses its safety margin and can be damaged from a light impact or as a result of a sharp temperature drop. Before laying corrugated sheets, mount a lining of glassine or roofing material.

Video: slate is an excellent roofing material

Plastic roof coverings

Manufacturers produce several options for plastic materials that are low cost and allow you to create a high-quality roof covering for a gazebo, utility room, veranda or shed. For these purposes, you can use sheets of plastic sheeting or polycarbonate. In the first case, the material has a thickness of 2 mm, and the length of the sheet can be up to 30 m, which is important for overall flat roofs. If plastic polycarbonate is used, then it has a honeycomb structure, which provides good thermal insulation of the room under the roof.

Plastic corrugated board completely repeats the shape of its metal counterpart, but has lower quality characteristics, therefore it is mainly used on outbuildings

Plastic corrugated board differs from polycarbonate in higher light transmittance, ease of installation and low cost. Polycarbonate is more expensive and requires a neat fit. Materials can be colored, fully or partially transparent.

Wood roof

A rare, complex and beautiful option is a shingle covering, which is rectangular or semicircular wood elements. It belongs to piece roofing materials, and the weight of 1 m 2 is no more than 16 kg. Shingle production involves careful selection of high density wood, splitting into chips and 10 technological operations for processing each element. As a result, flat figured parts are obtained, which are used for arranging the roofing.

Wooden shingles belong to exclusive roofing coverings and are more suitable for regions with warm climates

For roofs with an area of 100-500 m 2, shingles with a length of 40 cm are used. There are also products with a length of 45, 50 and 60 cm. The width of the parts can vary from 6 to 20 cm. The material is optimal for arranging slopes with a slope of 20-90 o, for a residential building it is laid in three layers, and for gazebos, two layers of shingle are enough. To install a wooden roof, waterproofing is placed on the rafter system, then a boardwalk is equipped with edged lumber, and then a sparse sheathing with a pitch of 165-340 mm (depending on the size of the roofing element and the number of layers), on which the shingles are mounted.

Zinc-titanium roof

Zinc-titanium alloy, alloyed with copper and aluminum, is the basis for creating metal roofing elements that serve as a strong and durable roof covering. This material is used to create sheets for standing seam roofing or tiled shingles. They are mounted on a crate, equipped over a waterproofing layer.

Zinc-titanium alloy metal sheets provide a long-lasting roof covering with unique anti-corrosion properties

The characteristics of zinc are increased by the alloying method: it gives the desired ductility and high strength. Zinc-titanium alloy consists of the following components:

- pure zinc - 99.71%;

- titanium - 0.17%;

- copper - 0.12%.

For the manufacture of roofing sheets used. On sale the material is presented in sheets and rolls. Zinc-titanium roofing differs from most other coatings in durability, strength and resistance to mechanical stress.

Slate roof

Slate roofing is an expensive and sustainable option. Tiles for such coatings have a thickness of 4 mm, a weight of 25 kg / m 2, a width of 15 or 30 cm, a length of 20 or 60 cm. The material is of natural origin, and the tiles are processed manually, and this is due to the high cost of slate roofing.

Slate roofing is durable and has an exclusive look

Rectangular slate elements are laid on a crate equipped over waterproofing and rafters. Parts are fastened with galvanized or copper nails, the number of which depends on the slope.

- with a slope of less than 40 o, 2 nails will be needed;

- for steeper roofs 3 attachment points are required.

With proper installation, a slate roof will last more than 100 years and will not lose color or resistance to UV and humidity.

Video: slate roof

Comparison of popular roofing materials

A large selection of materials for roofing requires knowledge of the characteristics of each of them. For this purpose, you can see the table, which presents the main characteristics of popular roofing coatings.

Table: comparison of materials for the roof

| Material | Service life, years | Thickness, mm | UV resistance | Installation features |

| Metal tile | 30-50 | up to 0.7 | Does not fade during the first 5 years of use | Fastened with self-tapping screws on the lathing with a pitch of about 50 cm. The lathing is erected over the waterproofing film and rafters. |

| Ondulin | about 40 | from 3 | Retains its appearance during the first 5 years of operation | For corners more than 15 o, the lathing step is 60 cm. Special nails are used for fastening. A slope from 10 to 15 o requires lathing from a bar of 50x50 cm with a step of 45 cm. |

| Soft roof | up to 70 | from 3 |

Does not fade, but at first the basalt layer crumbles from the tiles |

The minimum roof pitch is 11 o. This coating requires a continuous sheathing of waterproof plywood or thick OSB boards. At angles of inclination up to 18 o, an additional layer of roll coating is laid. |

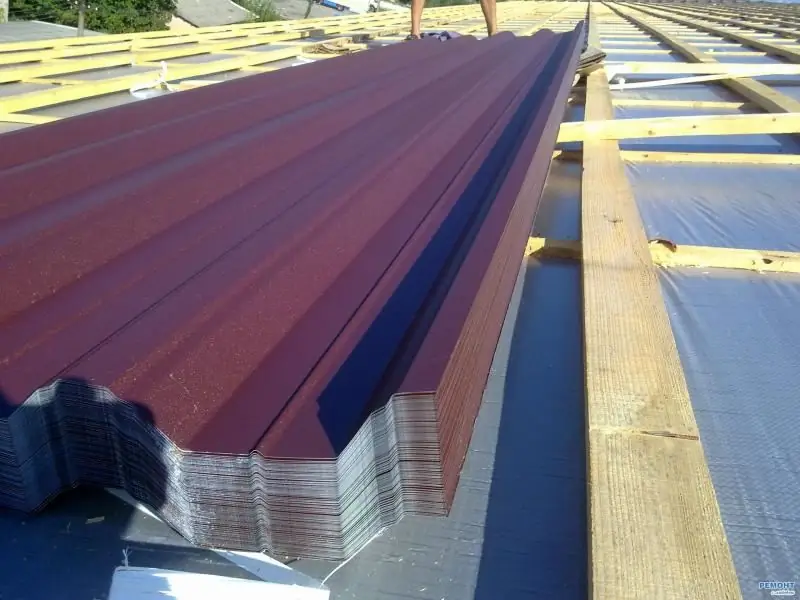

| Roofing corrugated board | up to 50 | from 0.5 | Does not lose color during the first 3-4 years of operation | The roof slope must be at least 10 o. During installation, an overlap of about 20 cm is made, which, with a slight slope of the roof, is additionally treated with a sealant. Fixation is carried out with self-tapping screws, the number of which is from 6 to 8 pieces per square meter. |

| Ceramic tiles | up to 150 | from 4 | Virtually does not lose its original color | Elements of the tiles (they are placed with an overlap of the upper tile on the lower one) are connected with special locks. The tiles are attached to the crate with nails through special holes. |

How to choose the best roofing material for a private house

When choosing the optimal roofing for a private house, several main factors are taken into account. One of them is the moisture resistance of the material and the resistance to temperature extremes. This requirement is relevant for the central and northern part of Russia, i.e., regions with long and cold winters. In such areas, the thickness of the metal roofing should be at least 0.5 mm, and bitumen or ceramic tiles are rarely used, since these materials do not contribute to the rapid melting of snow from the roof and have a rough porous surface.

For regions with snowy winters, a smooth and durable roof covering is needed, from which snow will melt faster

You can determine the best coverage option taking into account the following restrictions:

- the budget for the arrangement of the roofing. Materials such as ceramic tiles, zinc-titanium sheets, copper or slate roofing have a high cost, ranging from 4000 rubles / m 2. Installation of such materials must be carried out by professional craftsmen, which also requires significant additional costs. Common and inexpensive coatings are metal tiles, roofing sheeting or ondulin, which are easy to lay with your own hands;

- residential or non-residential attic. In the first case, the coating must have high sound insulating properties. All metallic materials are poorly suited for this purpose. If the attic is non-residential, then it is possible to lay any external coating;

- resistance to mechanical and climatic influences. Ceramic tiles, slate, corrugated board or metal tiles with a thickness of less than 0.5 mm require frequent repairs, as dents and cracks form on them. Copper or zinc-titanium sheets, ondulin, polyurea are stronger and more durable.

The appearance and color of the coating should be considered last, if the durability of the roof plays a major role. Manufacturers produce a wide variety of roofing colors, so choosing the best option is easy.

Video: the pros and cons of various roofing materials

Reviews of different materials for the roof

The choice of an external roof covering depends on a set of factors, but first of all it is necessary to take into account the characteristics of the materials and their compliance with climatic conditions. Having made the right decision at the design stage, you can ensure that there is no need for frequent and costly roof repairs, and you can maintain the appearance and performance of the coating for many years.

Recommended:

Types Of Roofing Materials With A Description And Characteristics And Reviews, Including Roll, As Well As Features Of Their Operation

Types of roofing materials: sheet, soft and tile roofs. Technical characteristics and features of operation of various types of coatings

Which Corrugated Board Is Better To Choose For The Roof Of The House, What Needs To Be Considered, As Well As A Description Of Popular Brands With Characteristics And Reviews

Selection rules and types of metal corrugated board for the roof of the house. What are the features of the material of different brands and manufacturers. Reviews about corrugated roofing

Roofing Elements Made Of Metal Tiles, Including Their Description And Characteristics, As Well As The Ridge For The Roof, Its Structure And Installation

The main elements used in the construction of metal roofing. Their description, characteristics and purpose. Features of mounting the ridge strip

Metal Roofing Device, Including A Description Of The Roof Left, Depending On The Purpose Of The Roof Space

How is a metal roofing structure arranged? Differences between cold and warm roofs. List of layers in a roofing cake

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size