Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Moving a gas pipe in the kitchen: how to do it right

The need to move the gas pipe in the kitchen may be required for various reasons. Quite often, in new homes, the gas pipeline is made in such a way that it is impossible to correctly install kitchen furniture or equipment. Sometimes, during major repairs, redevelopment is done with the transfer of all communications. The production of such works is associated with a number of difficulties.

Content

- 1 Norms and rules for the location of gas pipes in an apartment

-

2 Moving the gas pipe: procedure

-

2.1 Obtaining permission to move a pipe

2.1.1 Video: redevelopment of gas equipment

-

2.2 Transfer technology of gas pipes

2.2.1 Video: Gas Pipe Installation

-

-

3 Checking the entire system for leaks and overall performance

3.1 Video: why amateurs cannot be trusted to work with gas

Norms and rules for the location of gas pipes in an apartment

Since household gas, both network natural and bottled propane-butane, is a potentially hazardous substance, certain strict requirements are imposed on the location of gas pipes to ensure their safe operation. The rules for the placement of gas-using equipment in residential premises are set out in the regulatory document SNiP 2.04.08-87.

SNiP 2.04.08-87 sets out the rules for the safe placement of gas-using equipment

The main standards of the current SNiP are as follows:

- the gas pipeline is laid only in an open way, that is, the entire system should be easily accessible for inspection and installation;

- it is forbidden to lay and brick up pipes in walls, as well as cover them with decorative cladding (the only exceptions are easily removable structures);

- it is strictly forbidden to transfer gas taps to residential premises;

- put gas pipes into ventilation wells and cannot cross them;

- it is not allowed to lay a gas pipeline through door and window openings;

- a shut-off (shut-off) valve must be located at a height of at least 1.5 m from the floor level;

- gas pipes are laid at least 0.25 m from the electric cable, while at least 0.5 m is left to the switchboard;

- all surfaces (walls, ceiling, floor, etc.) close to gas equipment must be covered with non-combustible materials (plaster, metal sheets, etc.);

- in places where people pass, gas pipes are mounted at a height of at least 2.2 m;

- the gas tap is not allowed to be located directly above the heating zone (stove), it must be at a distance of at least 0.2 m;

- the intersection of the gas pipeline with building structures is carried out only through special built-in construction cases;

- with other devices and structures in the room, the pipes to be laid should not come into contact;

- it is allowed to use flexible hoses (rubber with fabric or metal braid, bellows sleeve, etc.) for connecting gas equipment (stoves, boilers, etc.), only from the tap to the device (their length is not more than 3 m);

- to fix the elements of the gas pipeline on the walls, ceilings and columns, fasteners specified in SNiP are used (hooks, clamps, hangers, brackets, etc.);

- the required slope when laying the pipeline - from 3%;

- All gas pipes must be coated with moisture-resistant dyes to protect against corrosion.

Gas pipes cannot be moved arbitrarily, for this there are special standards and rules

As a flexible hose, in those days when there were no special reinforced hoses and corrugated stainless pipes, we used an oxygen hose to connect the gas stove, which was fixed to the fittings using simple aluminum clamps for a screwdriver.

Gas pipe relocation: procedure

It is strictly forbidden to carry gas pipes on your own; such work is performed only after agreement with the relevant government organizations. The transfer is carried out by specialists with the required qualifications. Without permission, you can only move the slab a little to the side (no more than 0.4 m), if it is connected with a flexible bend.

Without permission, you can only move the slab slightly to the right or left

Obtaining permission to move a pipe

The procedure is as follows:

-

First of all, the owner of the premises should contact the gas supply organization at the place of residence (Gorgaz), where he should fill out an application of the established form on the need to carry out work on replacing or transferring gas pipes to connect the stove. It is necessary to indicate what exactly needs to be redone and for what reason.

Statement First you need to write an application for the transfer of gas pipes or replacement of equipment

- The abandoned application will be the basis for calling a representative of the gas service. The date of the visit is usually negotiated immediately. The arriving technician carefully examines the premises, listens to all wishes, examines the submitted project and assesses the possibility of its implementation, taking into account all technical standards. If necessary, they are made adjustments and changes or provided with other options.

-

After the final transfer scheme is approved, the service provider draws up cost estimates for the work being done.

Estimate After agreeing on the project, the settlement organization provides an estimate for the work performed

- The compiled estimate must be agreed with the landlord, who must give his consent.

- Upon receipt of all documentation, payment is made.

- Within 5 days after depositing the funds, gas workers arrive at the work site and carry out the transfer of gas pipes according to the developed plan.

So that the process of transferring gas pipes does not drag on indefinitely, it is necessary to carry out a number of preparatory measures:

-

Meet with the gas technicians in person or call them by phone and find out what additional materials will be required. Everything should be purchased and prepared in advance. As a rule, workers bring all pipes and fittings with them, as their cost is included in the estimate. But flexible hoses for connecting gas appliances are purchased separately.

Bellows hose Flexible hose usually has to be purchased separately

- Excess equipment and furniture must be removed from the premises, providing unhindered access to all elements of the gas system.

- If it is impossible to dismantle, you need to protect all valuables with sackcloth, plastic wrap, tarpaulin, etc. This is necessary, since the upcoming activity is accompanied by increased dust formation.

Video: redevelopment of gas equipment

Gas pipe transfer technology

The process of transferring gas pipes consists of the following sequential actions:

-

Immediately after the arrival of the foremen and immediately before starting work, it is necessary to shut off the gas supply using a valve.

Valve Before starting work, you need to turn off the gas

- Residual gas must be vented through the stove or heating boiler, and the pipe must be blown through to remove debris and dust.

-

Cut off fragments of the pipeline that have become unnecessary with a grinder or welding, according to the adopted plan.

Cutting pipes Old pipes can be cut with a grinder or welding

- Close the hole with a special plug or weld it.

- Make a new hole for the gas outlet in a different place in the pipeline.

-

Mount and weld a new metal pipe element to the hole made, guided by the project.

New gas outlet New gas outlet is welded in the right place

- At the free end of the welded bend, cut a thread and install a tap using seals (FUM tape, tow, etc.).

-

Connect the necessary gas equipment with a flexible hose.

Elbow with flexible hose Gas equipment is connected using a flexible hose

Our neighbor undertook to move the gas pipes in the house on his own. He considered that in fact he could very simply legalize everything. But it turned out to be much more difficult than he thought. At first he was ordered to dismantle everything, then draw up a project and start over. Through a long walk through various authorities and the payment of a decent amount, it was possible to resolve this issue. As a result, the rework was much more expensive.

Video: installation of a gas pipe

Checking the entire system for leaks and general performance

The final stage of the transfer of gas pipes - checking the overall performance and tightness of the system is extremely responsible. Everything should be carried out in accordance with the design, all fittings are screwed in, properly sealed, etc. Before turning on the gas equipment, the gas pipeline system is checked for leaks.

The tightness of the gas pipe connections is checked with a soap solution

Testing is carried out in the traditional old-fashioned way using a simple soap solution, which is prepared on the basis of water and any soap. You need to whip up some foam and apply it with a sponge or brush to new gas pipe connections, as well as to possible leaks. Bubbles that appear at the junctions of the nodes after the gas is supplied to the system (opening the valve) indicate the poor quality of the seal made. In this case, the work on sealing the joints will have to be redone.

There are special devices for monitoring gas leaks

Video: why amateurs cannot be trusted to work with gas

Although the work on the transfer of gas pipes is not particularly difficult, in some cases it is not possible to perform them for a number of important reasons related to compliance with safety requirements. You should not act at your own peril and risk, it is better to trust the opinion of the competent authorities and not risk your own life and the lives of your household.

Recommended:

How To Choose A Hood For The Kitchen - In Terms Of Power And Other Parameters, What To Look For When Buying A Built-in And Built-in, For A Gas And Electric Stove, Professional Advi

What parameters should you pay attention to when choosing a cooker hood for the kitchen: types of devices, how much the prices differ. Model overview and manufacturer information

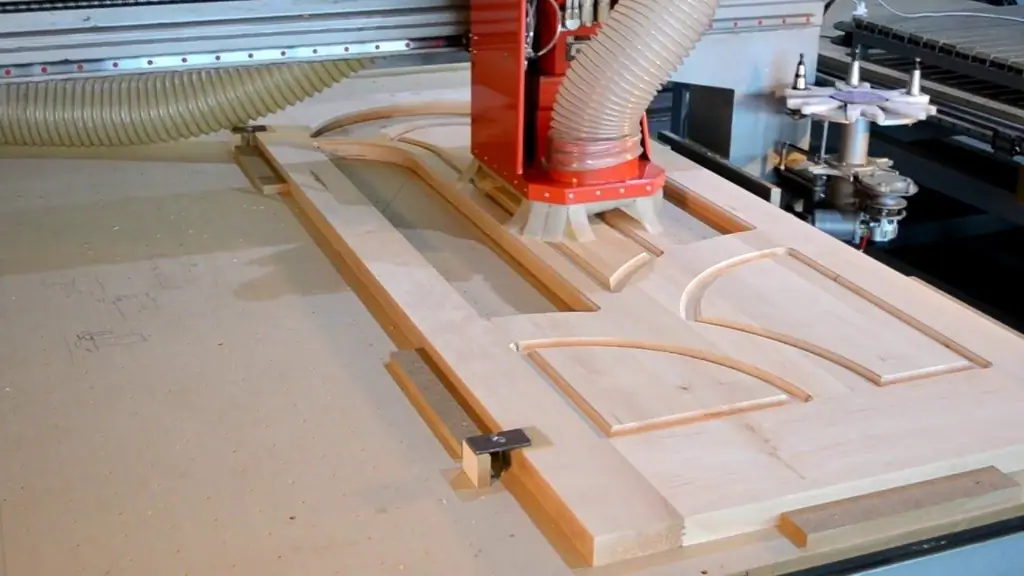

Production Of Interior Doors, Basic Rules And Requirements For The Manufacturing Process

Manufacturing of interior doors: technical rules and GOST requirements for the production process. Required materials and equipment

Overhead Sink For The Kitchen: Design Features, Recommendations For Choosing

What is an overhead kitchen sink, its pros and cons, how it differs from a mortise one. The choice of shape and size, material, manufacturer. Installation features. Care

How To Choose A Laminate For The Kitchen: Types, Pros And Cons, Recommendations, Reviews, Photos Before And After Installation

Advantages and disadvantages of laminate flooring in the kitchen, as well as the rules for choosing and maintaining flooring. Features of kitchen design with laminate

Kitchen With Patina On The Kitchen Set And Furniture: What It Is, Interior Design Features, Photo

What is patina. Advantages and disadvantages of patination. Kitchen design with patina: colors, styles and interior features