Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Requirements and GOST marking for metal doors

Metal doors are installed both in residential and industrial, public premises. They are durable and reliable, and this is achieved due to compliance with the requirements of GOST, which relate to the manufacture and installation of doors. It is this standard that ensures the durability and safety of metal sheets for various purposes.

Content

-

1 Standards for the production and installation of metal doors

- 1.1 Video: design features of metal doors

- 1.2 General provisions of GOST for metal doors

- 1.3 Insulated doors in accordance with GOST

- 1.4 Steel fire doors

- 1.5 External doors made of steel in accordance with GOST

- 1.6 Metal doors with glass

- 1.7 Parameters of metal doors in accordance with GOST

- 1.8 Requirements for fittings

- 2 GOST: marking and completeness of metal doors

Standards for the production and installation of metal doors

The manufacture of doors from metal, as well as from other materials, is regulated by established and current standards, namely GOST. This code includes the basic rules of production, requirements for parameters and materials, as well as technology for mounting metal doors. Thanks to this, the structures are reliable, have a long service life and ensure human safety.

Any metal doors must meet the requirements of GOST

The main document regulating the production of metal doors of various types is GOST 31173-2003. Additionally, they take into account sanitary norms and rules (SNiP), which are a set of requirements for the quality and safety of products. These documents regulate the manufacture of metal doors, and the installation of structures is carried out taking into account additional documentation, namely the technological map developed and submitted by the manufacturer.

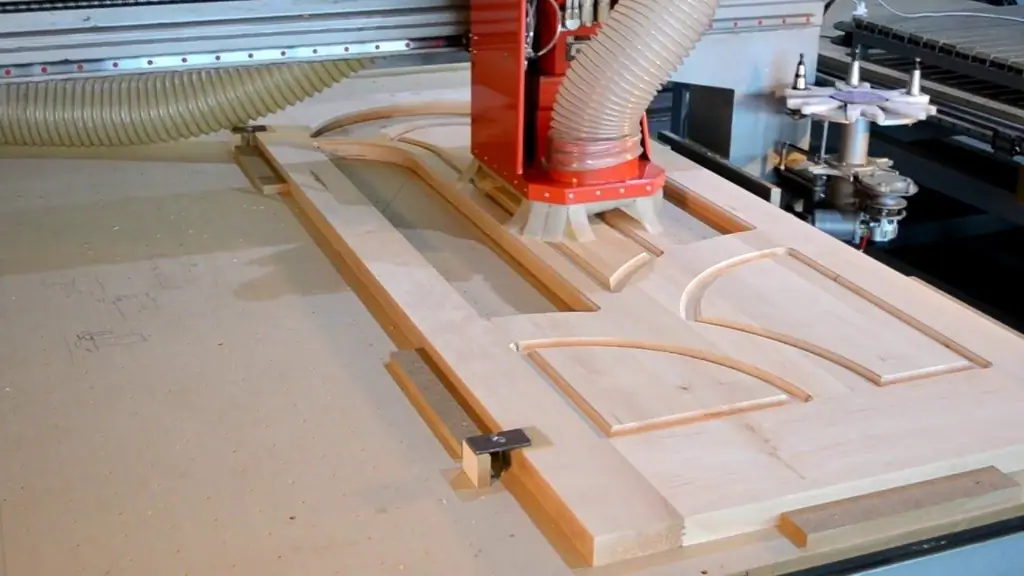

Video: design features of metal doors

General GOST provisions for metal doors

GOST 31173-2003 is used for metal door blocks equipped with locking devices and used in buildings and structures of various types. At the same time, the document does not apply to special-purpose products, for example, bullet-proof or fire-resistant versions, as well as explosion-proof models.

Doors that comply with GOST are reliable protection of premises

The standard assumes the classification of metal sheets according to the following criteria:

- purpose, namely external or internal systems;

- the structure can have a U-shaped box or with a closed loop, as well as with a threshold;

- the system can be from one sash, two identical or different canvases, with opening outward or inward;

- the number of circuits providing sealing - one or two;

- the finishing of the canvas can be in the form of a painted surface, cladding with leather and insulation, cladding made of glass, wood or wood-tile structures;

- the level of sound insulation - 1st class (up to 32 dB), 2nd class (26-31 dB) and 3rd class (20-25 dB);

- degree of protection: ordinary, reinforced and protective doors. In each case, there are locks of the corresponding strength level.

The regulatory document takes into account all the features of metal door systems. For example, seams and joints of metal parts must be welded. The box can be made of a curved profile, but the thickness of this element must be from 1.5 mm. And also for the door frame, a box made of a rectangular profile is appropriate, and its minimum section is 40x50 mm.

The frame is an integral part of the door system

GOST includes not only the mandatory requirements for the manufacture of metal doors, but also recommendations for creating reliable products. For example, the standard recommends the use of horizontal and metal reinforcement profiles in door construction. They are called mullions and make the canvas durable, resistant to mechanical stress.

Inside the sash, you can use a solid sheet of steel, which is an additional reinforcement of the door. A plate consisting of elements welded together is also an acceptable option. In this case, the weld passes along the reinforcement profiles, which ensures the strength of the final product. The inner supplementary sheet can be in the form of fibreboard or other solid sheet-type materials. These door components are used in the manufacture of various types of canvases, for example, entrance or heat-insulated.

Insulated doors in accordance with GOST

The construction of insulated doors assumes maximum protection of the room from heat loss through the leaf and prevention of cold penetration through the cracks. Such doors have a thermal insulation material in their structure, which is located between the outer and inner skin.

Insulated doors are often external

The standard assumes the following features of manufacturing and installation of insulated doors:

- thermal insulation is provided by at least two sealing circuits located along the perimeter of the entire vestibule;

- all materials used for the manufacture of canvas and boxes must have a sanitary certificate on the safety of the structure;

- paints and varnishes must have high adhesion to the metal door surface, and the finish should not flake off, creating cracks and contributing to heat loss;

- if the finish is made of wood or chipboard, then such surfaces should not have cracks that can cause blowing of the canvas;

- insulated door models, like any others, are mounted only in a prepared opening with smooth edges;

- during installation, all the gaps between the box and the wall are treated with foam and other structures that eliminate the gaps;

- the materials used to create the assembly seam must be durable, safe, strong, not subject to decay.

Requirements for the production and installation of insulated systems involve the creation of sealed seams and joints. This eliminates the possibility of heat loss from the room.

Steel fire doors

The production of steel fire doors is regulated by GOST R 57327-2016, which includes the basic requirements for this type of structure. This document applies to single- or double-leafed metal doors with glass up to 25% or without it, fixed as fire barriers and possessing appropriate protective properties.

Fire protection sheets are characterized by resistance to fire and tightness

The fire resistance of systems is characterized by such indicators as E - loss of the integrity of the canvas when exposed to heat, I - loss of heat-insulating qualities, S - loss of smoke and gas tightness resulting from fire. The flame resistance limit can be 15 to 60 minutes.

The main GOST requirements for these structures, their production and installation are expressed in the following:

- finished products of fire-fighting type withstand the number of openings / closings of at least 200,000;

- fire doors are always equipped with door closers. For double-leaf structures, devices are also needed to control the sequential closing of the sheets;

- a door with a door closer opened at 90 ° should close tightly in less than 5 seconds. The opening of the web can be carried out with a force not exceeding 100 N;

- smoke and gas tight systems always have a closed box with a threshold. If the canvas is located on the path of movement of people with disabilities, then the threshold should not be present;

- for sealing, polymer gaskets are used, between which a gap is not allowed. Expandable gasket options prevent smoke and carbon dioxide from spreading;

- installation involves the use of non-combustible sealants. Latches, locks and other structural elements are always made from fire-resistant structures, which is also important for filling canvases. If there is glass, then it is necessarily fire resistant;

- the service life of the finished structure is at least 10 years. At the same time, the product should not sag, which is achieved by correct installation and careful preparation of the opening.

Fire doors can have either one or two leaves

Fire protection sheets can be supplemented with attachments, for example, video cameras, communication elements. In this case, no tests are required to determine their level of fire resistance. It is worth considering that there can be no sharp, strongly protruding parts in the fittings.

External doors made of steel according to GOST

Metal sheets are a popular option as entrance doors. Such products are durable, resistant to climatic influences and other external factors. Their manufacture is carried out in accordance with GOST 31173-2003, which includes the basic requirements for quality, production and installation.

External doors should be as strong and durable as possible

According to the standard, the system can have fixed inserts of a horizontal or vertical type. The maximum weight of moving blades should not exceed 200 kg.

Entrance systems are resistant to temperature extremes and other climatic influences

Burglar-resistant or conventional outdoor structures are often equipped with reinforced elements to prevent the door from being opened illegally. The requirements for such parts, the manufacture of canvases and their installation are expressed in the following:

- anti-removable crossbars are recommended to be mounted on the side of the curtain where the hinges are located. The pins are fixed by welding or pressing, and their number is determined by the working documentation, the type of doors;

- the box is equipped with "ears" on both sides. These parts are used to firmly fasten the canvas in the opening. "Ears" are fixed to the box by welding;

- the inner filling of the web is made of sound and heat insulating materials, which are placed tightly in the frame, excluding the formation of voids;

- the minimum level of sound insulation is 20 dB. This is ensured by the use of modern, high-quality and high-tech materials;

- welds are required to be made smooth, without cracks and surface scaling. Irregularity of the seams, the presence of fusion or burn-through is not allowed;

- during installation, the quality of work is checked by the construction hydraulic level.

External doors protect the premises from cold, noise, unauthorized access. Therefore, they must be of high quality, and security is ensured by the presence of anti-burglary devices, for example, vertical crossbars.

Metal doors with glass

Entrance, vestibule or other steel doors can be equipped with glass. According to GOST requirements, such an insert should not occupy more than 25% of the entire sash area. This is due to safety requirements and allows you to provide comfortable conditions in the room.

Glass is often complemented with wrought iron grates

The basic requirements of the standards suggest that the insert must be made of tempered glass or triplex material, which does not form fragments when damaged. This makes the doors safe against fire, impact or other factors.

The standards ensuring the quality of glazed products assume the following design features:

- the connection of the glass and the door leaf is a sealed area that ensures reliable fixation of the insert;

- when installing the curtain and frame, the presence of cracks and gaps is not allowed, since condensation can form on the glass;

- installation is carried out using wedges made of plastic or wood, and the vertical deviations should not be more than 2 mm.

Sashes with glass are often complemented by a metal grill or a forged insert. Thanks to this, the product acquires an aesthetic appearance and resists burglary.

Parameters of metal doors according to GOST

The current standard assumes certain requirements for the dimensions of metal door systems. This is due to the fact that the products must have the optimal ratio of size and weight, necessary for comfortable operation and durability of the door.

Doors are varied not only in appearance, but also in size

When manufacturing, the following GOST standards are taken into account regarding product parameters:

- the diagonals of the flaps with an area of 1 m 2 should have lengths with a difference of no more than 2 mm. If the area of the canvas is larger, then the difference in lengths cannot be more than 3 mm;

- the edges of the canvas and the frame are straight, and the deviation from this cannot be more than 1 mm per 1 m of length;

- the box is fastened with anchor bolts, the cross-section of which is at least 10 mm;

- the area of external or other metal doors does not exceed 9 m 2. The recommended sash height is 2200 mm, and the width is up to 1200 mm.

Hardware requirements

In the manufacture of metal doors are equipped with locking devices that meet the requirements of standard 5089 and 538. All hinges, locks, crossbars and other parts are made of durable and refractory metal.

The fittings must comply with GOST, like the door itself

During production and installation, the following features are taken into account:

- models weighing more than 200 kg or doors intended for hospitals and other public buildings are fixed on three overhead bearing hinges or parts that allow you to adjust the canvas;

- locks and other latches necessarily provide a tight porch, careful pressing to the box and seals;

- doors of public premises are equipped with anti-panic devices, door closers, smoke detectors and other devices that ensure quick opening of the system;

- burglar-proof or reinforced canvases are equipped with multi-pin locking devices with additional locking in the horizontal frame profiles.

The protective properties of a metal door depend on the quality of the lock, handle, hinges, armored padding on the lock. The type and parameters of these parts are provided before the manufacture of the canvas.

GOST: marking and completeness of metal doors

Ready-made door systems are necessarily supplied assembled, and the locking mechanisms are already installed on the door leaf. This facilitates installation even with a non-professional approach, for example, if the buyer decided to install the structure himself.

Metal doors are installed using parts from the kit

Mandatory marking involves the designation of each product with a label or inscription with a waterproof marker. The content includes the name of the manufacturer as well as the brand of the door and the date of its production. The order number and the stamp of acceptance of the product by the quality control system must be present.

The finished kit includes a manual for the operation of a metal door and a quality certificate. In these documents, the consumer can find recommendations for installing the element. The kit assumes the presence of a lock, handle, hinges and other parts specified by the manufacturer in the description of the door model or ordered by the buyer additionally.

The requirements of the current standards apply to metal doors of various types. The application of these standards in practice allows you to obtain quality products and ensure correct installation.

Recommended:

Screens-partitions For Zoning Space In The Room: Varieties And Design Features, Manufacturing And Installation By Hand

What is a partition-screen. What are the types of screens, their features, advantages and disadvantages. How to make a partition screen yourself

Double-leaf Doors: Entrance And Interior Doors, As Well As Their Varieties With A Description Of The Device And Installation

Double-leaf doors: types, standard sizes. Accessories for double doors. Installation stages and operation features. Reviews

MDF Doors: Entrance And Interior Doors, Their Varieties With A Description And Characteristics, Advantages And Disadvantages, As Well As Installation And Operation Features

Doors from MDF: features, characteristics, varieties. Making and installing MDF doors with your own hands. Door restoration. Reviews, photos, videos

Production Of Interior Doors, Basic Rules And Requirements For The Manufacturing Process

Manufacturing of interior doors: technical rules and GOST requirements for the production process. Required materials and equipment

Restoration And Renovation Of Metal Entrance Doors, Including How And How To Paint

Do-it-yourself renovation and restoration of the entrance metal door. Restoration methods and technology for their implementation. How you can refine your front doors