Table of contents:

- How to make a steam room in a bath with your own hands

- Steam room in the bath - general arrangement

- Preparatory work: determining the optimal size of the room

- Material selection

- Calculation of the amount of material and the necessary tools

- Do-it-yourself steam room - step-by-step instructions for construction and decoration

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

How to make a steam room in a bath with your own hands

The steam room is the central part of the bath, since the quality of bath procedures, the formation of steam, as well as the safety of visitors depend on it. That is why, during the construction of the bathhouse, the steam room project is given great attention and the owners often do not hire builders, but do everything with their own hands.

Content

- 1 Steam room in the bath - general arrangement

-

2 Preparatory work: determining the optimal size of the room

2.1 Types of ovens for the steam room

- 3 Material selection

- 4 Calculation of the amount of material and the necessary tools

-

5 Do-it-yourself steam room - step-by-step instructions for construction and decoration

- 5.1 Floor Installation Instructions

- 5.2 Instructions for vapor barrier and ceiling installation

- 5.3 Instructions for wall insulation

-

5.4 Instructions for installing the oven

- 5.4.1 Installing the electric heater

- 5.4.2 Installing a brick oven

- 5.5 Door installation instructions

- 5.6 Instructions for the installation of shelves

- 5.7 Instructions for ventilation device

- 5.8 Instructions for the device of electricity

- 5.9 Video: how to make a steam room in a bath correctly

Steam room in the bath - general arrangement

The device of a steam room should be quite simple, but at the same time convenient and comfortable for people who will take a steam bath. The main thing is that it contains the required number of shelves and racks.

The stove is the main element of the steam room, since it is it that is designed to provide the required temperature and microclimate in the room. Today, any type of oven can be installed in the steam room: brick, stone, metal or electric.

Sauna stove in the steam room

Sauna shelves are traditionally made of wooden planks, leaving small gaps for the free flow of water. The wood from which the shelves are installed must be non-coniferous. Usually the shelves are attached to the walls of the room so that there is as much free space as possible and it can be easily removed after visiting the steam room. Various bath accessories are located under them: buckets, ladles, brooms, etc. The distance from the floor to the shelves should be as high as possible, since the coldest air is just below. From the ceiling to the top shelf, there should be a little more than 1 meter. They can also be fold-out or pull-out.

Two-level shelves in the steam room

The steam room should be of optimal dimensions so that it can warm up to the required temperature. Experts recommend designing a room area of 2x2.5 meters (height 2.1 meters). It is a convenient and economical steam room device.

The walls of the room should be insulated with a special material that can retain heat for a long time and not release harmful substances into the air. The floor in the steam room is usually made of wooden planks or tiles that can be easily and quickly cleaned.

The door to the steam room should be as small as possible, since it is an additional source of heat loss. The best option for arranging doors is considered near the stove. It should open and close very easily, and also not have any constipation, as it can jam due to the high humidity in the room. There are no windows in the steam room, but if they need to be installed, they must be very small and deaf. It is recommended to place them as close as possible to the ceiling, where the air is least heated.

Wooden door to the steam room

The ventilation system is obligatory in order for it to remove excess moisture from the room and provide fresh air. Traditionally, a supply and exhaust system is used for this. The openings for air intake are located near the oven, and the hood is opposite.

Steam room ventilation duct

Since there are no windows in the room, you cannot do without lighting devices. Luminaires should be made specifically for humid rooms where there is a temperature difference. It should be noted that there is no artificial lighting in the Finnish sauna, since it is created by embers in the stove.

Steam room lighting system

Preparatory work: determining the optimal size of the room

The steam room project must be developed even before the construction of the bath begins, since its size can depend on a large number of factors.

The design takes into account such indicators as:

-

The maximum number of visitors who will be in the steam room at the same time. According to the standards, at least 0.7 2 areas are required for each person.

Recommended bath sizes Recommended sizes of bath rooms

- It is necessary to focus on the growth of the tallest person in the family. This figure requires about 20 cm. Also, when calculating, you must take into account the thickness of the insulation, which will "take" a few centimeters. Too high a steam room will cause additional heat consumption and insufficient heating of the room. The optimum height is 2.2-2.4 meters.

- Options for placing people on the shelves. If there are seating benches in the steam room, it will be possible to make the room more compact. The recumbent position will require more space. In this case, the dimensions of the steam room should be 20 cm larger than human height.

-

Type, power and dimensions of the furnace. It should be installed at a distance of at least 32 cm from all wooden elements of the structure. If the walls are covered with special fire-fighting material - at least 26 cm.

Steam room projects Steam room projects with shelves

Types of stoves for steam rooms

-

The metal stove has a high degree of power, small dimensions and is able to warm up the entire volume of the room as quickly as possible. But since its surface is heated to a high temperature, people in the steam room can accidentally get burns. Therefore, it is best to make a protective fence for her.

Metal oven Metal stove in the steam room

-

A brick oven heats up for a long time, is large and keeps warm for a long time. It is almost impossible to burn yourself on such a stove, so it can be placed in the immediate vicinity of the shelves.

Brick oven Brick oven in the steam room

-

An electric heater can only heat a small steam room. Therefore, it is chosen for small rooms.

Electric oven Electric oven in the steam room

Material selection

A bathhouse, including a steam room, can be built from brick, natural stone, gas or foam blocks, but a good tree is considered the best "bath" material. Usually planed and rounded logs or timber are taken for the steam room. Glued laminated timber, which has the maximum degree of resistance to moisture, is excellent. But it is the most expensive of all materials.

The most affordable and convenient in laying, as well as resistant to various kinds of deformations, is a profiled beam

It is best to build a steam room from larch, aspen, birch, linden, since these rocks do not emit tar. But if, nevertheless, you decide to choose pine, then it is best to erect only walls from it, and make the interior decoration from non-coniferous wood.

Calculation of the amount of material and the necessary tools

To build a bath (steam room) we need:

- Beam 15x15 for the construction of walls. For two or three lower crowns, we take larch, and for the upper ones, a pine beam.

- Beam 15x10 for the construction of partitions.

- Concrete mortar.

- Sand, crushed stone, clay.

- Fittings for foundation construction.

- Second-class formwork boards.

- Waterproofing materials (roofing material).

- Flat stones.

- Refractory bricks.

- Insulation (jute or tow).

- Aspen, linden or alder lining (recommended 12 mm thick for wall cladding and 50 mm for ceiling).

- Tile.

- Foil or special foil material for heat and vapor barrier.

- Minvata.

- Slate, roofing felt and galvanized.

- Antiseptic agents.

- Lighting fixtures, cables, fan, switches and junction boxes.

Tools

- Shovels or small excavator.

- Electric or gasoline saw.

- Concrete vibrator.

- Axes.

- Electric drill.

- Hammers.

- Electric screwdriver.

- Mallet and caulk.

- Construction stapler.

- Rule and level.

Do-it-yourself steam room - step-by-step instructions for construction and decoration

After the project is fully drawn up, you can proceed with the construction of the foundation and the construction of walls.

-

Laying the foundation. To do this, we need to dig a rectangular pit. The depth should reach ½ of the soil freezing. The height above the ground is about 15-20 cm. If there is no basement, then raise it by 60 cm. The width of the foundation should be about 10 cm greater than the width of the timber. From above we install the reinforcement, on which we will attach the first crown.

Formwork with fittings for a bath Formwork with reinforcement for the construction of a wooden bath

-

We make the formwork and fill the foundation with concrete and remove the bubbles with a vibrator.

Pouring concrete Pour concrete into the formwork

-

We dig a drainage pit under the washing hole 1.8x1.8x1.5 m and fill its walls with concrete.

Drain pit under the sink We dig a drain hole under the sink

-

Let the foundation stand for about 5-7 days. In the upper part we make ventilation holes, which are located on opposite walls.

Ventilation duct in the foundation The ventilation duct in the bath foundation

-

We make a blind area around the entire foundation (1.2-1.5 meters). To do this, we take clay and mix it with rubble. We add a layer of 5-10 cm.

Clay blind area with rubble Blind area around the foundation made of clay with rubble

-

On top of the perimeter of the concrete foundation, we lay the roofing material in several layers. It should extend beyond the base by 5 cm.

Foundation waterproofing Foundation waterproofing with roofing material

-

For the construction of walls, we can take factory wall kits. Or we can cut the timber ourselves into workpieces of the required length. Then cut the necessary grooves and tenons. In the initial row we mark in accordance with the installation of the reinforcement and drill Ø25mm holes.

Laying the first crown Laying the first crown of the bath walls

- We put the first crown on the pins, connect the bars, and seal the connection points.

-

We put the second row, we drill holes, which will go by ½ the height of the first row. We remove the second row and hammer the dowels into the holes of the first one and a half of the height of the bar. Then we fill the next row on them. We connect the crowns with dowels. We insulate the grooves with jute. We leave space for doorways. Thus, we build a sauna with a steam room up to a certain height.

We build the walls of the bath We build the walls of the bath by driving in dowels

-

We cut the floor beams into the upper crown, and in them the lower ends of the rafters. We connect the upper ends in the ridge. We make a step between the rafters about 1-1.2 m, and we nail the skate board and the crate to them. We lay hydro and vapor barrier on top, and then slate or other roofing material. We provide for embedded pipes in advance.

Roof device Bath roof device

Floor Installation Instructions

The floor is installed immediately. In the steam room, its level should be higher than in other rooms. Let's consider several ways of laying the floor.

-

For the construction of a wooden floor, we put logs from a wooden bar on the prepared foundation.

We lay logs We lay the support logs

-

We nail boards on them with a step of 5-10 mm. The distance between the floor and the ground must remain at least 50 cm.

We stuff the boards on logs For a pouring floor, we fill the boards on logs

-

We made ventilation holes in the foundation in advance.

Wooden floor device Installation of a wooden floor in the steam room

-

A concrete floor is much stronger and more durable, but it costs a lot more. In the steam room and the washing room, we dig out a pit (depth 10-15 cm) for the drain. We fix the walls with concrete mortar. We put a metal crate on top. From the sump, the waste water will drain into the sewer drain pipe.

Floor device with pit Construction of a concrete floor with a pit

-

After the drain device, we make a screed. First, on the walls, mark the points to which the floor level will be brought. We mark down from them the distance for filling the screed.

Screed layers diagram Floor screed layer scheme

-

We carefully level the ground, removing a little of the upper part.

Soil preparation Preparing soil for flooring

-

Pour sand with crushed stone (30-40 cm), water and tamp well. We envisage a slope towards the drain.

Reinforced pillow Reinforcing mesh pillow

-

We fill in the first layer of concrete solution 5 cm.

First layer of concrete Pour the first layer of concrete

-

After the screed is dry, we roll out roofing material or glass insulating material on it.

We lay roofing material We put roofing material on the screed

-

We put heat-insulating thick 50 mm material on the waterproofing.

Laying insulation material Laying insulation material on the floor

-

We lay a rigid metal mesh reinforcement.

Reinforcement laying Reinforcing mesh laying

-

We fill in the second layer of concrete solution 10 cm.

Second layer of concrete Putting the second layer of concrete

-

We level the concrete, not forgetting the drain slope.

Leveling the floor Align the floor with the arrow rule

-

We lay the tiles.

We lay the tiles Laying tiles in the steam room

Instructions for vapor barrier and ceiling installation

-

We attach material for hydro-vapor barrier to the floor beams. To do this, you can use foil, special foil-clad foam insulation or a hydro-vapor barrier membrane. We mount the material with a stapler and staples 8-12 mm. We put the sheets with an overlap of 20 cm, and strengthen the joints with adhesive tape. We wrap them on the walls with a 15 cm ledge.

Ceiling vapor barrier Steam insulation of the ceiling in the steam room

- We fasten wooden slats (50x25 mm) to the floor beams in increments of no more than 70 cm. Maintain the level. Before fastening, we treat with an antiseptic solution.

-

We fasten the lining perpendicular to the crate with studs or clamps to the slats.

We fix the lining We fix the lining to the ceiling

- We cut out grooves in the beams and install fasteners for the chimney device in them.

-

On the ceiling we cut out the opening for the chimney.

Chimney opening in the ceiling Chimney opening in the ceiling of the steam room

-

We put insulation between the beams in the attic (it is better to take 150-200 mm).

Insulation laying Laying insulation in the attic of a bath

-

We lay out the windproof membrane from above and fix it with staples with a stapler.

Spreading the windproof membrane we spread the windproof membrane on the insulation

-

We carry out the laying of boards on the floor of the attic.

Laying floorboards in the attic Laying floorboards in a steam room attic

Wall insulation instructions

-

First, we saw through an opening in the wall for mounting the stove.

Oven opening Cutting the opening for the oven

-

Since the walls were erected from profiled timber, we simply nail foil onto them and attach a wooden lathing on top.

Insulation and lathing of walls Insulation and lathing of walls for lining

-

We carry out the installation of the lining to it.

Mounting lining on the wall Installation of lining on the wall of the steam room

Furnace installation instructions

-

We install the selected oven on a flat base. If it is a metal or electric stove, then it is necessary to make a concrete base under it. A special foundation is made for laying a brick wall.

Oven base Base for installing the oven

-

We cover the stove with bricks, passing along the walls adjacent to it and inside the adjoining partition. We seal the cracks with basalt material. We use refractory bricks for lining the heater.

We cover the oven with bricks we cover the furnace with refractory bricks

-

In the opening on the ceiling, we attach a metal sheet to create a chimney outlet. We make an opening for the pipe in advance in the sheet.

We fix a sheet with a hole to the ceiling We attach a metal sheet with a hole for the chimney to the ceiling

-

On top of the stove we install a galvanized or stainless steel pipe and a gate. We fix the tank and release a reinforced chimney with two walls through the ceiling. We make insulation with non-combustible materials.

Insulate the pipe We isolate the pipe from the wood covering

-

We nail an iron sheet on the roof, with a hole made for the pipe.

We nail a metal sheet on the roof We nail a metal protective sheet on the roof

Installation of an electric heater

-

We install it on a flat base or hang it on the wall. For this we nail in special strong brackets. There is no chimney for this oven.

Installing an electric heater in a steam room Installing the sauna heater on the wall

- We study the instructions and maintain the distances indicated by the manufacturer from the stove to the walls of the steam room and the ceiling.

Installing a brick oven

- We put a traditional brick oven at the stage of the construction of the bath itself.

-

Only a small part of it will go inside the steam room, in which stones will be located. The combustion chamber must be located in a special room or taken out into the street.

Brick oven in the steam room The device of a brick oven in the steam room

Door installation instructions

At the very end, we install the door. It should be very tightly closed so that the heat from the steam room does not escape.

-

We collect a jamb from a bar (100x150 mm). We fit the doorway exactly under it.

Diagram of a window Diagram of the device

-

On the end parts of the timber in the opening, we cut out a spike slightly smaller than the dimensions of the groove on the window. At the same time, do not forget that we will lay a sealant (tow or jute) between the box and the timber.

Thorn cutting scheme The scheme of cutting a thorn for a jig

-

We install a threshold in the opening, and then the rest of the box details.

Door frame installation Installation of a door frame in a bath

-

We fasten the top element of the box so that it is a few centimeters below the door opening. This is necessary in order for the timber to have free play during shrinkage. We seal all the cracks between it and the wall.

We maintain the gap Maintain a gap for shrinkage

-

We hang the door and nail the platbands with small carnations.

We hang the doors we hang the doors and fasten the platbands

-

You can also install the door in the second way. To do this, cut grooves in the opening. We put the bars in them so that their ends do not touch 5-10 cm of the top of the opening. And then we mount the door frame to them.

Okosyachka in the groove The second way of mounting the box is a box in a groove

Shelf assembly instructions

The number of shelves depends on its size. The standard solution includes three-level shelves, each of which has a height of 35 cm. But two shelves can also be made.

-

First, we select the shape of the shelves and assemble their frames. We recommend making it from larch. The shelves can be made rectangular or angular.

Shelf frame Steam room shelf frame

-

On top of the frames, we lay the prepared wooden boards.

We fasten the shields We fasten the shields to the frames

-

We place the boards loosely with a step of about 1 cm. The boards can be made from aspen or linden.

Placement of shelves Placement of shelves in the steam room

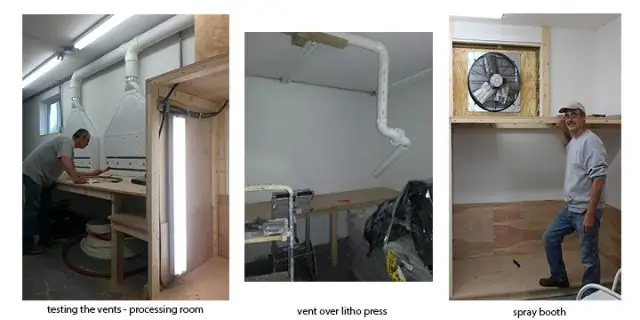

Ventilation device instructions

There are several ways to ventilate the steam room. The choice depends on the size of the room, as well as the convenience for the owners of the bath. The opening should be at a distance of 25 cm from the floor. The air is removed naturally through the opening on the opposite side.

- We make ventilation ducts in the wall near the stove. The lower one is for air intake, and the upper channel is for ventilation. We install a fan in it.

- Oxygen enters through a small hole behind the stove, which is made 20 cm from the floor. The withdrawal is carried out through the genital slits. A duct is created near the building, which will draw exhaust air from under the floorboards.

- We drill a 10x10 cm hole in the floor for the flow of cold air. We install the ventilation box in the wall opposite the stove. We make an exhaust opening under the ceiling. A canal with a valve will be led out into the street through a wall hole.

-

If there is a firebox with a blower in the room, then it is necessary to make an opening in the floor of 10x10 cm and close it with a grate. Air will pass through it, and leave the chimney.

Ventilation schemes in the steam room Various ventilation schemes in the steam room

-

For ventilation ducts, we take stainless steel or galvanized pipes.

Galvanized pipes for ventilation Galvanized pipes for ventilation in the steam room

-

Having chosen a ventilation system, we make openings of the required diameters in the walls or floor (but not less than 10 cm).

Ventilation hole Hole for the ventilation system in the steam room

-

We insert ventilation ducts into the openings. We lay the cracks between the wall and the pipe with non-combustible material.

We insert ventilation ducts into the openings We insert ventilation ducts into the openings

-

We install a protective grill outside.

Protective grill Protective grill outside the bath

Instructions for the device of electricity

At the last stage of the steam room installation, we carry out the installation of electrical wiring.

-

We take all switches, sockets and boxes outside the steam room.

Installation of electrical wiring Installation of electrical wiring in the steam room

-

We lay cables in the engineering corrugation on top of the lining.

Wiring in corrugation Wiring in the steam room in the corrugation

-

In the steam room we protect all wires with baseboards.

Wiring under skirting boards We start the wiring under the plinth

-

We protect the luminaires with wooden gratings.

We install lamps with protection We install luminaires with protective grilles

Video: how to make a steam room in a bath correctly

The construction and installation of a steam room in a bath is not an easy job, as it requires certain skills in working with various types of materials and tools. But if you do everything efficiently and approach the issue responsibly, then you can make an excellent bath with a steam room on your site, which will serve you and your family for many years and will delight you with its healing steam.

Recommended:

Living Room And Bedroom In One Room: How To Combine, Interior Design, Ideas + Photos

How to distribute space in one room: living room combined with a bedroom. Several ways of zoning a room

How To Make A Kite With Your Own Hands At Home: Options With Drawings And Sizes + Photos And Videos

DIY kite: the necessary materials, diagrams, drawings, manufacturing steps. How to make a kite of different shapes. Secrets of a Successful Launch

How To Choose And Build A Foundation For A Bath With Your Own Hands - 4x6, 3x4 And Other Sizes, Tips, Instructions, Photos And Videos

How to make a foundation for a bath with your own hands. Types and features of foundations. The choice of materials and technology, installation rules and step-by-step instructions

Interior Sliding Partitions For Zoning The Space Of A Room: Design And Material Features, Their Pros And Cons, As Well As Installation Instructions, Photos

The device and purpose of interior sliding partitions. Varieties of partitions by design. Independent production and installation

Dropper For Metal Tiles, Including Its Types And Sizes, As Well As Device And Installation

What is a drip. Purpose and types of eaves aprons on a metal roof. How to install a drip on the roof yourself