Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Properties and application features of waterproofing membranes for the roof

Protection of the roof from moisture is an important aspect that must be taken into account when arranging a roof. For this purpose, various types of waterproofing membranes are used.

Content

-

1 What is a membrane for roof waterproofing

- 1.1 Characteristics and properties

- 1.2 Types of membranes

- 1.3 How to choose a membrane for roof waterproofing

-

2 Preparation and installation rules

-

2.1 Installation steps

2.1.1 Video: Installation of membranes on the roof

-

What is a membrane for roof waterproofing

When building a house, it is important to use not only high-quality materials, but also protective layers that prevent deformation of the supporting elements of the building. The waterproofing membrane is one of the most important elements of the coating used in the construction of the roof.

Its main function is to protect the roof truss system from moisture and precipitation. This prevents rotting of wooden rafters, the appearance of cracks in concrete slabs and other unpleasant consequences.

The waterproofing membrane is an indispensable part of the roofing pie, designed to drain moisture from the under-roof space into the drainage system

Membranes are often confused with roofing waterproofing films. When choosing a material, it is worth considering that the membrane is an improved version of the film and has better technical characteristics than film sheets.

Characteristics and properties

Membrane materials for roof waterproofing are diverse, but have common features. Their important advantage is that they are saturated with fire retardants and enhance the fire protection of the roof. The high degree of elasticity makes it easy to lay the membranes on any surface. This is due to the presence of plasticizers, stabilizers and other fillers in the composition.

Waterproofing membranes are laid just before installing the roofing material

Many characteristics of waterproofing membranes differ depending on their type, but a number of important qualities are present in all such products:

- light shade of the fabric to prevent heating of the membrane;

- frost resistance and the ability to operate at temperatures below -18 ° C;

- resistance to mechanical stress and stress;

- service life is about 30 years depending on the type of material.

Types of membranes

Different structures serve as the basis for the manufacture of waterproofing sheets, and therefore there are several types of membranes. Material characteristics, installation features and other parameters differ significantly.

Membranes vary in appearance, characteristics and installation methods

When choosing a specific waterproofing option for the roof, it is worth considering the task that the material must perform. Moisture protection is the main function, but installation considerations, cost and other parameters should also be taken into account. Therefore, you first need to study the main types of waterproofing membranes:

-

PVC canvases based on plasticized polyvinyl chloride film. The material is reinforced with a polyester mesh and therefore can withstand up to 200% stretch. The technical characteristics of the membrane are maintained at operating temperatures from -40 to +60 ° C. PVC sheets are supplied in rolls with various widths and lengths;

PVC membrane in rolls PVC membrane is dense and tear resistant

-

EPMD membranes are made from synthetic polymerized rubber, stabilizing additives and reinforcing mesh. The service life is from 50 years, while the coating is environmentally friendly and harmless to human health and the environment. Elongation can reach 400%, but the structure is resistant to higher loads;

EPMD membrane Synthetic membranes based on polymerized rubber are highly elastic and environmentally friendly

-

TPO structures are made from olefins of the thermoplastic type, which are based on rubber and polypropylene. The material has a very high resistance to abrasion and mechanical stress, therefore it is durable - its service life is more than 50 years. Compared to other membranes, TPO-sheets have less elasticity, but are compatible with any roofing materials based on bitumen and polystyrene;

TPO membranes TPO-fabrics have a very high resistance to mechanical stress, therefore they serve for more than 50 years

-

Profiled membranes for roof waterproofing are made of high strength polyethylene and have a surface with many protrusions. The web can consist of three layers of film. The material is suitable for waterproofing roofs and other building elements.

Profiled membrane Profiled sheets are used for waterproofing any building elements, including the roof

How to choose a membrane for roof waterproofing

The range of waterproofing materials includes various options that differ in characteristics, appearance, quality level and other parameters. Therefore, before choosing, you need to determine the key factors that are taken into account when determining the appropriate material option. When choosing a waterproofing membrane, you should pay attention to the following parameters:

- composition - the waterproofing film must necessarily be impregnated with fire retardants, which increase the protection against fire;

- service life - the material must perform its functions for at least 30 years;

- fastening method - it must be borne in mind that some membranes are designed for fusion installation, which is suitable for flat roofs;

-

cost of material - it should not be too low compared to the average market price, because this may be an indicator of poor quality or marriage.

Laying the membrane on the roof Different types of films are laid and attached in different ways: they are nailed with a stapler, glued with mastic or a special compound, or fused with a gas torch

In the building materials market, products from several manufacturers stand out. Products of such brands as:

-

Jutafol is a manufacturer of a wide range of materials for waterproofing and vapor barrier of various types of roofs. Membrane films in the Yutafol assortment are distinguished by their compliance with current quality standards, as well as durability, strength and resistance to temperature extremes;

Membranes "Yutafol" Waterproofing membranes "Yutafol" are especially in demand and are distinguished by their durability

-

Tyvek. The company specializes in the manufacture of roofing materials, and membranes occupy one of the main positions in the brand's assortment. Steam and waterproofing membranes can withstand operation at low temperatures, help steam out and prevent moisture from entering the room;

Tyvek roofing membranes Modern waterproofing membranes manufactured by Tyvek are distinguished by high moisture resistance and elasticity

-

Technonikol. A well-known domestic manufacturer of building materials produces goods focused on Russian climatic zones. Waterproofing films and membranes are suitable for regions with severe winters and high humidity, as they are resistant to ultraviolet light, aggressive substances and high tension.

Membranes "Technonikol" Profile membranes "Technonikol" are designed for use at low temperatures and high humidity

Preparation and installation rules

The installation of the membrane is distinguished by a simple technology, but in order to achieve a good result, it is important to consider the following simple preparation rules:

- the distance between the rafters should not be more than 1.2 m;

- the gap between the waterproofing and the roof insulation must be at least 40 mm;

- all work must be carried out only in dry weather;

- films or membranes must be spread from the eaves to the ridge, making an overlap of about 15 cm;

- Do not pull the fabric too tight. The optimum sag depth is approx. 20 mm.

The amount of overlap is determined depending on the angle of inclination of the roof:

- if the slope is 30 °, then the canvases are superimposed on each other by 15-20 cm;

- at an inclination of 12-30 °, the overlap is made equal to 25 cm;

- for steep hipped roofs on ridges, the overlap is increased to 30 cm.

Membrane sheets are laid with an overlap, the value of which depends on the angle of inclination of the roof

Installation steps

The method of installing waterproofing films differs depending on the type of material. Self-adhesive sheets do not require mechanical fastening, as they are fixed to flat surfaces by heating. Profile membranes, on the other hand, do not have an adhesive base, therefore they are fixed with nails or staples. The installation sequence of the profile membrane is as follows:

-

The roll is rolled out over the roof surface and strips of the required length are cut.

Cutting membrane webs The rolls are spread on the roof taking into account the overlap and the canvases are cut to the required length

-

The membrane is fixed with staples, and then thin strips are nailed to ensure a better fit of the canvas to the base.

Fastening the waterproofing membrane A crate for roofing material is mounted on top of the waterproofing

-

At the joints of the roof, the placement of pipes and the abutments of vertical surfaces, the canvas is carefully cut, the edges are sealed with a special compound having the consistency of a paste. In the area of the valley and other difficult knots, the edges of the material are sealed with special adhesive tape.

Arrangement of joints and abutments At the joints of the roof slopes and the passage of the stove and ventilation pipes, the film is carefully cut, and the edges are fixed with adhesive tape

Video: installation of membranes on the roof

Waterproofing membranes are necessary to protect the load-bearing elements of the roof from precipitation, which ultimately ensures the durability of the entire structure. To achieve this effect, it is important to choose the right material and perform installation in accordance with the recommended technology.

Recommended:

Interior Door Lock: Types And Their Characteristics, How To Choose And Install Correctly

Types of locks for interior doors, their features, advantages and disadvantages. Self-installation, repair and replacement of the lock on the interior door

Door Locks: Types And Their Characteristics, How To Choose And Install Correctly, As Well As A Rating For Reliability

Varieties of door locks. How to choose the most reliable device. Do-it-yourself door lock installation and repair. Operating tips

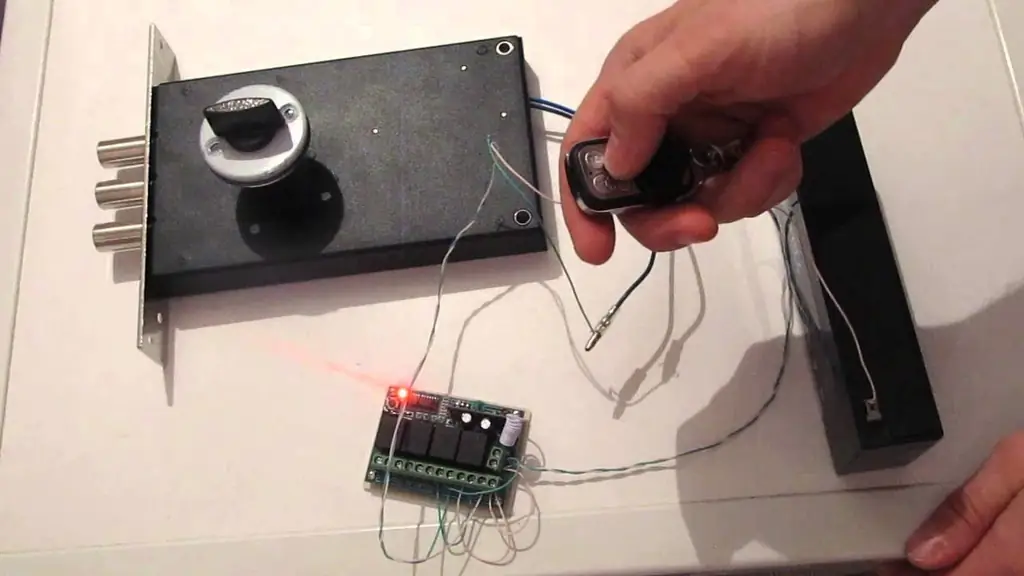

Electromechanical Door Lock: Types And Design Features, How To Choose And Install Correctly

What is an electromechanical lock. Features of its device and existing types. Installation of an electromechanical lock, its repair and operation

Electromagnetic Lock For Doors: Varieties And Design Features, How To Choose And Install Correctly

Types of electromagnetic locks and how they work. Self-installation, repair and operating features of electromagnetic locks

Waterproofing The Roof With Liquid Rubber, How To Do It Right, Including Preparing The Roof For Work

Liquid rubber: properties and characteristics. Calculation of the material. Technology and methods of application. Step by step instructions for work