Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Door closer: device, types and selection criteria

It is difficult to imagine any modern opening system without a door closer. This useful attribute helps to smoothly and silently close the front door to the room, conserving heat in winter and keeping cool in summer. Until recently, an ordinary steel spring or even a piece of elastic rubber was used for this purpose.

Content

-

1 Varieties of door closers

- 1.1 Table: international classification of door closers by closing force

- 1.2 Principle of operation and design

- 1.3 Overhead door closers

- 1.4 Lower door closers

- 1.5 Embedded devices

-

1.6 How to choose a door closer

1.6.1 Video: how to choose the right door closer

-

2 Installing the door closer

2.1 Video: installation of the surface-mounted door closer

-

3 Adjustments and repairs

3.1 Video: adjusting the closer

- 4 Reviews

Varieties of door closers

It is possible to choose a finishing mechanism not only for the external entrance door, but also for internal interior door structures. Everything here is determined by the characteristics of the canvas itself, in particular, its weight and dimensions (width).

Table: international classification of door closers by closing force

| Closer class (EN) | Door leaf weight (kg) | Web width (m) |

| one | up to 20 | up to 0.75 |

| 2 | 20-40 | 0.75-0.85 |

| 3 | 40-60 | 0.85-0.95 |

| 4 | 60-80 | 0.95-1.1 |

| 5 | 80-100 | 1.1-1.25 |

| 6 | 100-120 | 1.25-1.4 |

| 7 | 120-160 | 1.4-1.6 |

Working principle and design

The main working element of any door closing mechanism is a powerful stainless steel spring. It is housed in a special cylinder filled with oil. When the door leaf is opened, the force is transmitted to the piston by means of the traction lever, which then presses and compresses the spring. The oil flows through the valve into the vacated compartment. As soon as the door is no longer held and released, the compressed spring begins to return to its original state and press on the piston, while the working fluid flows back into the primary chamber through the system of hydraulic channels.

In some cases, simple door springs are still used today

The speed of the oil flow, as well as the translational movement of the spring and the closing of the door, respectively, depends on the cross-section of the channels. This parameter is regulated by special screws located on the mechanism body. More modern and advanced models are equipped with a large number of adjustments that allow you to hold the sash at the very end, not to swing open from sudden gusts of wind, etc.

The main working element of the closer is the spring

All door closers, regardless of class, are divided into three main groups by type of placement:

- top (overhead);

- bottom (floor);

- embedded (hidden).

Overhead door closers

The most common, versatile and simple type of mechanisms. Most often they are used on heavy and metal entrance doors. The working body is located at the top of the opening structure. If the sash opens towards itself, then the device is mounted on the surface of the canvas, while the lever is attached to the door frame (or on the wall above it). When the door swings open from itself, the device is installed on the upper crossbar of the door jamb, and the lever is located on the canvas.

Top-placed door closers are most often used.

According to the method of transferring force from the working spring, mechanisms are divided into the following types:

-

Lever (knee or articulated). The most common and reliable design, in which the movement from the lever (rod) to the spring is transmitted by means of a toothed pin or gear. In such a device, the levers stick out perpendicular to the plane of the opening, which visually does not look very attractive. For interior doors, this type is practically not used. The disadvantage is the need to apply more and more force as the sash opens.

Lever door closer In a lever structure, the movement is transmitted by means of a gear or a toothed pin

-

Sliding. The spring and two working pistons (closing and opening) are driven by a cam-shaped heart-shaped rod. The levers do not stick out to the side, but are parallel to the opening. The design itself is much less cumbersome and looks more attractive, but so far it is rarely used. When the sash is opened by about a third (30 °), its further movement is greatly facilitated, which is extremely convenient for children, elderly people and those who are simply physically weak.

Sliding cam mechanism The spring is driven by a cam bar

- Crank. An outdated design, consisting of a hydraulic oil control piston and a coil spring located in individual chambers. It has no adjustments, but a very simple and inexpensive mechanism. Due to its massiveness and large size, it requires installation quite high under the ceiling. It is still sometimes used because of its high power.

Lower door closers

Such a mechanism is mounted in a recess in the floor, opens the sash according to the principle of a pendulum in both directions. The installation is usually taken into account already at the design stage. Only the upper metal plate remains visible, so such devices are used in those places where the design is given increased importance and ugly protruding details are undesirable. Most often, bottom closers are used in shopping centers and offices. This is especially true of glass partitions, the competent organization of doorways in which there is no alternative.

The floor spring is installed in a recess in the floor

The principle of operation of the floor mechanism is very similar to the external closer equipped with a sliding rod. But there are no levers that drive the axle. The door leaf is attached to the door closer axis and rests on it with all its mass, while it moves along the other axis of rotation. It is imperative that both axes lie in the same plane and strictly perpendicular to each other. The mechanism simultaneously fixes the canvas in the opening and, in a sense, is a loop.

The principle of operation of a floor closer is similar to that of a sliding mechanism.

The heart-shaped shaft, which is the lower support for the curtain, turns when the door is opened and acts on the roller, which is located between the two plates. These strips are connected to the piston by means of a rod, which is placed inside the compressing helical spring. Thus, the rotating movements of the support shaft lead to the compression of the spring and the accumulation of energy by it when opening the sash, which is subsequently spent on a smooth and uniform closing.

You can also find lever-type floor closers on sale. But they are not very popular, since they are much more expensive than conventional overhead mechanisms for top mounting, do not look very presentable and are often mechanically damaged during operation.

Overhead floor structures are rarely used

Several years ago I had the opportunity to order glass partitions for the arrangement of a retail outlet in a large furniture center. It was necessary to provide for a doorway of sufficient width and height so that it was possible to freely bring in and take out the overall furniture. The issue with the choice of accessories was solved quite simply. You can, of course, use ordinary swing hinges and not install a door closer in the floor, but then the sash will open only in one direction and be fixed in only one position by a locking mechanism (lock). We ordered a soft closing mechanism, as we listened to the advice of experienced people, and did not regret it. You can swing the doors outward and inward. They cannot accidentally slam shut, since they are reliably held by the closer in the extreme positions. The only thing,that at the moment of their opening, some physical effort was required. Especially in the early days, the mechanism worked rather tightly and the doors were difficult to open.

Embedded devices

Hidden mechanisms are mounted directly in the doorframe or in the sash itself, so they are almost invisible visually. They are divided into two types, which are fundamentally different in design:

-

Closer loop. The smallest device of this type. The mechanism is hidden in the body of the door shed; during its installation, additional work is not required (chiselling or drilling the canvas), excluding the installation of the hinges themselves. But it is rather difficult to mount them correctly, since for good operation of the closer, exact alignment between the hinges is required. The miniaturization of the mechanism limits the scope of its application: it cannot be used on heavy canvas and its service life is short.

Concealed door closer The closing mechanism in the hinge closer is built directly into the canopy

-

Sliding rod devices. In fact, they are one of the options for a door overhead mechanism with an upper placement method, the difference is only in the dimensions and installation method. The small size of the device allows it to be cut into a door frame or directly into an array of canvas.

Concealed door closer with sliding rod The built-in door closer with a sliding rod differs from the surface-mounted door closer only in its smaller dimensions, which allow it to be embedded into the door leaf or into the door frame

How to choose a door closer

When choosing a device for smoothly closing the door leaf, the following important points must be considered:

- Power (class). The required force of the closer is determined based on two main indicators: the width of the sash and its weight. The larger and more massive the door leaf, the more difficult it is to close it and the more powerful the finishing mechanism should be and the higher its class. But an overly strong device creates an additional load on the fittings (hinges) and provokes their premature wear, and it is much more difficult to open such doors.

- Installation method. The most common overhead door closers are top-mounted and are suitable for almost all door designs (except for solid glass).

- Opening side: universal, right and left.

-

Frost resistance. It is necessary to consider at what temperatures the device will work. There are the following types of closers, depending on the temperature regime:

- ordinary - from -10 to +40 ° C (installed on interior doors);

- thermostable - from -35 to +70 ° C (used on entrance structures in regions with a relatively warm climate and on internal access doors);

- frost-resistant - from -45 to +70 ° C (used at extremely low temperatures).

The permissible temperature indicators at which the closer works correctly are always indicated on the packaging

When choosing a closer, it is recommended to pay attention to several additional options:

- wind brake (opening damper) - a separate hydraulic circuit with its own adjustment, which does not allow the sash to swing open sharply in case of a sudden gust of wind;

- slamming - accelerating the course of the web at the very end to overcome the resistance of rubber seals and the lock latch;

- closing delay - the doors remain open for a while (usually no more than 30 seconds), and then they close;

- position fixing - the sash is fixed at a certain value of the opening angle using a locking lever or electromagnets (for fire doors).

Video: how to choose the right door closer

Installing a door closer

It is recommended to independently install only closers of the upper outdoor location. It is better to entrust the installation of floor and hidden mechanisms to professionals, since very specific work requires a special tool and a certain skill.

For almost every package with a product, the manufacturer encloses detailed and understandable installation instructions, as well as an installation template, which shows schematically all parts of the mechanism in full size and the location of mounting mounting holes for each part. On one side of the sheet, a diagram of the installation is drawn when opening the sash towards you, on the back - from yourself.

The mounting template indicates the location of the mounting holes

To complete the work you will need: a drill, a screwdriver, pencils or a marker and a measuring tool (tape measure, ruler, etc.). Fasteners for different types of door leaves (wood, metal, plastic) are included.

The kit usually includes fasteners

We carry out the installation of the closer using the following technology:

- We apply the template to the upper part of the canvas, focusing on the red lines on it (for convenience, it is better to fix the sheet with tape). A long horizontal line must be combined with the upper edge of the sash, we set the vertical line perpendicular to it along the axis of the hinges.

- Mark the necessary mounting holes through the paper with an awl.

- We remove the template and drill holes of the required diameter, which is indicated in the instructions.

- If the mechanism is completely assembled, then you need to separate the levers and the body. To do this, unscrew the screw connecting them.

- We attach the body to the marked holes and tighten the fasteners.

- Mount the link arm in the same way.

- We connect the lever to the body.

It is not difficult to install a door closer on your own

Video: installation of an overhead closer

Adjustment and repair

To ensure the reliable and long-term operation of the bringing device, it is necessary to correctly adjust the mechanism immediately after its installation. As a preventive measure, this procedure is carried out at least twice a year.

Most models are equipped with two special adjusting screws, which are located on the decorative cover or at the end of the case.

There are two adjusting screws at the end of the closer or on its body

The screw adjustment elements are indicated by the following numbers:

- Screw that adjusts the opening angle of the sash from 90 to 180 °. Turning the screw in a clockwise direction decreases the opening angle of the door leaf, turning it counter-clockwise increases it.

- A screw that regulates the speed of the mechanism at the last 7-15 ° (clap). Turning the adjusting screw clockwise reduces the closing speed of the web, turning in the opposite direction increases it.

It is quite easy to adjust the closer

The adjusting elements should not be tightened more than 1/4 of a turn at a time, since the adjustment is quite subtle and the differences will be noticeable immediately. Otherwise, the screws can be tightened too much or loosened too much, which will damage the mechanism. First, the first element is regulated, only then the second.

More complex devices have more adjustments

If the closer is used improperly, the mechanism may not work well or even break down. In this case, the device is first dismantled and carefully inspected for mechanical damage to the case (cracks, dents, etc.). If there are defects in the levers, then they are corrected: they are cleaned of rust, bends and curvatures are straightened with a hammer, fractures are eliminated by welding. If a depressurization of the housing and oil leakage is detected, which can be caused by various reasons (wear of oil seals, a crack in the housing, etc.), you should contact the repair organization. But in most cases, repairs are impossible and the entire mechanism will have to be replaced.

If used incorrectly, the life of the door closer is greatly reduced

In the recent past, when no one had ever heard of any door closers, the front entrance doors of houses were equipped with ordinary steel springs. As a rule, they were adjusted with a margin, so that the door would probably close. They especially tried to follow this in the winter. The sash slammed shut with a deafening crash. We then lived on the first floor and you could hear everything. We, children, were repeatedly pinched hands, feet, and sometimes other parts of the body. Sometimes it was not so easy to bring skis or sledges into the entrance, because the frozen hands and feet refused to react quickly, and sometimes it was not possible to quickly slip through the door that opened for a short time. However, the spring stretched quickly enough and the driveway doors were open again.

Video: adjusting the closer

Reviews

Nowadays, door closers are not uncommon; they have become an integral part of almost all opening systems. A well-chosen and correctly installed mechanism guarantees a smooth movement of the sash and will serve for many years with the correct operating mode.

Recommended:

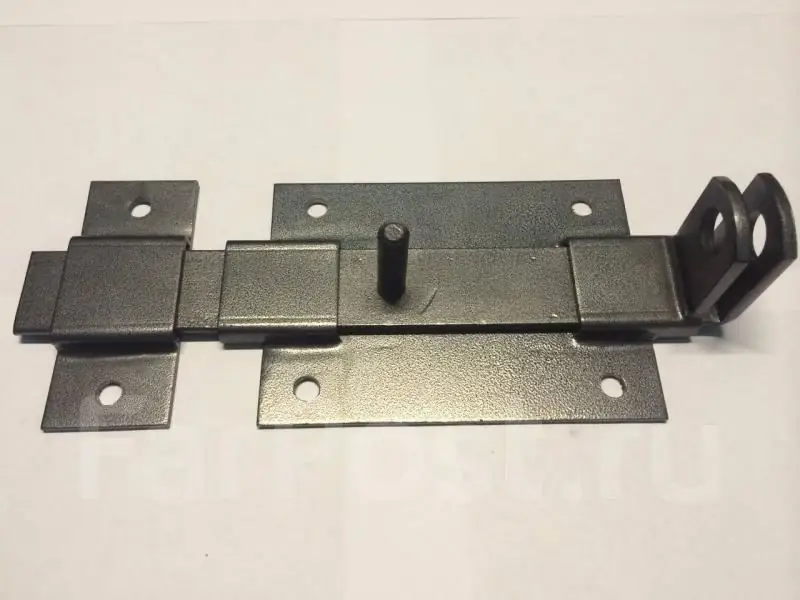

Door Latch (latch): Varieties With Description And Characteristics, Pros And Cons, As Well As How To Properly Install On The Door

The purpose of the door latch. Principle of operation. Types of door valves. Installation of various types of valves. Features of installation on different types of doors

Entrance Doors: Varieties, Material Of Manufacture, Features Of Installation And Operation, As Well As What You Need To Consider When Choosing, Photos, Reviews

Entrance doors: device, principle of operation and varieties. How to choose and install entrance doors correctly. Tips for operation and repair

Door Slopes: Functions And Device, As Well As Do-it-yourself Installation And Finishing Features

What is a door slope, its functions and device. What materials are used for finishing the slopes. Step-by-step instructions for plastering door slopes

Door Latch: Varieties With A Description And Characteristics, Pros And Cons, As Well As How To Properly Install On The Door

Purpose of the door latch. Types of door latches, features of their device, advantages and disadvantages. The process of mounting and dismantling the door latch

Mauerlat, Its Purpose And Functions, As Well As Features Of The Device And Installation

Appointment, features and calculation of the Mauerlat. Principles of mounting the base under the truss system. Methods for attaching the Mauerlat to walls made of different materials