Table of contents:

- Author Bailey Albertson albertson@usefultipsdiy.com.

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

Without which installation is impossible: tools and equipment for seam roofing

Arrangement of seam roofing has its own characteristic features. The technology of joining metal sheets requires certain knowledge and skills, and the covering material requires significant, but very careful impact. Each master who professionally deals with the fold has his own toolkit, without which it is difficult and sometimes impossible to perform installation work first-class and quickly. Today we will talk about the necessary tools and mechanisms for this work, a general idea of which every developer should have, at least in order to determine the qualification level of hired workers.

Content

-

1 Tools and equipment for seam roofing

- 1.1 Video: hammer and mandrel

- 1.2 Video: a tool for forming envelopes "Heron" when installing abutments

-

2 Machines for creating seam roofing

-

2.1 Manufacturing of seam panels

- 2.1.1 Video: Making Roofing Pictures

- 2.1.2 Video: roofing machine SFP3

- 2.1.3 Video: making roofing pictures on a homemade listogib

-

2.2 Making a bending machine yourself

- 2.2.1 Assembling a homemade listogib

- 2.2.2 Video: the simplest bending machine

- 2.2.3 Operating rules of the bending machine

-

-

3 Folding machines

-

3.1 Hand tools

3.1.1 Video: hand tool for closing a double standing seam

-

3.2 Semi-automatic semiautomatic folding machines

3.2.1 Video: Operation of the semi-automatic folding sewing machine

-

3.3 Automatic folding machines

3.3.1 Video: Wuko Folder Seamer

-

Tools and equipment for standing seam roofing

A good specialist has more than forty different tools in stock that are used when installing a seam roof. The standard roofer kit includes:

- wedge-shaped mallet, drill or screwdriver;

- roofing and folded hammer;

- scissors for metal;

- roof mandrels and rebate pliers;

-

a set of pliers and all kinds of measuring devices.

Roofer standard kit When installing a standing seam roof, in addition to experience and skill, you will need a set of simple and easy-to-use tools, on which the speed and quality of work depends

Video: hammer and mandrel

However, standard tools are still secondary, although necessary. Their role in creating a folded roof is not as great as those used for punching panels and forming bending units - a folding machine and a folding machine. Therefore, let us dwell on this particular equipment.

Video: tool for forming envelopes "Heron" when arranging abutments

Seam roofing machines

A folded-rolling (folding, folding) machine is the main technical equipment for arranging a folded roof. He rolls metal roll or sheet material, converting it into panels with curved edges in a special way - pictures.

Modern folding machines are small in size and weight, that is, they are mobile, so they can be installed on the roof to speed up installation work and protect the finished panels from deformation during lifting.

Roof panel roll forming machine can be installed directly on the roof to simplify and speed up work

Working with a folding machine requires certain qualifications, and it is quite expensive, therefore, such equipment is found only among professionals. The fact that the roofers hired by you have their own machine most likely indicates that they specialize in the manufacture of seam roofs and have sufficient experience in such work.

A high-quality and beautiful folded roof can be created only with a lot of experience and special equipment, which only professionals have

A good roofing machine costs from 1 to 4 million rubles. depending on the model, performance and additional functions - control over the strip width, decoiler, length counter, the possibility of making a double fold, etc. Therefore, this equipment is often rented for the period of work. The most reliable and high-quality are the folding machines of the German company Schlebach (Germany).

The main task of the folding machine is the formation of a lock connection and the closure of the longitudinal seam seam by molding

Manufacturing of seam panels

Let's consider the production of paintings using the example of a modern mid-price category rolling folding machine Schlebach Mini-Prof-Plus with a standard set:

- decoiler for metal raw materials with a maximum load of 300 kg;

- disk shears with adjustment of blanks for fractional trimming before profiling;

- an electromechanical counter (length controller) for rolling pictures with an accuracy of a centimeter;

- roller knife with grip for cross-cutting of sheet metal before embossing.

Mini-Prof-Plus is a small piece of equipment weighing 315 kg, so it is well suited for work on the roof. In addition, the equipment with telescopic scissors allows the production of panels even when installed on an inclined plane. The quality of rolled products is guaranteed by 7 pairs of rollers made of special steel, which make it possible to work with metal with a protective polymer coating, and at the same time do not leave scratches and dents on it.

The Mini-Prof-Plus folding machine has a length controller, which makes it possible to roll roof panels with an accuracy of a centimeter, and a manual cut immediately before profiling

How Mini-Prof-Plus works:

- Sheet or rolled metal is fed from the tape-layer (decoiler) to the tape of the bending machine.

-

Passing through the bending machine, the metal blanks are transformed into roof panels with a double standing seam (longitudinal connection) of the planned length controlled by the counter.

Manufacturing of roof panels on a machine At the exit from the machine, coil or sheet metal is converted into finished products with a double fold

Video: making roofing pictures

For the manufacture of self-locking folded panels, the SFP3 machine is used - inexpensive, quiet and well-proven equipment, on which two teams can work simultaneously in several shifts.

The SFP3 machine allows the production of panels with a click-fold and edge notches and provides loading of two teams at once

The paintings processed on this machine have ready-made strips with notches for quick fastening of the canvases to the frame and stiffening ribs, due to which the strength of the roofing is significantly increased. SFP3 and similar models are conveniently used for arranging pitched roofs with an angle of inclination greater than 15 °.

Click-rebate roofing panels have a unique lock, the use of which does not require special tools during installation, which simplifies and speeds up roofing without losing the quality and beauty of the folded structure

Video: roofing machine SFP3

To make roofing pictures when building a house with your own hands, you can use a sheet bending machine. It can be bought at a price of 150 thousand rubles. for a simple manual model up to 5 million rubles. for a fully functional programmed machine.

Buying a manual sheet bending machine can be quite justified if you need a small-scale production of roofing panels

The bending machine can be made with your own hands. This will significantly facilitate and reduce the cost of manufacturing roofing panels when self-erecting a roof. The assembly process of the bending machine will be discussed in more detail below.

Video: making roofing pictures on a homemade listogib

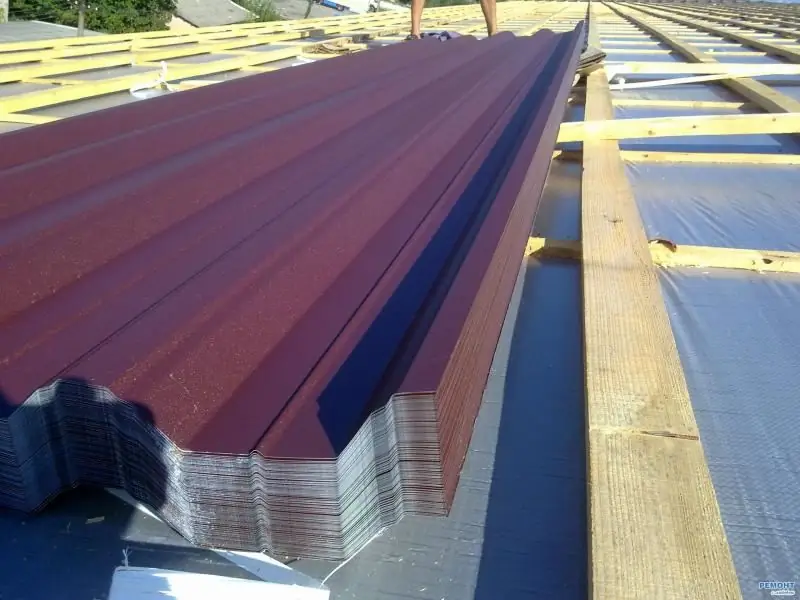

The main advantage of using automatic rolling machines is that the size of the canvases can be varied at will. This allows you to make a roll seam roof with the length of the pictures from the eaves to the ridge and thus avoid transverse seams, which are most vulnerable to leaks. Rolled roofs look more noble and, moreover, they are more profitable - there are fewer scraps left during metal rolling, less fasteners and insulating material are required, and installation work is also much faster.

Automatic folding machines allow the production of roof panels in the full length of the slope, they make the roof more even and beautiful, and also save it from the transverse seams, which are most vulnerable to leaks

Making a bending machine yourself

When making a homemade listogib, first of all, you need to determine the technical requirements, which are set by the parameters of the manufactured products and the manufacturing technology of the machine itself:

- the maximum width of rolled metal products should not exceed 1 m, the thickness of galvanized steel - 0.6 mm, copper sheet - 1 mm and aluminum sheet - 0.7 mm;

- the number of planned uninterrupted cycles is more than 1200;

- bending angle - not less than 120 ° without manual finishing;

- the use of non-standard blanks for the manufacture of paintings should not be included in the parameters;

- to limit as much as possible the use of welding, from which some machine components can lead, and to carry out turning and milling processing separately, if possible.

A homemade machine must meet certain technical conditions - work on it should not be hard and exhausting.

Consider the most elementary version of a machine for use in everyday life, which allows you to bend plates at the required angle using the physical strength of one person. To make the fold of the pictures even and of high quality, you need to press harder on the traverse, giving it slightly forward. The work of almost all homemade bending devices is based on this rule.

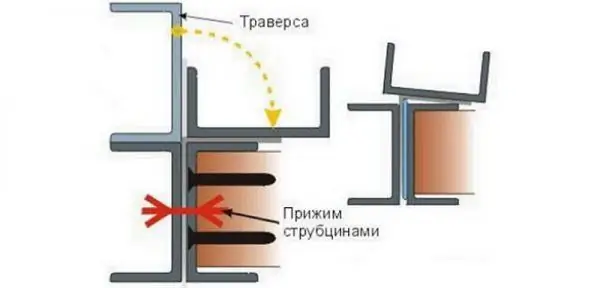

The principle of operation of a homemade bending device is to use a person's muscle strength when pressing the traverse, which bends the sheet at the desired angle

On the net you can find many methods for assembling sheet bending machines with your own hands, but the diagram below is considered the most successful and simple. This design with a maximum tilt angle of 135 ° will perform well on any starting material.

A simple and effective home-made sheet bending machine with an angle of inclination of 135 ° from angle rolled products will allow even an unskilled craftsman to bend workpieces with high quality

To make a bending device, you need the following materials:

- timber for a pillow;

- angle (L-shaped section) 60-80 mm for pressure beam welding;

- rolled metal sheet with a thickness of about 6-8 mm for cheeks;

- pin Ø 10 mm as a traverse axis and a rod of the same diameter for the lever;

- corner 80-100 mm for forming a traverse or channel of a similar size;

- U-shaped channel 100-120 mm wide for the base of the bending machine.

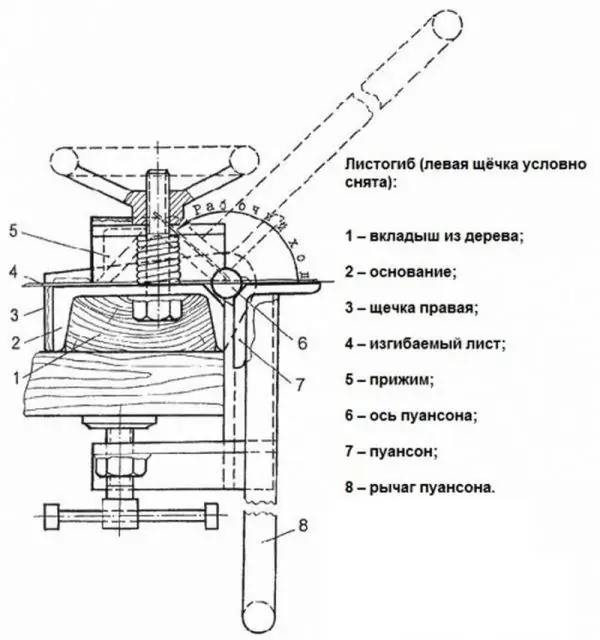

Detailing of a self-made listogib contains the following items:

- The clamp used for tight fixing of the machine elements is an angle up to 60 mm in size and an M8 or M10 screw with a heel and a knob.

- Cheek.

- The base of the structure.

- Clamp bracket made of 110 mm angle.

- Beam for pressing and holding workpieces along the entire length.

- Traverse axis.

-

Traverse that exerts pressure on the workpiece.

Detailing of a homemade listogib The use of a manual bending mechanism guarantees the absence of deformations at the bending part of the sheet, which cannot be achieved with a traditional mallet and mandrel

Some of the nuances to consider when manufacturing:

- The plane at the bottom of the clamp, which forms the fold, must be milled after welding the assembly. Precisely to mill, and not to level with a file or a grinder. A surface roughness of half the minimum thickness of the workpiece used is allowed, otherwise after one hundred, maximum two hundred cycles, swollen folds will be obtained.

- Mount to the table. The bending machine is fixed to the table by means of clamps that are welded to the machine. But the fragility of the weld creates the danger of its rupture during the course of the traverse, which will not allow the continuation of work, although all other elements and nodes will be in perfect order. It is possible to refuse from fastening through clamps. As a result, cheeks and welding will be unnecessary. This can be done as follows - lengthen the support beyond the edges of the table equally in both directions and through the U-shaped holes (lugs) at its ends, fix it to the table with M10 pins with shaped nuts.

- Fastening the traverse. If you get rid of the clamps and cheeks, then the structure will be collapsible. This is much more convenient, since the traverse must be changed periodically, and the reliability of the fastening with the pins leaves much to be desired. In the modified design, the traverse can be fixed with butterfly hinges (hardware for metal doors), which are fastened with countersunk screws and do not require cutting. If, in addition, you use red lead iron under them, you will get a reliable and durable mechanism with an opening angle of up to 160 °.

-

Assembly. The design uses flywheel nuts. But in order to lay the sheet for processing, the clamp must be raised by 2-3 mm, and to remove the finished picture with a formed fold - by 30 mm. With an M10 thread pitch, it will be long and tiring. It is much more efficient to replace the flywheels with wing nuts.

Homemade listogib assembly Professionals advise the flywheel nuts, which are most often used in home-made bending devices, to replace with wing nuts, which will greatly facilitate manual lifting of the pressure beam.

Assembling a homemade listogib

The assembly process of a homemade press brake is carried out in several stages:

- The base is made of U-shaped bent rolled steel - channel.

- The clamp is welded from the L-shaped section (angles) rolled stock, making it 50-70 mm smaller than the base and, if necessary, reinforcing it with an additional profile.

- The holders are welded to the ends of the pressure beam, a Ø8 mm hole is drilled in the center of each of them.

- In the places of contact of the clamp with the rolled metal, the shelves of the corners are milled along the edges, making them parallel to the base.

-

They make a traverse 10 mm shorter than the clamping beam and weld a previously prepared lever-handle to it. It is advisable to use a channel for the traverse.

Traverse manufacturing The clamp is made shorter than the base by 50-70 mm, and the traverse is shorter than the clamp by about 10 mm and levers-handles from a bar of reinforcing steel, bent in the form of a bracket, are welded to it

- Cheeks are made of rolled steel and a Ø10 mm hole is drilled into them.

- Chamfer the end sides of the traverse and base. This is necessary to insert the pins.

- Axles are welded from Ø10 mm pins. In this case, the direction of the longitudinal lines of the bar must coincide with the edges of the corners.

- They make a rough assembly - they fix the traverse and the support base with a bench vice so that the shelves of the corners and the channel are at the same level. Cheeks are put on the axle and lightly gripped by electric welding.

-

A test bending is carried out - the workpiece is laid and fixed on top with a pressure beam, pressing it with clamps to the base. The position of the cheeks is examined and, if no problems are identified, then they are welded to the base thoroughly.

Test bending of the workpiece Before the final assembly, a test bending is carried out - a sheet of soft metal with a thickness of about 1 mm is placed on the working surface and pressed from above with a clamp temporarily attached with clamps to the base

- Drill holes Ø8 mm in the base of the bending machine and make a thread in them for M10. Tighten the bolts by welding the heads.

- Attach the clamp to the base of the bending machine with M10 nuts.

These works are not particularly difficult, especially for those who are at least a little versed in carpentry and plumbing. Beginners will have to spend a little time to understand the intricacies. But on the other hand, having mastered the manufacturing technique and using inexpensive materials at the same time, you can get good equipment, which will be useful not only when arranging a seam roof, but will also become an assistant in the backyard.

Video: the simplest bending machine

Operating rules of the bending machine

Listogib is a traumatic mechanism, and made independently - even more so. Therefore, when operating the machine, the primary rule is to comply with the labor protection conditions prescribed in GOST 12.0.002-80:

- When purchasing factory equipment, you need to read the operating instructions in detail and follow all safety instructions.

-

Inspect overalls and shoes - before turning on the bending machine, you need to fasten zippers and buttons, and also fill in all hanging elements.

Work on a bending device Before turning on the listogib, work clothes and shoes must be fastened and laced up, and all hanging elements must be tucked in

- Carefully check the condition of the working units and fasteners. If defects are found, eliminate the problem.

- Organize a workplace (at least 1 m) around the press and provide free access to it. Check if there is sufficient lighting for work.

-

Do not use workpieces that exceed the permissible thickness in thickness, and in no case leave the machine turned on unattended.

Bending machine operation Operation of an automated bending machine provides for compliance with safety rules, one of which is not to leave the turned on machine unattended

Folding machines

The second most important type of equipment required to create a folded roof is a folding machine. They fall into several categories.

Hand tools

Manual folding machines are often called frames or haps. They form a double standing seam in two steps. The work, of course, is laborious, but the manual mechanism has one indisputable advantage - it can be used on steep roofs and in hard-to-reach places where the automated device will not work. Therefore, a serious team of roofers, in addition to modern equipment, must have a folding handbrake.

The manual folding mechanism allows you to get a high-quality seam in hard-to-reach places of the roof, where the use of electrical devices is impossible

Video: hand tool for closing a double standing seam

Semi-automatic folding semiautomatic machines

Semi-automatic folding machines are installed at the beginning of the future seam and pulled with a cable, leaving behind a double folded joint. The use of semiautomatic devices provides a high speed of installation in comparison with the manual method, as well as a careful attitude to the protective polymer layer of the metal. Semi-automatic folding machines are most effective when laying long pictures.

Semi-automatic seamers are most effective when creating double seam seams on long panels

Video: the operation of the semi-automatic folding device

Automatic folding machines

Electric constructions for seam seams are based on modern technologies that minimize the human factor when creating seam seams and increase labor productivity many times over. The mechanism of use is very simple - the device is installed in the right place and turned on. The machine, moving in a given direction, itself connects the workpieces with a double fold. The result of their application is a strong and perfectly flat seam roof in record time.

Electric folding machines connect roofing panels with a double standing seam practically without human intervention, creating a high-quality seam in one pass

Video: Wuko folding machine

Unfortunately, on the domestic market, the choice of automatic folding machines is limited. The products of the famous German company Schlebach are represented by only three models:

- Flitzer.

- Piccolo.

- FK1.

The first one costs 337 thousand rubles, and the rest - about half a million. The folding machines of the Austrian brand Wuko are not much cheaper - the only Wuko 1006 series can be purchased for 210 thousand rubles. Naturally, such perfect technical equipment can be found only in real professionals.

Reliability, longevity, quality and undeniable attractiveness of standing seam roofing is a union of advanced technologies and skill of installation, which is based on the knowledge, experience, tools and equipment necessary to perform such works. That is why their high cost is fully justified, which more than pays off with the further operation of the seam roofing without the need for special care and repair.

Recommended:

Self-locking Seam Roof With A Description And Characteristics, As Well As Features Of Its Design And Installation

The concept of a self-locking seam roof. The best manufacturers of clickfold panels. Construction, installation and maintenance of a self-locking roof

Roofing Elements Made Of Metal Tiles, Including Their Description And Characteristics, As Well As The Ridge For The Roof, Its Structure And Installation

The main elements used in the construction of metal roofing. Their description, characteristics and purpose. Features of mounting the ridge strip

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size

Seam Roofing, Including The Features Of Its Construction, Operation And Repair, As Well As How To Avoid Mistakes During Installation

Features of the design and characteristics of the folded roof. Required tools and installation sequence. Repair and operation of seam roofing

Roof Waterproofing And Its Types, As Well As Features Of Its Design And Installation, Depending On The Roofing Material

What materials can be used to arrange reliable waterproofing of the roof and how to install it