Table of contents:

- Author Bailey Albertson [email protected].

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

The choice of corrugated board: how to get to the point:

Produced in various variations and constantly improving, the corrugated board has gained striking popularity. True, for some builders, a wide assortment of profiled sheets causes not joy, but confusion: it is not clear by what criteria to choose the material. I must say that the corrugated board has enviable performance characteristics, which are quite easy to understand.

Content

-

1 Types of corrugated board

- 1.1 Meaning of letters

- 1.2 Meaning of numbers

- 1.3 Video: how not to get confused in the marking of corrugated board

-

2 Dimensions of the roofing sheet

- 2.1 Thickness

- 2.2 Length

- 2.3 Width

- 2.4 Wave height

-

2.5 Weight

2.5.1 Table: weight of "NS" grade corrugated board depending on wave height and sheet thickness

- 3 Choosing the optimal sheet size

-

4 Length of overlap of corrugated board on the roof

4.1 Video: we cover the roof with corrugated board

Types of corrugated board

To determine the type of profiled sheet, you need to look at its brand - letters and numbers on the material label.

Information about how one sheet differs from another is contained in the numbers and letters of the marking

Meaning of letters

One or more letters at the beginning of the material marking refers to the strength parameter and the scope of use:

- "H" - indicates a significant wave height with additional folds in the place of its fall, a large thickness and the highest degree of strength of the sheet, which is usually used as an element of the supporting structure;

-

"NS" - testifies to the versatility of the material, which has average thickness and wave height and is considered an intermediate option between the load-bearing and wall construction raw materials;

Professional flooring brand "NS" The professional flooring of the NS brand has special parameters that allow it to be a material for both walls and roofs

- "C" - indicates a small height of the ridge and relatively low strength of the sheet, because the raw material for its manufacture is thin and therefore inexpensive steel;

- "MP" - means that the material is versatile and is characterized by galvanized or polymer coating, and its wave reaches 18 or 20 mm in height.

In terms of dimensions, profiles "A" and "B" are more suitable for walls, and "R" - for roofs

Meaning of numbers

The numbers behind the letters in the marking of the material serve to indicate:

- wave height;

- sheet steel thickness;

- the width of the profiled sheet, taking into account the overlap of waves during installation work;

- sheet length (optional, since at the request of the customer this parameter can be any).

All dimensions are in millimeters. For example, according to the marking C10-0.5-1100, you can find out that the wave height of the corrugated board is 10 mm, the thickness is 0.5 mm, and the useful width is 1100 mm.

The numbers in the marking indicate the dimensions of the profiled sheet - wave height, thickness and useful width

Video: how not to get confused in the marking of corrugated board

Dimensions of the roofing profiled sheet

The dimensions of the corrugated board are specified in GOST 24045-94. The service life of this material is usually determined by the manufacturer and is indicated in the accompanying documentation.

Thickness

The thickness of the rolled steel, from which the profiled sheet is made, is in the range of 0.45-1.2 mm.

The thicker the sheet of corrugated board, the stronger and heavier it is

The thickness of the corrugated board is determined by its brand. For material marked "Н", "НС" or "С", it is usually within the same limits as for sheet steel - 0.4-1.2 mm, and for profiled sheet of grade "MP-R" - 0, 4-0.8 mm.

Length

Factory equipment can produce sheet material up to 14 meters long. Larger sheets are usually not needed, because they will be inconvenient in terms of delivery to the construction site and installation on the roof.

The standard length of the profiled sheet is different for all manufacturers, and on request you can buy sheets up to 14 m long

Width

According to the standard, the width of sheet steel is 125 cm. True, after corrugation, that is, creating waves, this indicator changes. What exactly it will be depends on the height of the formed ridges and the shape of the sheet.

The width of the corrugated board is considered from two points of view

The width is taken as the distance from one edge of the profiled sheet to the other, and the part of the material that will cover a certain section of the roof, taking into account the overlaps. The first is called the total sheet width, and the second is called the "working" or "functional" width.

To avoid confusion, you need to clearly understand what width we are talking about: full or working

Wave height

Most often, the roof is covered with profiled sheets with waves of at least 1.8 cm in height. The maximum rise of the ridge of the material by 7.5 cm is considered.

For roofing work, it is better to choose sheets with a large wave height, starting from 18 mm

According to the observations of builders, the most stable in relation to various loads during operation shows itself to be the professional flooring of grades "NS" and "N" with grooves at the base of the wave

Weight

The weight of the profiled sheet depends on the thickness of the metal, the configuration of the profile and the dimensions of the protective coating. Therefore, the range of specific weights of corrugated board is quite wide: from 5.4 to 17.2 kg / m².

Table: weight of "NS" grade corrugated board depending on wave height and sheet thickness

| Profiled sheet marking | Metal thickness in mm | Mass of a running meter of material in kg | Weight of 1 m2 of corrugated board in kg |

| НС35-1000 | 0.5 | 5.4 | 5.4 |

| НС35-1000 | 0.55 | 5.9 | 5.9 |

| НС35-1000 | 0.7 | 7.4 | 7.4 |

| НС44-1000 | 0.5 | 5.4 | 5.4 |

| НС44-1000 | 0.55 | 5.9 | 5.9 |

| НС44-1000 | 0.77 | 7.4 | 7.4 |

Choosing the optimal sheet size

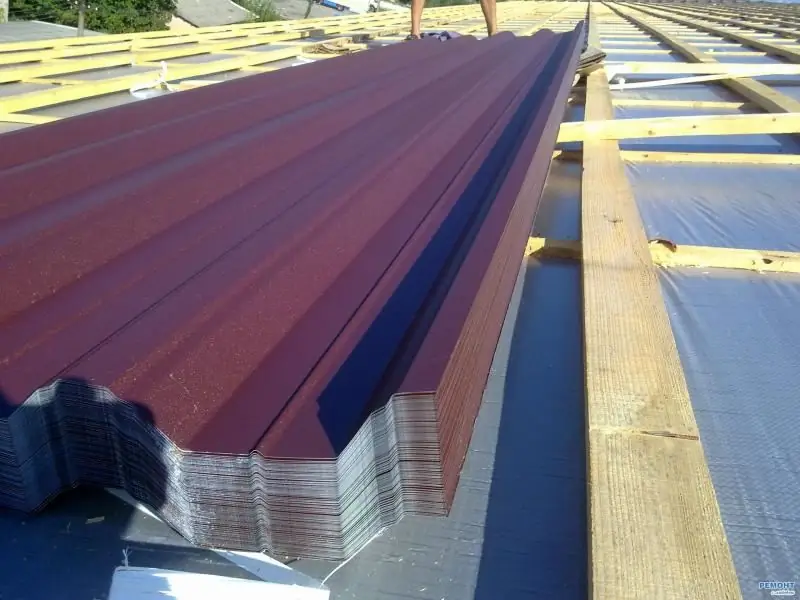

To facilitate roofing work, the corrugated board must be carefully sized.

The ideal situation is when the length of the profiled sheet is equal to the length of the roof slope, taking into account the roof overhang. It is more difficult and longer to close the roof with small pieces of corrugated board.

True, corrugated board with a length of more than 6 meters is not easy to deliver to the roof and attach to the crate without accidentally changing its shape. Professional sheets in an unconventional format often have to be lifted to the house with special equipment.

If the length of the slope is more than 6 meters, it will be difficult to lift the sheets to the roof; but if this can be done, then the quality of the roofing will be higher

The best thickness values for roofing are 0.5 and 0.6 mm. These figures indicate that the corrugated board will withstand the influence of weather conditions and the weight of snow in winter.

Profiled sheet metal less than 0.5 mm thick is considered to be too susceptible to mechanical stress. He will be able to cope with the loads imposed on him only in the conditions of creating a frequent or absolute deaf crate.

Material with a thickness of more than 0.7 mm under the influence of unfavorable factors does not bend and does not lose its quality characteristics for a long time.

For the rest of the dimensions (width, wave height, etc.), you should adhere to the standards.

The length of the overlap of the corrugated board on the roof

The side edges of the profiled sheets should be in contact by one or two waves, depending on the power of the roof supporting structure and the expected load on the material.

Horizontally, the sheets are laid with an overlap in one or two waves, vertically - 20 cm

In centimeters, the amount of overlap is determined based on the degree of slope of the roof

- When the roof is tilted less than 15 degrees, one edge of the sheet is superimposed on the other by 20 cm.

- If the roof slope is steeper (up to 30 degrees), then the corrugated board is attached to the crate, making overlaps of 15-20 cm.

- With a roof slope of 35-50 degrees, contact of the edges of the sheets by 10-15 cm will be enough.

If necessary, make a horizontal overlap stop at 20 centimeters. The formed seams must be sealed with silicone sealant or bitumen mastic.

Video: we cover the roof with corrugated board

The parameters of the profiled sheet are determined by its grade. Without focusing on the size of the corrugated board, it will not be possible to make the roof project correct. In addition, a careful selection of the parameters of the profiled sheet is the key to acquiring the optimal volume of building material.

Recommended:

Types Of Roofing Materials With A Description And Characteristics And Reviews, Including Roll, As Well As Features Of Their Operation

Types of roofing materials: sheet, soft and tile roofs. Technical characteristics and features of operation of various types of coatings

Which Corrugated Board Is Better To Choose For The Roof Of The House, What Needs To Be Considered, As Well As A Description Of Popular Brands With Characteristics And Reviews

Selection rules and types of metal corrugated board for the roof of the house. What are the features of the material of different brands and manufacturers. Reviews about corrugated roofing

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size

Roofing Sheeting, Including Types And Brands With Descriptions, Characteristics And Reviews

What kind of corrugated board is considered roofing. Features of different brands. Types and advantages of corrugated board. How to choose it and calculate the required amount. Reviews

The Slope Of The Roofing From The Profiled Sheet, Including How To Choose The Right Brand Of This Roofing Material, Depending On The Angle Of The Roof

What is the slope of the roof. The angle of inclination of the roof from the profiled sheet: minimum and permissible. The choice of the brand of corrugated board according to the degree of roof slope