Table of contents:

- How and what to sheathe the pediment at home

- How to sheathe the pediment at home

- The most popular materials for the exterior of the gable

- Tools and equipment for covering the gable

- Calculation of the material for sheathing the pediment

- How to sheathe the pediment correctly

- Reviews of finishing materials for the pediment

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

How and what to sheathe the pediment at home

The pediment, along with other external elements, forms the "face" of the building. The pursuit of excellence is inherent in every person, and especially in the homeowner. It can be implemented at the stage of finishing work. In addition, the finish carries a number of functional loads. So, in the case of the pediment, this is the strengthening of the end surface of the roof and the insulation of the attic.

Content

- 1 How to sheathe the pediment at home

-

2 The most popular materials for the exterior of the gable

-

2.1 Finishing the gable with siding

2.1.1 Video: do-it-yourself siding of the roof gable

-

2.2 Finishing the pediment with corrugated board

2.2.1 Video: how to make a pediment from corrugated board

-

2.3 Sheathing the gable with clapboard

1 Video: clapboard gable cladding

-

2.4 Sheathing the pediment with foam

- 2.4.1 Photo gallery: houses with foam-faced pediments

- 2.4.2 Video: how to evenly stick the foam

-

-

3 Tools and equipment for covering the pediment

3.1 Video: Homemade Scaffolding with Variable Deck Height

- 4 Calculation of the material for sheathing the gable

-

5 How to sheathe the pediment correctly

- 5.1 Video: how to sheathe a pediment with siding

- 5.2 Stages of work on covering the pediment

- 6 Reviews of finishing materials for the pediment

How to sheathe the pediment at home

The word "pediment" comes from the Latin frontis, which means the front of the wall, forehead. In modern construction terminology, a pediment is understood as a facade space enclosed between the roof slopes and bounded from below by a cornice.

The purpose of the pediment as part of the overall facade of the building is as follows:

- protection of the attic space (half-attic, attic) from precipitation, moisture and wind;

- the formation of a support for the roof on a par with other load-bearing structures;

- keeping warm inside the house;

- improving the appearance of the building.

There are various geometric forms of pediments.

-

The keel pediment has the shape of a convex triangle, similar to the inverted keel of a sea vessel. It was often practiced by architects who built Orthodox churches to decorate gates, prayer cells, belfries. The traditional finish consists of wood ornaments.

Keel pediment The keel-shaped pediments of the monasteries delight the eye not only with the selection of a harmonious combination of shape and size, but also with decorations from artistic woodcarving

-

The bow pediment, as the name implies, has the shape of a small bow. Finished with plaster, decorated with artistic stone stucco.

Bow pediment The space inside the bow pediment is filled with bas-relief sculpture and graphics.

- Interrupted pediment - the space between the roof slopes, not limited by the cornice. If the interrupted pediment is located on two anchor points (such as columns), it is called a semi-pediment. The cladding is mainly made with sand-cement coating, marble or ceramic tiles and other similar materials.

-

A semicircular pediment is a half (or segment) of a regular circle. Accompanying the domed roof. Exterior decoration can be made with any materials, but taking into account the specifics of the shape of the building (for example, the installation of the lining will be associated with the complexity of using standard skirting boards).

Semicircular pediment Semicircular pediments of pavilions and hangars can be made both of glass and using stone finishing materials

-

The loose pediment is characterized by elements protruding from the wall. They are called breakouts. The coating of these elements consists of sand-cement plaster.

Loose pediment Cutouts emphasize the monumentality of the columns and walls of the building

-

The torn pediment looks like a triangle, the top corner of which is torn. Inside the gap, a place is equipped for stucco molding or other decorative elements - sculptures, vases, bowls, etc.

Torn pediment The torn pediment has the shape of an open triangle, in the area of the vertex of which decorative elements are placed

-

A stepped pediment looks like steps that rise upward. Traditionally used in the construction of Gothic religious buildings. Such forms are characterized by stone finishing. In a modern version - glass.

Stepped pediment Stepped gables are finished with stone, glass or ceramic tiles

-

A male pediment is a continuation of a log (or squared) wall, tapering upward in the shape of a roof. It is used to this day in Russian northern architecture. Has a triangular or trapezoidal shape. It is made of the same material as the load-bearing wall and is its continuation.

Male pediment The male pediment is a continuation of the wall and is limited from the sides by the shape of the roof

-

The triangular pediment has the shape of an equilateral triangle. One of the most common types of pediment. A variety of materials are used for finishing, ranging from vinyl siding to "wet facade".

Triangular pediment A triangular pediment most often has sides of equal length

-

Trapezoidal pediment - isosceles trapezoid. The horizontal edges are cornices that protrude beyond the pediment. The cladding can be very diverse.

Trapezoidal pediment Trapezoidal gables are usually found in houses with a residential attic

Distinguish between the interior and exterior of the pediment. The first is intended for insulation and interior decoration of the attic or attic space. The second is carried out outside the house and serves as protection against adverse climatic factors.

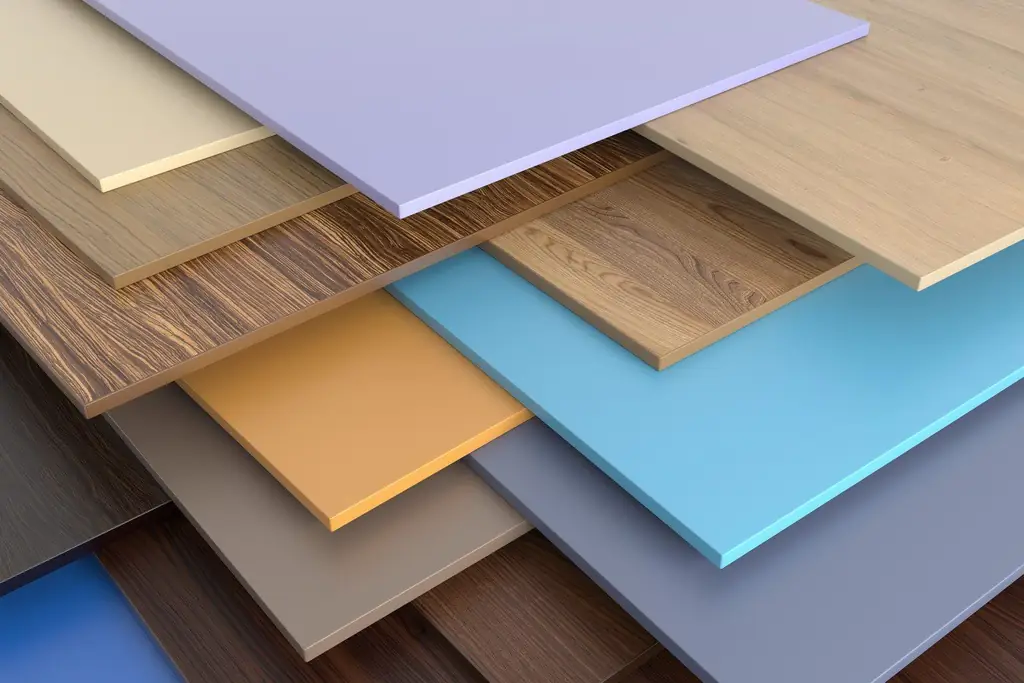

The most popular materials for the exterior of the gable

Technologically, the process of strengthening and warming the pediment can be done in two ways.

-

Sheathing on the frame. To fix the facing materials, a pre-assembled frame structure is used. This method is used for finishing with all types of siding, clapboard, profiled sheet and other panel materials. The lower part of the posts rests directly on the wall, the upper part is attached to the roof plane. The big advantage of the frame structure is its lightness and ease of installation. Its device does not require high qualifications, you only need accuracy, standard woodworking tools and fasteners.

Gable sheathing on the frame For the frame for finishing the pediment, both wooden and metal crate can be used

-

Solid wall cladding. The finished wall plane is covered with insulation without using an additional raster. This is how polystyrene, mineral wool, penoplex, etc. are attached. The finished blocks are glued or fixed with special mushroom-shaped dowel-nails on the pediment. A protective layer of special paint with a fine fraction of sand or crushed stone is applied over the insulation. The disadvantages include the fact that such a coating "does not breathe", that is, does not let air through itself. But this has its advantages - the lack of circulating ventilation prevents moisture from destroying the structure. Therefore, the cladding must be installed taking into account the dew point, and the interior must be well ventilated.

Sheathing without frame The frontal plane is covered with a finishing material directly along the wall surface, without the use of a frame

Let us dwell in more detail on the most common types of external cladding of gables.

Construction document governing the construction of gables using frames - SP 31-105-2002. It reflects the regulatory requirements that must be observed when designing this element of the roof structure.

- The distance between the vertical elements of the frame cannot exceed the pitch of the main wall studs. Fastening is carried out to the upper trim of the structure

- The distance between posts above a log, squared, brick or block wall is determined by the wind load in a particular region. The minimum step is 0.3 m, the maximum - 0.9 m. In this case, the strength of the load-bearing frame elements must be selected taking into account the load.

- When equipping the gable with standard thermal insulation materials, the width between the supports is tied to the dimensions of the slabs or mats.

- The outer side of the heat insulator is covered with waterproofing - polyethylene film or membrane.

- Installation of gables with large overhangs is carried out at the same level with the outer perimeter of the auxiliary beams.

Nails and screws are used as fasteners for the construction of frames. Places of increased load are fixed with additional connecting elements - corners, brackets, toothed metal brackets. More complex solutions are also possible - the production of grooves, locks and spikes on wooden frame elements.

Metal brackets are used at joints operating under increased loads.

The sequence of works on sheathing the pediment can be different. Some lay down measures in the plan of a house under construction and mount the crate before arranging the roof. Others, due to circumstances, carry out insulation in an already finished house.

Most craftsmen prefer the first option, since the presence of gables prepared before laying the roof sheathing certainly increases the safety of work. In addition, it is more convenient to work on the roof with ready-made gables, because they:

- serve as the basis for geometric reference;

- strengthen the rigidity of the structure as a whole;

- close the construction site from side wind, which saves roofers from great inconvenience.

If there are window openings or doors in the plane of the gable, it is necessary to insert a double-glazed window or door leaf before installing the battens. Platbands are installed after sheathing the entire plane of the pediment with insulation. However, it is not a big deal if the window crashes after the insulation was laid. The same applies to the door.

Platbands on doors and windows are installed last

The material for the lathing for finishing the pediments is metal profiles or wooden bars. Many specialists give preference to metal coated with an anti-corrosion zinc layer. Bars made of wood treated with antibacterial and fire-fighting impregnations also have their supporters. They are more affordable and easier to install. In any case, it must be remembered that in places where metal and wood come into contact, hydrophobic gaskets, for example, roofing material or building board, are necessarily laid. This is necessary so that condensation does not form at the junction of materials with different thermal conductivity.

Roofing material serves as an excellent moisture insulator when joining materials with different thermal conductivity coefficients

As a rule, finishing is carried out from the bottom up. They begin to lay the finishing materials, tying themselves to the lower cornice above the load-bearing wall and gradually covering the entire area of the pediment. But, as with any rule, there are exceptions. For example, when facing with wooden lining, located vertically.

Siding gable trim

One of the most popular materials for cladding the gable of a building these days is siding. A wide range of siding coatings allows you to choose the optimal color, texture and size for cladding a house. There are several types of siding:

-

Vinyl. The panels are based on polymer made in the form of strips of various lengths and widths. Along the long sides, there are locking grooves, with the help of which the rails are coupled together into a single monolithic plane. The products are distinguished by a wide range of colors, lightness, resistance to changes in atmospheric conditions (operated at air temperatures from -50 to +50 o C) and a very affordable price. The disadvantages include low resistance to mechanical damage, the appearance of deformations under the influence of solar radiation, a relatively short service life.

Gable trim with vinyl siding Vinyl siding can have a convex shape that mimics a rounded log

-

Wooden siding. It is made of solid wood in the form of planed boards with grooves for fastening to each other. Compared to other types of siding, wood is more vulnerable - it is destroyed by the influence of fungus, mold, wood-boring insects. Therefore, it is used mainly in country and suburban construction. Useful properties - a high level of thermal insulation, aesthetic appearance, environmental friendliness. Disadvantages - flammability, cracking on drying, the need for careful maintenance (impregnation, staining) and a rather high price.

House decoration with wooden siding Wooden siding is widely used in low-rise suburban construction

-

Metal siding. Very practical stuff. It comes in steel, aluminum or zinc. Aluminum products can be easily painted in any color and therefore are quite popular with users. The advantages of metal siding are strength, insensitivity to biological effects, unlimited service life. The disadvantages include poor sound insulation (especially during rain) and the appearance of corrosion in the places of the cuts (the ends of the rails).

Metal siding There is a large selection of metal siding in both color and shape

-

Fiber cement siding. A new and very promising type of finishing coating. Manufactured from cellulose fibers, sand and cement. Its properties are not inferior to stone finishing. Compared to vinyl siding, the fiber cement counterpart looks more natural and is much easier to install. It also favorably differs from metal and wooden types of siding, because it is devoid of almost all of their disadvantages. Experts note a number of unconditional advantages of fiber cement siding: non-flammable, does not need maintenance, does not rot, is reliable and durable. In Russia, this type of coating is quite rare, although in Western Europe it has been used for more than a century.

Finishing the pediment with fiber cement siding Fastening of fiber cement siding is carried out using special metal clamps

Installation of siding is carried out according to the technology developed by the manufacturer. When installing a frame structure on the pediment, it is necessary to observe the step size of the bearing supports and fasten the bars taking into account the properties of the material from which the siding is made. In the conditions of the northern regions, the facing of the pediment is always combined with insulation. Therefore, there the most common method of fastening to the frame. In the south of the country, siding is used as a decorative solution designed to hide defects in rough masonry. In this case, the fixation is carried out directly to the wall of the pediment.

Video: do-it-yourself roof gable cladding with siding

Finishing the pediment with corrugated board

Decking is akin to metal siding, it is also made from sheet steel by stamping, but differs in size and shape. The profiled steel sheet is produced in the form of a corrugated plate and is a universal roofing material. Even the cheapest option of corrugated board has an anti-corrosion zinc layer on the surface. More expensive products are additionally covered over the entire area with a polymer layer. This makes the sheet virtually immune to corrosion. Finishing the gable with profiled steel sheet is used everywhere, regardless of the region. The material is durable, lightweight, versatile in terms of design.

The frame for the installation of corrugated board is mounted both from wooden blocks and from metal profiles

The price of a corrugated board in terms of per square meter of area is less than that of metal siding. The material is laid in two ways: with an overlap or with the use of additional siding elements. The profiled sheet is placed mainly vertically. This arrangement allows you to hide sheet overlaps and contributes to better drainage of water during rains. The recommended overlap size is 15-20 cm vertically and one wave horizontally (according to the slate principle). Fastening is carried out with special screws with a wide head.

The calculation of the harvested material is made taking into account the usable area, which is calculated by subtracting the size of the overlap. To the resulting amount of material, a stock for cutting is necessarily added - the shape of the pediment assumes an oblique and trapezoidal configuration of corrugated sheets in the upper part. An accurate calculation can be obtained by depicting the pediment on a reduced scale on paper and the location of the corrugated sheets on it.

When decorating the joints or ends of the pediment, additional elements for siding are used

Video: how to make a pediment from corrugated board

Sheathing the pediment with clapboard

For outdoor work on facing the pediment, lining of conifers is often used: spruce, pine, larch or fir. Wood resin protects the slats from the damaging effects of moisture, mildew and mildew.

Larch was recognized as the best material for the production of lining. According to the number of knots on the front side, the lining is divided into the first, second and third classes. The fewer knots on the surface, the less chance of deformation due to changes in humidity and temperature. Pine lining is usually ranked in the first class. Its texture is homogeneous and natural color pleasing to the eye.

During installation, it is necessary to remember some of the features associated with the properties of the wood material.

- it is imperative to use a vapor barrier;

- when preparing the frame, bars with a size of at least 40x50 mm should be used;

- it is better to lay the heat-insulating layer in two layers with an offset of the joints;

- roll waterproofing must be laid with an overlap of up to 100-150 mm;

- lining is recommended to be done from the bottom up.

The horizontal arrangement of the lining slats is considered more acceptable. With diagonal and vertical laying, the level of moisture resistance of the coating is sharply reduced.

Wooden lining can have a different surface shape, including imitating a bar or log

The lining can be fastened in two ways:

- By directly fixing the board to the lathing with screws or nails without heads.

- Fixing with special clamps - clamps.

Clamping is considered more aesthetic. In this case, the boards are not damaged, therefore, the risk of their premature wear is reduced. But the requirements for the quality of the lining are increasing, since the size of the groove must exactly correspond to the specified parameters along the entire length.

The clamp is fixed to the frame or the bearing wall with nails or self-tapping screws, and the lining groove is inserted into it

The algorithm for cladding with wooden clapboard consists of the following operations:

- The starting bottom board is installed at the base of the pediment. The lower tenon is cut in advance, the groove is directed upwards.

- Careful leveling is performed on the horizontal level. The geometry of all subsequent cladding depends on how the first board will be exposed. An error of no more than 2 mm per 2 running meters is allowed.

-

The next rail is inserted with a spike into the groove of the first. To obtain a reliable connection, use a mallet with a rubber butt. The board is fixed only after complete coincidence of the locks.

Clapboard connection using a clamp In order for the spike of one board to fit tightly into the groove of the other, the free end must be knocked out with a rubber mallet

-

They do the same with all other slats. They are cut during installation, each time adjusting the dimensions and bevel angles at the ends.

Gable clapboard technology With horizontal finishing, the lining is laid with a middle spike up

- Having sewn up the entire pediment, plinths are installed around the perimeter. If there are windows or doors in the wall, they are framed with platbands.

-

At the end of the installation work, they proceed to finishing the entire surface. The plane is covered with biological impregnations, fire retardants and water repellents. After drying, the lining can be painted or coated with a special varnish.

Lining processing The upholstered pediment is treated with antiseptic and decorative compounds to protect against environmental influences and give the surface a beautiful appearance

Video: clapboard gable sheathing

Sheathing of the pediment with foam

Polyfoam is widely used to create an outer thermal insulation layer. They insulate the foundation, floor, attics and walls of houses. The facade is no exception. With the help of a simple technology, it is possible to veneer the outer part of the pediment, at the same time giving it a beautiful appearance and strengthening its strength. The huge advantage of this type of cladding is the low cost of the material and ease of installation.

Photo gallery: houses with foam-faced pediments

-

Pediment of a country house - After installing the foam, the pediment is plastered and painted in the color of the wall

-

Finishing the pediment of a house in the village - Small pediment can be covered with foam in one day

-

Cottage with a wet facade gable - The huge popularity of the "wet facade" is due to the thermal insulation properties of the foam

The service life of the foam lining is estimated at 50 years, the coating is resistant to mechanical stress, not subject to chemical and biological degradation

If the installation standards are observed, it does not require further maintenance. The only condition that must be met is to provide a continuous, even surface of the base on which the cladding is applied.

In brick, block and cast concrete houses, the pediments are an extension of the load-bearing walls. And the foam lining is quite appropriate here, and without additional preparation.

In wooden houses, the pinch is sewn up with chipboards and foam blocks are attached to them. In each case, the calculation must be made based on the specific situation. But practice shows that polystyrene cladding is one of the most inexpensive and fastest ways to finish a pediment. Among other things, the weight of the foam is so low that the cladding does not weigh down the building structure at all. And this is an important factor that allows you to save on the size of the foundation and the thickness of the bearing walls.

Polyfoam can be used for cladding not only the pediment, but also the bearing walls of the building

The essence of the finishing is to evenly cover the entire surface of the pediment with a layer of foam. With a foam polymer thickness of 10-15 cm, no frost can penetrate into the house. By means of the topcoat - a special facade paint with the addition of silicone - the entire plane is transformed into a monolithic slab, hermetically adjacent to the outer surface of the building.

Facing the pediment with foam plastic using the "wet facade" technology is carried out in the same way as finishing the walls of the building

When starting to finish the pediment with foam, you need to pay attention to the following points.

-

It is necessary to select polystyrene not only in terms of size and thickness, but also in terms of flammability. Preference is given to low-flammable compounds of the G2 class.

Non-combustible foam The degree of flammability of the foam is reflected in the technical data sheet of the product

-

The adhesive should not contain active solvents, as they react with polypropylene. The ideal option is a PVA-based adhesive. It is allowed to use tile adhesive when installing on a stone base.

Facade glue When installing foam on a brick facade, you can use tile glue and additionally fix the insulation sheets with disc dowels

-

Before sticking and fixing to the wall, its surface must be treated with a primer of the "Betonokontakt" type.

Primer "Betonokontakt" Primer "Betonkontakt" forms a relief coating with a high degree of adhesion

-

On top of the polystyrene, it is imperative to pull the plaster mesh (serpyanka) and fix it with a continuous layer of glue. This will provide good adhesion for the topcoat.

Installing a painting net If the outer mesh is not installed on the foam, the paint layer will very quickly fall off and crumble

-

After planting the foam plates on the glue, it is necessary to additionally fix them with dowel-nails with mushroom heads.

Fastening foam with dowel-nails Each sheet is fastened with five dowel-nails - in all corners and in the center

- It is necessary to strive to ensure that there are no gaps between the foam sheets. If they are still formed, select the slots with polyurethane foam or glue.

-

The bottom row should not be installed on the cornice, but in a special support metal profile, matched to the thickness of the foam.

Foam starter profile The first row of foam is installed in the metal starter profile

-

The paint must be applied evenly with a plastering trowel. The thickness of the coating is determined by the size of the structural particles that make up the paint.

Facade paint Paint consumption is determined based on the technical data indicated on the package

Video: how to evenly stick foam

Tools and equipment for covering the gable

All exterior cladding works are tied to weather conditions. Therefore, if a fine day is issued, you need to act quickly and smoothly. In addition to the materials required, it is important to have the following tools ready.

-

To prepare the crate for siding:

- saw or jigsaw;

- screwdriver;

- hammer, mallet;

- measuring instruments - tape measure, plumb line, hydraulic level, construction thread;

- a knife for cutting plastic, a hacksaw for metal;

- perforator (when installing the lathing on a stone base);

- long rule (from 2 m);

-

construction laser level.

Laser level In outdoor conditions in bright light, a low-power laser with red beams will not be visible, so a green laser is needed

-

If a crate of metal profiles is installed, metal scissors (or a grinder) are additionally needed. Metal spatulas are used to cover the foam insulation with facade paint.

Ironer The scalloped side of the universal trowel is used to apply glue under the foam sheets, and the smooth side is used for finishing

As a rule, all of the listed tools are in the arsenal of any master. But what sometimes becomes a problem is scaffolding. Work is carried out at a height of 3 meters and more, the installer must move freely along the wall of the pediment. Lifting materials is difficult, especially if a person works alone. You can, of course, use stairs, but the pace of work will be significantly reduced. It's hard to talk about security at all. Without sustainable and reliable forests, work will turn into torment (which will certainly affect the quality of the end result).

Prefabricated scaffolding is quick to assemble and allows for platform height adjustments

In short, it is necessary to solve this problem in advance. There are several options here.

- rent forests;

- purchase a construction "tour";

- make scaffolding on your own using materials at hand.

Which way to go - everyone decides independently based on the specific situation. But the urgency of this task cannot be underestimated.

Video: homemade scaffolding with variable deck height

Calculation of the material for sheathing the pediment

In this paragraph, we will consider how to determine the amount of materials required.

- Vinyl siding, lining, polystyrene. Their number is determined by the area of the pediment. To calculate it, we use the formula S = ½ ∙ a ∙ h, where a is the base, h is the height of the triangle, S is the required area. In other words, the area of the triangular pediment is equal to half the product of the base (conventionally - the length of the cornice) by the height. To determine the height, it is necessary to draw a perpendicular from the middle of the base to the apex of the triangle. If the shape of the wall has a different configuration, it is divided into separate parts, their areas are calculated and folded. It should be noted that during the installation process, the material is cut into predetermined lengths, so waste inevitably occurs. It is customary for building codes to add a 10% stock of material for these cases.

- The amount of timber for the lathing is determined empirically depending on the pitch of the support posts. The easiest way is to make an accurate plan of the pediment and calculate the consumption of the bars according to the drawing. The plan must be proportional to the actual size, otherwise the result will be wrong. But the preliminary calculation is very simple: the length of the pediment base is divided by the support step. For example, if the base of the pediment is 10 m, and the distance between the posts is 0.5 m, then in total you will need 10 / 0.5 = 20 bars with a length equal to the height of the triangle (h).

- Fasteners are also calculated using the plan. They take one square meter and calculate the required number of screws to secure the siding. Next, the resulting figure is multiplied by the total area and 10% is added.

-

Paint, glue, varnish and other consumables are calculated based on the consumption rates prescribed on the package.

Paint consumption The approximate paint consumption can be calculated using the standard values indicated for each type of coating

- For foam, the number of dowel-nails is considered separately. For example, if the area of one sheet is 0.6 mx 1.2 m = 0.72 m 2, and it is fastened with five mushroom dowel-nails (four in the corners and one in the center), then the total number of dowels with an area of 25 m 2 will be (25 / 0.72) x 5 = 173.6 pcs. As in the previous case, it is recommended to purchase fasteners with a certain margin.

How to sheathe the pediment correctly

It is difficult to describe a detailed description of the work on sheathing the pediment in a small article. Everything depends on the particular situation. We got acquainted with the general principles above. Further it is necessary to act according to the circumstances. The tasks that are solved by facing the pediment can be varied, but when installing any type of coating, you should first of all follow the instructions developed by the manufacturer of the material. You can use the services of professionals or do it yourself.

Video: how to sheathe a pediment with siding

Stages of work on sheathing the pediment

Well-organized activity always brings positive results. Reasonably planned work process allows you to achieve your goal with minimal cost. Therefore, let us dwell on the main stages of facing the pediment in chronological order.

-

Preparatory work. Includes measurements and calculations of the required amount of materials. The estimate includes not only the cost of blanks, but also transportation costs. After the delivery of everything necessary to the construction site, the scaffolding is installed (independently or with the help of specialized companies).

Preparatory work for plating the pediment Scaffolding must comply with safety standards and contribute to the comfortable work of the installer

-

Depending on the selected type of cladding, the primary processing of the pediment is carried out. This can be the coating of a brick base with a primer or the installation of lathing. At this stage it is important to observe processing conditions: primer applied at an air temperature of not less than -5 about C, to observe step strut, etc…

Gable priming Coating with a primer can only be carried out in warm weather without precipitation

-

They mark and install guide profiles. In the case of foam cladding, this work consists in fixing the starter profile above the cornice. For vinyl siding - in fixing the J-profile along the entire perimeter of the gable plane.

Gable markings for cladding The placement of the starting profiles is carried out before the installation of vinyl siding.

- Sheathing starts from the bottom, from the eaves. Adjusting the material to the shape of the facing surface, install the first and all subsequent rows. Here it is required to strictly observe the horizontal laying, to ensure that as few gaps are formed, excluding those of them that must be left when attaching vinyl siding lamellas.

-

Upon completion of the finishing, finishing work is carried out. Polyfoam is covered with a facade coating, the lining is impregnated with protective compounds and painted. Decking and vinyl siding do not require any topcoats.

Coating the lining with varnish Solvent-based varnish reliably protects the wood surface from moisture and ultraviolet radiation and gives it a beautiful noble shade

- Install protective fittings - drainage and baseboards. If there are windows and doors in the plane of the pediment, platbands are installed.

Reviews of finishing materials for the pediment

Finishing work on the outer surface of the building forms the appearance of the house. Such events are held at least once every 10 years. Therefore, the main concern of the homeowner is to select quality materials with a long service life, high strength and durability. Before purchasing a specific coating, it is advisable to familiarize yourself not only with the technical characteristics, but also with user reviews about it.

By installing additional protection on the pediment in the form of some kind of finishing material, the homeowner solves two practical tasks at once - increasing the strength of the lateral planes of the attic and warming the interior of the house as a whole. Along the way, the building is decorated, acquires an aesthetically finished design.

Recommended:

Sheathing The Front Door With MDF Panels, How To Choose The Material And Carry Out The Work

What is MDF panel on the front door and how to choose it correctly. Do-it-yourself plating of entrance metal doors and doorways with MDF panels

Making Glass Doors, As Well As How To Install Them Correctly And What Tools Are Required To Carry Out The Work

Self-manufacturing technology of glass doors. How to install, adjust, dismantle them correctly. What tools can be used

Do-it-yourself Installation Of Interior Doors, As Well As What Tool Is Required To Carry Out The Work

Types and methods of installing interior doors. The order of work when installing doors. Tools and supplies. Features and nuances of installing fittings

Do-it-yourself Installation Of Entrance Doors, As Well As What Tool Is Required To Carry Out The Work

Do-it-yourself installation of entrance doors. The sequence of work. Checking the correct installation. How to dismantle the front door

Armopoyas For Mauerlat And Its Purpose, As Well As How To Properly Carry Out Installation Work

Armopoyas functions and its main parameters. How to make your own concrete mix. Instructions for the construction of an armored belt and attaching a Mauerlat to it