Table of contents:

- All the best for the roof: roofing screws

- Definition and application of roofing screws

- Types of self-tapping screws for the roof

- Distinctive characteristics of roofing screws

- Sizes of roofing screws

- Rules for choosing self-tapping screws for roofing material

- How to use roofing screws

- Reviews of roofing screws

- Author Bailey Albertson [email protected].

- Public 2023-12-17 12:53.

- Last modified 2025-06-01 07:32.

All the best for the roof: roofing screws

The performance characteristics of the roof depend on the fasteners, since the degree of tightness of the places of fixing the roofing material to the lathing depends on the quality of the screws. Therefore, their choice should not be neglected.

Content

-

1 Definition and application of roofing screws

1.1 Table: use of self-tapping screws depending on size

-

2 Types of self-tapping screws for the roof

- 2.1 Fasteners for metal

- 2.2 Self-tapping screws for wood

- 2.3 Stainless steel

- 2.4 Carbon steel

- 2.5 Galvanized fasteners

- 2.6 Fasteners for sandwich panels and corrugated board

- 2.7 Painted self-tapping screws

- 2.8 Standard self-tapping screws for a regular screwdriver

- 2.9 Self-tapping screws for special bits

- 2.10 Fasteners with press washer

- 3 Distinctive characteristics of roofing screws

-

4 Dimensions of roofing screws

-

4.1 Sizing roof fasteners

4.1.1 Table: Dimensions of roofing screws

-

4.2 Dimensions of roofing screws with rubber gasket

4.2.1 Table: parameters of fasteners with spacers

-

-

5 Rules for choosing self-tapping screws for roofing material

5.1 Video: finding a self-tapping screw suitable for the roof

-

6 How to use roofing screws

- 6.1 Fastening the roof with self-tapping screws

- 6.2 How to screw self-tapping screws into metal

- 7 Reviews about roofing screws

Definition and application of roofing screws

The self-tapping screw for the roof is a fastening element made specifically for attaching roofing materials to the supporting structure of the roof.

These parts are used as anchors for sheet metal or shingles on metal or timber roof structures

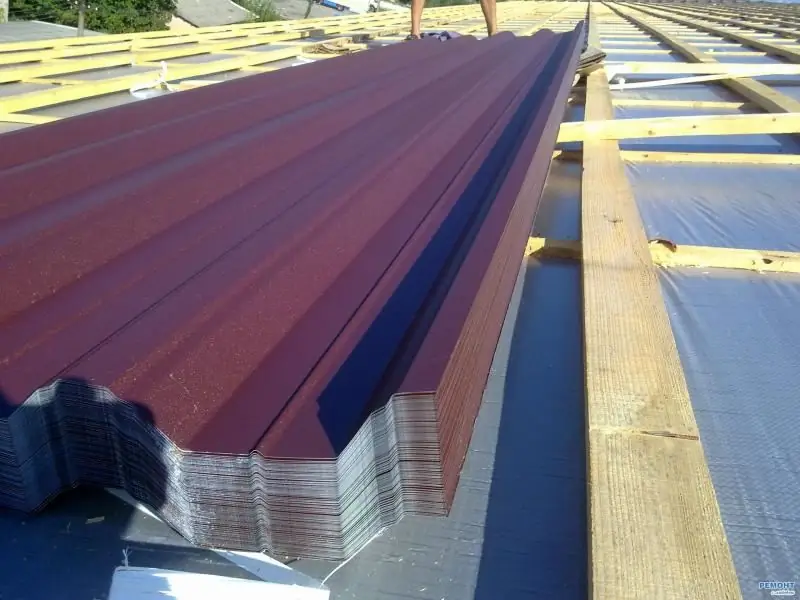

Profiled sheeting is attached to the self-tapping screws on the roof support system

Table: the use of self-tapping screws depending on the size

| Size (mm) | Scope of application | Mount type |

| 4.8 × 29 | Fastening of corrugated board, siding, metal tiles and polycarbonate to wooden lathing made of beams 30-50 mm thick and fixing ebb | Metal-wood |

| 4.8 × 35 | ||

| 4.8 × 38 | ||

| 4.8 × 50 | Fastening of corrugated board, siding, metal tiles and polycarbonate to wooden lathing made of 50 mm thick beams and fixing the ridge and other roofing components | |

| 4.8 × 60 | Fastening of additional elements through the profiled sheet to the timber lathing | |

| 4.8 × 65 | ||

| 4.8 × 70 | ||

| 4.8 × 80 | ||

| 5.5 × 19 | Connection of profiled sheets to each other and fastening of polycarbonate | Metal-metal |

| 5.5 × 25 | ||

| 5.5 × 32 | Fastening profiled sheets to metal crate, fixing polycarbonate | |

| 5.5 × 38 | ||

| 5.5 × 51 | Fastening of additional elements through the profiled sheet to the metal crate | |

| 5.5 × 64 | ||

| 5.5 × 76 | ||

| 6.3 × 19 | Connection of profiled sheets to each other (in the overlap zone) | Metal-metal |

| 6.3 × 25 | ||

| 6.3 × 32 | Fastening profiled sheets to metal crate | |

| 6.3 × 38 | ||

| 6.3 × 45 | ||

| 6.3 × 51 | Fastening of additional elements through corrugated board to the crate of metal parts | |

| 6.3 × 70 | ||

| 6.3 × 100 | Fastening profiled sheets to the crate, with materials laid between them, for example, insulation | |

| 6.3 × 130 | ||

| 6.3 × 150 |

Types of self-tapping screws for the roof

Fasteners for roofing material differ from each other in the following parameters:

-

by the type of head, which is countersunk, half-countersunk, hexagonal and hemispherical;

Varieties of self-tapping head The shape of the head and spitz of a self-tapping screw can be both complex and simple

- by the nature of the thread, made rarely (for fastening metal material) or often (for fastening to wooden products);

- by the type of spitz (flat, cruciform, and so on);

-

by the type of tip (pointed or with a drill bit).

Self-tapping tip types A bur or lance at the end is a distinctive feature of a self-tapping screw

In general, the classification of roofing screws is based on their shape and function, as well as the type of material used to make the fasteners

Fasteners for metal

Self-tapping screws for metal are used if you need to fix tiles or sheet metal from metal on the metal supporting structure of the roof.

Their features include:

- frequent carving;

- large diameter (in comparison with wood screws);

- rather long brownish tip with a drill.

Self-tapping screws for metal are distinguished by a massive drill-shaped tip that bites well into durable metal

The advantages of clamps of roofing material to a metal base are:

- instant soldering of parts;

- reliable fastening;

- low risk of rusting;

- ability to serve for many years;

- affordable price;

- compatibility with the bonded material.

No significant negative characteristics were found for metal screws. This is because stainless or carbon steel fasteners are coated with a protective sheath - zinc and paint.

Self-tapping screws for metal after galvanizing and painting serve for many years

Self-tapping screws for wood

Roofing screws for wood are analogous to fasteners for metal, but with noticeable differences - a smaller drill at the base and a relatively small diameter.

Additional features of wood fasteners are:

- cross connector;

- secret or semicircular hat;

- rare thread pitch;

- pointed tip.

Self-tapping screws for wood are recognized by the pointed tip and rare carving

The need for self-tapping screws for wood arises when the roofing material needs to be fixed on a wood base.

The main advantage of self-tapping screws for wood is through immersion in the material, which frees the master from special drilling of holes in the finishing roof covering. The thin pointed end of a self-tapping screw for wood, if you make holes in the wooden crate in advance, allows you to fix a metal sheet on the base of the roof without any problems.

The ideal version of a self-tapping screw for a roof - fasteners with a hex head and washer

Stainless steel

Stainless steel is the most popular raw material for roofing screws.

Steel, which is not afraid of corrosion, gives fasteners such advantages as:

- unsurpassed strength;

- reliability of fixation;

- fire resistance;

- long service life.

When alloying components, such as sulfur or nickel, are added to stainless steel, the self-tapping screw acquires the name of alloy steel fasteners.

Roofing screws are always made of stainless steel

Carbon steel

Carbon steel fasteners are a product of the joining of steel to carbon.

Self-tapping screw made of carbon steel has high strength characteristics

Carbon steel gives self-tapping screws a significant advantage - good ductility

Galvanized fasteners

Galvanized roofing screws are a copy of conventional roof fasteners covered with a layer of zinc.

Thanks to the zinc sheath, steel roofing screws have an invaluable advantage - the ability to withstand the harmful effects of atmospheric precipitation. With a protective layer, the roof fasteners are insured against rusting.

The fact that self-tapping screws are covered with zinc must be indicated on the label

Fasteners for sandwich panels and corrugated board

Self-tapping screws made of carbon steel and zinc plated are suitable for sandwich panels and profiled sheets. Such fasteners should have a turnkey hex head, rubber gasket, washer and sharp drill.

To fix the corrugated board, self-tapping screws with a hex head and a sharp tip are taken

The highlight of self-tapping screws for sandwich panels and corrugated board is the increase in the thread diameter directly under the head. For the rest of the leg of the special fastener, this parameter is slightly less.

Painted self-tapping screws

Most often, the head of the roof fastener is painted in the following colors:

- green;

- cherry;

- blue;

- white;

- brown.

Self-tapping paint provides additional protection against corrosion

Painting gives the self-tapping screw a significant advantage - unsurpassed protection against rusting.

Standard self-tapping screws for a regular screwdriver

Self-tapping screws of a standard type are made for an ordinary flat screwdriver. Therefore, the spitz or special groove on the end of the head of these fasteners is straight.

Standard self-tapping screws are screwed in with a flat or Phillips screwdriver

Self-tapping screws with a straight pin were replaced by fasteners with a cross-shaped recess in the head. They are easily screwed into the material using a screwdriver, the tip of which also resembles a cross in shape and does not jump off the recess in the head of the fastener.

Self-tapping screws for special bits

Self-tapping screws for a bit or a special working attachment of a screwdriver look like fasteners with a hex head.

Fasteners for a screwdriver bit are rated better than a conventional self-tapping screw, because it adheres well to the tool nozzle and does not lose close contact with it even when twisting at a certain angle with respect to the head

What kind of bat the screws are screwed in is indicated on the product label

There are self-tapping screws with a more complex Spitz shape, into which only a cruciform bit with off-center beams or a three-sided screwdriver nozzle can enter.

Fasteners with press washer

Self-tapping screws with a press washer are characterized by the following features:

- hemispherical head with washer;

- Spitz for a Phillips screwdriver;

- galvanized coating.

Self-tapping screws equipped with a press washer ensure reliable grip of thin parts. Weakening of such fastening is not threatened even after a significant period of operation of the roof.

Roofing screws with a press washer are considered the most reliable fasteners

Self-tapping screws with a press washer are divided into two types:

- fasteners with a drill, suitable for aligning sheet metal;

- sharp fasteners used when attaching material to a wooden surface.

Distinctive characteristics of roofing screws

The structural parts of the roofing screw are:

- hex head;

- leg with inclined thread;

- drill at the tip of the leg;

- elastic rubber pad;

- washer.

The rubber seal acts as a shield against moisture and is resistant to constant pressure fluctuations on the roof and temperature changes. And the pointed tip helps the self-tapping screw to bite into the roofing material of the previously created holes.

The roofing screw must be provided with a rubber gasket

Sizes of roofing screws

When evaluating roof fasteners, attention is paid to two parameters - length and diameter.

L is the length of the product and dk is the thread diameter at the outer edge

Sizing Roof Fasteners

The diameter of the roofing screw is determined by the size of the circle along the outer edges of the thread of its body. This parameter is always indicated first on the product label and fits into frames from 4.8 to 6.3 mm. The second on the label indicates the length of the fastener, taking into account its head. This size ranges between 16 and 150 mm.

The choice of the standard size of the roofing screw depends on the load that the connection will have to experience and the parameters of the parts to be fastened. Manufacturers indicate recommendations regarding the length of the product on the packaging.

The minimum length of the roofing screw is 16 mm, and the maximum is 150 mm

If there is no information about the choice of self-tapping screws, then you can decide on the right size yourself. The diameter of the roof fasteners is standardized and equals 4.8 mm. And the length should be such that the product occupies 4.5 cm of the thickness of the batten, if it is wooden, or goes beyond it by at least 5 mm, when the base for the roofing is made of metal.

Table: dimensions of roofing screws

| Length (cm) | Diameter (mm) | Length (cm) | Diameter (mm) | |

| 1.6 | 4.8 | 3.8 | 5.5 | |

| 1.9 | 5.1 | |||

| 2.5 | 7.6 | |||

| 2.9 | 1.9 | 6,3 | ||

| 3.2 | 2.5 | |||

| 3.5 | 3.2 | |||

| 3.8 | 3.8 | |||

| five | 5.1 | |||

| 6 | 6 | |||

| 6.5 | 7 | |||

| 7 | 8 | |||

| 8 | nine | |||

| 1.9 | 5.5 | ten | ||

| 2.5 | 13 | |||

| 3.2 | fifteen |

Dimensions of roofing screws with rubber gasket

For self-tapping screws with a gasket and a washer, there is a separate range of sizes, since due to the presence of additional elements, there is no need to strengthen the legs of the fasteners.

Table: parameters of fasteners with gasket

| Leg diameter (mm) | Product length (cm) |

| 4.2 | 1,3 |

| 1.4 | |

| 1.6 | |

| 1.9 | |

| 2.5 | |

| 3.2 | |

| 4.1 | |

| 5.1 | |

| 7.6 |

Rules for choosing self-tapping screws for roofing material

When buying self-tapping screws, it is recommended to inspect them properly.

Fasteners are considered to be of high quality if:

- stamped stamp on the head;

- the package indicates the thickness of the zinc coating (from 12 microns)

-

the gasket is firmly fixed on the washer (does not peel off);

Self-tapping screws with washer and gasket The self-tapping screw gasket must be in close contact with the washer

- the washer is more than 2 mm thick;

- press washer withstands test compression with pliers;

- the paint on the washer does not crack when exposed to pliers.

So that the roofing screws do not let you down in the operation process, you should not buy them at a low price.

Pay close attention to the gasket. If it is too porous or, conversely, extremely rigid, then self-tapping screws must be abandoned: they will not be able to protect the roofing material from displacement during exposure to strong winds. Also, bad rubber adjacent to the washer will cause the roof to leak in the areas where the screws were screwed in.

Video: finding a self-tapping screw suitable for the roof

How to use roofing screws

When using roofing screws, you must strictly follow the instructions, otherwise the roof will not be able to function for a long time without repair.

Fastening the roof with self-tapping screws

The work on fixing the roofing material with self-tapping screws is performed as follows:

- All corrugated board in the right order is laid out on the crate. In no case do they resort to laying and fixing each sheet separately, since this can lead to a distortion of the roof plane.

-

Determine at what distance from each other it is better to screw in the fasteners. Usually, roofing screws are screwed in every half a meter. Too small a step almost always causes damage to the sheets, and too large leads to poor fastening of the material. The distance is increased only if necessary to secure the roof ends as much as possible, which are under strong pressure from atmospheric phenomena.

Scheme of fastening corrugated board to self-tapping screws The corrugated board is supposed to be fastened with self-tapping screws through one wave, and 50 cm should be left between the fasteners

- Fasteners are purchased. The steeper the roof slope, the more screws are taken. On average, 8 fasteners are used for 1 m² of roofing.

-

Find a suitable tool - a drill with a soft trigger or a screwdriver. Self-tapping screws are immersed in the material straight, avoiding the inclination of the fasteners to the side. In this case, the clamps are pressed against the roofing with moderate force so that their heads do not inadvertently damage the metal sheets. In carrying out the task, the best guide is the rubber gasket: when 1-2 mm of gasket material is visible above the roof surface, there is nothing to worry about.

Screw screwing scheme Self-tapping screw is screwed into the bottom of the wave with moderate force

How to screw screws into metal

It happens that the self-tapping screw cannot be screwed through the roofing into the metal crate, even despite the tip of the fastener in the form of a drill. The problem is most often associated with insufficient sharpening of the lower part of the self-tapping screw and is solved by replacing the defective fastener with another, high-quality one.

However, for easy immersion of the self-tapping screw into thick metal, it is allowed to use some tricks:

-

reduce the speed of the screwdriver;

Fastening the roof with self-tapping screws By reducing the speed of the screwdriver, you can simplify the screwing of the self-tapping screw into the metal crate

- drill a hole in the metal, the diameter of which is slightly less than the diameter of the self-tapping screw body, taking into account the thread;

- process the screw or hole with machine oil or other lubricant.

Reviews of roofing screws

Roofing screws have a decisive influence on the reliability of the roof. This means that in the choice of their type, size and installation technology, mistakes cannot be made.

Recommended:

Types Of Roofing Materials With A Description And Characteristics And Reviews, Including Roll, As Well As Features Of Their Operation

Types of roofing materials: sheet, soft and tile roofs. Technical characteristics and features of operation of various types of coatings

Roofing From Vulture Panels, Its Structure And Main Elements, As Well As Features Of Installation And Operation

Brief information about roofing SIP panels. Design features of roofs assembled from multi-layer products. Sandwich panel installation rules

Roofing Profiled Sheet, Including Its Types With Description, Characteristics And Reviews, As Well As Processing And Use Features

Using a profiled sheet to cover the roof. Classification, features of work and operation of corrugated board. How to cut a profiled sheet into fragments of the desired size

Seam Roofing Tool With Description And Characteristics, As Well As Features Of Its Application

What equipment and tools are needed to create a seam roof. How to make a bending machine yourself. Types of folding machines

Roll Roofing Materials: Types With Descriptions, Characteristics And Reviews, Installation Features

What roll material to choose for the roof. How to mount it yourself. Use of self-adhesive materials. Dismantling old roofing