Table of contents:

- Making a metal furnace yourself

- How to make a potbelly stove with your own hands

- Equipping a potbelly stove with a water circuit

- Furnace design, its features

- Calculations of the parameters of the stove

- Materials and tools for making a potbelly stove

- Preparatory work

- Furnace installation

- Features of operation

- Video: how to make a potbelly stove with your own hands

- Care and maintenance of a potbelly stove

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2024-01-17 22:26.

- Last modified 2025-06-01 07:32.

Making a metal furnace yourself

The use of stove-stoves was usually associated with production. This is drying clothes and heating personnel in trailers, production facilities or greenhouses. The impetus for the further development of structures was their improvement in terms of the efficiency of heat transfer. The use of new technologies allows the production of designer metal furnaces.

Content

- 1 How to make a do-it-yourself stove-stove

- 2 Equipping a potbelly stove with a water circuit

-

3 Furnace design, its features

- 3.1 Photo Gallery: Metal Furnace Structures

-

3.2 Heat exchangers

3.2.1 Photo gallery: heat exchangers for wood-burning stoves

- 4 Calculations of the parameters of the stove

- 5 Materials and tools for making a potbelly stove

- 6 Preparatory work

- 7 Furnace installation

- 8 Features of operation

- 9 Video: how to make a potbelly stove with your own hands

- 10 Care and maintenance of a potbelly stove

How to make a potbelly stove with your own hands

First of all, you need to formulate the concept of "potbelly stove". As usual, it is a heat unit made of metal for the use of solid fuel. As a rule, firewood is used. For the removal of furnace gases, a metal pipe is installed, which is led out through a wall or window.

The advantage of this design is the rapid heating of the walls with subsequent heat transfer to the surrounding space. The disadvantage is that when the supply of firewood to the firebox is stopped, the stove cools down quickly, and you have to add them to keep the temperature in the room. Several such operations have to be performed during the night.

Potbelly stoves can be of various purposes

Equipping a potbelly stove with a water circuit

To eliminate this significant design flaw, such heating units are equipped with an additional heating system.

The purpose of this modification is to increase the total heat capacity, which will allow you to maintain a favorable temperature in the room for longer and, therefore, less often heat the stove.

The heating agent is heated directly from the furnace firebox. There are several ways to do this:

- Arrangement of "pockets" on the side walls, into which the coolant is poured.

- Installation of a water tank with outlets to the water heating system.

- Installation of a collector around the chimney in the immediate vicinity of the stove, passing through which the air is heated directly from the chimney.

- Installation of a water heater in the furnace firebox.

Potbelly stove can be used for water heating

When starting to manufacture a stove with a water heater, the home craftsman focuses primarily on the materials available and determines the heating method himself.

The advantages of such a heating device include its speed. The room can be warmed up to an acceptable temperature very quickly, and maintain the desired level for a long time.

The disadvantages include the following points:

- Such an oven requires constant attention and timely heating during the day.

- In a country house, where you periodically appear as a coolant, you have to use antifreeze or mineral oils, transformer oils are better, but simple working out is also possible. Otherwise, the water will freeze in winter and rupture the elements of the heating system. Repair in cold weather is not possible.

Metal furnace with a water jacket has a high level of efficiency

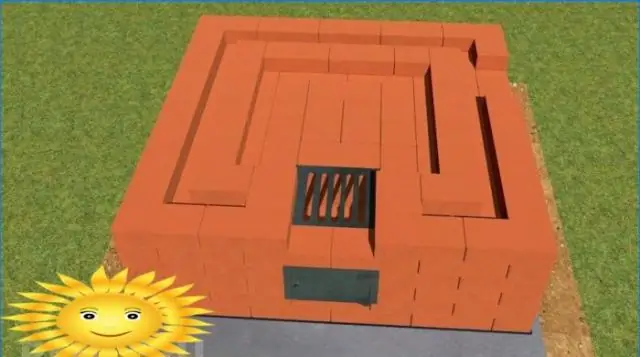

Furnace design, its features

The main elements of a potbelly stove are:

- Furnace compartment. Settles in approximately the middle third of the oven. Designed for burning fuel - wood or coal. Equipped with a door on the side wall of the oven for loading.

- The ash pan is needed to collect solid residues after burning wood or coal. It is separated from the combustion part from above by grate bars, which are cast iron rods of a special shape. Ash spills out between them and ends up in a waste collection tray. In the lower part of the ash pan, a bottom made of sheet metal with a thickness of 1.2-1.5 mm is welded.

- The tank with the coolant is a sheet metal tank filled with water or other heating agent. This device requires complete tightness. An outlet for water is arranged in the upper part of the tank, in the lower part there is a return pipe, through which the coolant cooled in the heating system returns.

- The chimney is installed in the upper part of the furnace body, it can be vertical, horizontal or inclined. Displays through the wall. For stove stoves, a pipe with a diameter of 150 mm is usually used.

- Supporting part - legs made of profile metal, providing a gap between the body and the floor of at least 20-25 cm. Under them you need to install a protective metal sheet with an asbestos backing. This is especially important if the heating unit is installed on a floor made of combustible materials.

Photo gallery: metal furnace designs

-

Diagram of the structure of a metal potbelly stove -

Before making a furnace, you need to draw a diagram of its structure.

-

Diagram of a potbelly stove with a "shirt" - The dimensions of the furnace must be correlated with the parameters of the room to be burned off.

-

Long burning furnace scheme - The Bubafonya stove is suitable for heating with sawdust

-

Homemade oven - The vertical cylindrical furnace can be made from a gas cylinder

Heat exchangers

The device of this unit depends on the design of the furnace. There are different types:

-

Rectangular. Such heating units are made of sheet metal up to three millimeters thick. Accordingly, the most technologically advanced heat exchanger is made in the form of a jacket surrounding the combustion compartment. The distance between the walls of the jacket and the furnace body depends on the volume of the heat exchanger. The larger it is, the slower the heating of the coolant in it occurs. Often, containers are installed on top of the furnace compartment, but in this case the cooking surface of the furnace becomes inaccessible.

Potbelly stove rectangular The rectangular shape of the stove is the most optimal for a stove

-

Cylindrical vertical. The material for such stoves is often metal barrels. In this case, labor costs are minimal. If you use two containers, placing them one in the other, a shirt is obtained from the gap between the barrels - a container for the coolant.

Potbelly stove is cylindrical vertical The cylindrical vertical stove is very cheap

-

Cylindrical horizontal. Such stoves can also be made from barrels, but large diameter pipes are more popular. A good combination can be a 530 mm inner tube with an 820 mm tube shell.

Initially, for such products, metal is used, which has high strength characteristics. They are designed for high pressure pipelines.

Potbelly stove from a pipe The potbelly stove can be made of a metal pipe designed for high-pressure pipeline

-

Lined potbelly stoves. Metal lining is carried out from the inside or outside using refractory bricks. Masonry mortar is also made on the basis of fireclay clay. The lining layer heats up more slowly, but keeps heat longer, continuing to heat the coolant. In this case, the time until the next loading of the furnace with fuel increases.

Furnace lining Lining can be compared to insulation

-

Long-burning furnaces on sawdust stand out separately. They are made from barrels or pipes and have a vertical orientation. They feature a removable top cover. When the furnace is open, a cone with a slope of approximately 1:10 is placed in the middle of the combustion chamber. Sawdust is tightly packed around it, after which the cone is removed and the top cover is placed. The furnace is fired up through an ash pan. Chips and small wood chips are placed in the tray. The tray is installed in its place, the kindling is ignited and pushed in with a small gap to create traction. Sawdust gradually flares up and smolders for a long time. One tab is enough for 8-12 hours of burning, depending on the capacity of the furnace. The evening bookmark is enough for the oven to work from evening to morning. This method of heating a home is the most economical,since practically waste material is used. Slow-burning stoves are often used to heat technical premises - greenhouses, winter gardens, garages and similar structures.

Potbelly stove for sawdust You can also heat the room with sawdust

Photo gallery: heat exchangers for wood-burning stoves

-

Copper heat exchanger - Making a copper heat exchanger is pretty simple

-

Furnace heat exchangers - A register for a wood-burning stove will allow you to use the stove more efficiently

-

Straight through heat exchanger - For a stove, you can use a water heater

-

Heat exchangers - Heat registers for ovens can be of different sizes

Calculations of the parameters of the stove

Heat engineering calculations of furnaces are rather complicated. In construction and manufacturing, such operations are performed by special laboratories. For household consumption, they are greatly simplified, leaving only the main parameters of heating units for independent determination:

- Calculation of the heat resistance of a room, that is, determining its ability to retain heat. This parameter depends on the material and thickness of the walls and floor, its thermal conductivity, design features of window and door structures. But in any case, heat resistance also depends on the quality of performance of all constituent elements.

- Calculation of the cross-section of the chimney ducts, since the quality and speed of fuel combustion in the furnace depends on this parameter. If the diameter is greater than the optimal one, then a significant part of the heat will go away without recoil, reducing the efficiency of the device. On the contrary, an insufficient cross-section can lead to incomplete combustion of fuel and gas pollution of the room. To determine the size of the chimney, a factor of 2.7 is applied in relation to the volume of the combustion chamber of the furnace. If this figure is 40 liters, then the optimal chimney size will be 40 / 2.7 = 14.8 cm.

The standard size of a metal chimney pipe is 150 mm. Usually, 15-20% is added to the calculated value. The final adjustment of the draft in the furnace is carried out with a gate, which allows you to effectively regulate the chimney cross section. It should be noted that the amount of thrust depends not only on the diameter, but also on the weather conditions; therefore, the use of a gate is considered mandatory.

The height of the chimney is important. There is a limiting parameter - its total height should not be more than 5 meters counting from the place of exit from the furnace. The elevation above the roof depends on the location in relation to the ridge.

It is very important to size the chimney correctly

Materials and tools for making a potbelly stove

The set of tools, fixtures and materials is small.

To make a furnace you will need:

- Manual grinding machine for cutting steel sheets and profiles.

- Metal cutting discs.

- Clamps, which are needed to fix parts during cutting and assembly.

- Household welding machine.

- Electrodes with a diameter of 3 and 4 mm, suitable for the material used.

- A hammer.

- Tool for performing masonry when creating lining.

Materials:

- Steel sheet 4-5 mm thick for the outer walls of the case.

- Steel sheet 1.5-3 mm thick for internal partitions and a jacket for the coolant.

- Rod grates (for rectangular ovens) or round cast grate.

- Large-diameter steel pipes for the manufacture of shells and jackets of cylindrical furnaces.

- Chimney pipes, including "sandwich".

- Steel corner 32 x 32 mm for pipe brackets and an outer stand for it.

- Stainless wire for chimney braces (if necessary, depending on the place of installation).

- Lining bricks and fireclay.

Other general purpose tools may be required depending on the design.

For the manufacture of a heating system, it is necessary to develop a draft design, on the basis of which the need for materials, shut-off, control and control valves is calculated. The use of metal-plastic pipes is preferable. The installation of such pipelines must not be carried out at a distance closer than 1.5 m from the furnace. It should be borne in mind that only a gravity heating system with an expansion tank can be used with a stove-stove.

Preparatory work

At this stage it is necessary:

- Complete a draft design of the furnace with detailing.

- Draw up a material sheet for the purchase.

- Purchase materials and missing tools.

- Craft all oven parts.

The last point is the most time consuming and responsible.

The potbelly stove can be connected to water heating

Furnace installation

This process is performed in the following sequence:

-

First you need to assemble the case. This should be done with potholders. After checking with the product drawing, perform the final welding of the parts, and then proceed to the next one. It is undesirable to leave elements on the potholders, as they may subsequently be unavailable. Gaps between parts, lack of penetration of seams should be excluded.

Assembling the stove body There should be no gaps between the parts in the stove body

- Install internal baffles and accessories.

-

When installing the water jacket, check each seam with kerosene. To do this, whitewash the outside with chalk, apply kerosene on the inside with a brush. In the place of poor-quality welding, greasy spots will appear on the chalk layer. Mark these areas and re-boil. The casing must be sealed.

Potbelly stove water jacket You can check the tightness of the welding with chalk and kerasin

- Weld into place according to the project the outlet and inlet branch pipes (for return) of the heating system.

- Place the oven in its intended place. The distance to the walls should be at least 1.2 m. If this is not possible, it is recommended to sheathe the walls with a metal sheet with an asbestos backing.

- Mount an open heating system with an expansion tank, connect it to the furnace.

- Fill the system with coolant, check for leaks, repair if necessary.

- Install a chimney.

A modern stove with water heating can fit into any interior

Features of operation

The use of a potbelly stove has a number of features:

- The chimney must be led out into the street through a wall or ceiling. Connecting the pipe to the ventilation system is not permissible. The intersections must be insulated with non-combustible materials.

- Modern metal stoves are capable of high-quality heating of one room up to 30 m 2. Moreover, it must be insulated with high quality.

- With a larger heated area, you must use a hot water heating system from the same stove.

- In a room with such an oven, you need to have a box of sand and keep a container of water ready.

- In the house, it is advisable to equip a separate room with a supply of firewood for the stove, since the fuel consumption is high.

Compliance with the rules of operation and fire safety will preserve your property and health.

Video: how to make a potbelly stove with your own hands

Care and maintenance of a potbelly stove

The stove will serve you for a long time if you follow the rules of its care:

- The condensate collector installed on the chimney must be opened weekly to drain the water.

- Before the start of the heating season, the chimney must be cleaned of soot with a special tool.

- During operation, the furnace body and chimney must be regularly inspected for smoke penetration into the room.

- Monitor the condition of the supply and exhaust ventilation.

Self-made metal wood stoves can be not only effective, but also become a true decoration of the interior of the room. But remember about the need to comply with the rules of installation and operation.

Recommended:

Making A Buleryan (breneran) Stove With Your Own Hands: Advantages And Disadvantages Of The Design, A Device With Drawings, Instructions With A Video, Etc

Design and principle of operation of the "Buleryan" furnace (breran). DIY recommendations with instructions and drawings. Maintenance and operation

How To Make A Potbelly Stove From A Gas Cylinder With Your Own Hands: Photos And Drawings, Videos And Secrets

Making furnaces of vertical and horizontal types from a gas cylinder with your own hands. Recommendations for the operation and repair of such stoves

How To Make A Long Burning Stove With Your Own Hands: Manufacturing Instructions With A Diagram And Drawings + Video

How to make a long burning stove with your own hands. Consumables, recommendations, diagrams, design features

Long-term Burning Stove (including Sawdust And Wood) With Your Own Hands: Diagram, Drawings, Etc. + Video

How does a long burning stove work. Production of a long-burning furnace from a gas cylinder and sheet metal. Features of operation and repair of furnaces

How To Make A Chimney For A Potbelly Stove With Your Own Hands: Diagram, Calculation (including Diameter), Photo, Video, Etc

A step-by-step guide for the manufacture and installation of a chimney with your own hands for a stove. The choice of material and rules of operation